Patents

Literature

32results about How to "Arrangement structure optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

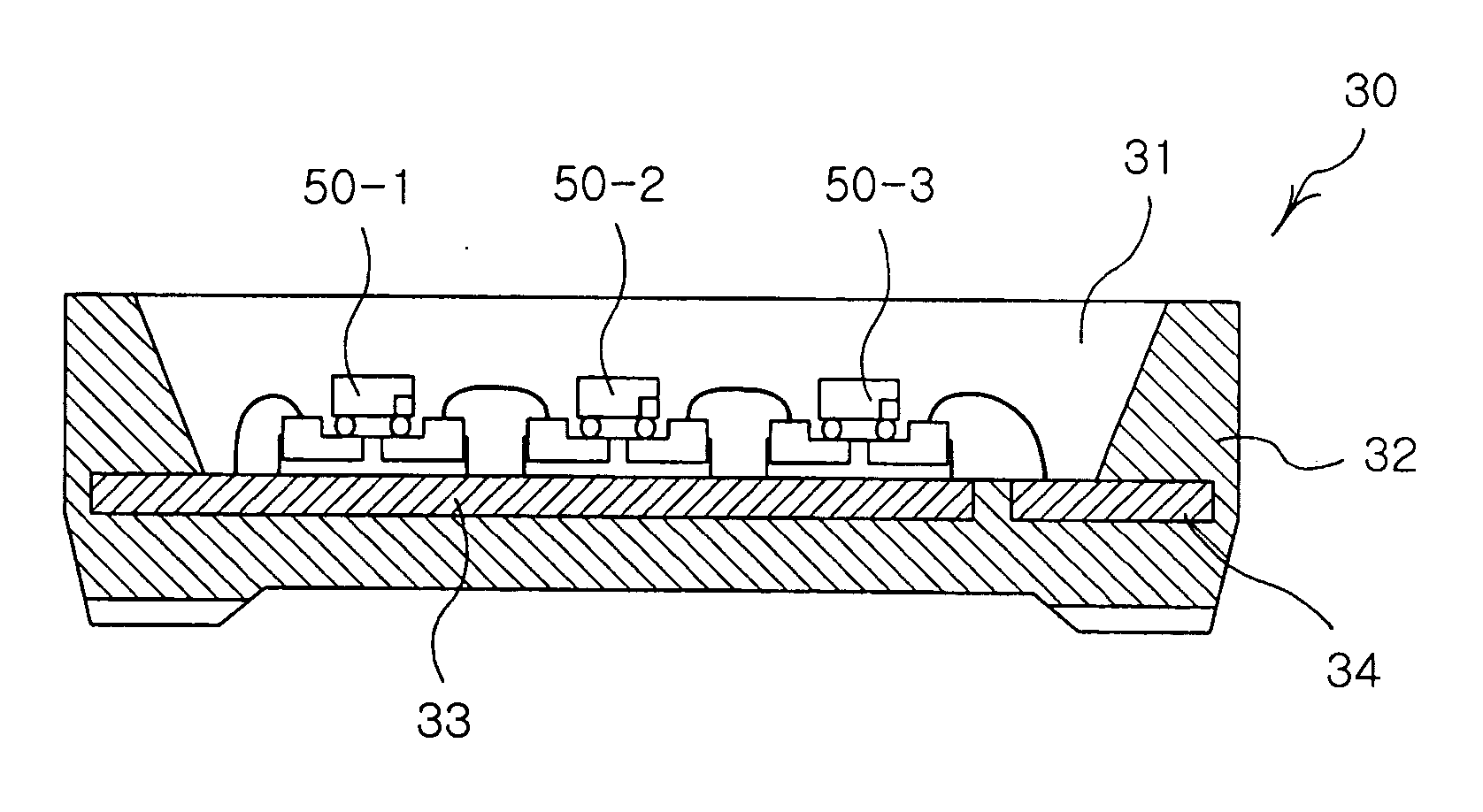

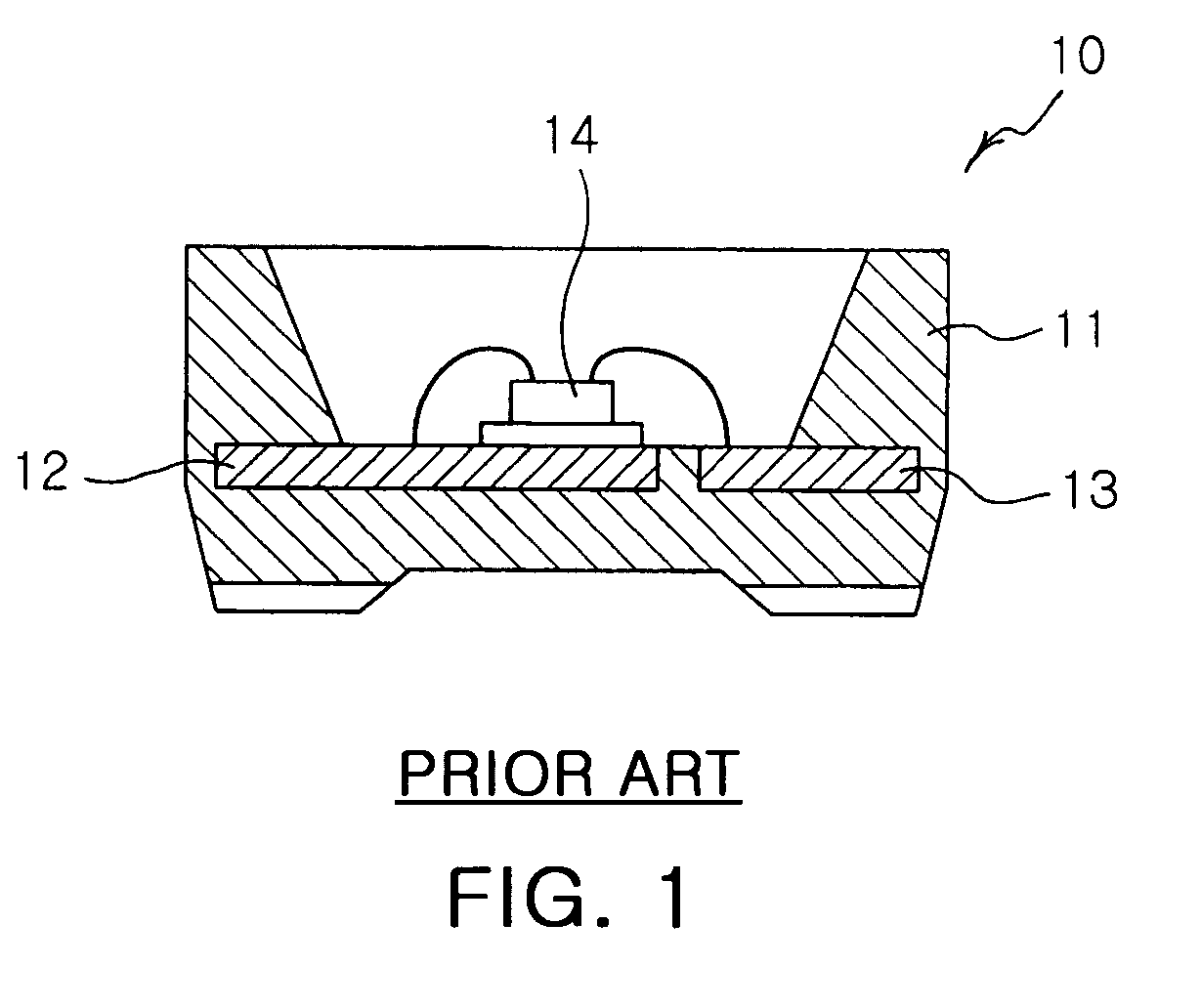

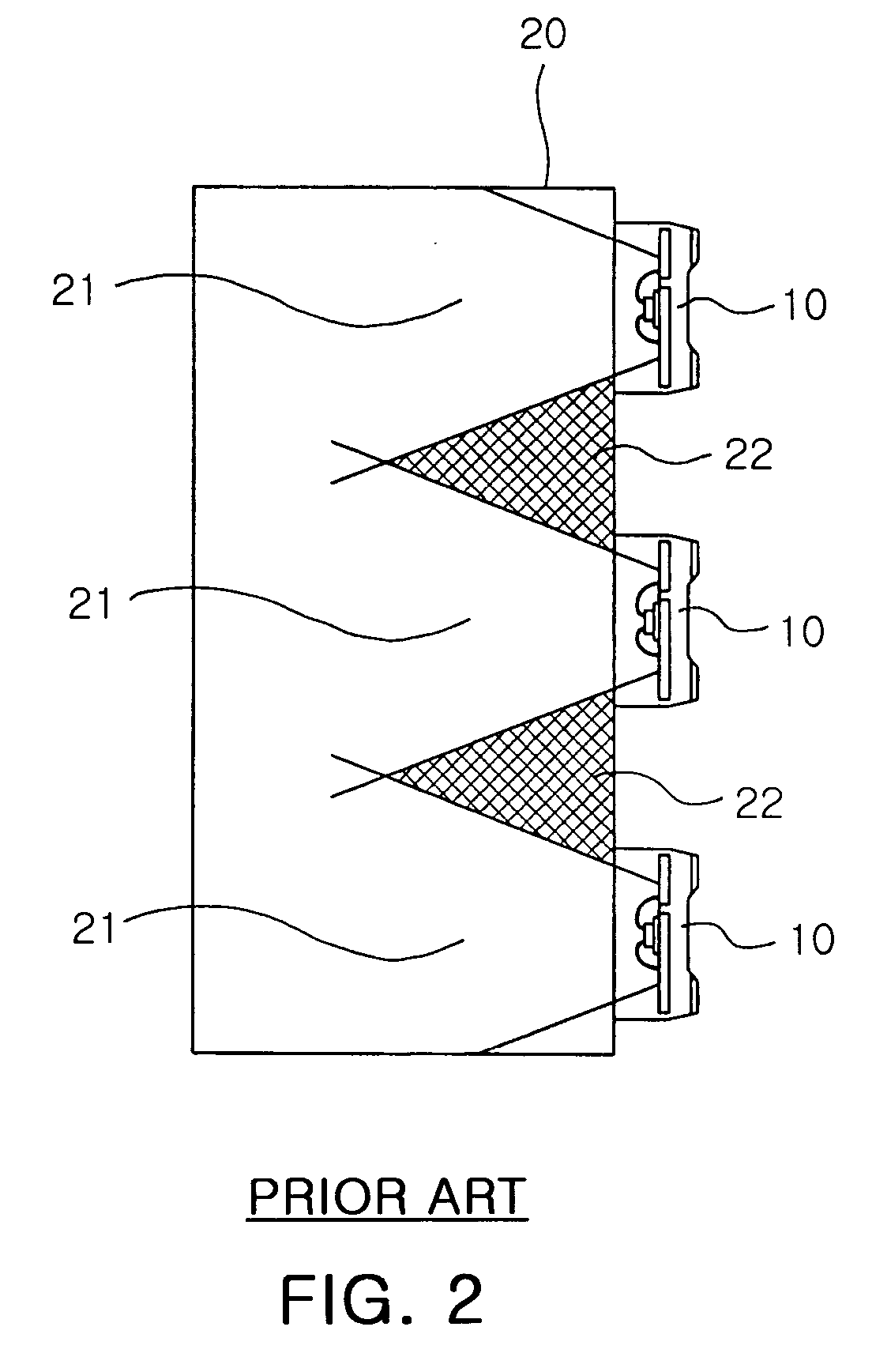

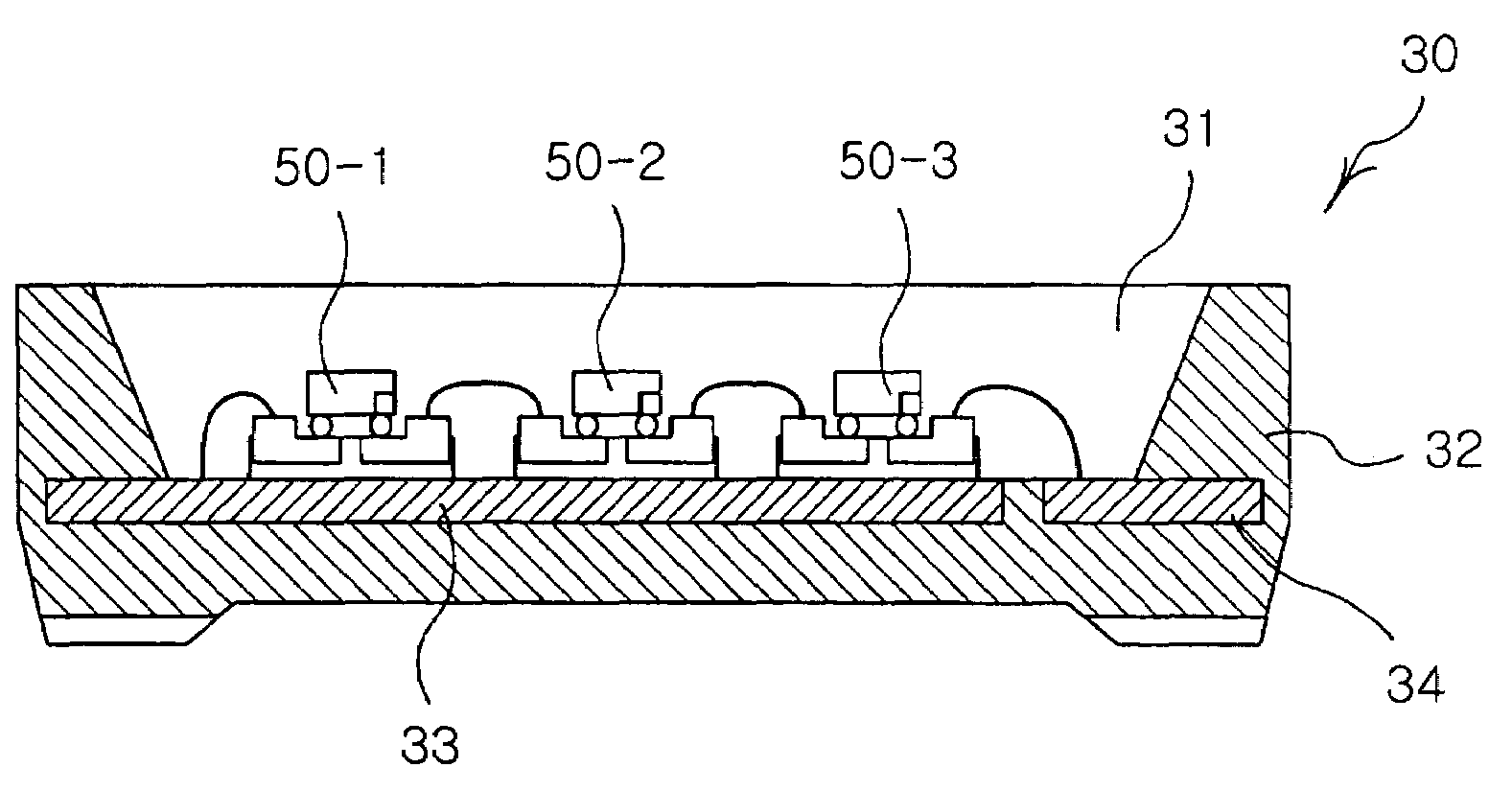

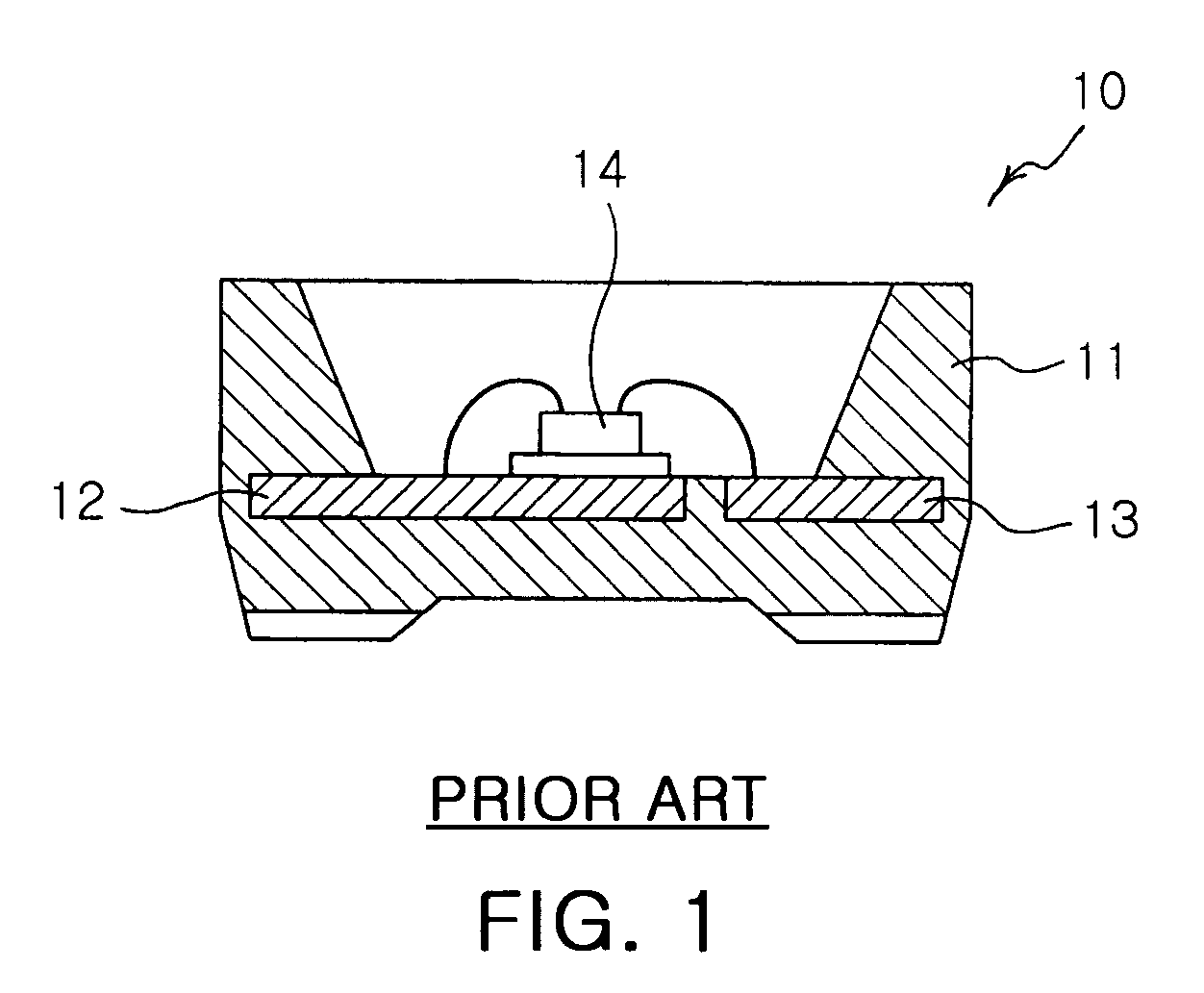

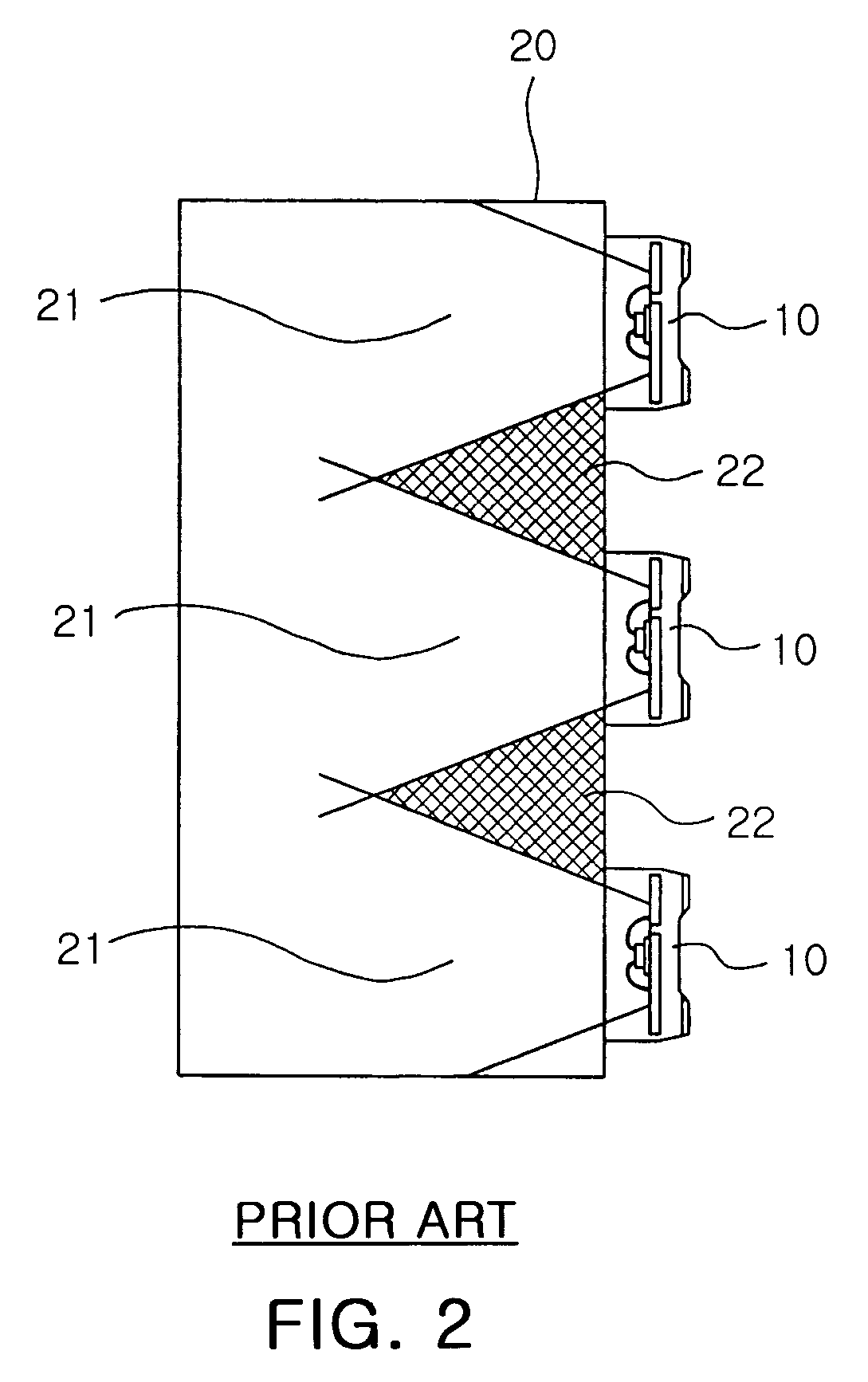

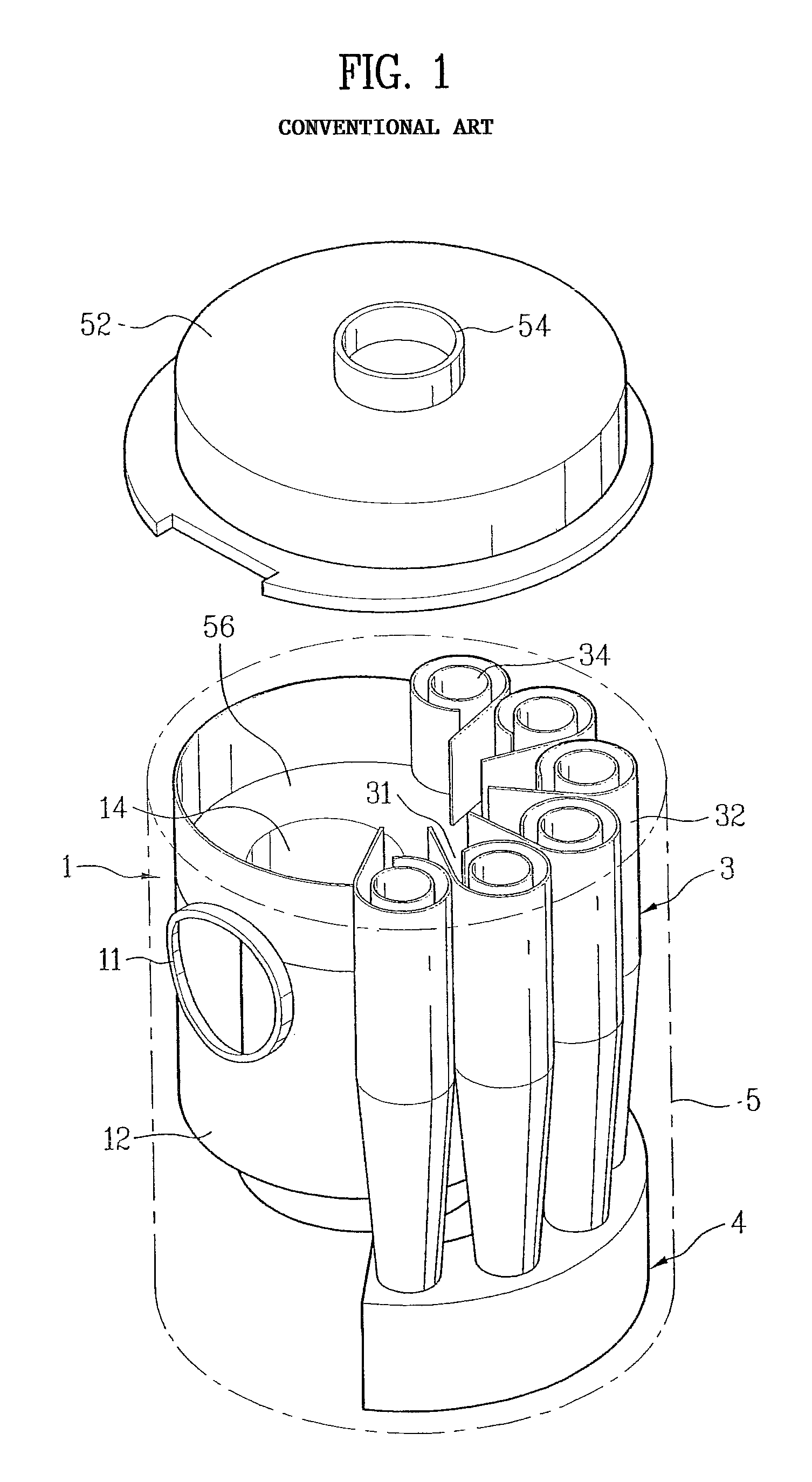

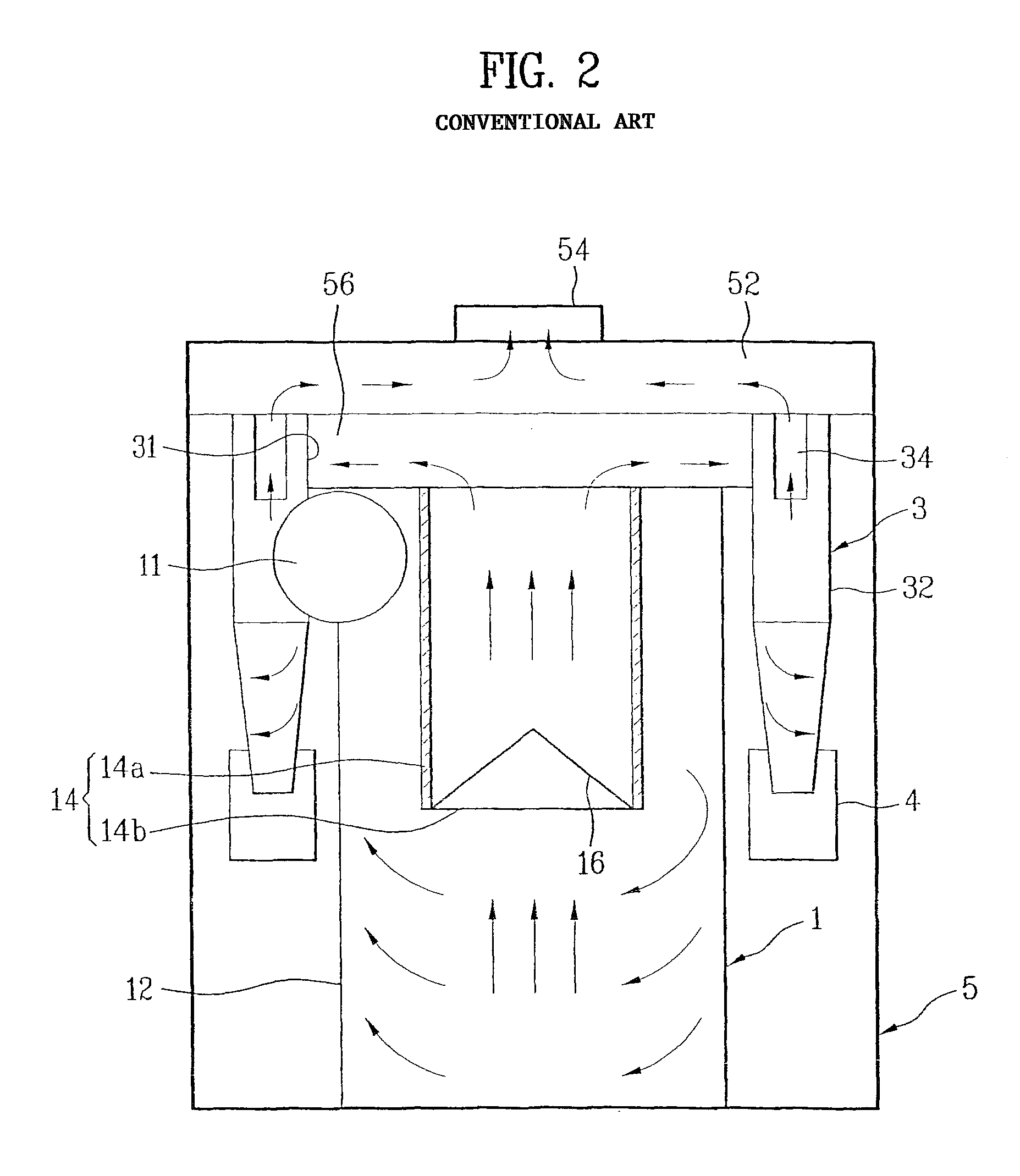

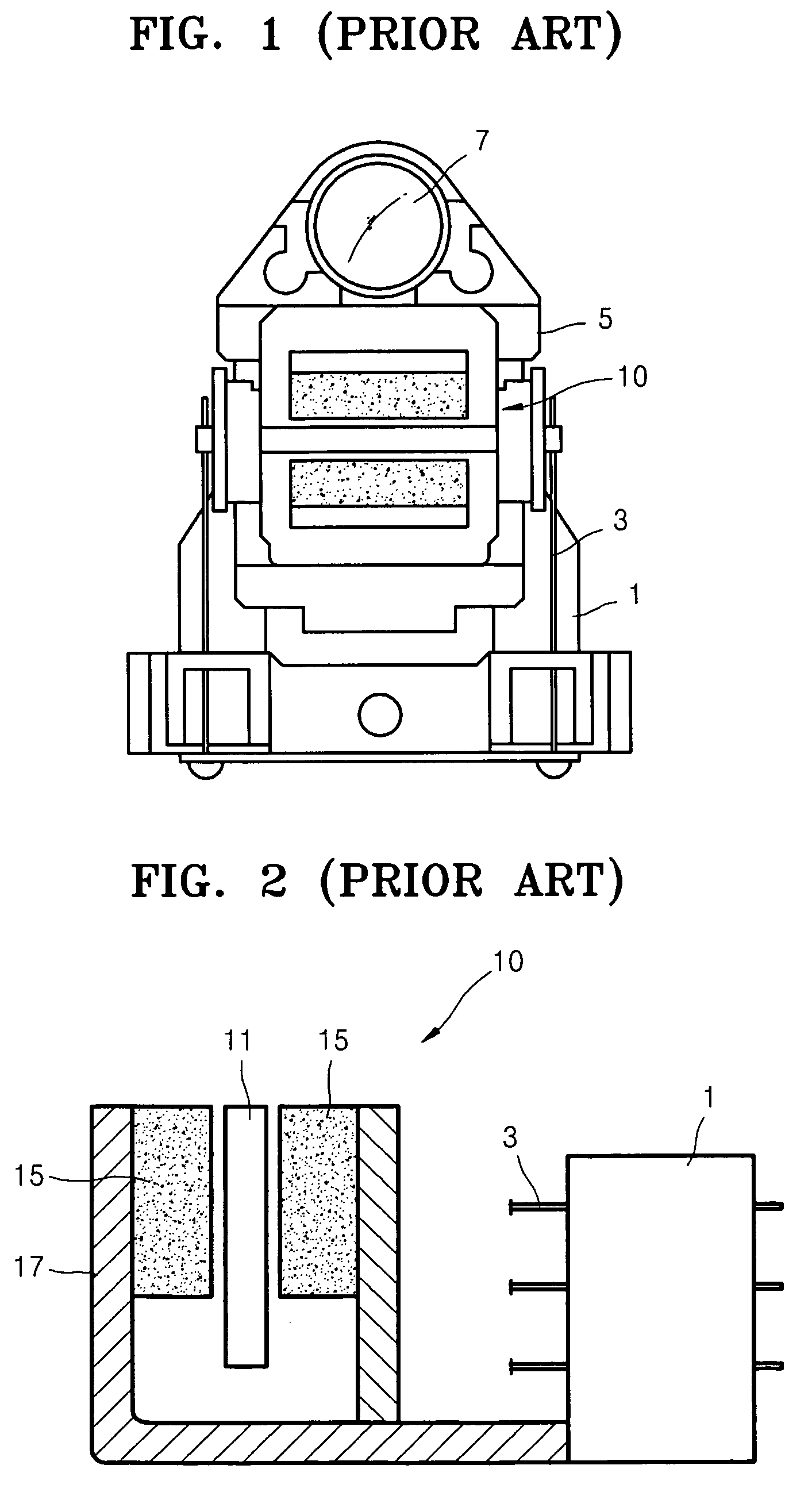

LED package for backlight unit

ActiveUS20060023451A1Avoid deformationImprove image qualityLighting support devicesGlass furnace apparatusEngineeringDie bonding

Disclosed herein is an LED package for a backlight unit. The LED package includes a plurality of LEDs, a die bonding part, a wire bonding part and a body. The die bonding part, on which the plurality of LEDs is arranged, allows the first electrodes of the LEDs to be electrically connected to an external circuit. The wire bonding part is spaced apart from the die bonding part by a predetermined distance to be insulated from the die bonding part and allows the second electrodes of the LEDs to be electrically connected to the external circuit so that the LEDs are operated. The body has a molding cup which is used to fill a space above the LEDs with transparent resin and a base on which the die bonding part and the wire bonding part are arranged.

Owner:SAMSUNG ELECTRONICS CO LTD

LED package for backlight unit

ActiveUS7156538B2Improve image qualityImprove luminous efficiencyLighting support devicesGlass furnace apparatusEngineeringDie bonding

