Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

a technology of cellulose solution and microfiber, which is applied in the direction of cellulose solution artificial filament washing/drying, streptospinning methods, etc., can solve the problem of failing to teach more details of a die with multiple orifices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0029] A ¾ inch extruder is fed with a NMMO solution comprising 10.5% by weight cellulose, 77.5% by weight of NMMO and the rest is mainly water. The solid solution are in the form of pellet of 0.05″˜0.08″ in size. The feeding hoper is filled with Argon gas to prevent moisture takeup. The cellulose has an average degree of polymerization from 330˜360.

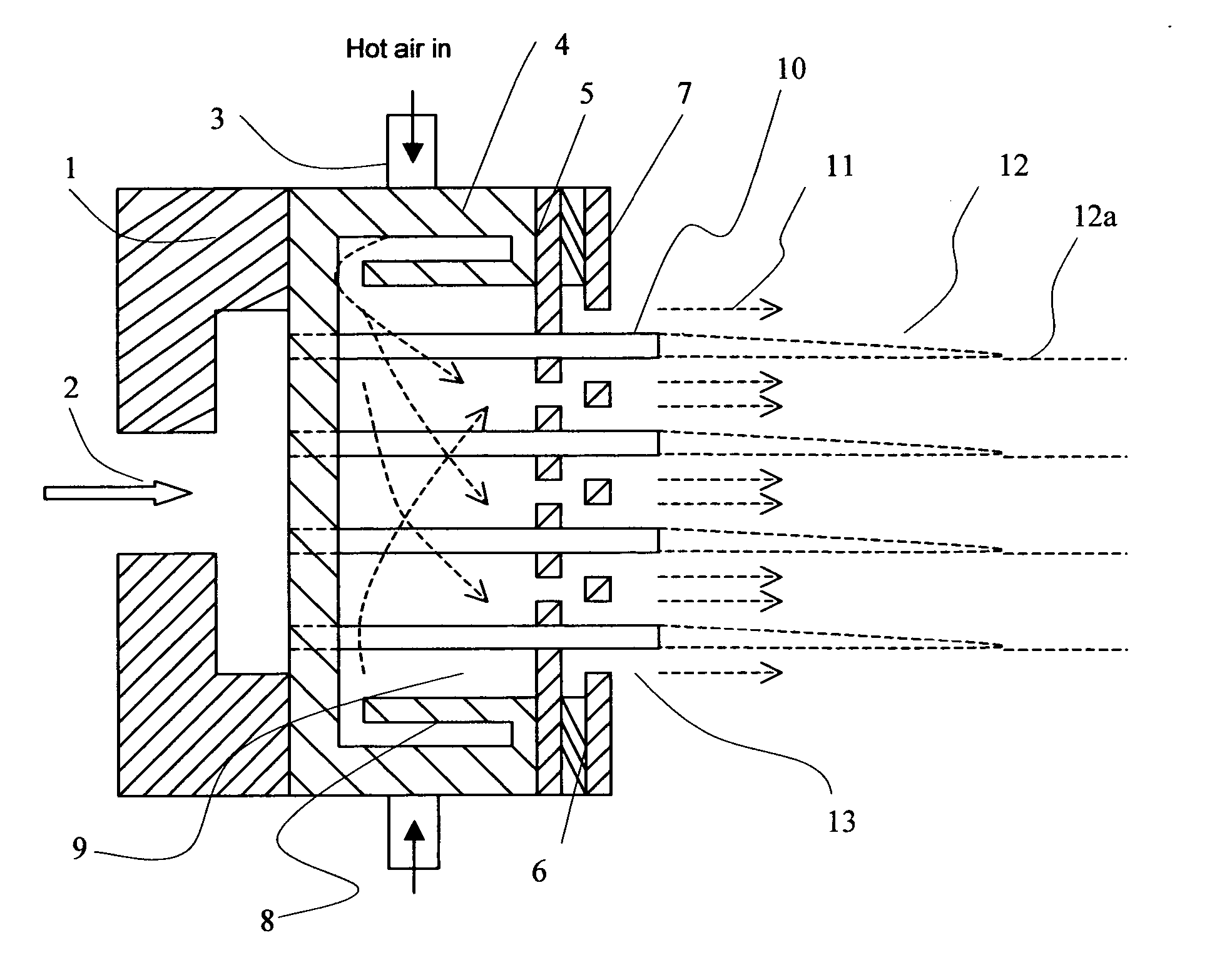

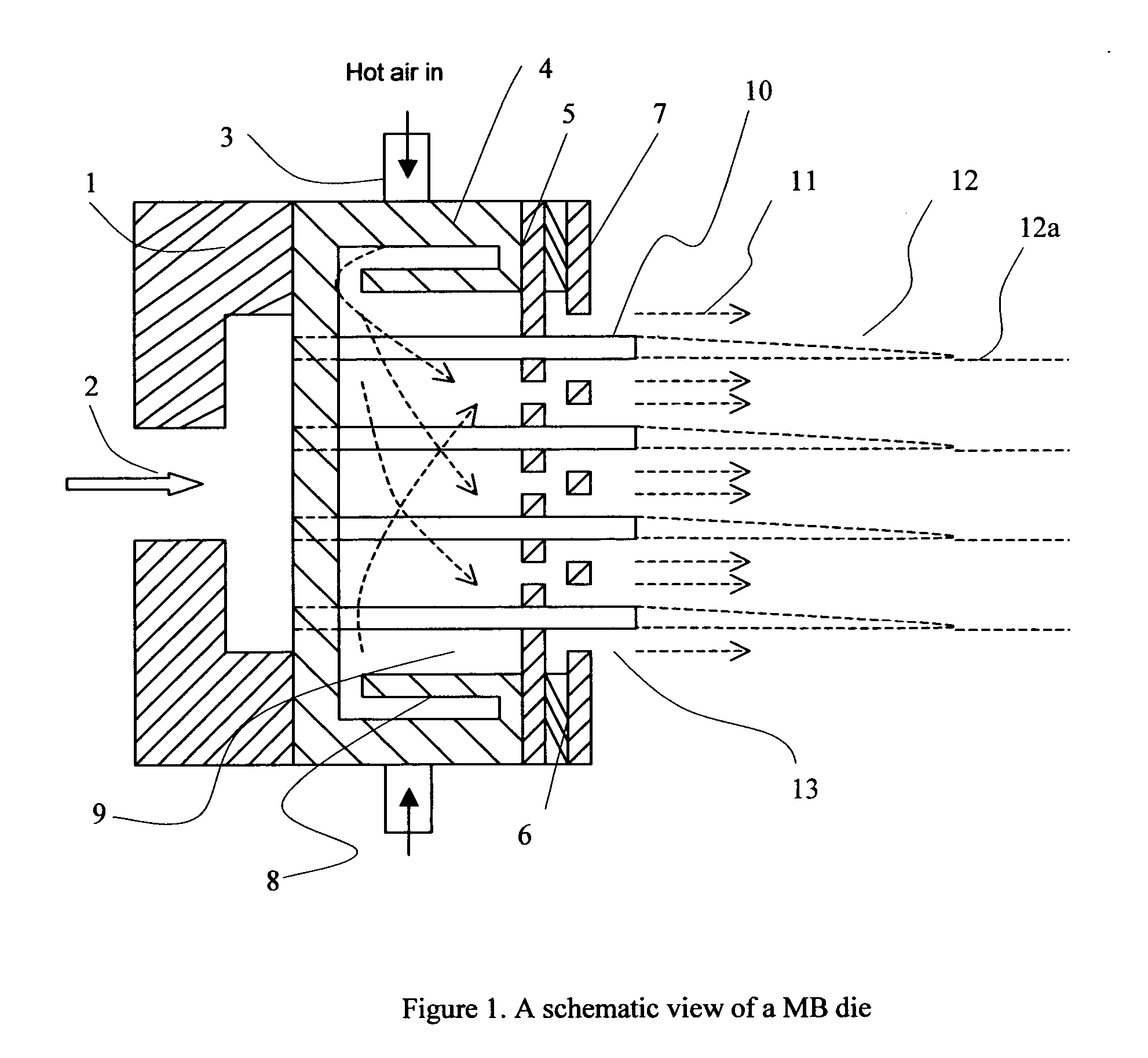

