Fully Closed, Zero Discharge, Clean Oxidizing Pulping Technology and Process

a pulping technology and technology of fully closed, zero discharge, can solve the problems of human beings facing the dilemma of insufficient oxygen to breathe, traditional process has seriously impacted the environment, and the supply of papermaking materials is shor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

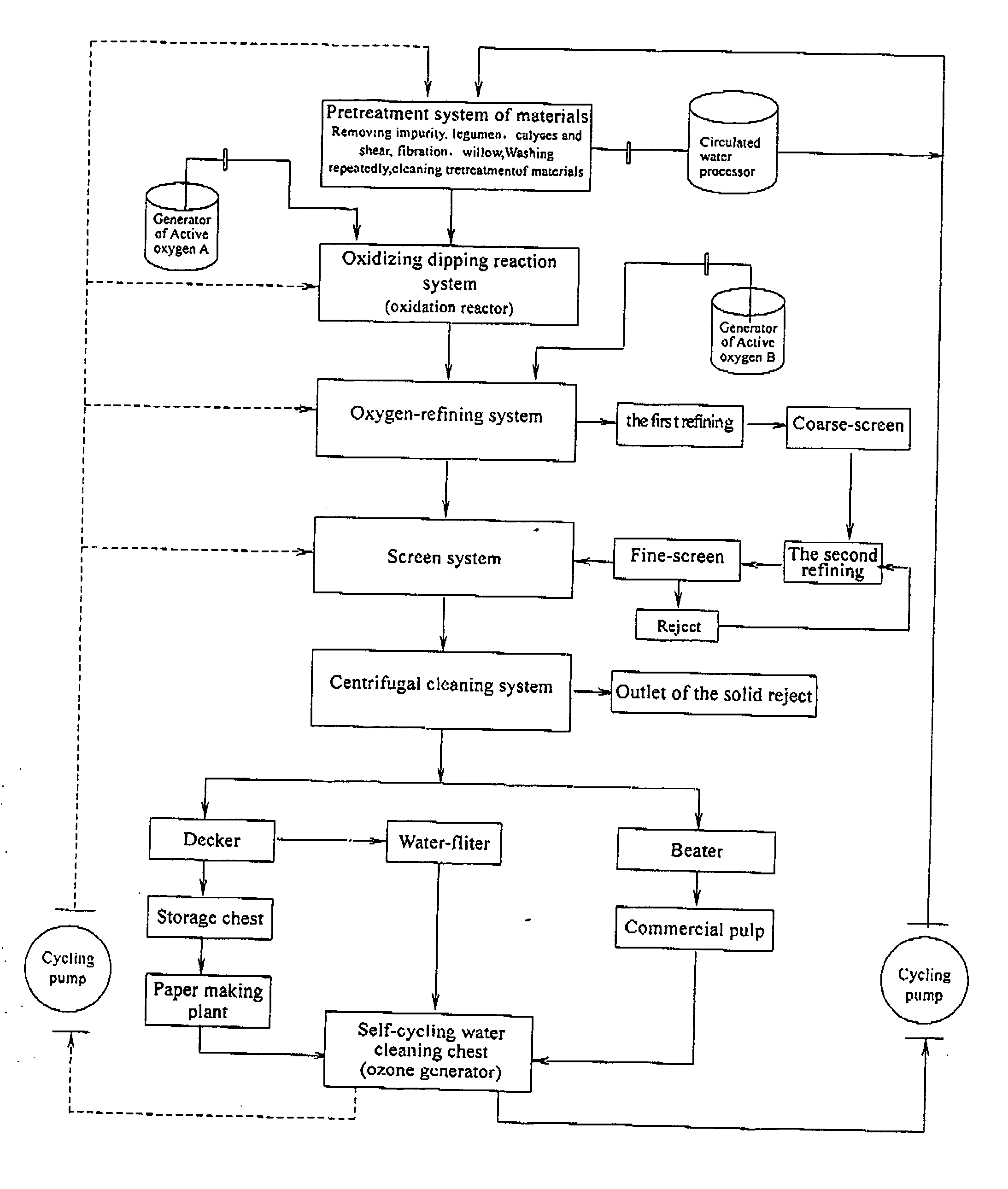

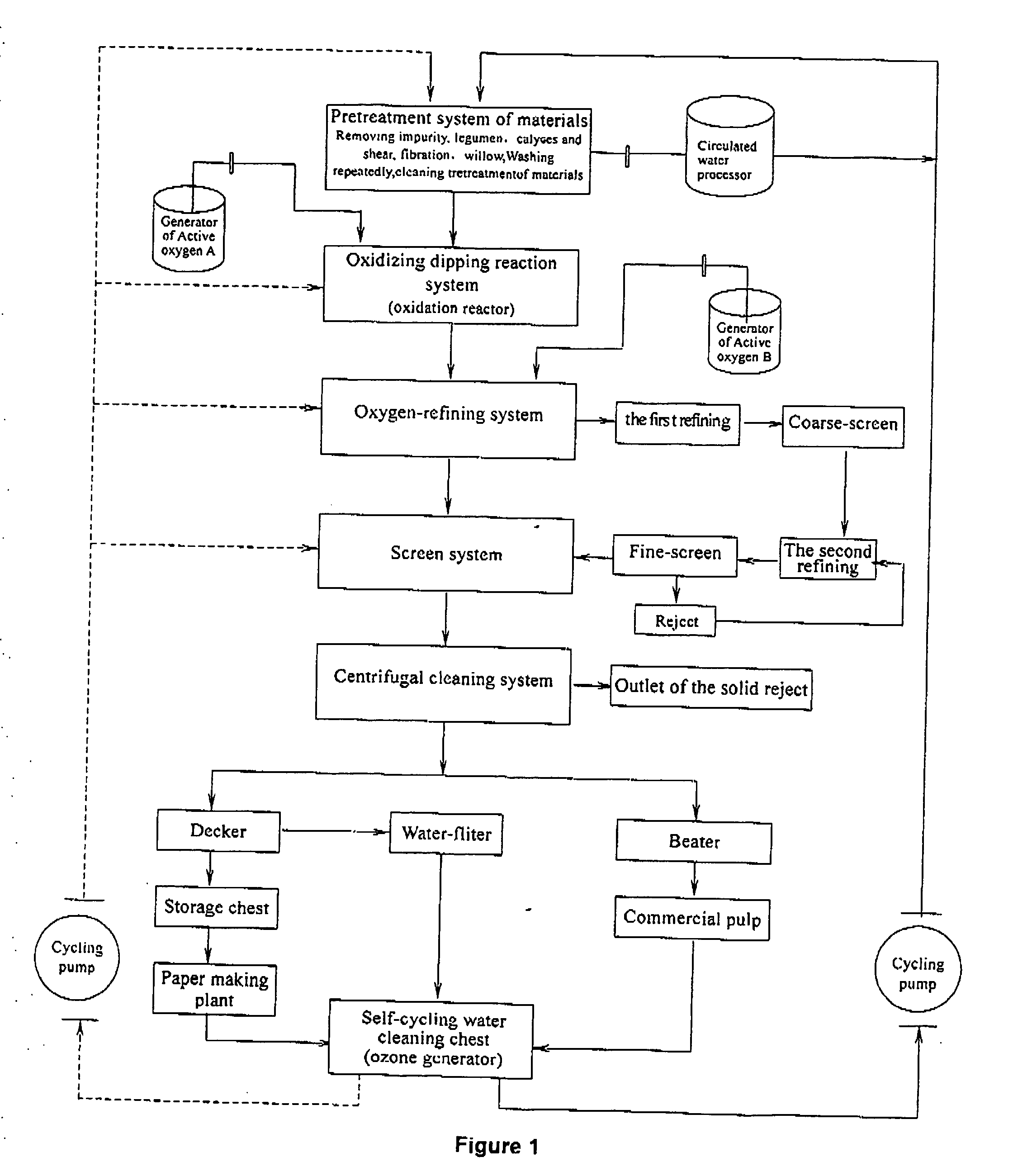

Method used

Image

Examples

example

[0059] Undermentioned examples are farther description of the invention. These examples are only used to describe the invention, not used to limit the conceptual framework of the invention.

example i

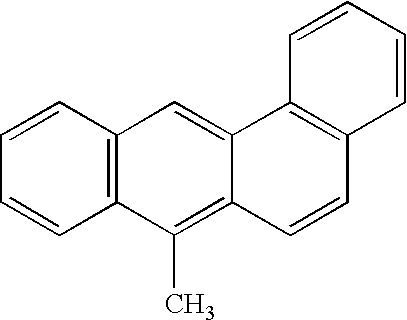

[0060] 100 kg full cotton stalks are removed legumen, calyces by crushing engine and cut into length of 5 cm and thick of 1.5 cm. Finally materials with forming rate 98% are obtained. Above materials are broken into plush by roller and crushing engine, removed dust and medulla by wind power, removed impurity by screening, washed by circular water before the materials is transported to the oxidation reactor (auto agitator is installed in the reactor) by screw feeder. The reaction conditions are at 60° C., pH 2.5, rotating speed of 60 r / s and MgCO3 0.02 kg, and bimethyl-bioxirane (DMD) 0.01 kg is added. After 0.5 h H2O2 solution with weight