Rubber plate used in an ion implanter and method of preparing the same

a technology of ion implants and rubber plates, which is applied in the direction of turning machine accessories, manufacturing tools, metal working apparatus, etc., can solve the problems of debris produced during the trimming process, sticky or broken wafers, damage to the platform, etc., and achieve the effect of ensuring the quality and efficiency of wafer production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

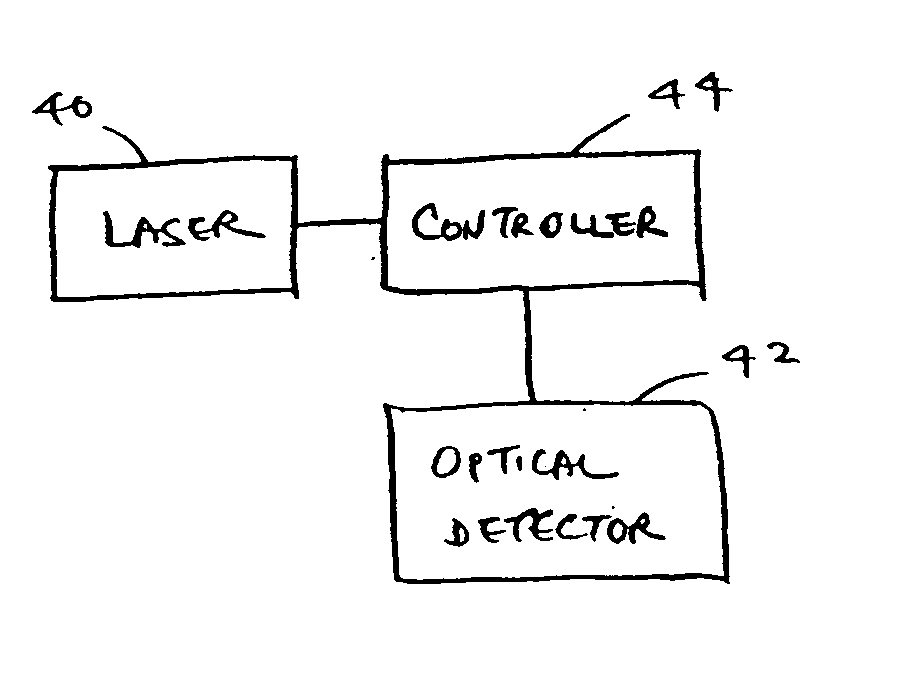

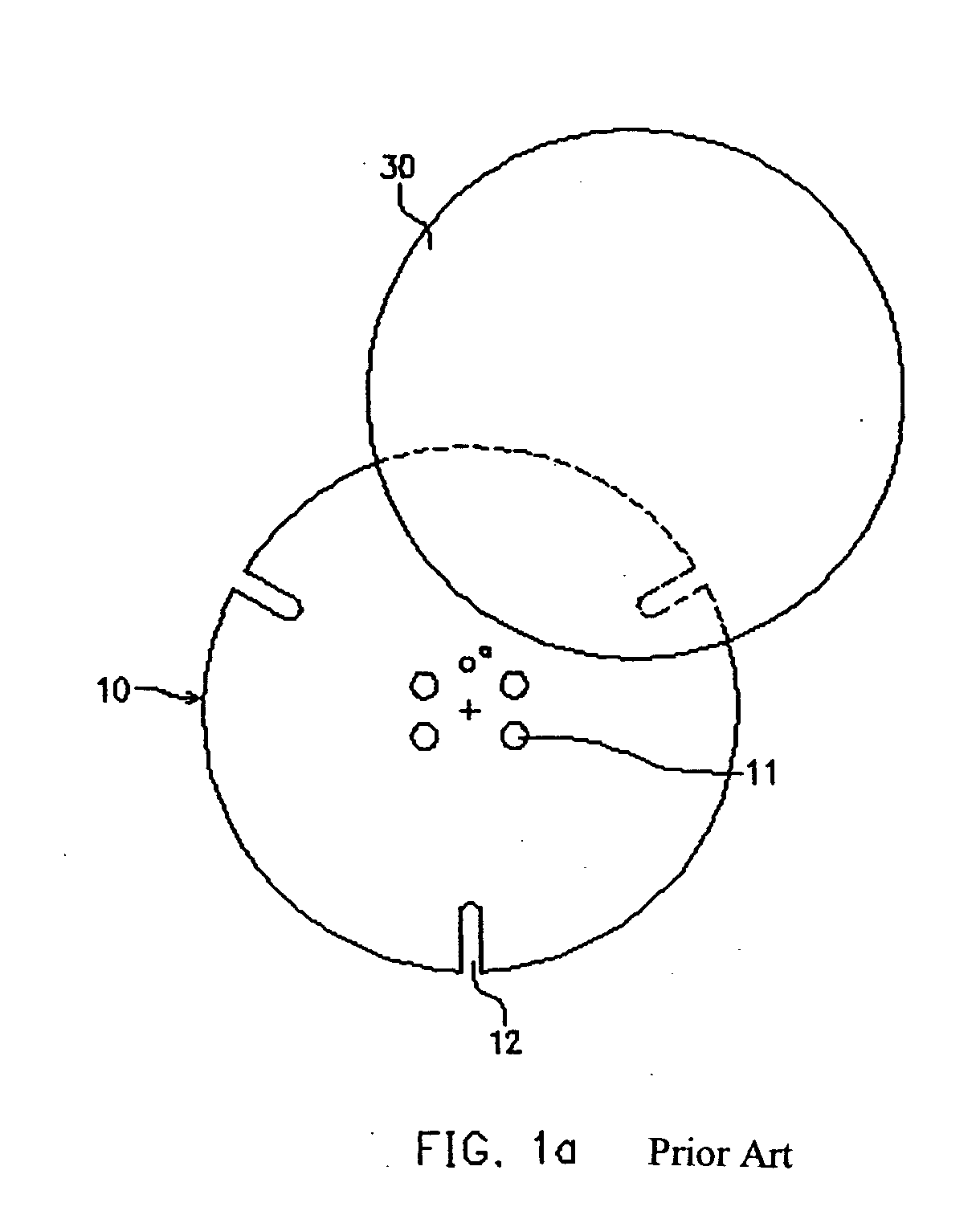

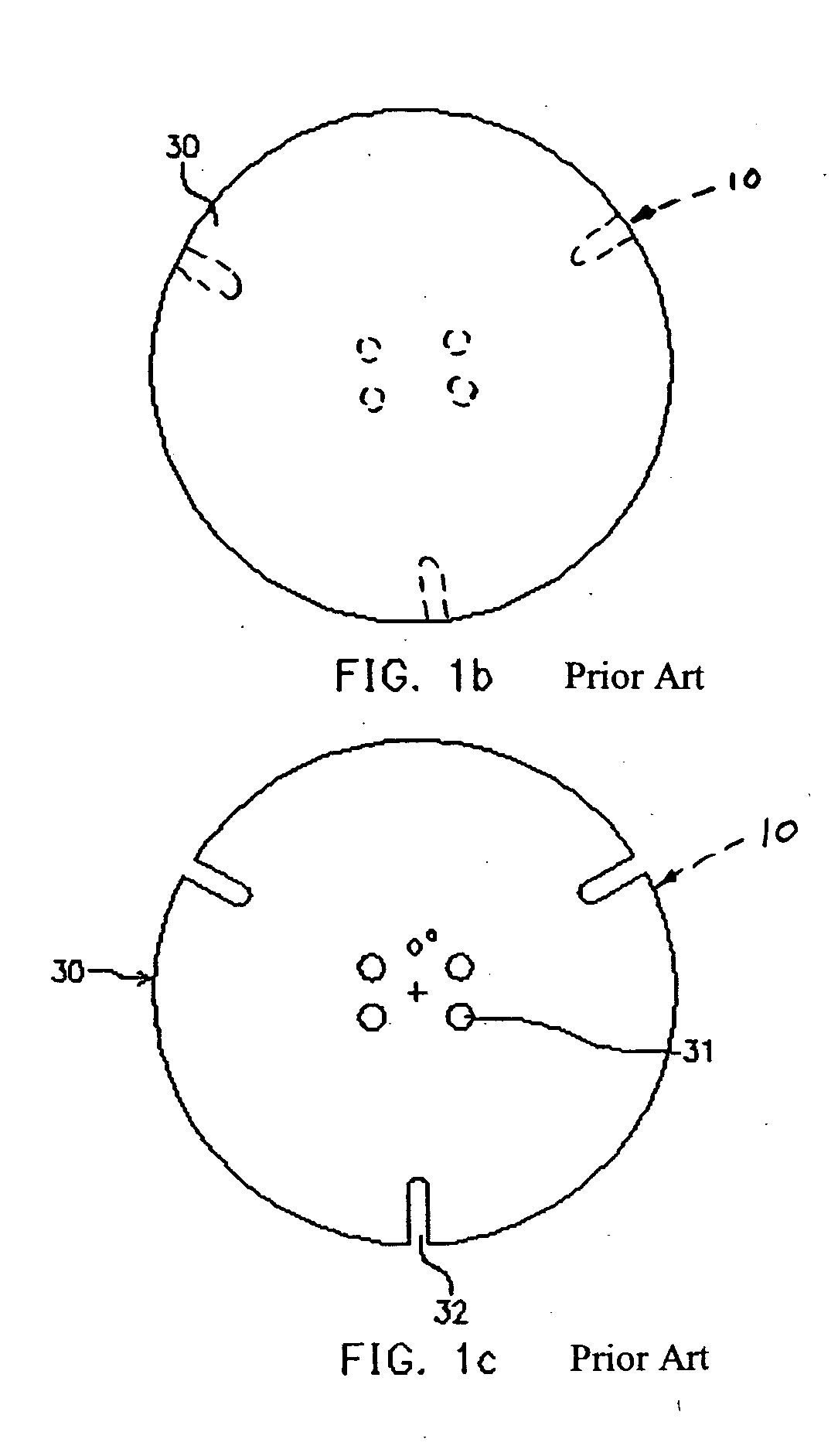

[0024] As shown in FIG. 2, the set of trimming accessories for a rubber plate used in an ion implanter comprises a template 20 and trimming equipment such as a knife or preferably a laser 40 used to trim the rubber plate 30 (FIG. 1a). The template 20 is configured to match the shape and features of the platform 10, including multiple secondary holes 21 which correspond to the primary holes 11 of the platform 10 and multiple secondary notches 22 which correspond to the primary notches 12 of the platform 10. The trimming equipment 40 includes a knife, a cutter, or more preferably a laser or the like. FIG. 2a shows a knife 40a or a laser 40b as the trimming member, for example. The template 20 is typically made of a metal but may be made of other materials that will not be damaged or altered by the trimming equipment 40. As shown in FIG. 2a, an optical detector 42 may be provided to detect the contours of the template 20 formed by the plurality of secondary holes 21 and the plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com