X-ray and gamma-ray shielding non-woven fabric and preparation method thereof

A technology of non-woven fabrics and γ-rays, which is applied in the manufacture of rayon, textiles and paper, and non-woven fabrics. It can solve the problems of reducing the softness and comfort of clothing, weak particle absorption capacity of lead, and limited addition of shielding materials. , to achieve the effects of no skin contact toxicity, low processing cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

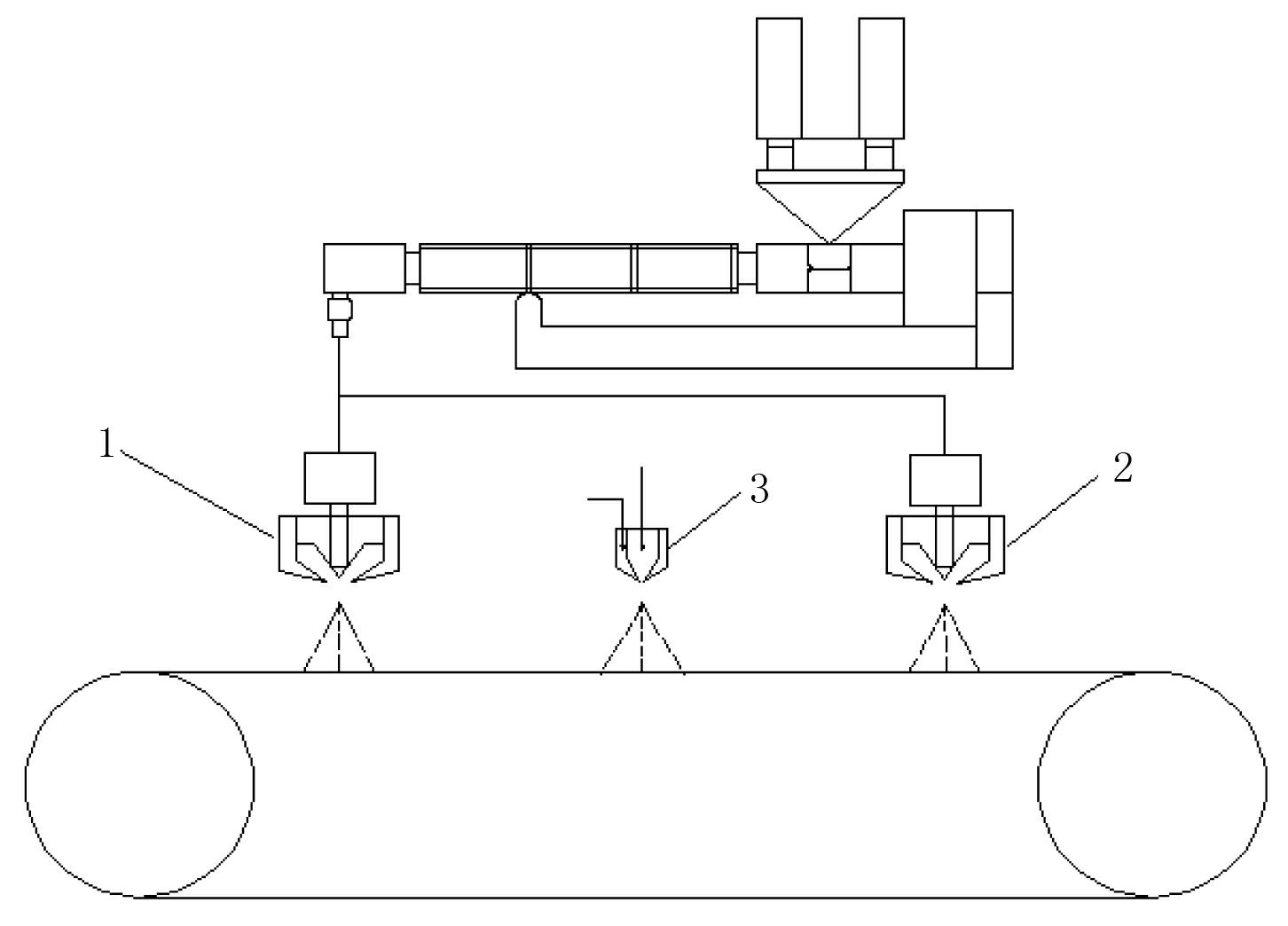

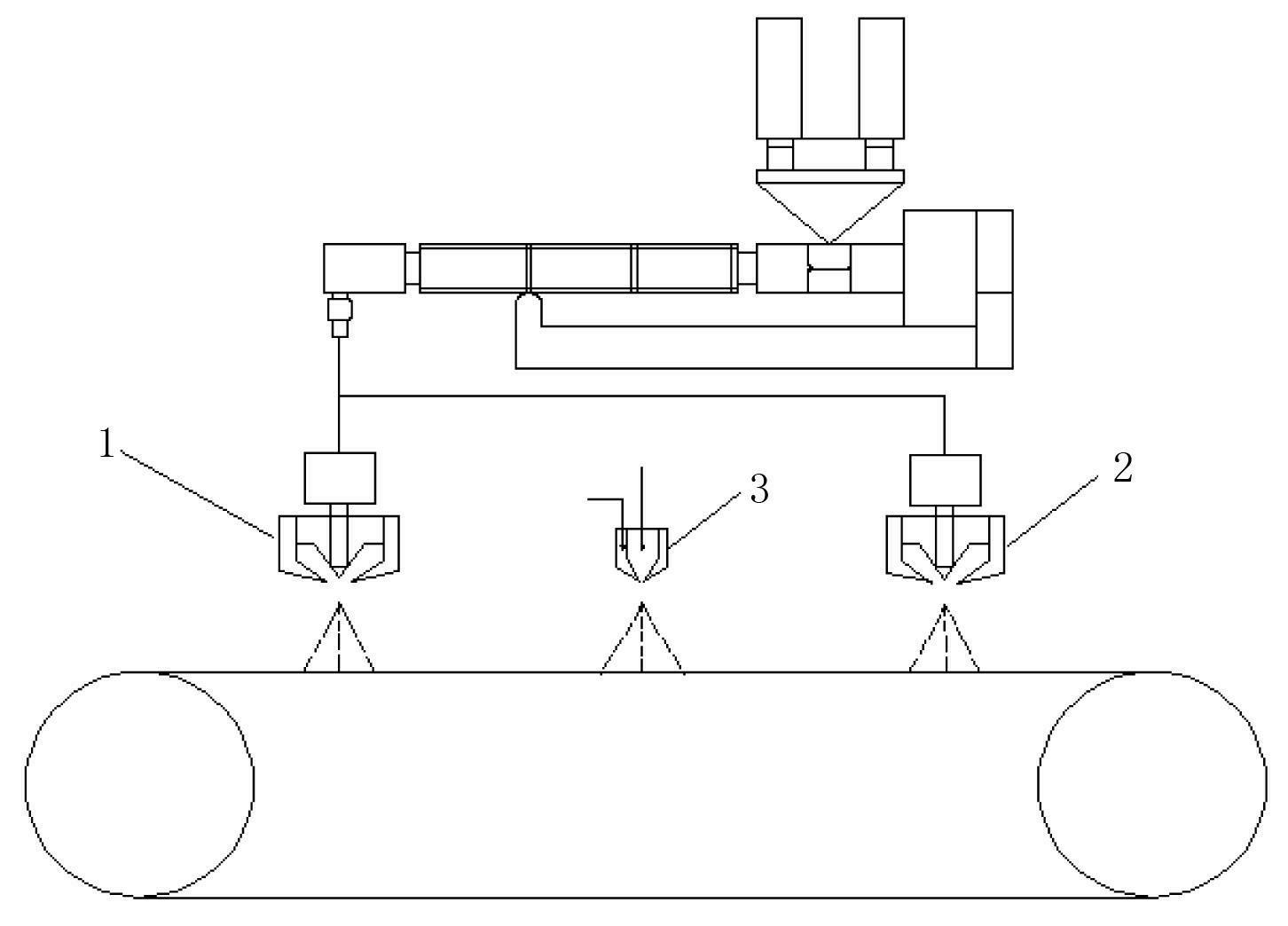

[0038] Dry polypropylene slices with a melt index of 75 until the water content is below 0.01%, then add 0.2% (wt) phenyl-α-naphthylamine antioxidant, and stir in a closed high-speed mixer at 600 rpm Mix for 10 minutes, then stir and mix for 10 minutes at a speed of 1500 rpm. The mixed material is fed into a screw extruder and extruded into the first metering pump and the second metering pump at a temperature of 340 ° C. The pump supply is 0.7 g / min is accurately metered into the melt distribution cavity, and then enters the spinning melt pool after rectification, and then is ejected from the first spinneret 1 and the second spinneret 2 at a die temperature of 350°C. The filaments were stretched under the jet stretching of a high-speed airflow at a speed of 25.7m / s and a temperature of 330°C to form fibers. The drawn fibers are formed on the collecting device under the guidance of the suction wind.

[0039] Stir functional fillers with an average particle size of about 10 μm ...

Embodiment 2