percentage concentration 0.2 is added. Then the rotating speed becomes 80 r / s and temperature is 80° C. After 1 h, impregnating softness number of the materials in the reactor is 98%. The materials change from deep yellow to pale white and accord with ISO whiteness 48-52° (hereinafter it is called whiteness or ISO whiteness for short). Above materi...

example ii

[0061] In accordance with EXAMPLE I, 100 kg raw materials are fed to refiner continuously and equally, In the first refining process H2O2 (weight percentage concentration is 1-5) prepared in advance are added to pulp in 1:0.12 (according to weight ratio) and mixed with pulp in refiner at 60° C., pH 3.8 and 12-15% consistency. The rotating speed of refiner is 1300 r / s and the gap between the disks is 0.15-0.1 mm. The pulp whiteness can be 60-750. In the secondary refining process O3 (concentration is 10umol / L) is added and mixed with pulp at 80° C., pH 3.8, 12-15% pulp consistency and pressure 0.4 Mpa. The rotating speed of refiner disc is 1300 r / s and the gap is 0.1 mm. After 0.5-1 h, the ISO whiteness can reach to 75-86°. The pulp is sent into the conventional screening process for fine screening. The refined pulp is sent into the centrifugal cleaning process before it is condensed with decker, beaten, and then sent into the storage process. When higher whiteness is required, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com