Preparation method of graft copolymerization carboxylate high-performance dehydragent

A technology of co-polymerized carboxylate and water-reducer, which is applied in the specific preparation field of graft-copolymerized carboxylic acid-based high-performance water-reducers, which can solve the problem of poor fluidity retention of comb polymer water-reducing rate, cumbersome intermediate separation and purification process, The feeding speed should not be controlled, etc., to achieve the effect of shortening the reaction time, short reaction time, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 80g of methoxypolyethylene glycol with a molecular weight of M1000 to the reaction vessel equipped with a stirring, condensing, and effluent reflux device, fully melt, the temperature is at 95°C, add 0.14g of polymerization inhibitor hydroquinone, and react for 15 minutes 14.4g of acrylic acid, 1.98g of concentrated sulfuric acid, and 14.4g of cyclohexane were added to the reaction vessel in sequence, and the temperature was kept constant for 4 hours. The esterification rate reached 97.6%, and the cyclohexane was removed by vacuuming to obtain methoxypolyethylene Alcohol acrylate (macromonomer). The recovered water-carrying agent is treated with 3A molecular sieve and can be recycled. During the second step of polymerization, all the macromonomers were prepared by adding esterification reaction into the four-necked flask, 55.19 g of water was stirred continuously, and the temperature was raised to 50° C. in a water bath. Add 1.26 g of mercaptoacetic acid, 4.54 g of...

Embodiment 2

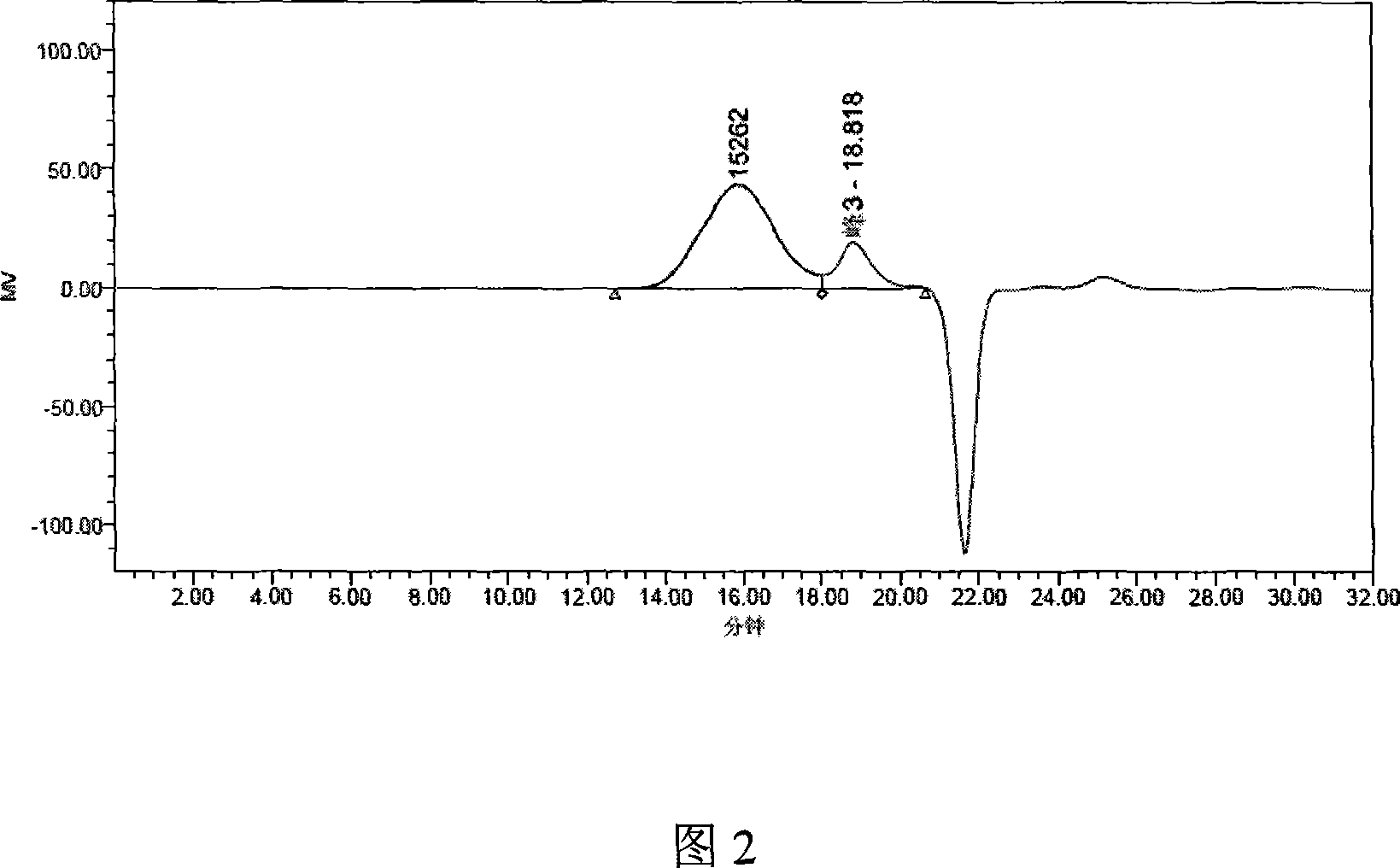

[0022] Add 90 g of methoxypolyethylene glycol with a molecular weight of M1300 to a reaction vessel equipped with a stirring, condensing, and effluent reflux device, fully melt, and add 0.89 g of a polymerization inhibitor phenothiazine at a temperature of 120 ° C, and react for 15 minutes. Add 29.76g of methacrylic acid, 4.55g of concentrated sulfuric acid, 4.55g of p-toluenesulfonic acid, and 37g of cyclohexane to the reaction vessel in sequence. After a constant temperature reaction time of 3.5 hours, the esterification rate reaches 96.6%. Hexane to give methoxypolyethylene glycol methacrylate (macromonomer). The recovered water-carrying agent is treated with 3A molecular sieve and can be recycled in the next production. During the second step of polymerization, all macromonomers were prepared by adding esterification reaction into a four-necked flask, 27.17g of water, stirring continuously, heating in a water bath to 60°C, adding 5.87g of mercaptopropionic acid, 8.86g of b...