Owner:SAMSUNG ELECTRONICS CO LTD

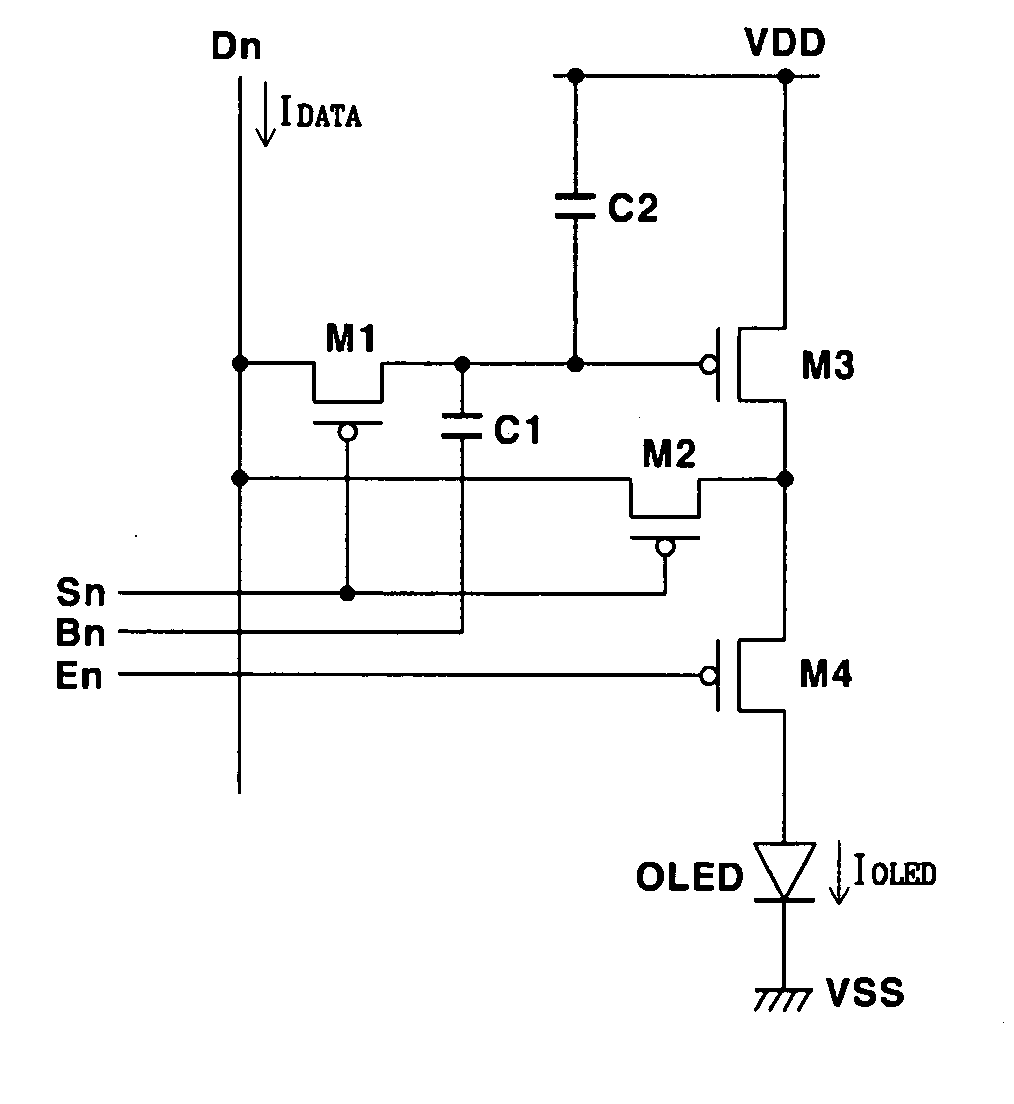

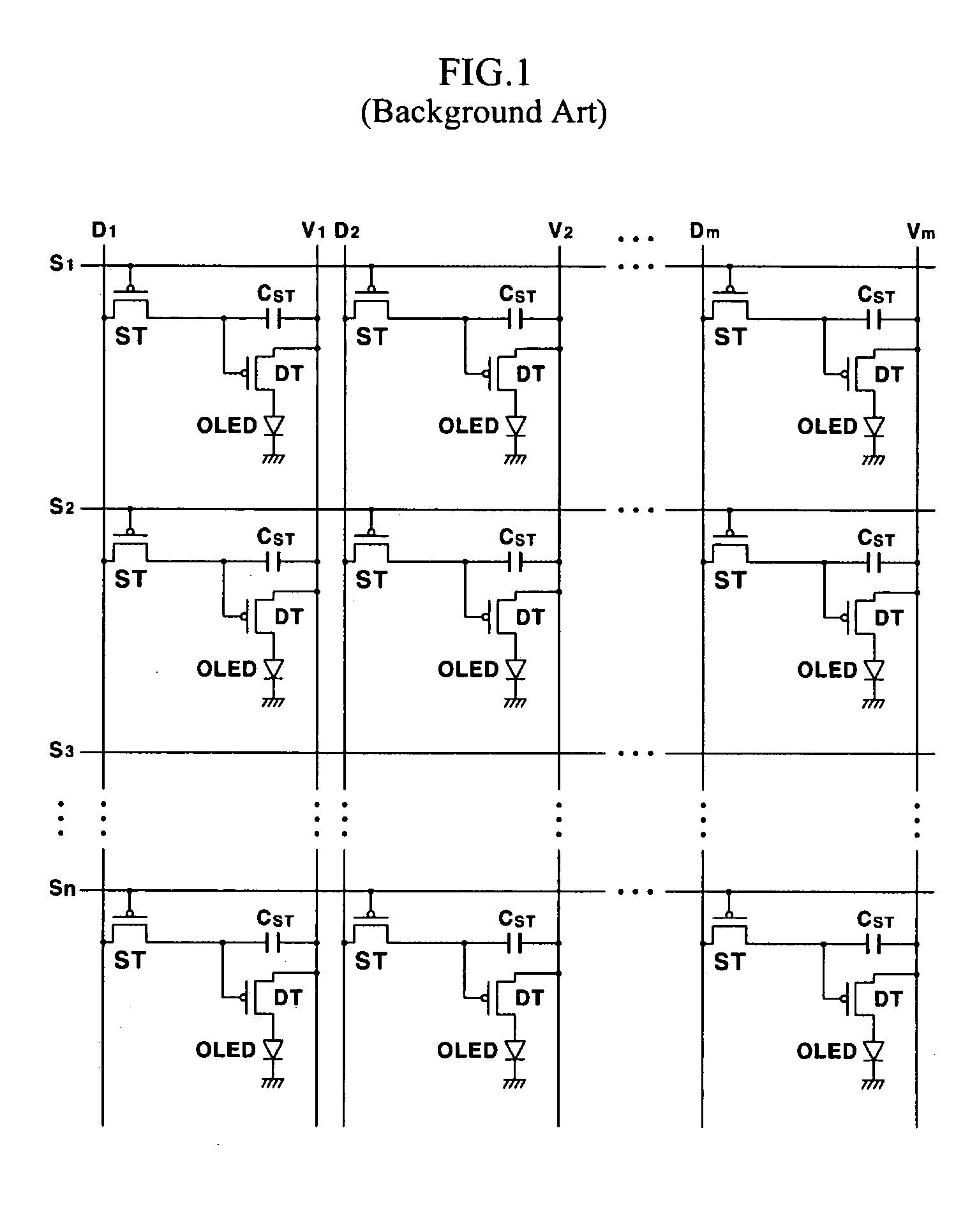

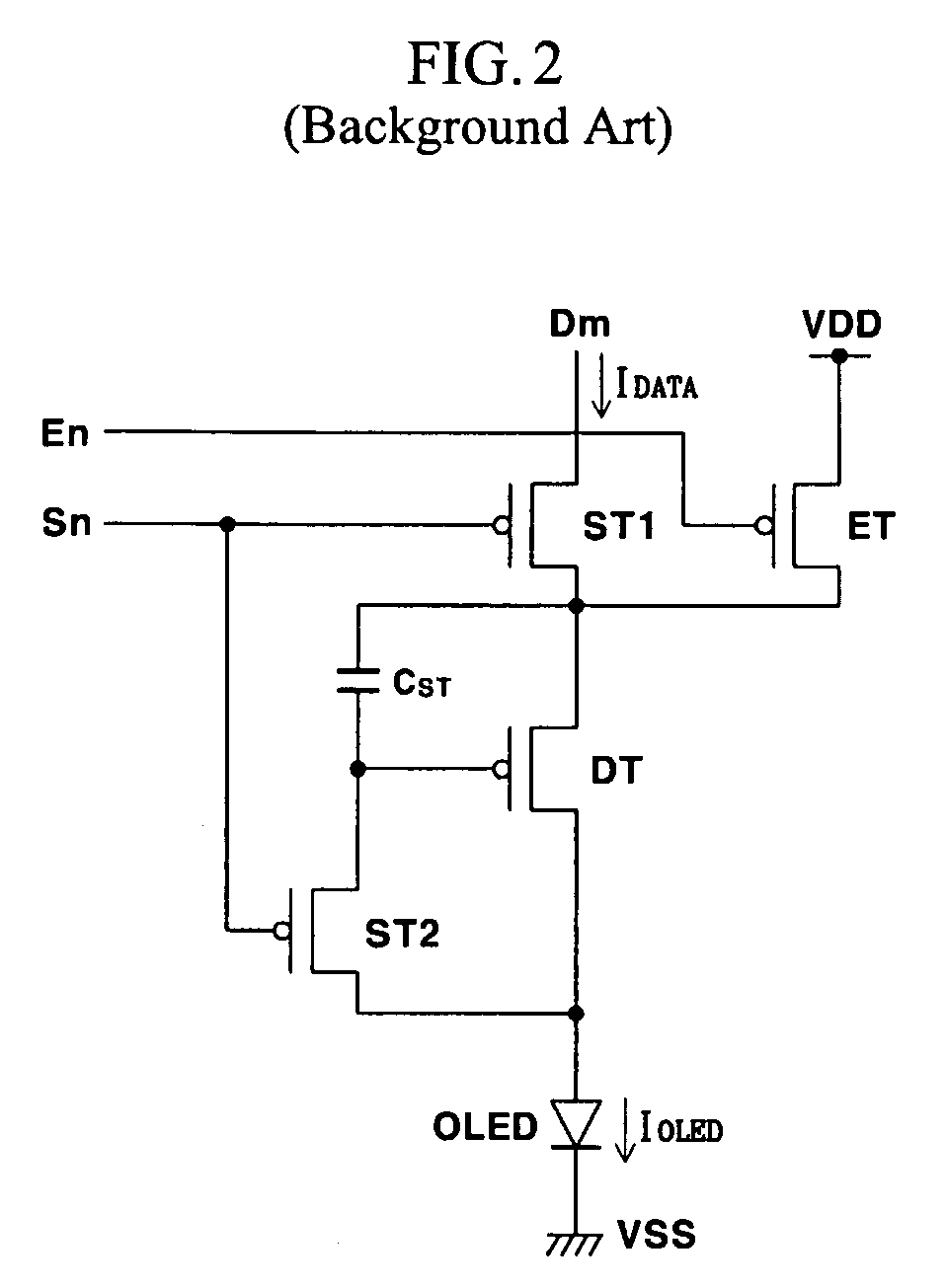

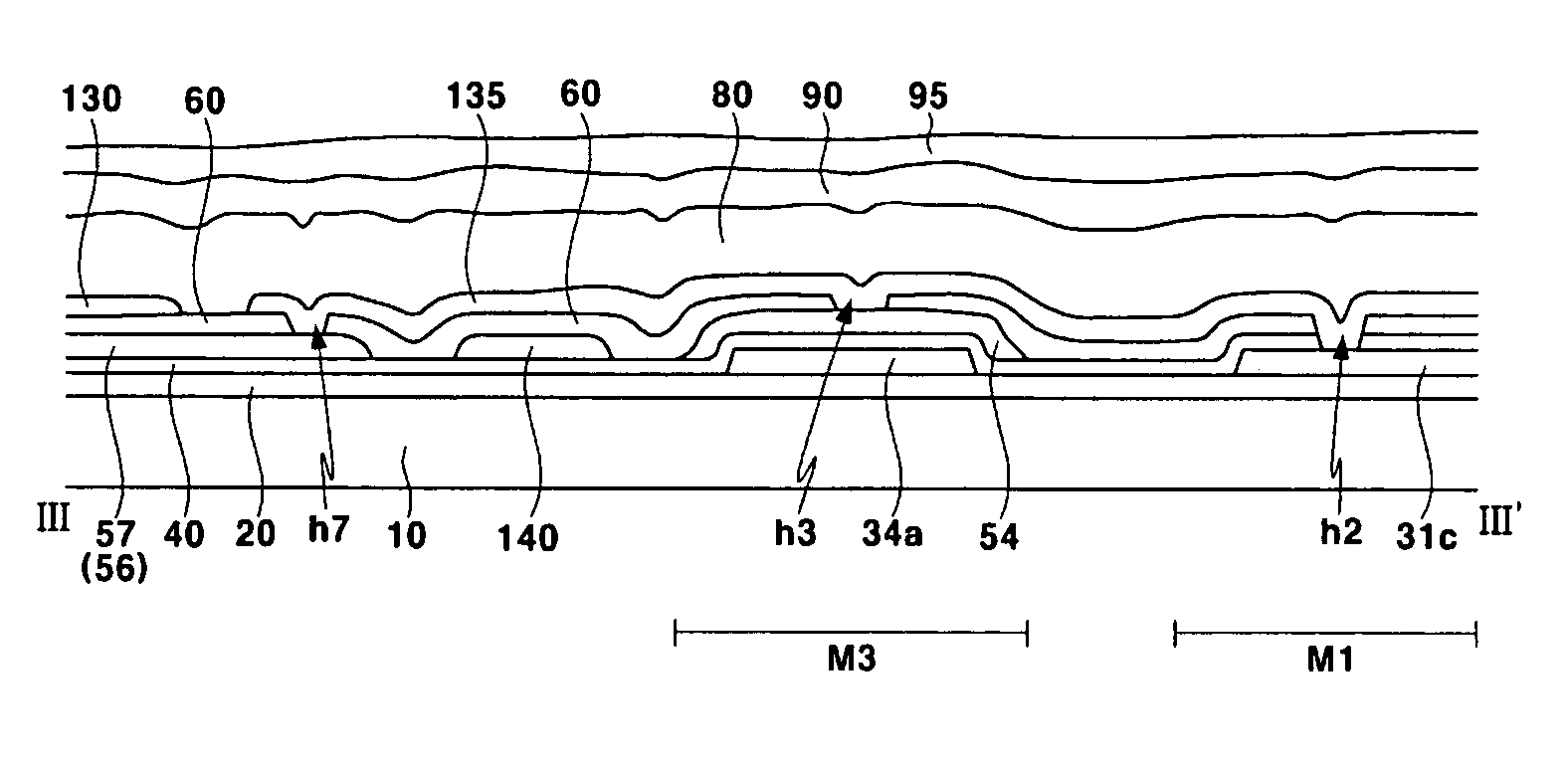

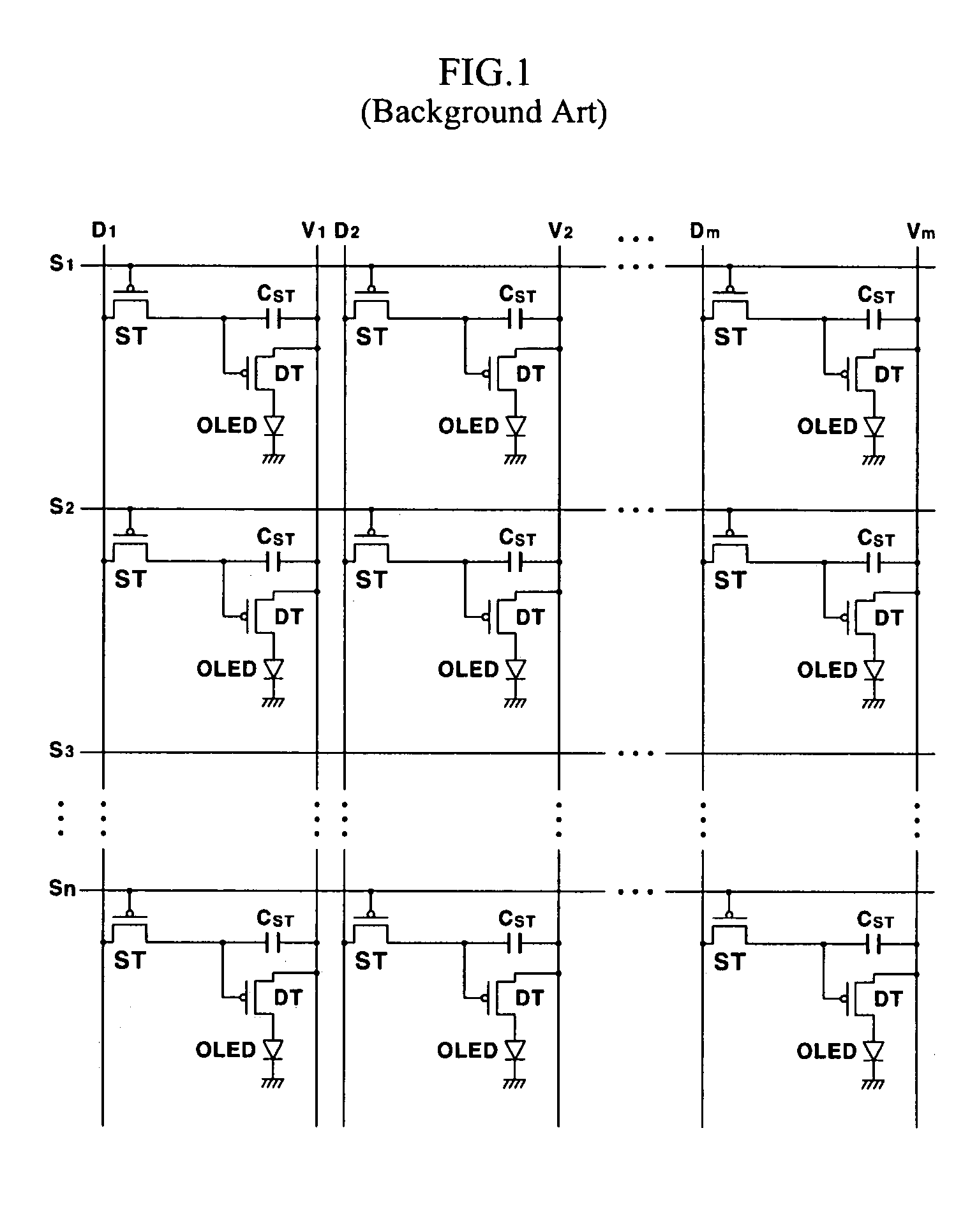

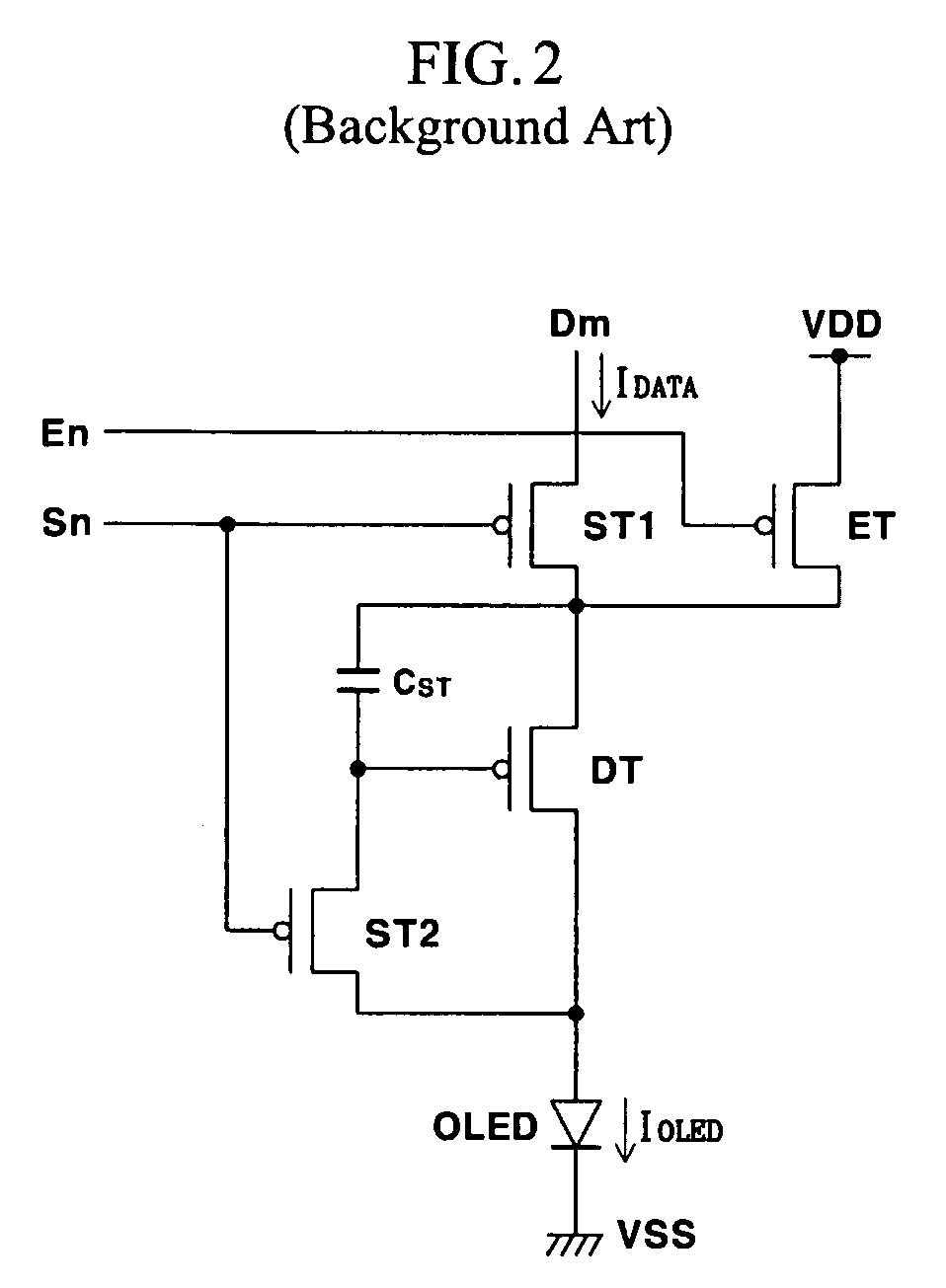

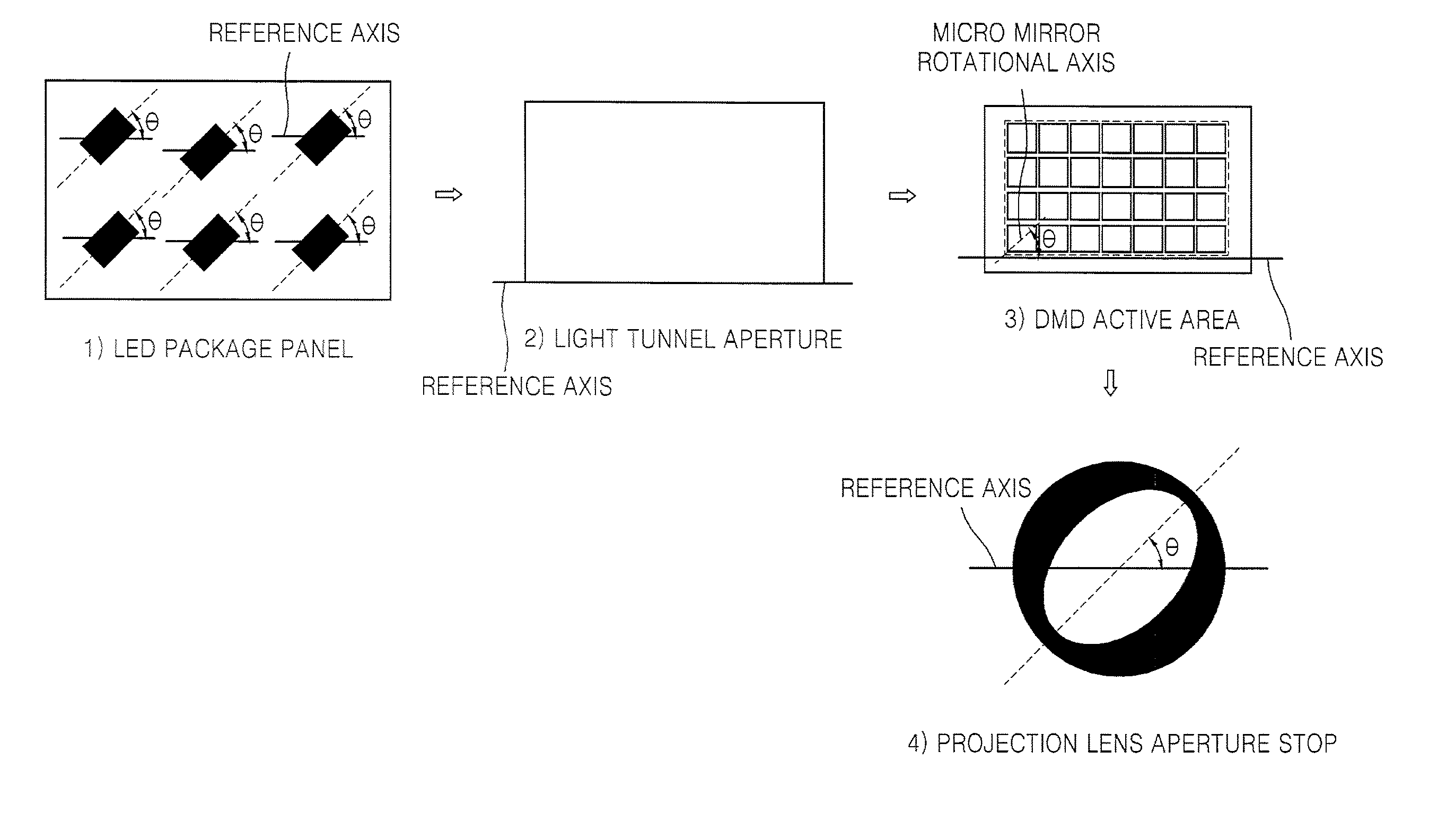

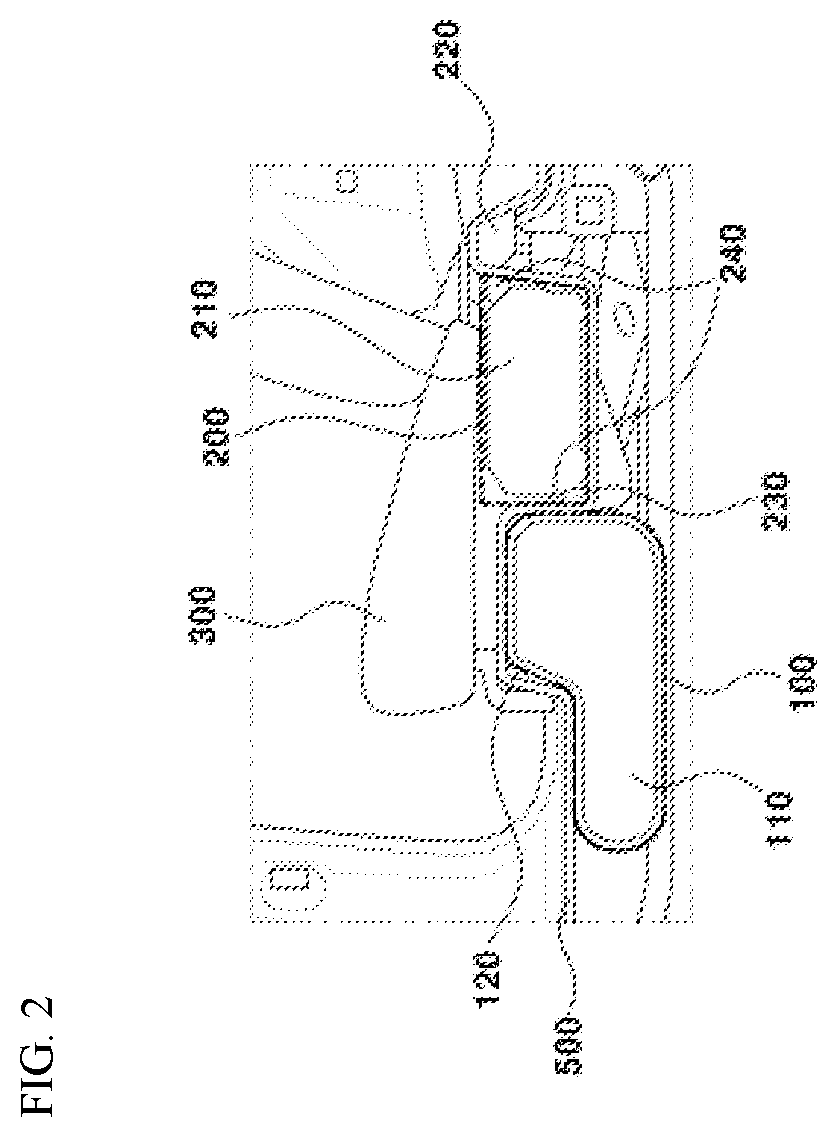

Organic electro luminescent display panel and fabricating method thereof

ActiveUS20050264228A1Arrangement structure optimizationIncrease the aperture ratioStatic indicating devicesElectroluminescent light sourcesOrganic electroluminescenceEngineering

There is provided an organic EL display panel having a pixel circuit that increases the panel's aperture ratio by an improved structure of a unit pixel. The present invention discloses an organic EL display panel including at least one pixel circuit for driving each pixel, wherein the pixel circuit comprises at least one organic light emitting element, at least two thin film transistors and at least one capacitor per pixel. The thin film transistors respectively comprise a gate electrode and a semiconductor layer in which a channel region, a source region and a drain region are formed. The conductive layer contacted on the gate electrode of one of the thin film transistors is coupled to another thin film transistor and at least one capacitor.

Owner:SAMSUNG DISPLAY CO LTD

Organic electro luminescent display panel and fabricating method thereof

ActiveUS7184006B2Increase the aperture ratioArrangement structure optimizationStatic indicating devicesElectroluminescent light sourcesEngineeringOrganic electroluminescence

