Preparation method and application of co-polymer of epoxy resin and unsaturated resin

An epoxy resin, unsaturated technology, applied in the field of copolymer preparation, can solve the problems of short storage period, poor chemical corrosion resistance, poor mechanical properties, etc., to reduce the density of ester bonds, improve production efficiency, and maintain stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

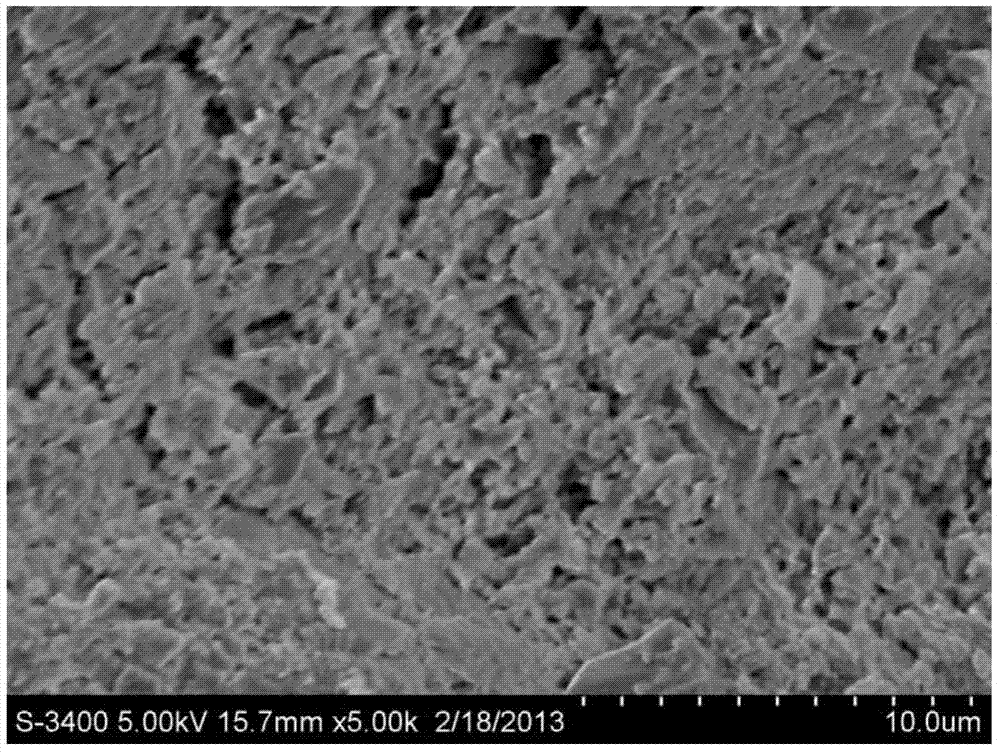

Embodiment 1

[0039] A kind of preparation method of the copolymer of above-mentioned epoxy resin and unsaturated resin, comprises the following steps:

[0040] Mix the m-benzene type unsaturated polyester resin and the bisphenol A type corrosion-resistant unsaturated polyester resin with a mass ratio of 1:1, add the m-benzene type unsaturated polyester resin and the bisphenol A type corrosion-resistant unsaturated polyester resin 10% bisphenol A type epoxy resin of the total mass of the ester resin, while adding an initiator methyl ethyl ketone peroxide accounting for 2% of the total mass of the isophthalic unsaturated polyester resin and the bisphenol A type corrosion-resistant unsaturated polyester resin And account for 2% accelerator naphthenic acid styrene solution of the total mass of isophthalic unsaturated polyester resin and bisphenol A type corrosion-resistant unsaturated polyester resin, accounting for isophthalic unsaturated polyester resin and bisphenol A Filler quartz powder w...

