Lignin degradation product removing method

A degradation product, lignin technology, applied in biofuel, fermentation, etc., can solve the problem of removal of lignin degradation products that have not been found yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

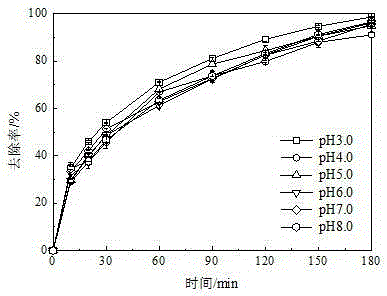

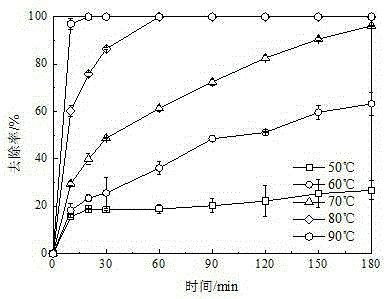

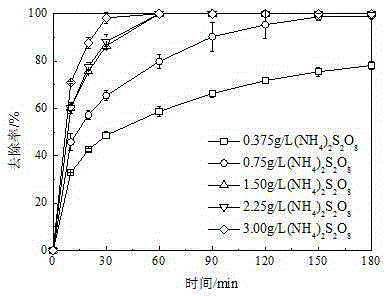

[0025] The removal method of lignin degradation products: mix typical lignin degradation products and ammonium persulfate in a certain molar ratio and place them in an electric constant temperature water bath shaker, control the reaction temperature and pH, and react under the condition of oscillation frequency 150r / min. The initial concentration of lignin degradation products was 0.1g / L, and the oxidation reaction was carried out in an electrothermal constant temperature water bath. The pH value of the reaction solution was adjusted by sodium hydroxide and sulfuric acid. The reaction solution with adjusted pH value was preheated for 10 minutes at the set temperature, and then the prepared ammonium persulfate stock solution (15g / L) was quickly added to start the reaction and start timing, and samples were taken for analysis at regular intervals.

[0026] Oxidation effect evaluation: The concentration of lignin degradation products before and after oxidation was analyzed by rev...

Embodiment 2

[0032] Pipette 5mL of ammonium persulfate stock solution (15g / L) and syringaldehyde concentrated solution (1g / L) into a 125mL Erlenmeyer flask, adjust the pH value to about 6.0 with sodium hydroxide and sulfuric acid, and add distilled water to the total volume 50mL, reacted at 80°C, shaking frequency 150r / min for 3h. During the reaction, samples were taken at regular intervals and analyzed by reversed-phase high-performance liquid chromatography (R-HPLC). Oxidation effect evaluation is with embodiment 1, and result is as follows Figure 4 shown. from Figure 4 It can be seen from the figure that under the optimal reaction conditions, the removal rate of syringaldehyde gradually increases with time, and reaches 100% when the reaction reaches 2 hours.

Embodiment 3

[0034] Pipette 5mL of ammonium persulfate stock solution (15g / L) and 4-hydroxybenzaldehyde concentrated solution (1g / L) into a 125mL Erlenmeyer flask, adjust the pH value to about 6.0 with sodium hydroxide and sulfuric acid, and add distilled water to The total volume is 50 mL, and the reaction is carried out at 80° C. with an oscillation frequency of 150 r / min for 3 h. During the reaction, samples were taken at regular intervals and analyzed by reversed-phase high-performance liquid chromatography (R-HPLC). Oxidation effect evaluation is with embodiment 1, and result is as follows Figure 5 shown. from Figure 5 It can be seen that under the optimal reaction conditions, the removal rate of 4-hydroxybenzaldehyde increases gradually with time, and reaches 100% when the reaction is carried out for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com