There is provided an organic EL display panel having a pixel circuit that increases the panel's aperture ratio by an improved structure of a unit pixel. The present invention discloses an organic EL display panel including at least one pixel circuit for driving each pixel, wherein the pixel circuit comprises at least one organic light emitting element, at least two thin film transistors and at least one capacitor per pixel. The thin film transistors respectively comprise a gate electrode and a semiconductor layer in which a channel region, a source region and a drain region are formed. The conductive layer contacted on the gate electrode of one of the thin film transistors is coupled to another thin film transistor and at least one capacitor.

Owner:SAMSUNG DISPLAY CO LTD

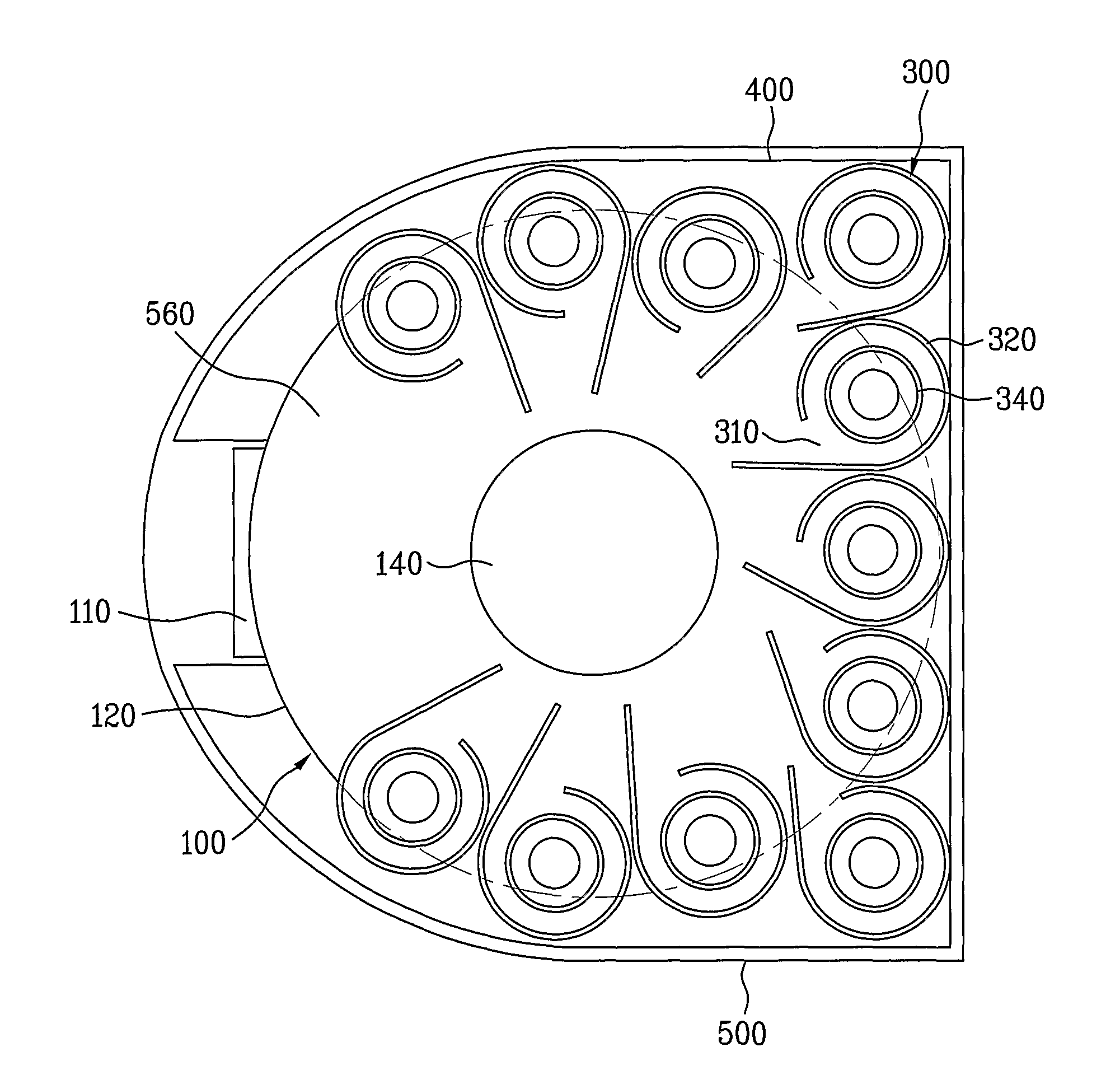

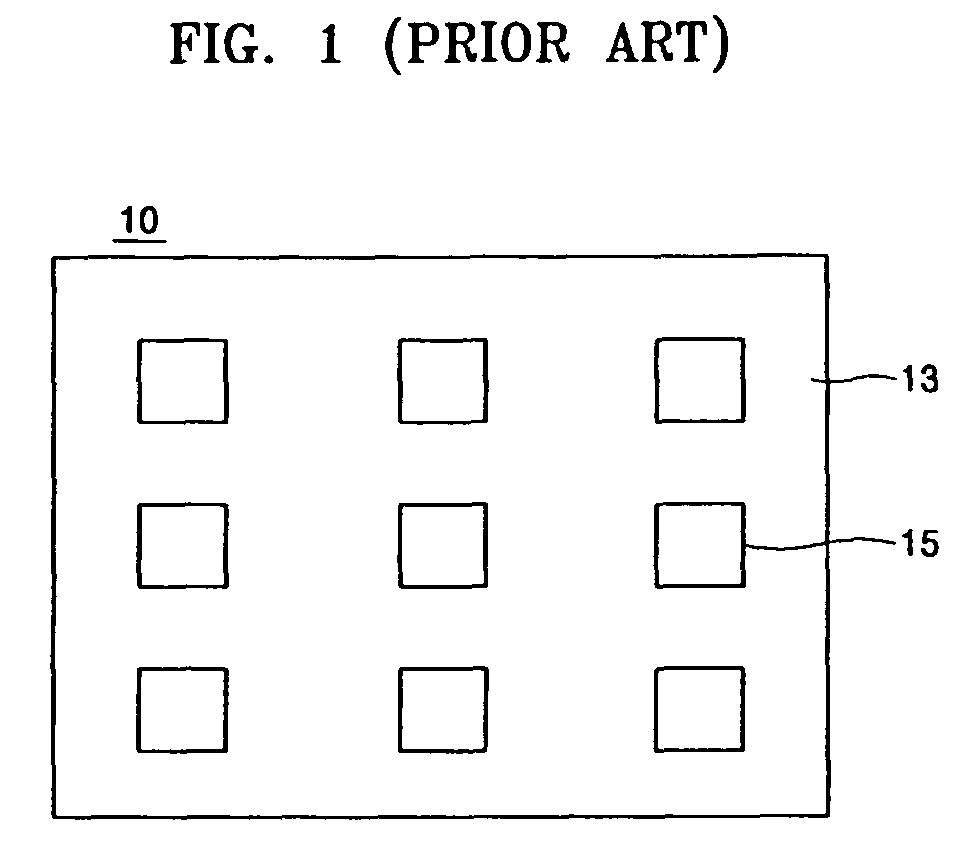

Multi cyclone collector

InactiveUS7815702B2Simple structureArrangement structure optimizationCleaning filter meansCombination devicesCycloneEngineering

A multi cyclone collector with an improved structure is disclosed for providing the highest number of second cyclone collector (300) by disposing a plurality of second cyclone collector (300) in a non circular shape (400) arrangement along a first cyclone collector, thereby increasing collecting efficiency.

Owner:LG ELECTRONICS INC

Novel straight-strut electrostatic spinning spray nozzle

InactiveCN101871130AArrangement structure optimizationEasy to receiveSpinnerette packsFilament/thread formingFiberTemperature control

The invention discloses a novel straight-strut electrostatic spinning spray nozzle, which belongs to the field of electrostatic spinning. The novel straight-strut electrostatic spinning spray nozzle comprises a connecting piece, a drainage core and a straight strut, wherein the connecting piece is in threaded connection with the drainage