[0042] Dry the polypropylene chips with a melt index of 75 to less than 0.01% water, then add 0.2% (wt) 4,4-methylene-bis-(2,6 di-tert-butyl)phenol antioxidant, Stir and mix in a high-speed mixer at 600 rpm for 10 minutes, then stir and mix at 1500 rpm for 10 minutes, and the mixed material is added to a screw extruder and extruded at a temperature of 340°C into the first The metering pump and the metering pump are accurately metered into the melt distribution chamber with a pump supply rate of 0.7 g / min, and then enter the spinning melt pool after rectification, and then flow from the first spinneret at a die temperature of 350 ° C 1 and the second spinneret 2 are sprayed into filaments, and are formed into fibers under the jet stretching of a high-speed airflow with a speed of 25.7m / s and a temperature of 330°C. The drawn fibers are formed on the collecting device under the guidance of the suction wind.

[0043] Stir functional fillers with an average particle size of about...

Embodiment 3

[0046]Dry the polypropylene slices with a melt flow rate of 1200g / 10min until the water content is below 0.01%, then add 0.2% (wt) of phenyl-β-naphthylamine antioxidant, in a closed high-speed mixer at 600 rpm Stir and mix for 10 minutes at a sub-rotation speed, then stir and mix for 10 minutes at a speed of 1500 rpm. The mixed material is added to a screw extruder and extruded into the first metering pump and the second metering pump at a temperature of 270 ° C. The pump supply rate is 0.7 g / min and is accurately metered into the melt distribution cavity, and then enters the spinning melt pool after rectification, and then flows from the first spinneret 1 and the second spinneret at a die temperature of 240°C. 2. Spray into filaments, and form fibers under the jet stretching of a high-speed airflow with a speed of 70m / s and a temperature of 255°C. The drawn fibers are formed on the collecting device under the guidance of the suction wind.

[0047] Stir functional fillers wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com