Automatic-rotating electrostatic spinning device assisted by high-pressure airflow and provided with nozzle

A technology of electrospinning and high-pressure airflow, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc. It can solve the problems of thick fiber diameter, low efficiency, and difficult die head processing, etc., and achieves simple device design, The effect of ensuring spinning quality and spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

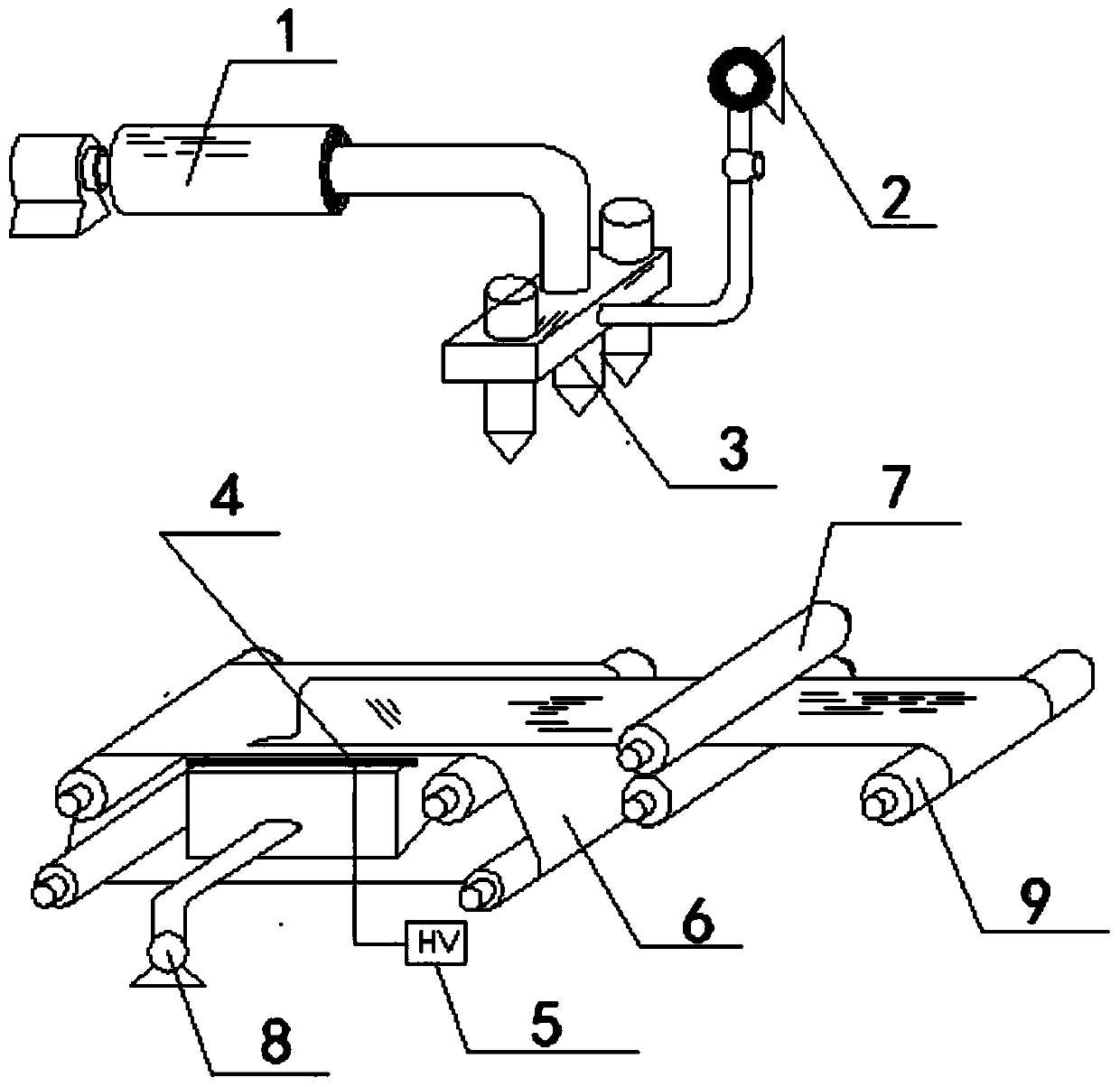

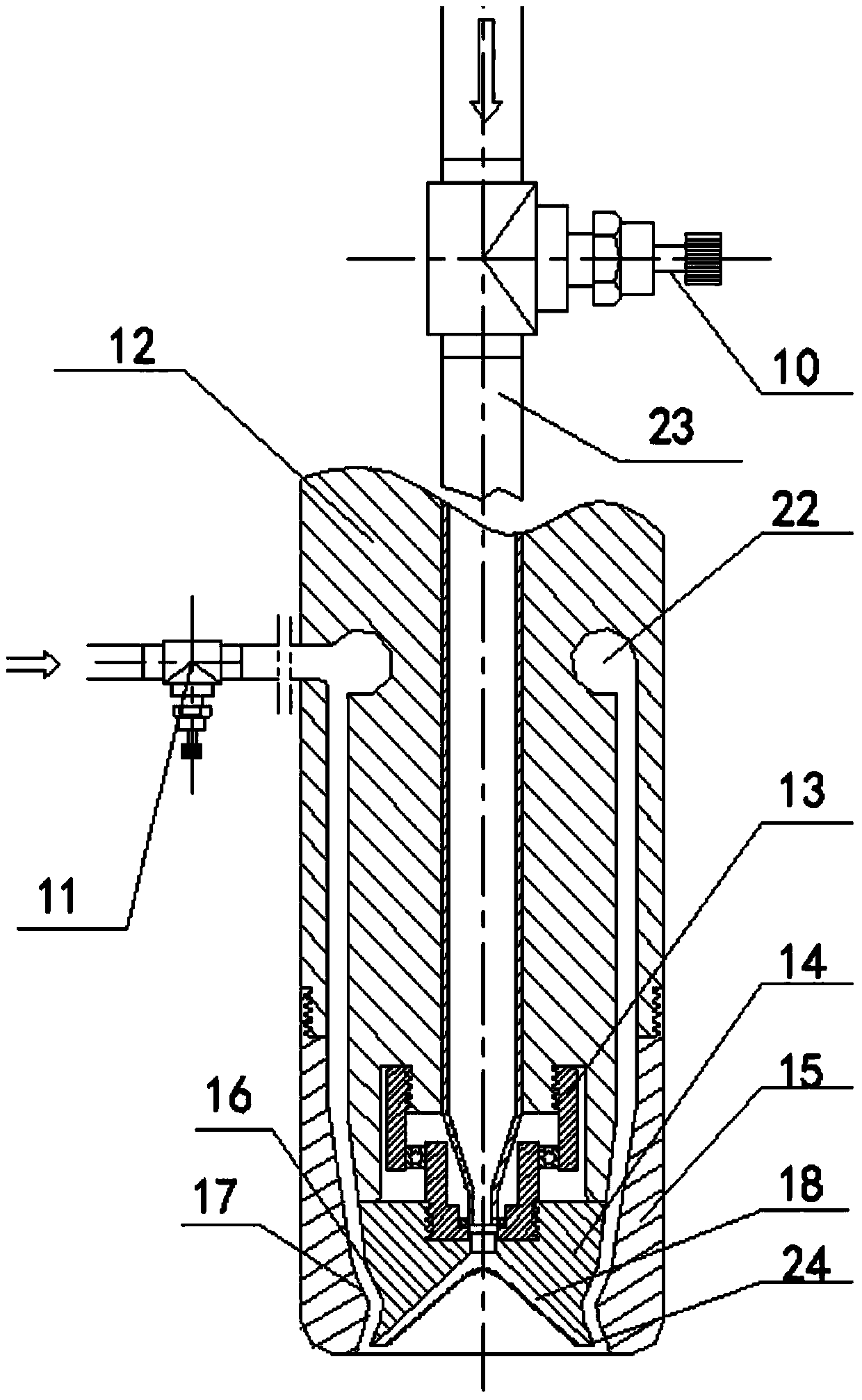

