Gear switch pin rotating device and pin rotating machining method

A gear switch and turning foot technology, applied in the direction of electrical switches, electrical components, circuits, etc., can solve the problems of processing errors and insufficient transmission reliability, and achieve the effect of ensuring processing quality, ensuring the processing effect of rotating feet, and low structural cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

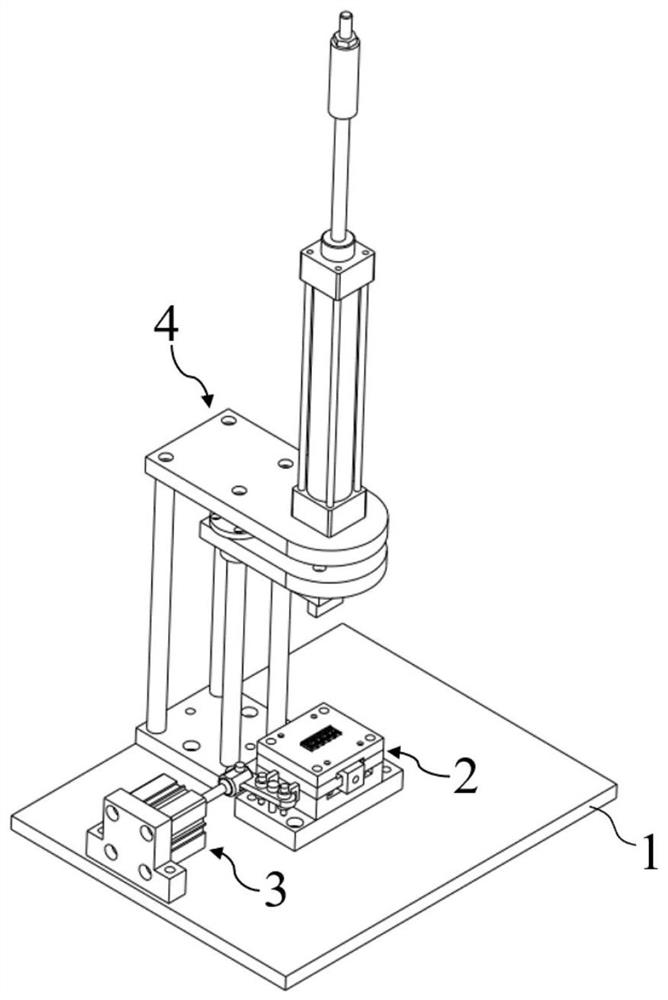

[0074] The gear switch foot rotation device of this embodiment includes,

[0075] Bottom plate 1,

[0076] The swivel unit 2 and the drive unit 3 fixed on the bottom plate 1;

[0077] The swivel unit 2 includes,

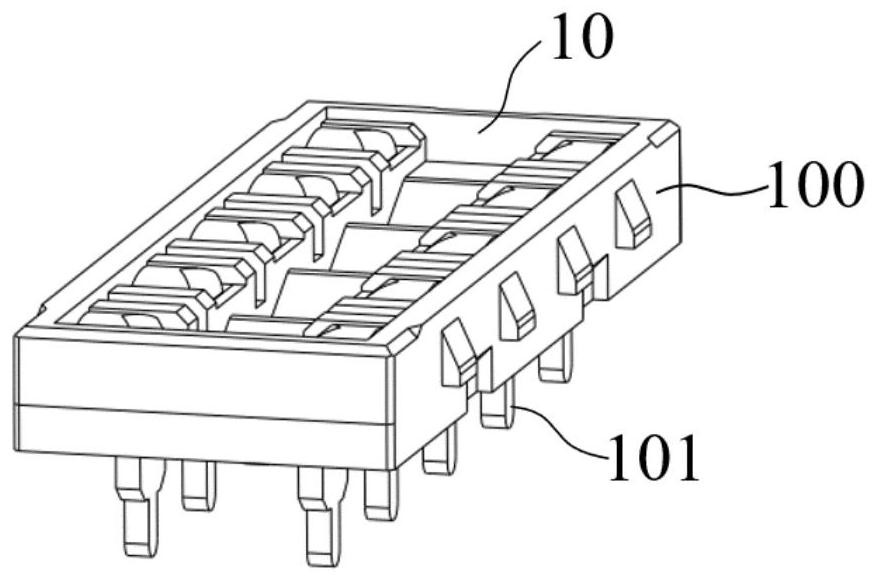

[0078] The workpiece mounting plate 20 is provided with a mounting groove 200 matching the gear switch 10, and a plurality of relief holes 201 are provided through the mounting groove 200 for the pins 101 of the gear switch 10 to protrude;

