Method for selectively producing lignin-degrading enzymes by using phanerochaete chrysosporium

A technology for lignin-degrading enzyme and Phoenicia protothecoides, which is applied in the biological field and can solve the problems that the selective production of lignin-degrading enzymes of P. protochaetans is not seen, the effect is not ideal, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

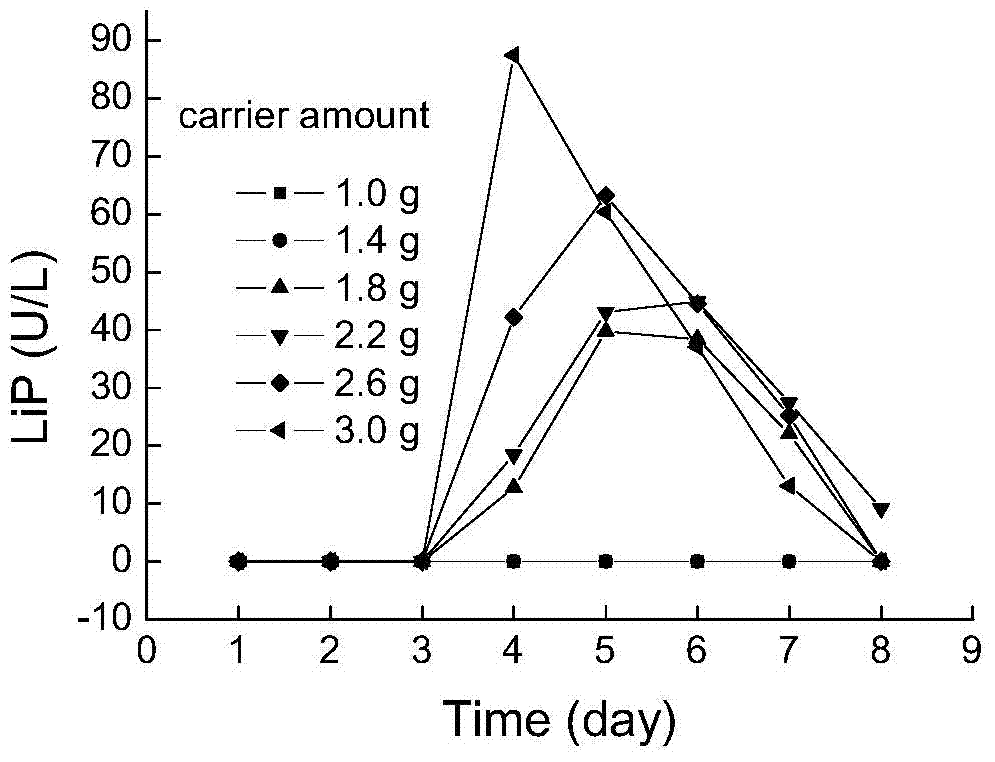

[0033] Embodiment 1, Phanerochaete chrysosporium selectively produces lignin peroxidase under carbon limitation

[0034] 1. Preparation of carbon-limited liquid medium

[0035] A carbon-limited liquid medium was used, and the medium was slightly modified based on the typical Tien and Kirk medium (1988). The C / N ratio (molar ratio) of the medium was 3.8, and the specific composition was as follows:

[0036] The carbon-limited liquid medium consists of a final concentration of 5.04g / L (28mM) glucose, a final concentration of 4.05g / L (NH 4 + 44mM) ammonium tartrate, the final concentration is 2.0g / L KH 2 PO 4 , the final concentration is 0.5g / L MgSO 4 , the final concentration is 0.1g / L CaCl 2 , the final concentration is 1mg / L vitamin B 1 , final concentration of 1.5mM veratrol, final concentration of 20mM (pH 4.4) acetate buffer, 70mL / L trace element solution and deionized water; pH is 4.4.

[0037] The trace element solution was prepared with a final concentration of 3g...

Embodiment 2

[0051] Embodiment 2, Phanerochaete chrysosporium selectively produces manganese peroxidase under nitrogen limitation

[0052] 1. Preparation of nitrogen-limited liquid medium

[0053] Nitrogen-limited liquid medium is adopted, and the C / N ratio (molar ratio) of the medium is 152.7, and the specific composition is as follows:

[0054] Nitrogen-limited liquid medium formula is the final concentration of 10.08g / L (56mM) glucose, 0.203g / L (NH 4 + 2.2mM) ammonium tartrate replaces glucose and ammonium tartrate in the carbon-limited liquid medium, and the remaining components are the same as the carbon-limited liquid medium in Example 1; pH is 4.4.

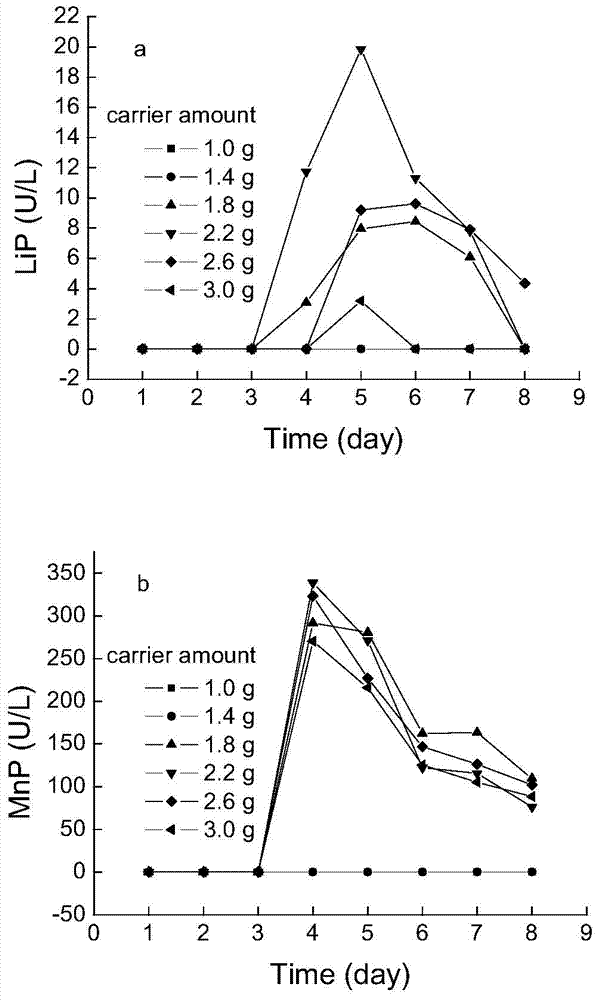

[0055] 2. Selective production of manganese peroxidase by Phanerochaete chrysosporium under nitrogen limitation

[0056] The culture conditions and analysis methods are the same as in Example 1, except that the culture medium is replaced by a nitrogen-limited liquid medium.

[0057] Lignin-degrading enzymes produce results such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com