Lithium ion battery anode piece preparation method, anode piece and lithium battery

A technology of lithium ion battery and negative pole piece, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of no performance improvement, and achieve the effect of improving performance, reducing process complexity, and excellent electrochemical cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

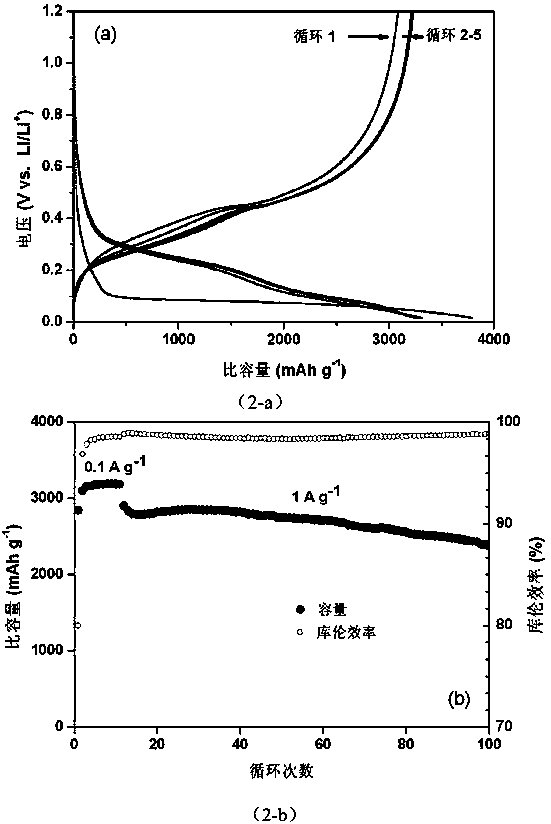

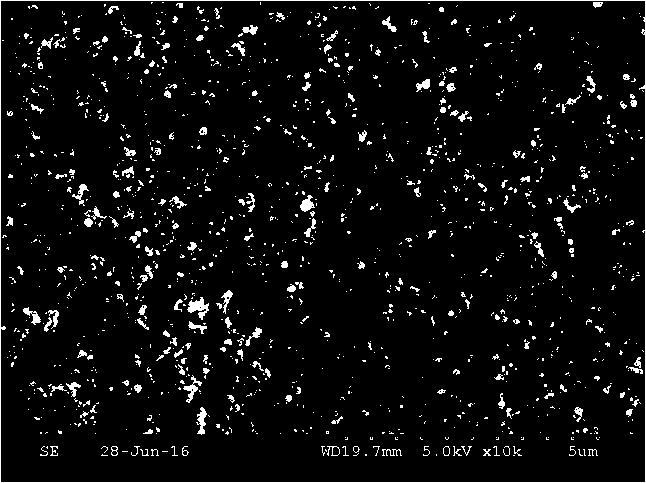

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] 1. Preparation of negative electrode sheet for lithium ion battery

[0031] Lithium-ion battery negative pole pieces were prepared according to the following three groups.

[0032] First group:

[0033]

[0034] The preparation steps of lithium-ion battery negative pole piece are as follows:

[0035] S01: Preparation of precursor solution: Take lignin, polyethylene oxide and dimethylformamide according to the formula in the above table and mix them uniformly. Heat the above mixed solution to 60°C and stir for 1 hour.

[0036] S02: Add nano-silicon powder to the precursor solution obtained in S01, the mass ratio of the added nano-silicon powder to lignin is 1:1; keep the temperature constant, and continue to apply magnetic force to the mixture of the precursor solution and nano-silicon powder Stir, and change the planetary mixer every half...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com