core; the drainage core is in screw connection with the straight strut; a drainage groove for material flow and an annular balancing groove for material redistribution are formed on the drainage core; a straight strut groove surface for material flow is formed on the straight strut; and the straight strut is provided with an independent temperature control device for heating, and after molten liquid or melts are distributed on the straight strut uniformly and an electrostatic field is added, multiple strands of spraying streams are formed at the top end of the straight strut. The novel straight-strut electrostatic spinning spray nozzle improves the efficiency of melt-electrostatic spinning greatly, and optimizes the arrangement structure of spinning fibers.

Owner:BEIJING UNIV OF CHEM TECH

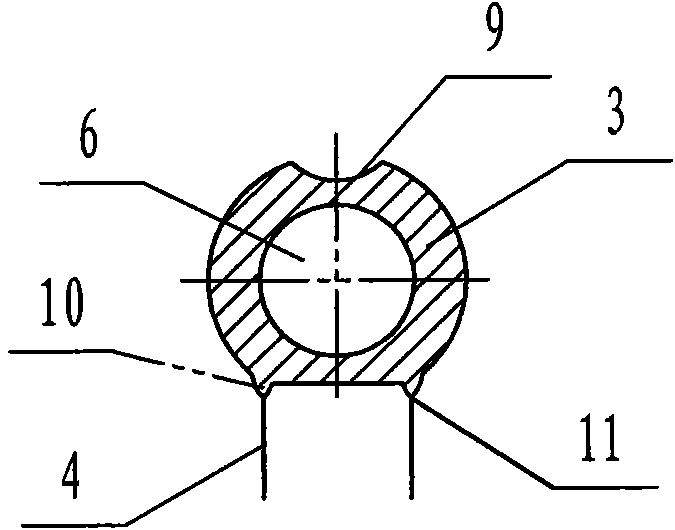

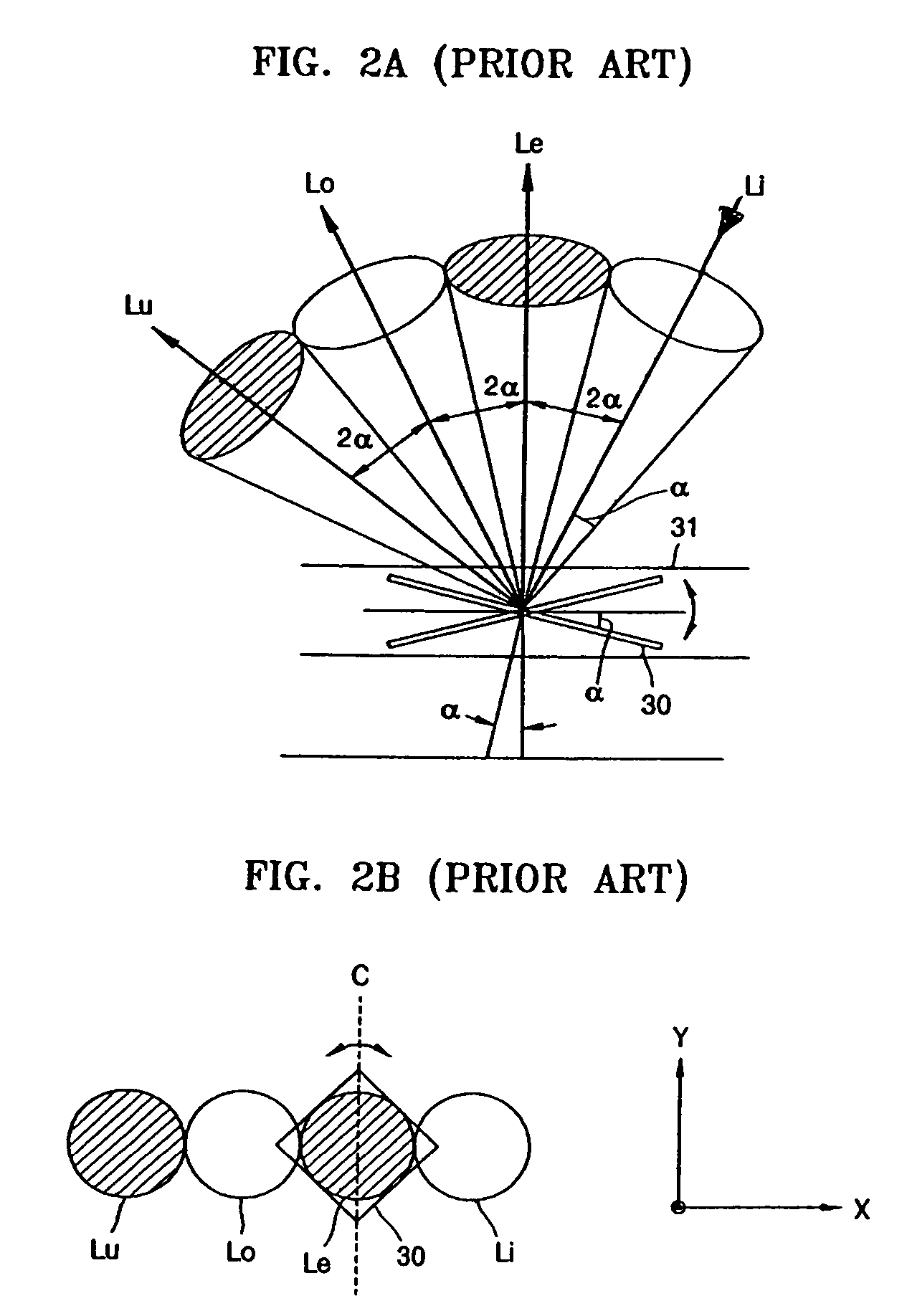

LED package, display panel, illumination system and projection system employing the same

InactiveUS7789517B2Improve lighting efficiencyArrangement structure optimizationTelevision system detailsData processing applicationsAsymmetric distributionEngineering

An LED package having improved light efficiency, and an illumination system and a projection system employing the LED package. An LED package to provide light to a display panel having a plurality of rotatable micromirrors to form images, the LED package includes a substrate and a plurality of LED chips. The plurality of LED chips are slanted with respect to the substrate at a predetermined angle. The LED package improves the light efficiency by arranging the plurality of LED chips so as to correspond to a shape of effective light having an asymmetric distribution with respect to a stop of a projection lens unit.

