Nanofiber composite membrane and preparation method thereof

A nanofiber and fiber membrane technology, applied in the field of spinning, can solve problems such as poor tensile strength of nanofiber composite membranes, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention provides a kind of preparation method of nanofiber composite membrane, comprises the following steps:

[0053] Dissolving the high-melting-point polymer in the spinning solvent to obtain a high-melting-point polymer spinning solution;

[0054] Melting the low-melting polymer to obtain a melt of the low-melting polymer;

[0055] The melting point difference between the high melting point polymer and the low melting point polymer is not less than 10°C;

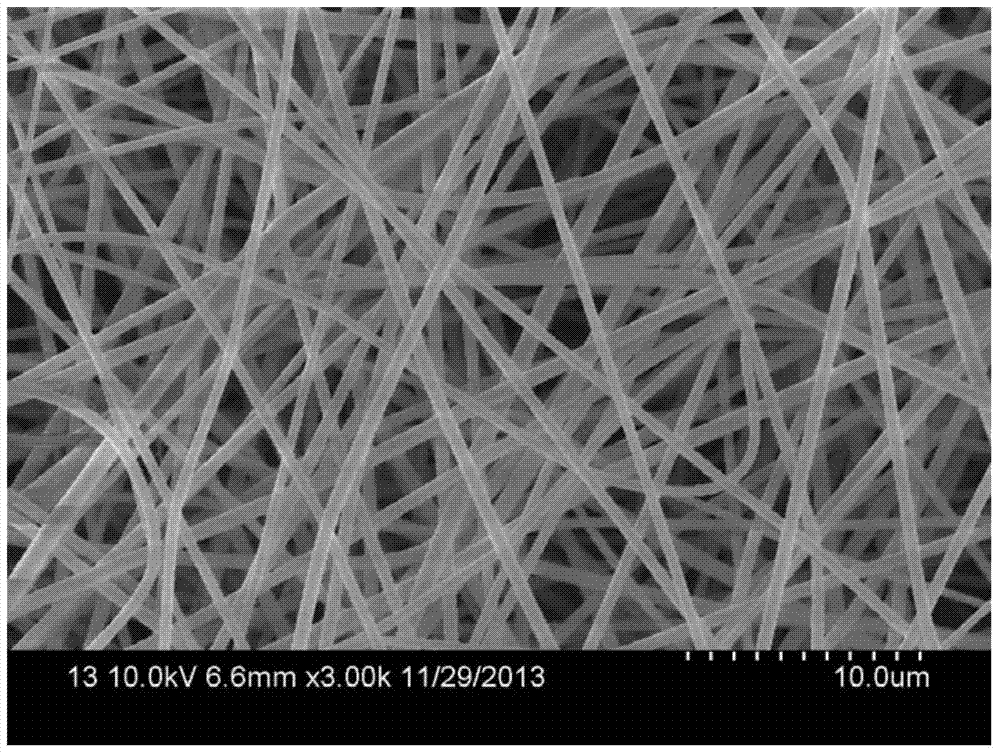

[0056] Electrospinning the resulting spinning solution of the high melting point polymer to obtain an electrospun high melting point polymer fiber membrane;

[0057] The melt of the obtained low-melting-point polymer is melt-blown and spun to obtain a melt-blown and spun low-melting-point polymer fiber film;

