Method for lignin aryl-ether bond catalytic pyrolysis with ReO<x>/AC

A technology of catalytic cracking and aryl ether, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of consuming large external hydrogen sources and destroying benzene rings , increase costs and other issues, to achieve the effect of high atom economy, mild conditions, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

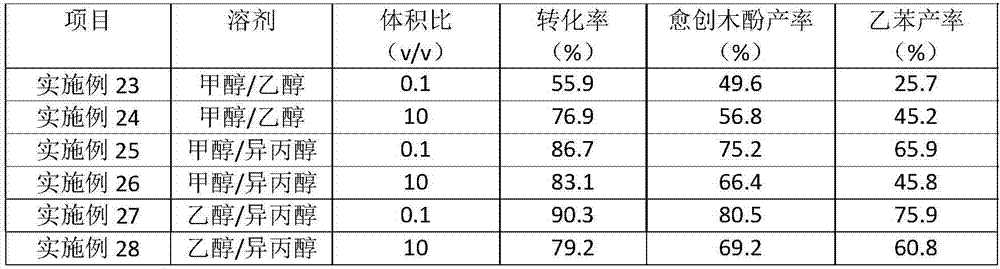

Examples

Embodiment 1

[0023] 100 mg lignin model compound 2-(2-methoxyphenoxy)-1-phenylethanol, 100 mg catalyst ReO x / AC(1wt%ReO x ), 15 milliliters of isopropanol was added into a 75 milliliter reaction kettle, and after passing through nitrogen to replace the gas three times, nitrogen was filled to 0.7 MPa, and the temperature was raised to 190° C. for 3 hours of reaction. After the reaction was finished, it was cooled to room temperature, and the centrifuged supernatant was subjected to chromatographic analysis. The conversion rate was 99.9%, the yield of ethylbenzene was 83.6%, and the yield of guaiacol was 85.0%.

Embodiment 2-6

[0025] Other process conditions and experimental steps are the same as in Example 1, but use different initial pressures, the results are shown in Table 1

[0026] Table 1. At different initial pressures, ReO x / AC(1wt%ReO x ) catalytic conversion of lignin experimental results

[0027] project

[0028] As shown in Table 1, as the initial pressure increased, the yields of guaiacol and ethylbenzene increased.

Embodiment 7-11

[0030] Other processing conditions and experimental steps are the same as in Example 1, but using different reaction temperatures, the results are shown in Table 2.

[0031] Table 2. ReO at different reaction temperatures x / AC(1wt%ReO x ) catalytic conversion of lignin experimental results

[0032] project

[0033] As shown in Table 2, as the reaction temperature increased, the yields of guaiacol and ethylbenzene also increased, and the conversion rate also increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com