Owner:SAMSUNG ELECTRONICS CO LTD

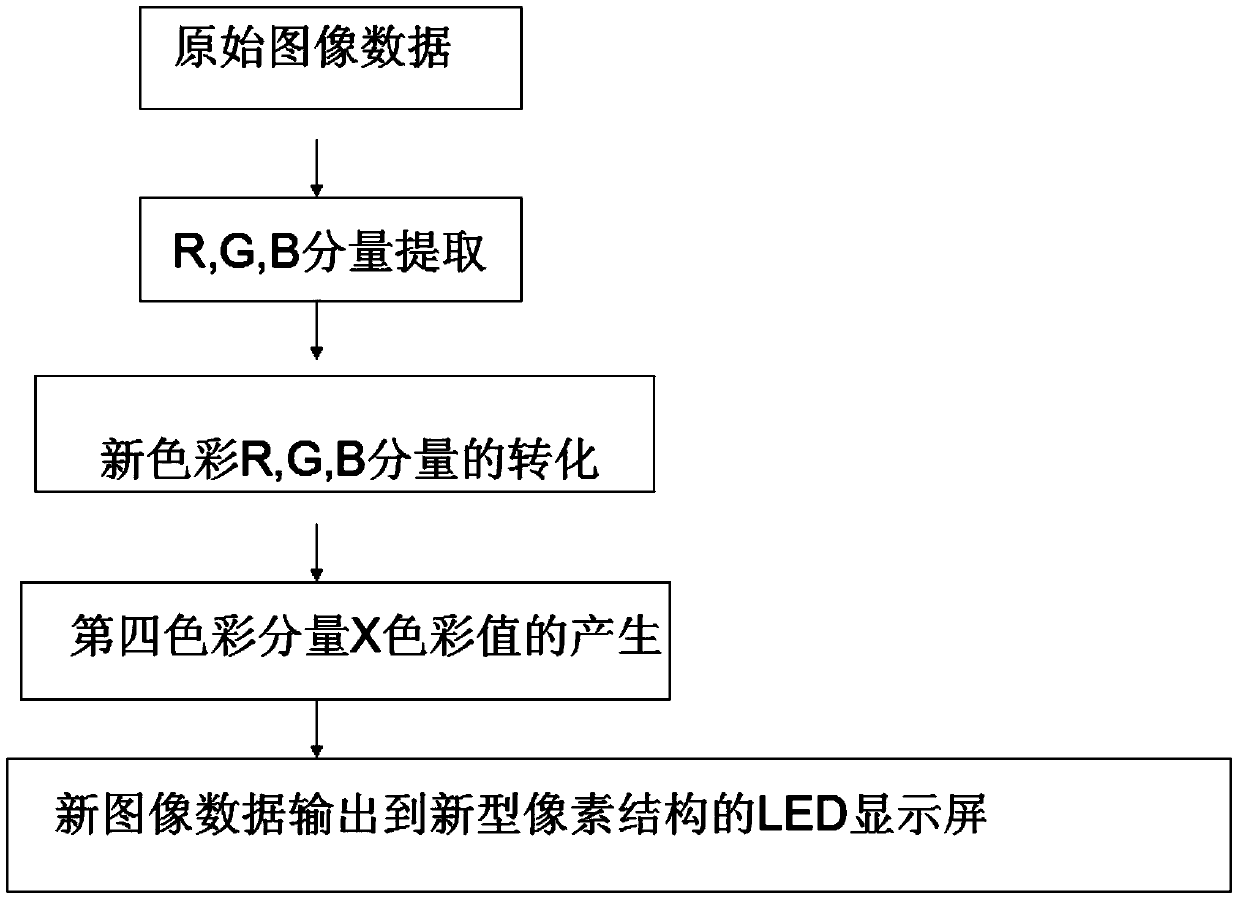

Display panel and pixel structure thereof

ActiveCN103529572AArrangement structure optimizationEnhanced resolution and color expressionStatic indicating devicesComputer science

Owner:TCL CORPORATION

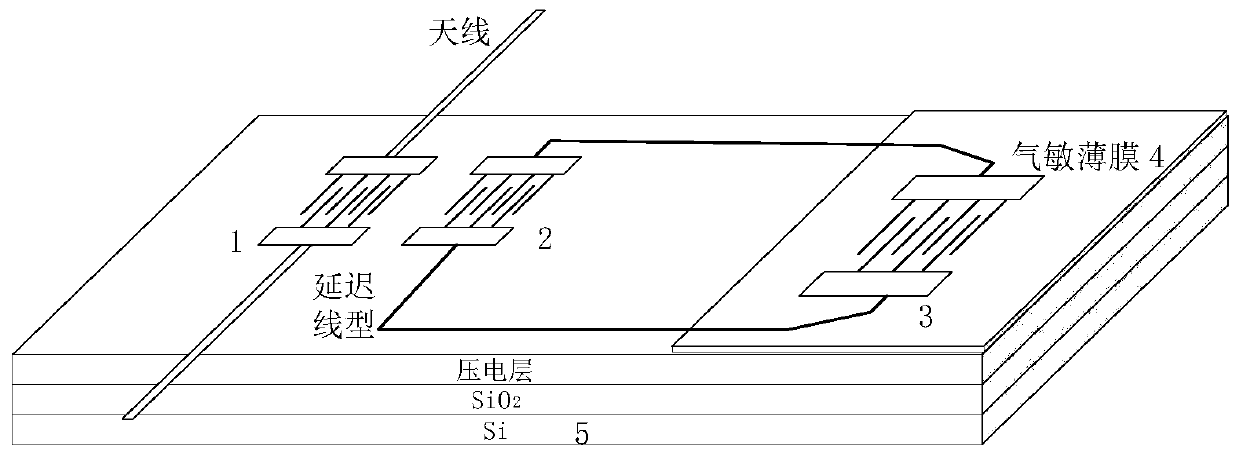

Integrated impedance-loaded sound surface wave gas sensor

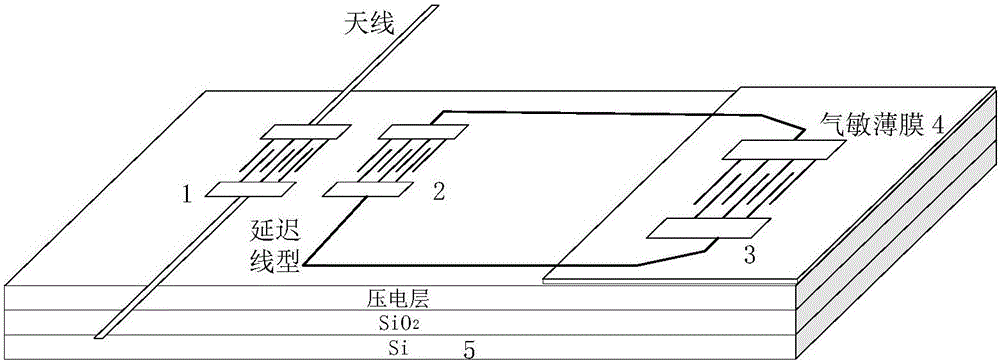

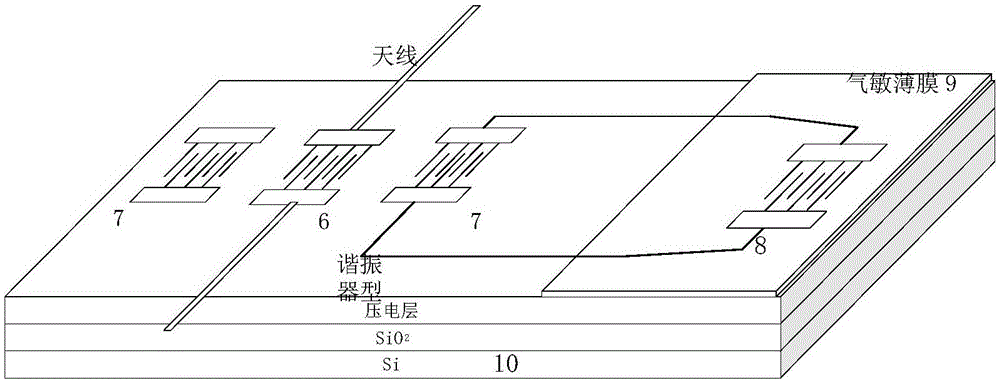

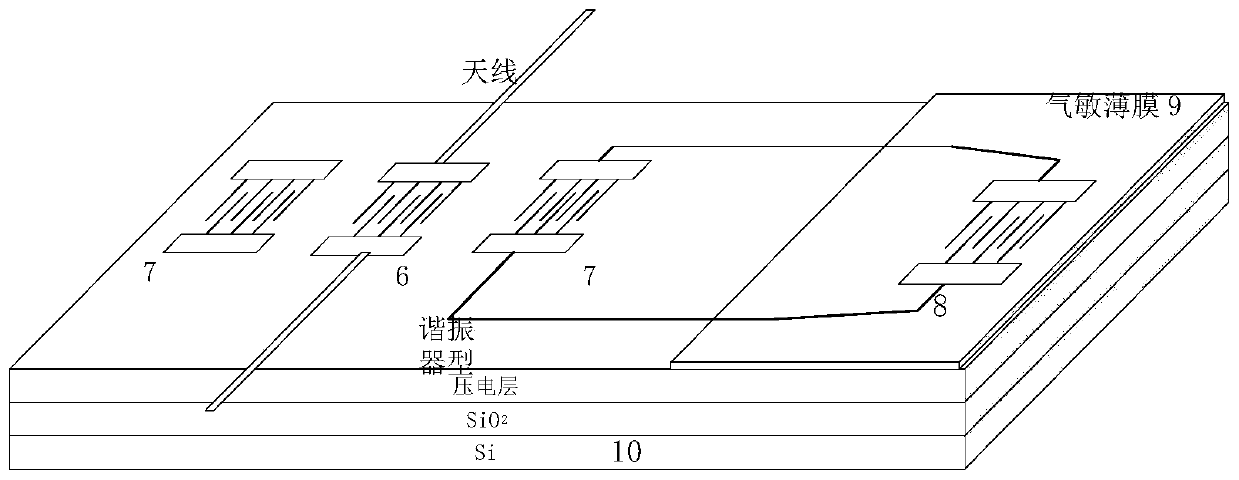

ActiveCN106841383ALow costSmall sizeAnalysing fluids using sonic/ultrasonic/infrasonic wavesInsulation layerSound wave

The invention discloses an integrated impedance-loaded sound surface wave gas sensor based on a Si (silicon) substrate. The integrated impedance-loaded sound surface wave gas sensor comprises a substrate, a piezoelectric layer, an input / output interdigital transducer, a reflective interdigital transducer, a sensitive interdigital electrode and a gas-sensitive thin film. The integrated impedance-loaded sound surface wave gas sensor has the advantages that by growing one thin SiO2 (silicon dioxide) insulation layer and one piezoelectric layer on the Si substrate, the good temperature characteristic is realized; the material of the Si substrate has the characteristics of low cost, large size and conductivity, and can be combined with the integrated circuit industry; the arrangement structure of the interdigital electrode is optimized, the sound wave reflection caused by the external sensor is reduced, and the parasitic effect caused by connecting wires is reduced; the interdigital transducer and the sensitive interdigital electrode are manufactured by one step, so that the simplicity in the manufacturing process is guaranteed, and the large-scale production is easily realized; the wireless passive measuring of the sensor is realized, the sensing part which is easily influenced by outside is separated from a signal sending part, and the application range of the sensor is widened.