Embodiment 3

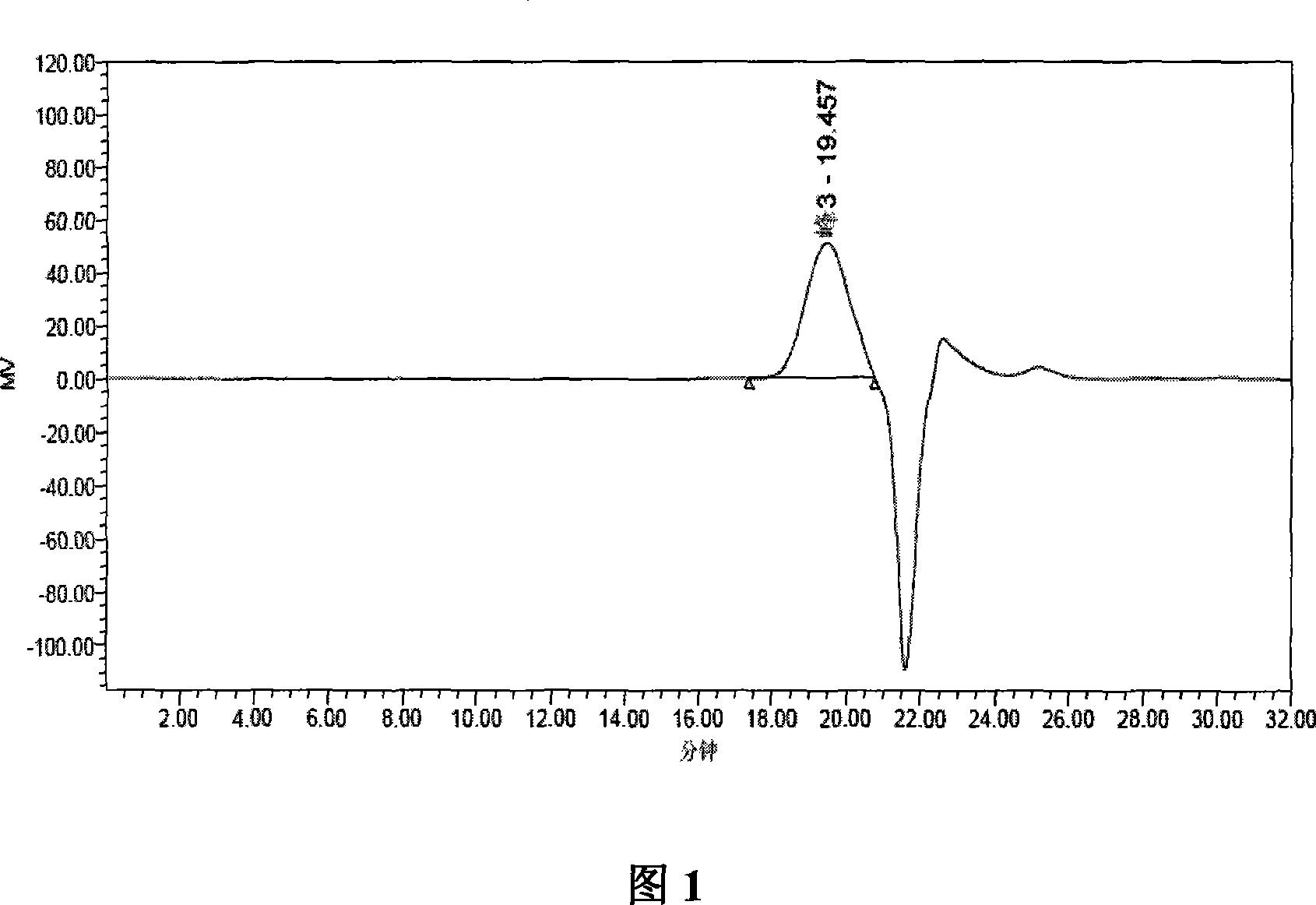

[0024]Add 100g of methoxypolyethylene glycol with a molecular weight of M1000 to the reaction vessel equipped with a stirring, condensing, and effluent reflux device, and fully melt it at a temperature of 130°C. Add 0.014g of a polymerization inhibitor hydroquinone, and react for 15 minutes 14.40g of acrylic acid, 1.14g of p-toluenesulfonic acid, and 23g of cyclohexane were added to the reaction vessel in sequence. After 4.5 hours of constant temperature reaction, the esterification rate reached 97.2%, and the cyclohexane was removed by vacuuming to obtain methane Oxy-polyethylene glycol acrylate (macromonomer). The recovered water-carrying agent is treated with 3A molecular sieve and can be recycled. During the second step of polymerization, all the macromonomers were prepared by adding esterification into the four-necked flask, 150.52 g of water was continuously stirred, and the temperature was raised to 65° C. in a water bath. 7.9 g of sodium allyl sulfonate, 32.4 g of an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com