Method for reinforcing smelting effect of bottom blowing smelting furnace and avoiding melt splashing

A smelting furnace and bottom blowing furnace technology, applied in the field of bottom blowing smelting, can solve the problems of large metal loss rate, low smelting efficiency, serious splashing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

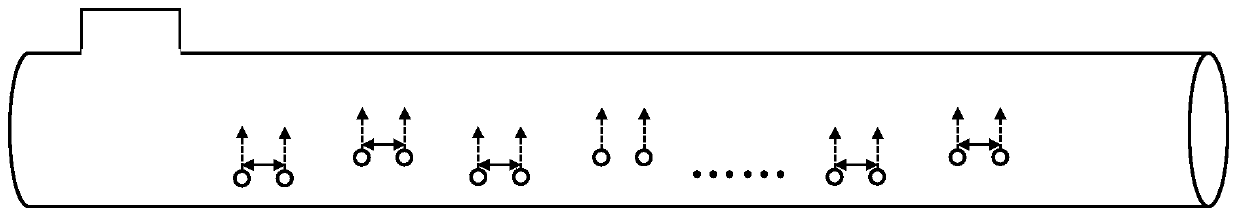

[0032] Embodiment 1 (cross-flow injection):

[0033] Taking an implementation of cross-flow blowing as an example (this example is to change the axial distance of the spray guns), all the spray guns of the bottom blowing furnace are numbered sequentially from the side close to the smoke exhaust port to ensure that the total air supply volume and the diameter of the spray guns are not changed. Change, and the air pressure or air supply volume of each spray gun is equal. A group of fans is used to supply air to two groups of spray guns, and the axial distance between odd-numbered spray guns and even-numbered spray guns is changed, so that the airflow distance injected into the melt by each adjacent two spray guns increases, and the airflow superposition effect becomes weaker, resulting in " "Cross-flow blowing" effect, the original spacing is 380mm, in this example the adjusted spacing is 610mm.

[0034] Solve the flow field in the furnace under the two working conditions throu...

Embodiment 2

[0035] Embodiment 2 (staggered peak injection):

[0036] Taking an implementation of staggered peak injection as an example (this example is to change the ratio of spray gun diameters), all the spray guns of the bottom blowing furnace are numbered sequentially from the side close to the smoke exhaust port, and a group of fans are used to supply air to the two groups of spray guns , to ensure that the total air supply volume, the total spray area and the outlet end pressure of each spray gun are the same, and by changing the diameter ratio of the odd and even two sets of spray guns, each adjacent two spray guns are sprayed into the melt with different airflow intensities, resulting in " Peak staggered injection" effect, the area ratio is 1:1 under the original working condition, now it is adjusted to 1.2:0.8, and the diameter ratio is 1.095:0.894.

[0037] Solve the flow field in the furnace under the two working conditions through numerical simulation, take the melt in the sti...

