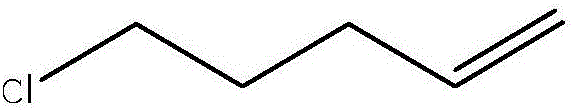

5-chloro-1-amylene synthesis method

A synthesis method and technology for pentene, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problem of low reaction yield, 5-chloro-1-pentene synthesis Problems such as high cost, to avoid side reactions, high selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] In a 2000ml four-necked flask equipped with a mechanical stirrer, a dropping funnel, a reflux condenser and a thermometer, 200g (2.33mol) of 4-penten-1-ol and 900g of pyridine were added. Under stirring, the temperature of the system was lowered to 0° C. with an ice-salt bath, and at this time, 238 g (2 mol) of thionyl chloride was added dropwise to the system with a dropping funnel. Control the dropping rate to ensure that the temperature of the material does not exceed 5°C. After the dropping, remove the ice-salt bath. The temperature was naturally raised to 10-30°C, and the reaction was stirred for 48 hours. When the temperature exceeds 30°C, cool it to below 30°C with an ice-salt bath. After the reaction, filter with a Buchner funnel, the filter cake is pyridine hydrochloride, and rinse the filter cake twice with 200ml acetone. Combine the filtrate and washings, pour into 1500ml of distilled water, let stand, and separate the lower oil layer. Continue to wash the...

example 2

[0037] In a 2000ml four-necked flask equipped with a mechanical stirrer, a dropping funnel, a reflux condenser and a thermometer, 200g (2.33mol) of 4-penten-1-ol and 700g of pyridine were added. Under stirring, the temperature of the system was lowered to 0° C. with an ice-salt bath, and at this time, 264 g (2.22 mol) of thionyl chloride was added dropwise to the system with a dropping funnel. Control the dropping rate to ensure that the temperature of the material does not exceed 5°C. After the dropping, remove the ice-salt bath. The temperature was naturally raised to 10-30°C, and the reaction was stirred for 24 hours. When the temperature exceeds 30°C, cool it to below 30°C with an ice-salt bath. After the reaction, filter with a Buchner funnel, the filter cake is pyridine hydrochloride, and rinse the filter cake twice with 200ml acetone. Combine the filtrate and washings, pour into 1500ml of distilled water, let stand, and separate the lower oil layer. Continue to wash ...

example 3

[0039]In a 2000ml four-necked flask equipped with a mechanical stirrer, a dropping funnel, a reflux condenser and a thermometer, 200g (2.33mol) of 4-penten-1-ol, 2g of bismuth trioxide and 700g of pyridine were added. Under stirring, the temperature of the system was lowered to 0° C. with an ice-salt bath, and at this time, 238 g (2 mol) of thionyl chloride was added dropwise to the system with a dropping funnel. Control the dropping rate to ensure that the temperature of the material does not exceed 5°C. After the dropping, remove the ice-salt bath. The temperature was naturally raised to 10-30°C, and the reaction was stirred for 72 hours. When the temperature exceeds 30°C, cool it to below 30°C with an ice-salt bath. After the reaction, filter with a Buchner funnel, the filter cake is catalyst and pyridine hydrochloride, and wash the filter cake twice with 200ml acetone. Combine the filtrate and washings, pour into 1500ml of distilled water, let stand, and separate the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com