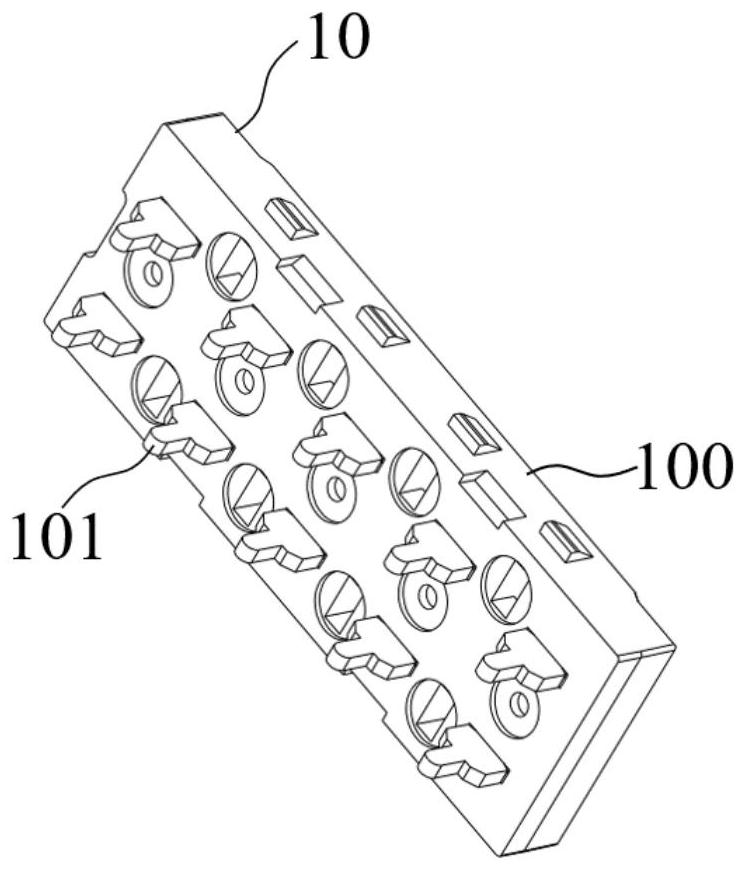

[0079] There are several swivel legs 21, which are correspondingly located below each relief hole 201. The top surface of the swivel leg 21 is provided with an assembly hole 210 matching the shape of the pin 101. The side of the swivel leg 21 is horizontally formed with a transmission rod 211, each The swivel legs 21 are arranged in two rows, and the transmission rods 211 of the two rows of swivel legs 21 are facing oppositely;

[0080] There are two driving rods 22, which are arranged horizontally on both sides of the swivel ...

Embodiment 2

[0091]The gear switch foot rotation device of this embodiment is further improved on the basis of Embodiment 1, and the bottom mounting block 23 is connected to the bottom plate 1 through the base plate 24 arranged below it;

[0092] The telescopic rod 31 of the drive unit 3 is transmission-connected with the drive pull rod 22 through the reversing drive mechanism 25; the reversing drive mechanism 25 includes:

[0093] Rotating rod 250, which is horizontally arranged between the driving rod 22 and the driving cylinder 1 30, one end of the rotating rod 250 corresponds to the two driving rods 22, and the other end corresponds to the telescopic rod 31;

[0094] Fixed turn pin 251, it is vertically arranged, and the bottom end is connected to the base plate 24 places between driving cylinder one 30 and bottom mounting block 23;

[0095] Waist-shaped hole 1 252, which is provided with two places on the rotating rod 250 corresponding to the positions of the two driving rods 22, and ...

Embodiment 3

[0105] The gear switch foot rotation device of this embodiment is further improved on the basis of Embodiments 1 and 2, and the bottom mounting block 23 includes:

[0106] Mounting hole one 230, which corresponds to the bottom position of each swivel foot 21, is opened on the top surface of the bottom mounting block 23, and the swivel leg 21 is rotationally connected with the bottom mounting block 23 through the mounting hole one 230;

[0107] The guide slots 231 corresponding to the positions of the driving rods 22 are opened on both sides of the installation hole 1 230, and limit the movement of the driving rods 22 along their lengthwise directions.

[0108] Such as Figure 5 and Figure 8 As shown, the mounting hole 1 230 on the top surface of the bottom mounting block 23 is used to limit the bottom of each swivel foot 21, and the guide groove 231 is used to limit and guide the movement of the driving rod 22. Through this embodiment The design of this device makes the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com