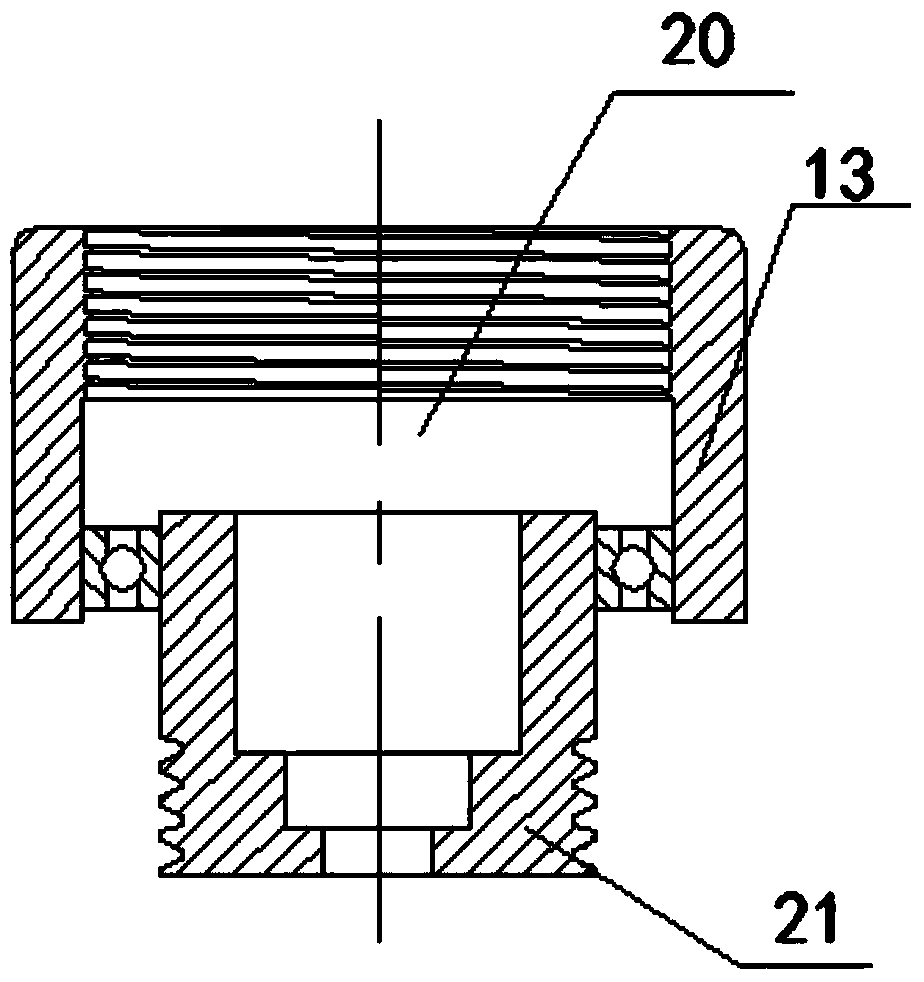

[0020] The invention provides a self-rotating electrostatic spinning device assisted by high-pressure airflow. The overall schematic diagram of the device is as figure 1 As shown, the spinning device includes a feeding device 1, an air compressor 2, a spinning nozzle 3, an electrode plate 4, a high-voltage electrostatic generator 5, a laying belt 6, a hot roller 7, an exhaust system 8 and a receiving device 9. The air compressor 2 is connected to the spinning nozzle flow path 22 through the gas flow regulating valve 11, the feeding device 1 is connected to the feeding flow path 23 through the solution flow regulating valve 10, and the mesh belt 6 is installed directly under the spinning nozzle 3, The electrode plate 4 is close to the upper surface of the mesh belt 6 and connected to the high-voltage electrostatic generator 5. In order to facilitate the normal operation of the ventilation system 8, the electrode plate 4 adopts a structure with uniform mesh holes, and the ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com