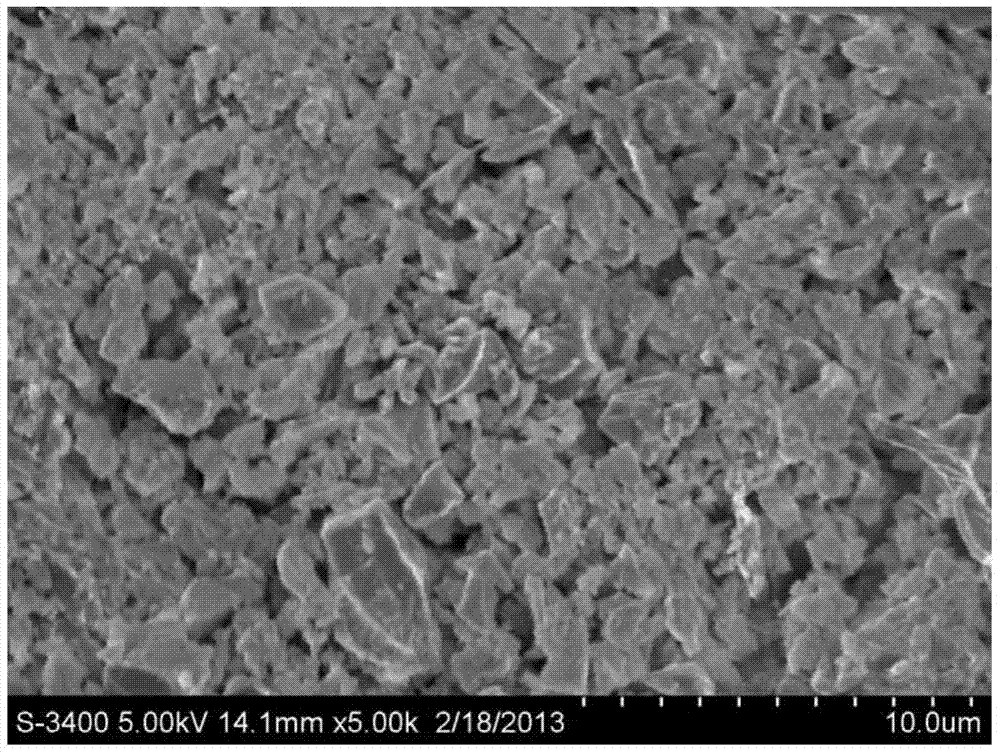

Embodiment 2

[0044] A kind of preparation method of the copolymer of above-mentioned epoxy resin and unsaturated resin, comprises the following steps:

[0045] Mix the m-benzene type unsaturated polyester resin and the bisphenol A type corrosion-resistant unsaturated polyester resin with a mass ratio of 1:1, add the m-benzene type unsaturated polyester resin and the bisphenol A type corrosion-resistant unsaturated polyester resin 15% bisphenol A type epoxy resin of the total mass of the ester resin, while adding an initiator methyl ethyl ketone peroxide accounting for 2% of the total mass of the isophthalic unsaturated polyester resin and the bisphenol A type corrosion-resistant unsaturated polyester resin And account for 2% accelerator naphthenic acid styrene solution of the total mass of isophthalic unsaturated polyester resin and bisphenol A type corrosion-resistant unsaturated polyester resin, accounting for isophthalic unsaturated polyester resin and bisphenol A Filler quartz powder w...

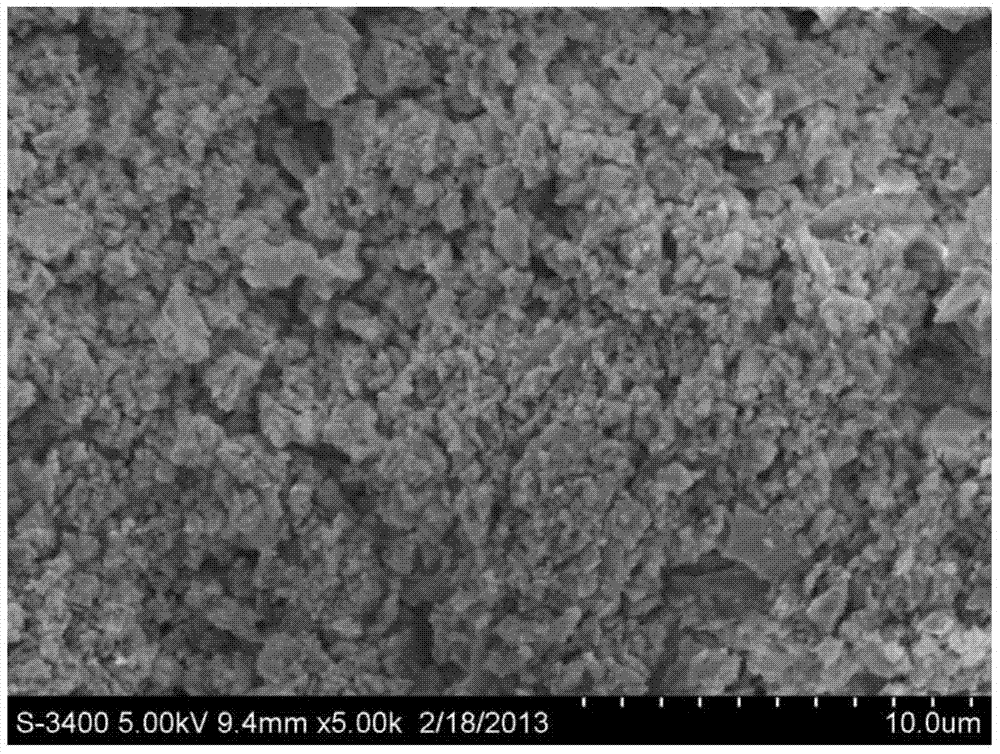

Embodiment 3

[0049] A kind of preparation method of the copolymer of above-mentioned epoxy resin and unsaturated resin, comprises the following steps:

[0050] Mix the m-benzene type unsaturated polyester resin and the bisphenol A type corrosion-resistant unsaturated polyester resin with a mass ratio of 1:1, add the m-benzene type unsaturated polyester resin and the bisphenol A type corrosion-resistant unsaturated polyester resin 20% bisphenol A type epoxy resin of the total mass of the ester resin, while adding an initiator methyl ethyl ketone peroxide accounting for 2% of the total mass of the isophthalic unsaturated polyester resin and the bisphenol A type corrosion-resistant unsaturated polyester resin And account for 2% accelerator naphthenic acid styrene solution of the total mass of isophthalic unsaturated polyester resin and bisphenol A type corrosion-resistant unsaturated polyester resin, accounting for isophthalic unsaturated polyester resin and bisphenol A Filler quartz powder w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com