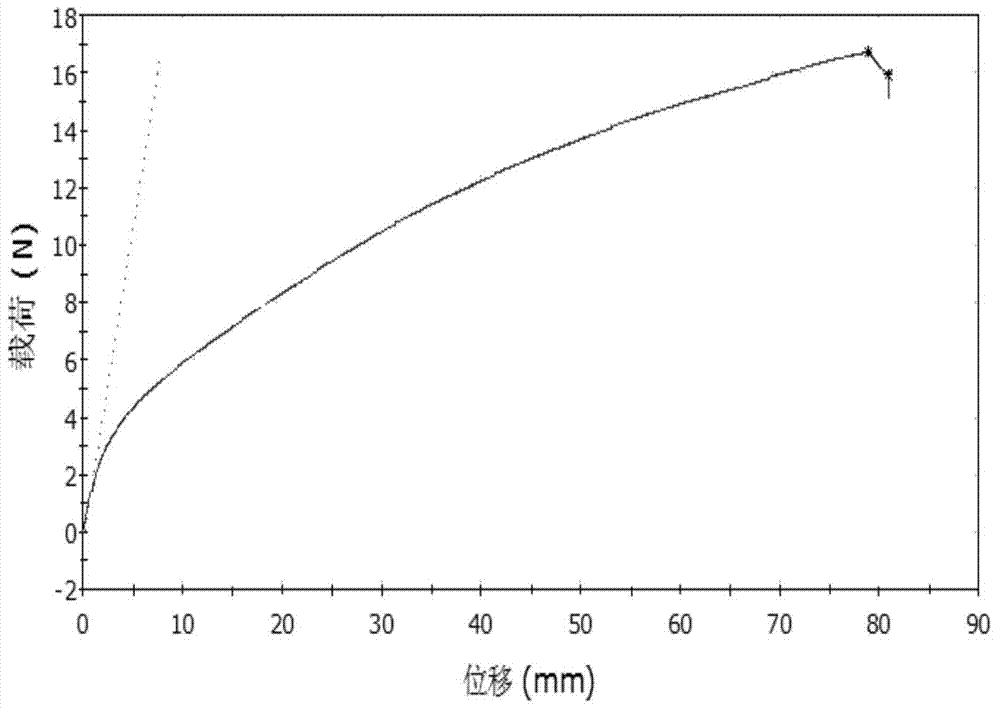

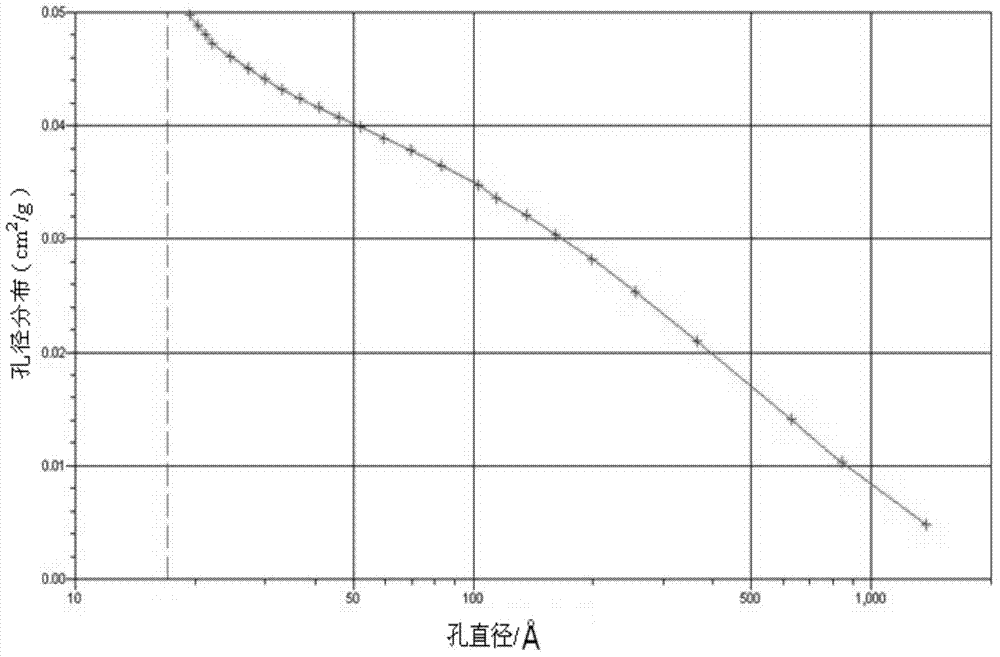

[0058] The obtained electrospun high-melting-point polymer fiber membrane and the melt-blown low-melting-point polymer fiber membrane are combined and hot-pressed to obtain a nanofiber composite membra...

Embodiment 1

[0114] Dry PVDF-HFP powder in a vacuum oven at 100°C for 12h, cool to room temperature, dissolve 150g of dried PVDF-HFP powder in a mixed solvent of 850g of acetone and DMF, stir at room temperature for 12h, and then add 1g of Nano-titanium dioxide particles, after ultrasonically dispersing the obtained mixed solution for 6 hours, obtain PVDF-HFP spinning solution, and set aside;

[0115] Dry PVDF powder in a vacuum oven at 100°C for 12h, cool to room temperature, dissolve 120g of dried PVDF powder in 880g of N,N-dimethylacetamide and acetone mixed solvent, and stir at room temperature for 12h to obtain PVDF Spinning solution, spare;

[0116] The viscosity of the PVDF-HFP spinning solution was measured, and the measured viscosity was 5.1Pa s; at a room temperature of 25°C and a relative air humidity of about 40%, the PVDF-HFP spinning solution was electrospun, and during the electrospinning process , forming each stable Taylor cone feeding (adding) liquid at a rate of 1.5mL / h...

Embodiment 2

[0129] After vacuum drying PVDF, PVDF-HFP, PE and PP at 100°C for 12 hours, put them in a desiccator for later use;

[0130] Dissolve 150g of vacuum-dried polyvinylidene fluoride-perfluoropropylene copolymer (PVDF-HFP) powder in a mixed solvent of 255g DMF and 595g acetone, and stir and dissolve at room temperature 25°C for 12h to form a uniform and transparent solution. PVDF-HFP spinning solution, spare;

[0131] Dissolve 120g of vacuum-dried polyvinylidene fluoride (PVDF) powder in a mixed solvent of 264g DMF and 616g of acetone, stir and dissolve at room temperature 25°C for 12h to form a uniform and transparent solution, and obtain PVDF spinning solution for subsequent use;

[0132] The viscosity of the above PVDF spinning solution was measured, and the measured viscosity was 4.9 Pa s. At a room temperature of 25°C and a relative air humidity of about 40%, the injection speed of the plastic injection pump was distributed during the electrospinning process of the PVDF spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com