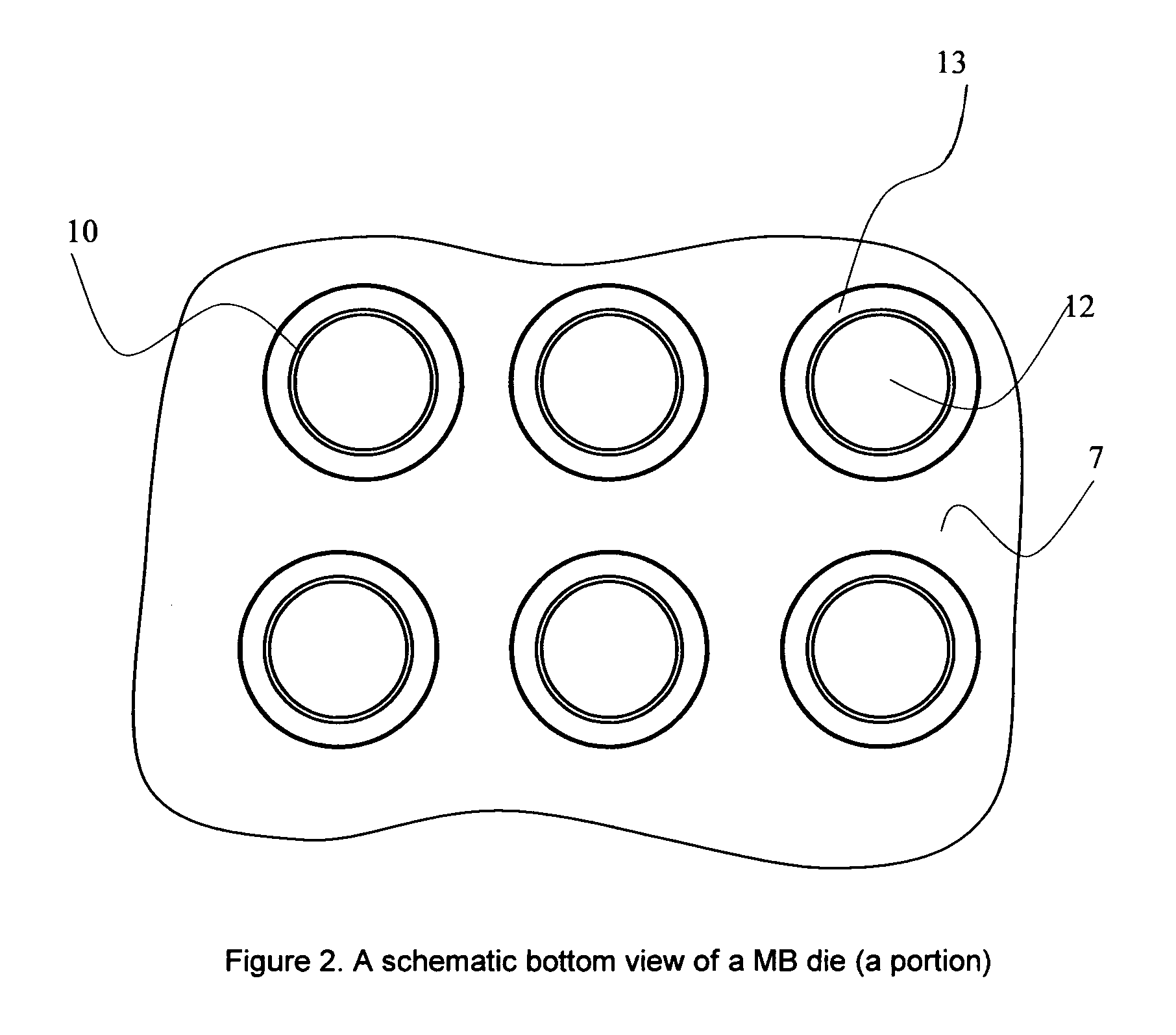

[0030] The extruder has three heating zones and the temperatures were set as 165° F. (Zone 1, near the feeding hoper), 210° F., 230° F., respectively. The molten solution was forced into the body of a 5-inch-2-row spinneret, with 126 spinning nozzles (I.D.=0.009″) and protruding length of 0.1915″. The solution temperature and pressure at the spinneret were kept in 230° F. and 600 PSI, respectively. The air temperature and pressure in the spinneret were held at 250° F. and 15 PSI respectively. The solution throughput was about 0.16 gram / nozzle / min.

[0031] The attenuated microfibers are deposited on a perforated rotating drum right after ...

example 2

[0032] A 1 inch extruder is fed with a NMMO solution comprising 14% by weight cellulose, 76% by weight of NMMO and the rest is mainly water. The solid solution are in the form of pellet of 0.05″˜0.08″ in size. The feeding hoper is filled with Argon gas to prevent moisture takeup. The cellulose has an average degree of polymerization of 670.

[0033] The extruder has three heating zones and the temperatures were set as 185° F. (Zone 1, near the feeding hoper), 230° F., 250° F., respectively. The molten solution was forced into the body of a 5-inch-2-row spinneret, with 63 spinning nozzles (I.D.=0.020″) and protruding length of 0.180″. The solution temperature and pressure at the spinneret were kept in 250° F. and 860 PSI, respectively. The air temperature and pressure in the spinneret were held at 270° F. and 10 PSI respectively. The solution throughput was about 0.8 gram / nozzle / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com