Owner:HUAZHONG UNIV OF SCI & TECH

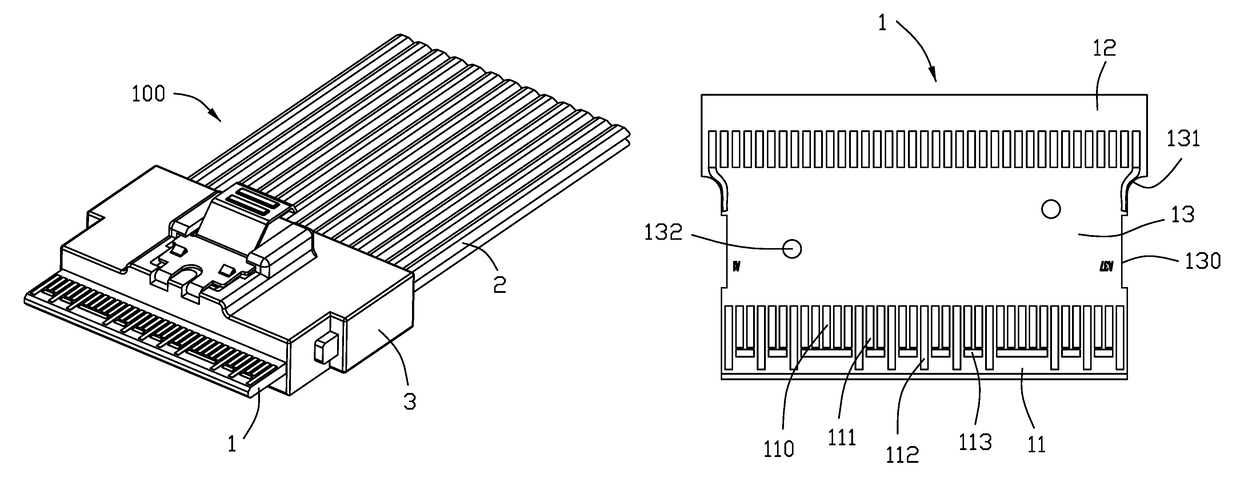

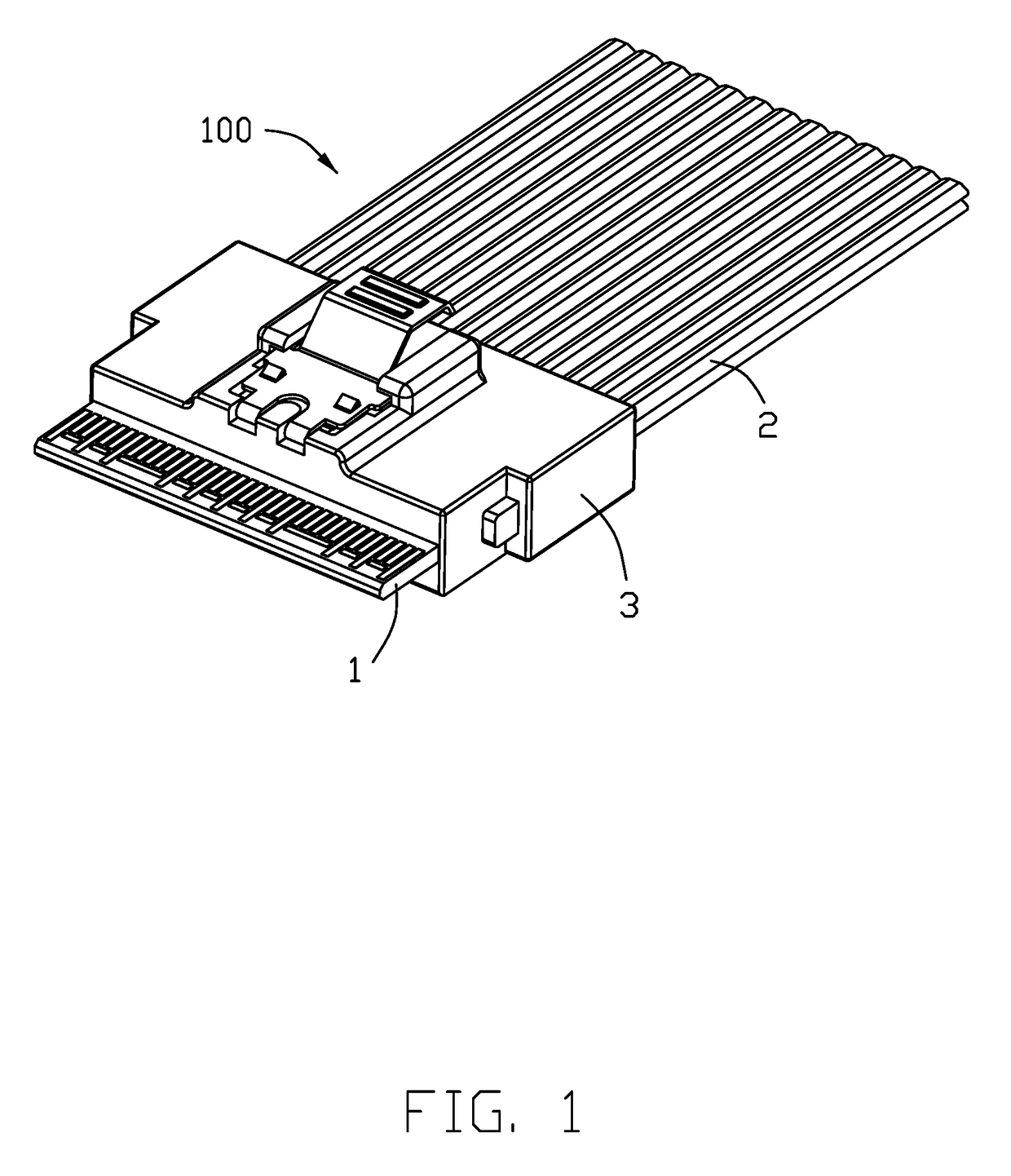

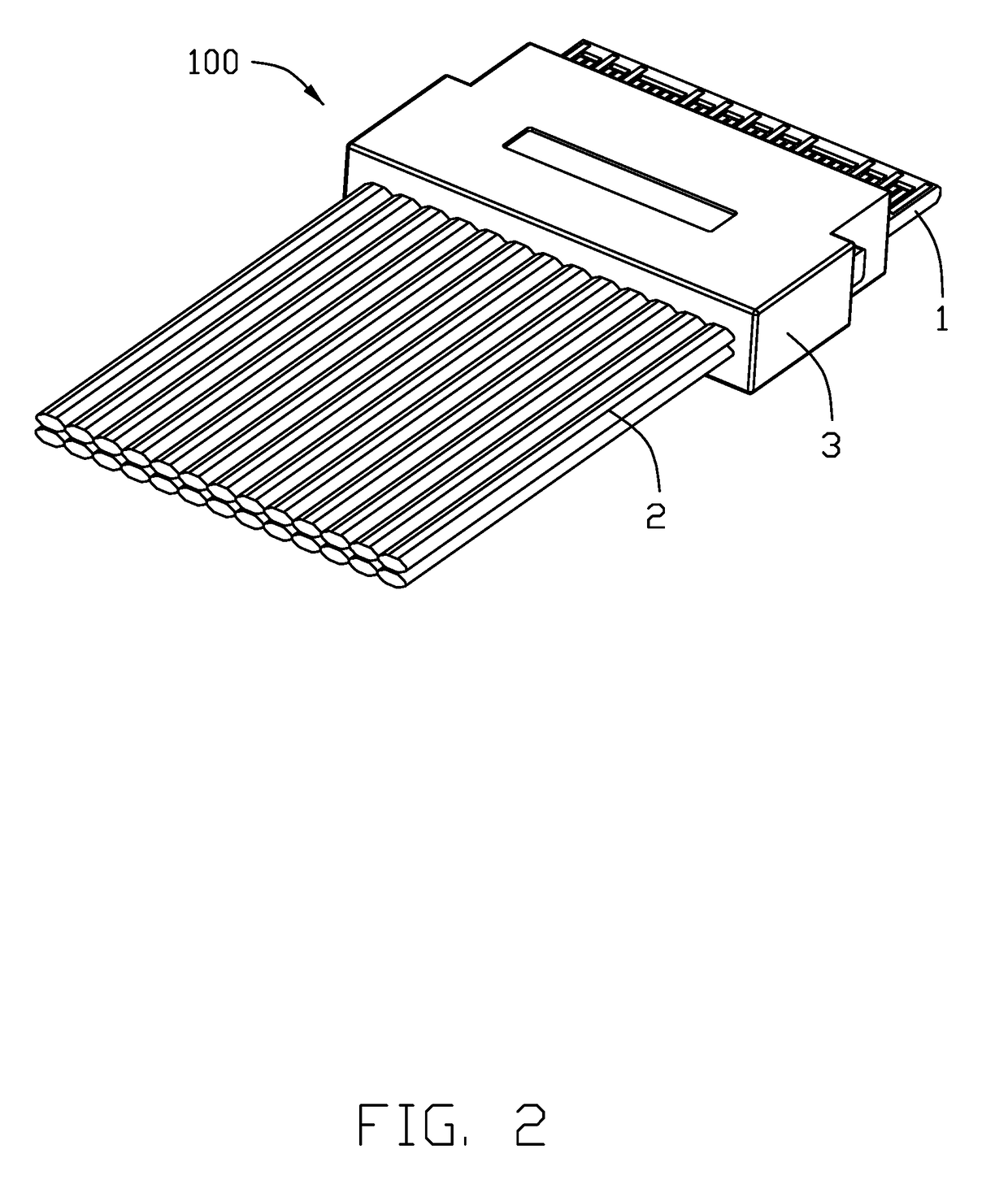

Plug connector assembly having improved arrangement structure between outer case and printed circuit board

ActiveUS10084271B2Arrangement structure optimizationEngagement/disengagement of coupling partsCouplings bases/casesEngineeringPrinted circuit board

A plug connector assembly includes: a cable; a printed circuit board including a mating end for inserting into a mating connector, a connecting end electrically connected with the cable, and an intermediate portion between the mating end and the connecting end, the mating end defining plural conductive pads extending along a longitudinal direction of the printed circuit board for electrically connecting with the mating connector and arranged in a horizontal direction perpendicular to the longitudinal direction; and an outer case enclosing the intermediate portion of the printed circuit board and a part of the cable; wherein the intermediate portion defines on each of two side edges thereof a recessing portion filled by the outer case.

