Variable efficiency faraday shield

A variable, efficient technology, applied in the field of electrical shielding, capable of solving problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

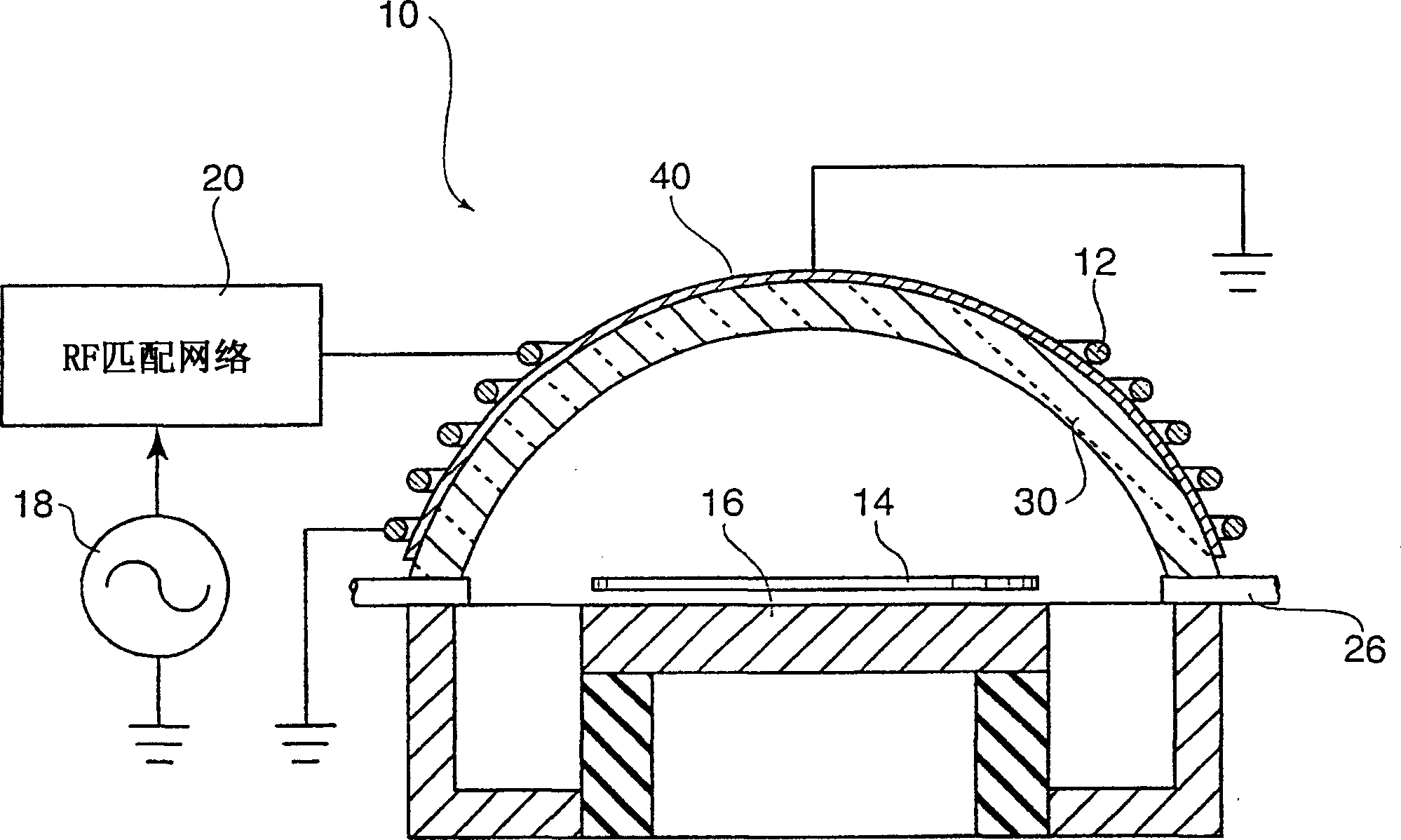

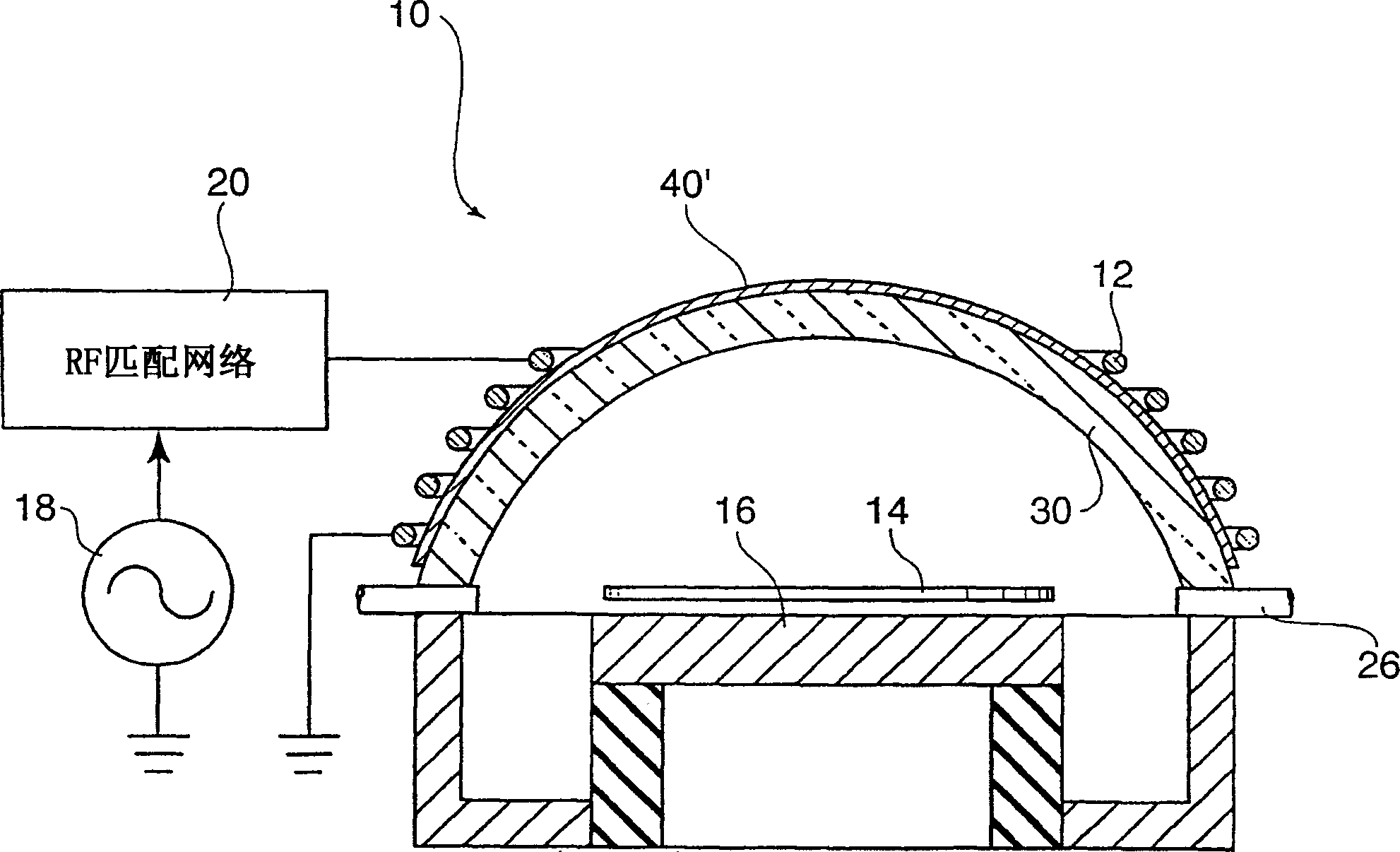

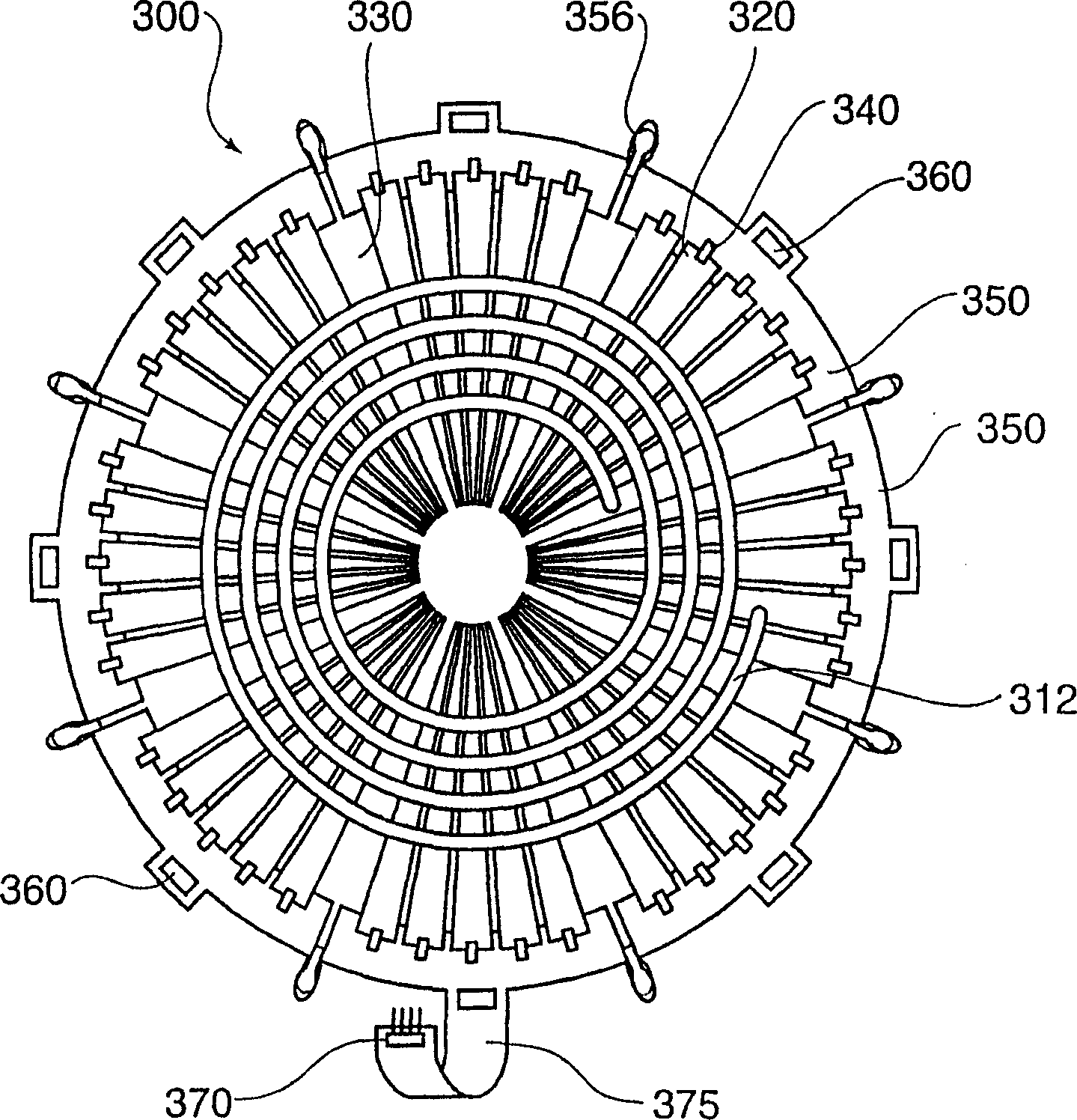

[0040] An ungrounded passive voltage distribution electrode (VDE) is typically placed between the excitation antenna coil and the RF dome in the etch chamber. This VDE is an example of an application specific ungrounded Faraday shield.

[0041] As noted above, grounded shielding is more effective at minimizing capacitive coupling between the excitation antenna and the chamber plasma, and thus reducing the plasma potential difference between the plasma body and the inner surface of the RF aperture. By lowering the plasma potential here, the sputter erosion rate of the ceramic material of the aperture is significantly reduced.

[0042] Unfortunately, the underside of a grounded shield design makes it very difficult to induce a plasma discharge in the chamber and causes the impedance of the focused antenna circuit to drop outside the nominal range of the tuned network. This is the main reason why more effective grounding designs have not been incorporated into prior art plasma c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com