Embodiment 3

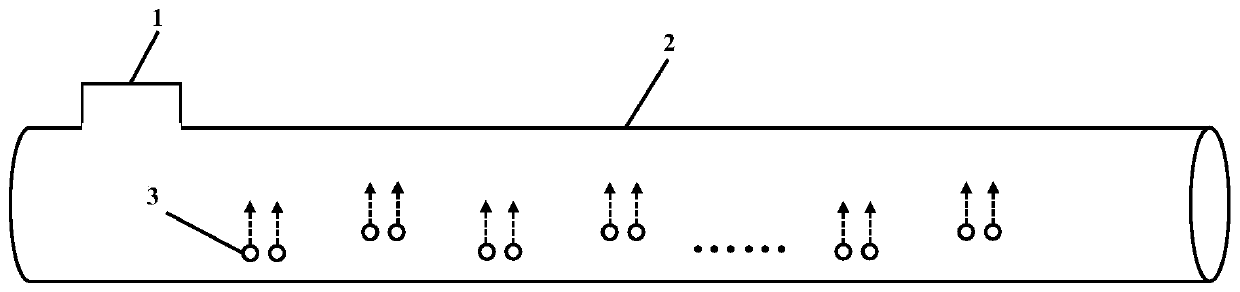

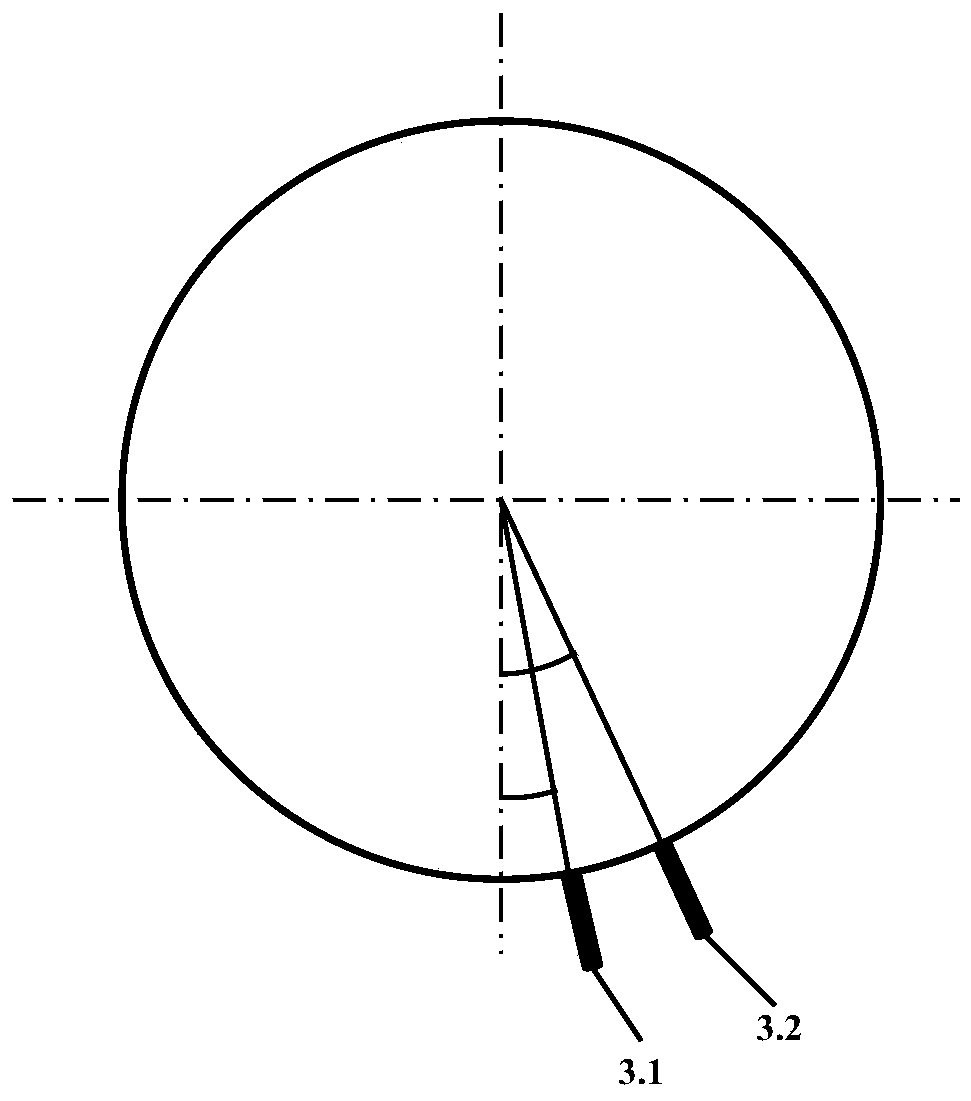

[0039] Taking a copper bottom blowing furnace as an example, there are 14 groups of spray guns on the same side of the center near the bottom of the furnace body. Every two spray guns form a group, with a total of 28 spray guns. The adjacent two groups of spray guns are arranged alternately. The 14 groups of spray guns are numbered sequentially from the side close to the smoke exhaust port, the angles of the 7 odd groups of spray guns can be adjusted from 6 to 12°, and the angles of the 7 even groups of spray guns can be adjusted from 21 to 27°. The distance between the two spray guns in each group is 380-610mm, and the distance between two adjacent groups of spray guns is 1150mm. Vertical to the wall of the furnace body, the airflow is blown into the furnace vertically from the outlet of the spray gun. A simple schematic diagram of a bottom-blown melting furnace figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com