Owner:FOXCONN INTERCONNECT TECH LTD

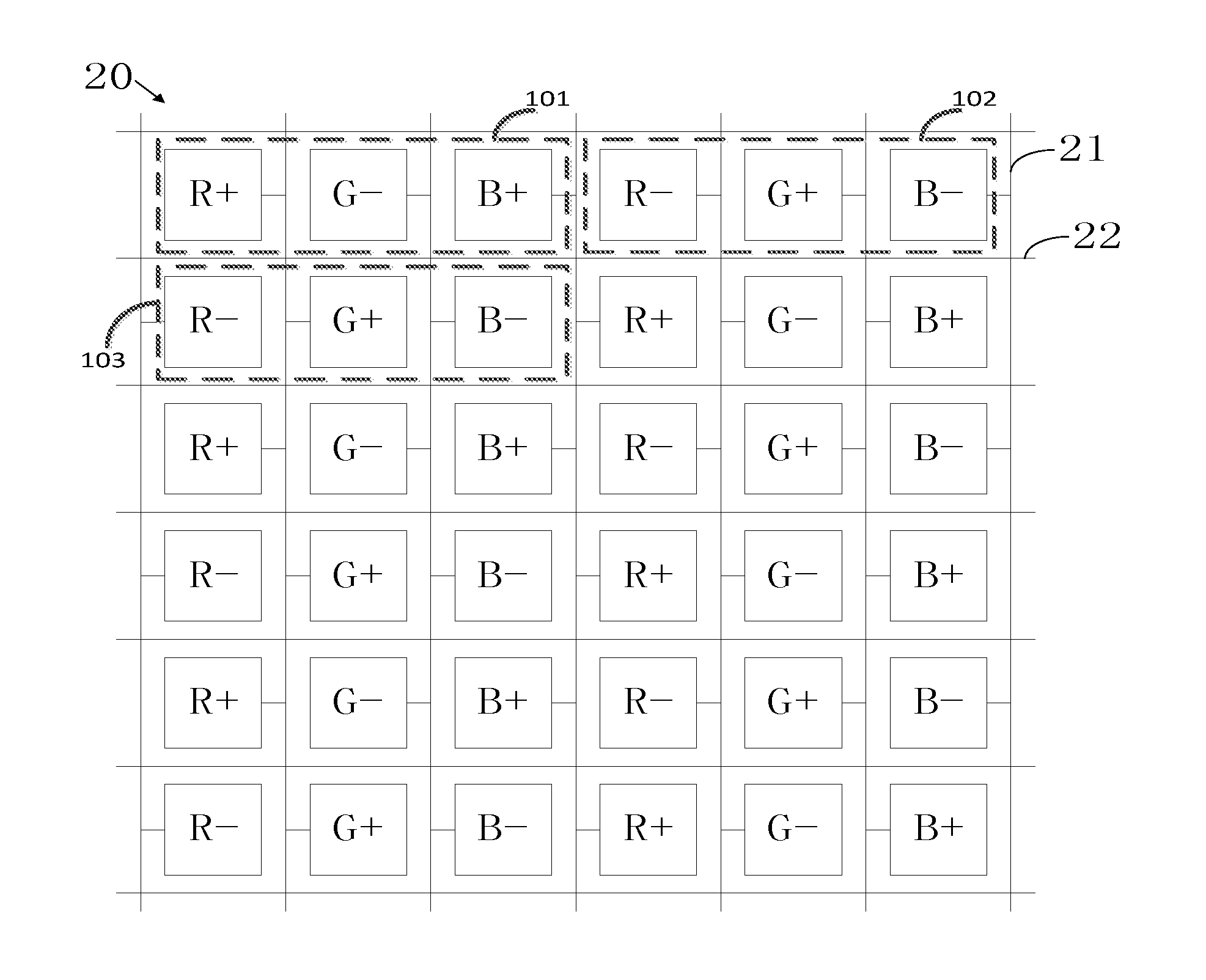

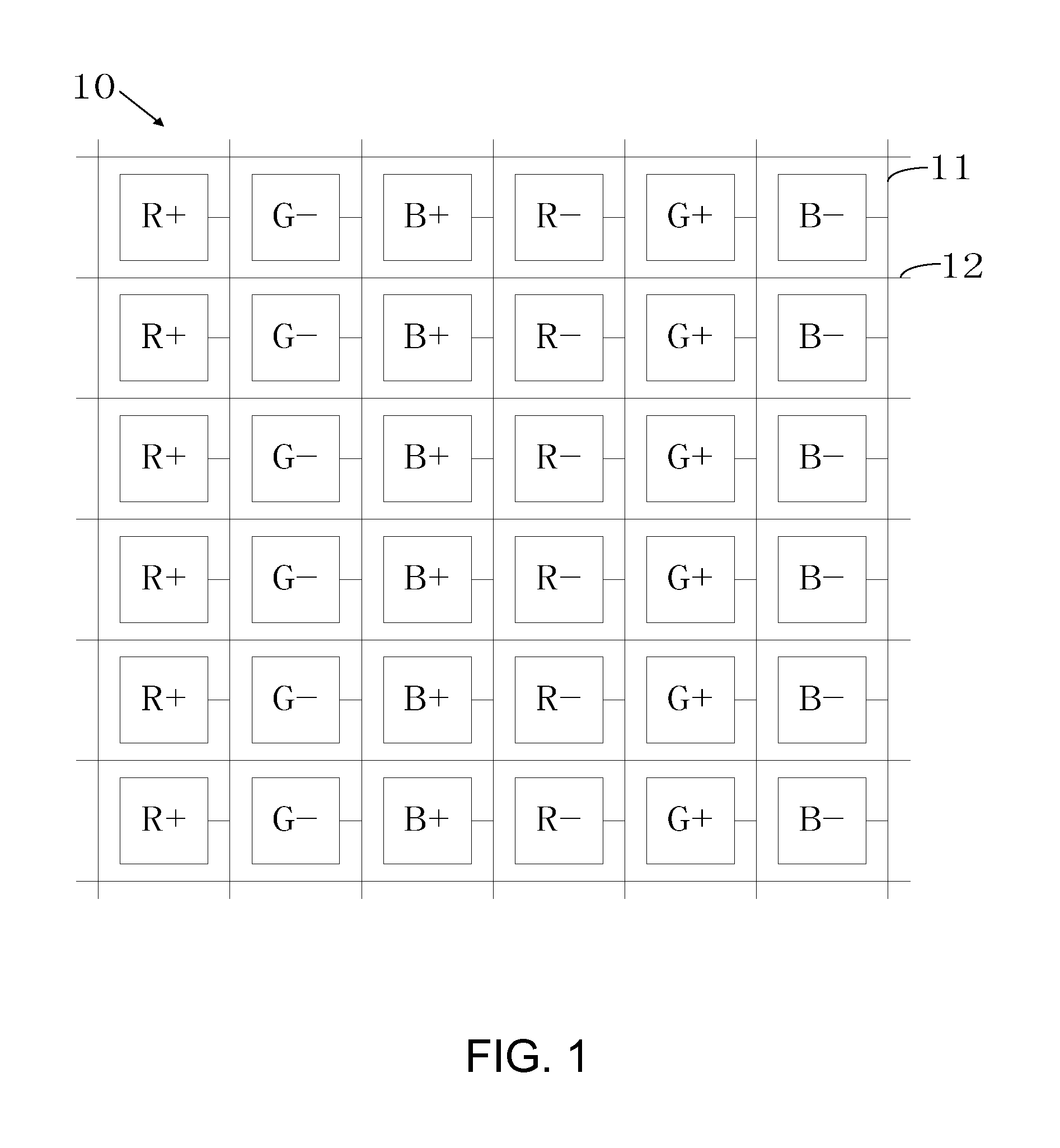

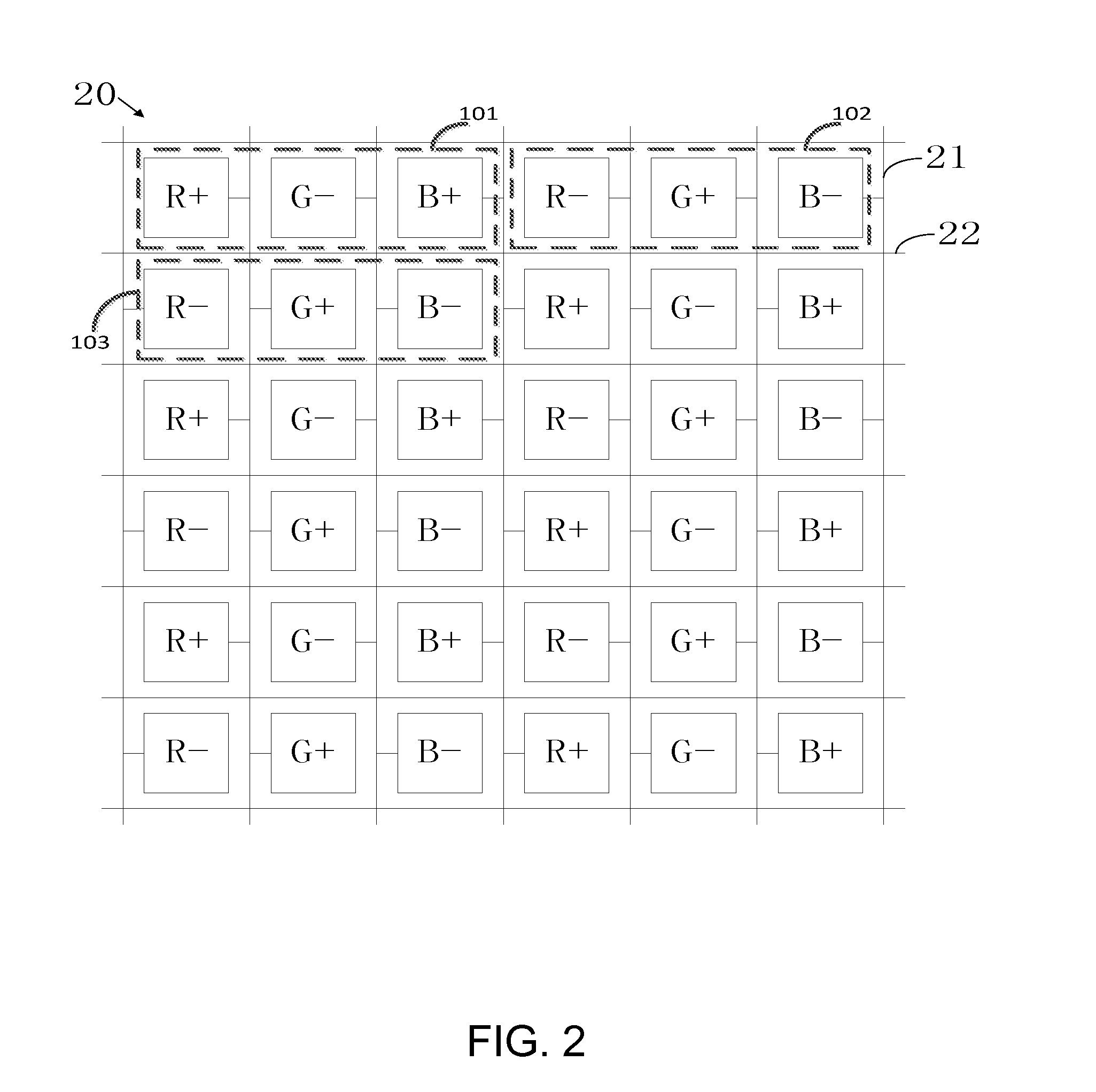

Liquid crystal display panel and device thereof

InactiveUS20160351136A1Ready emergenceImprove the display effectStatic indicating devicesNon-linear opticsPattern recognitionLiquid-crystal display

An LCD panel and an LCD device are provided. The LCD panel includes all pixels respectively defined by a plurality of data lines and a plurality of the scanning lines to form a plurality of pixel columns and a plurality of pixel rows. All of the pixels in each column have the same color, and the two adjacent pixels in each pixel unit have opposite polarities. The pixels having the same color in two adjacent pixel units have opposite polarities, and each of the data lines is connected with the pixels with the same polarity.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

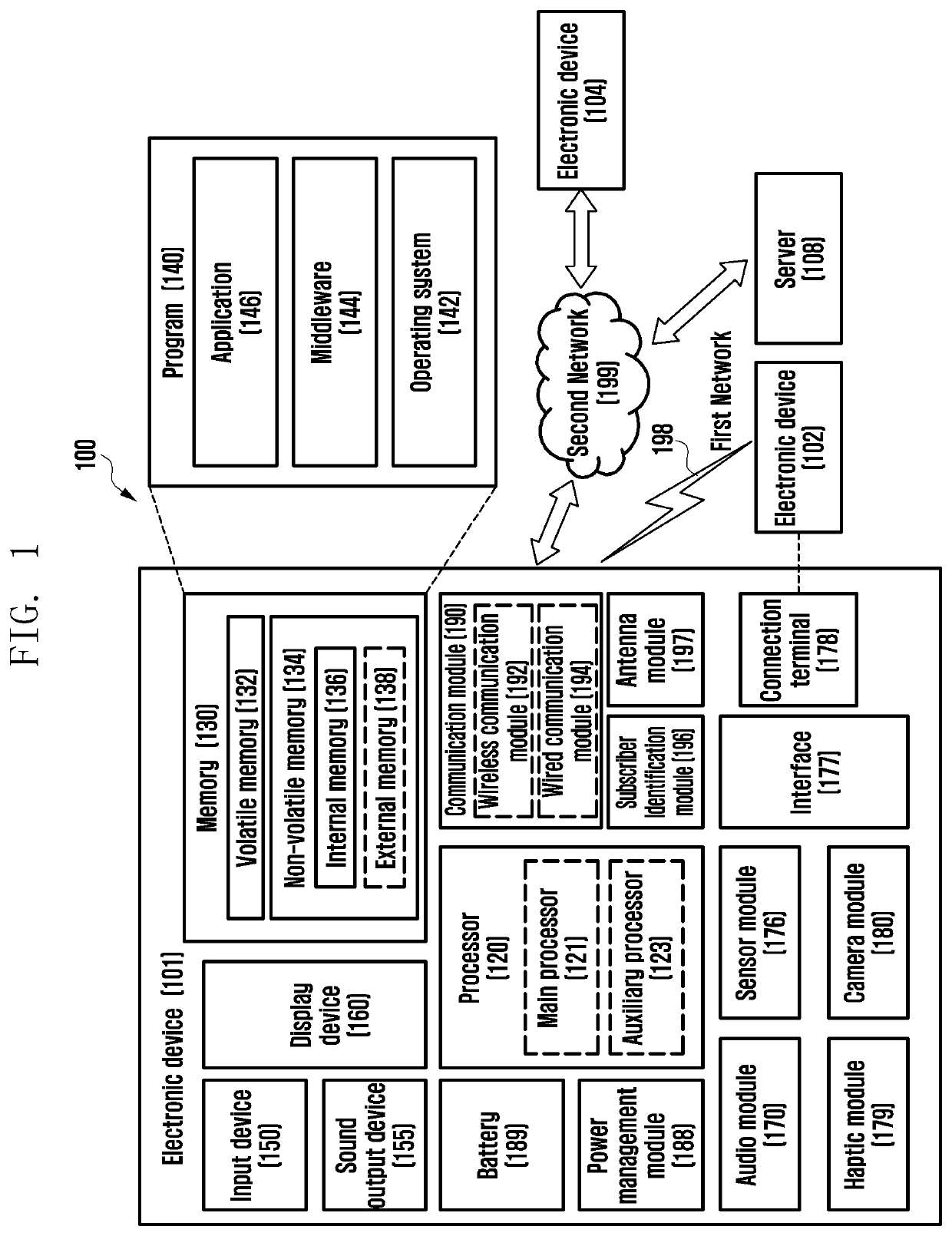

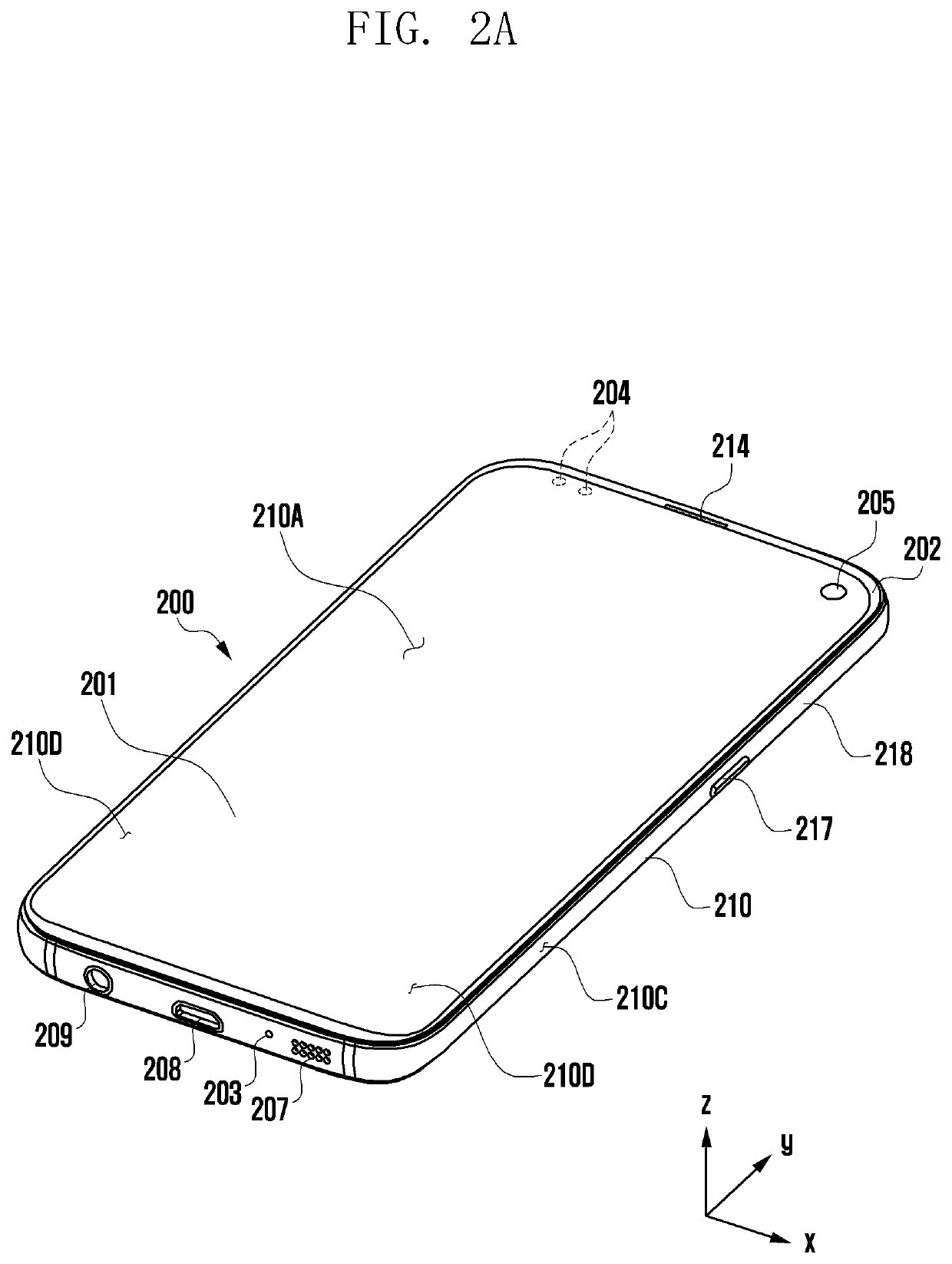

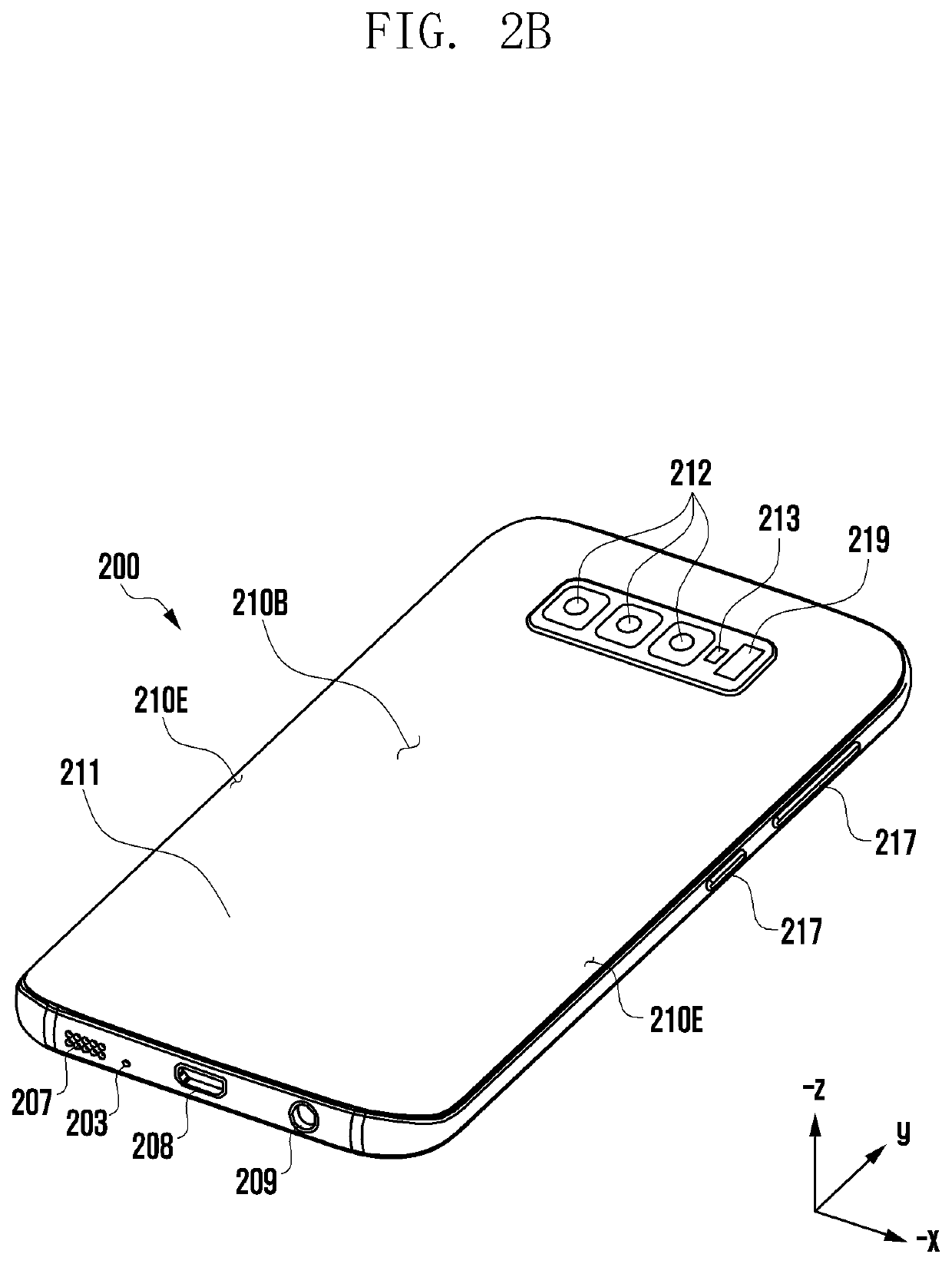

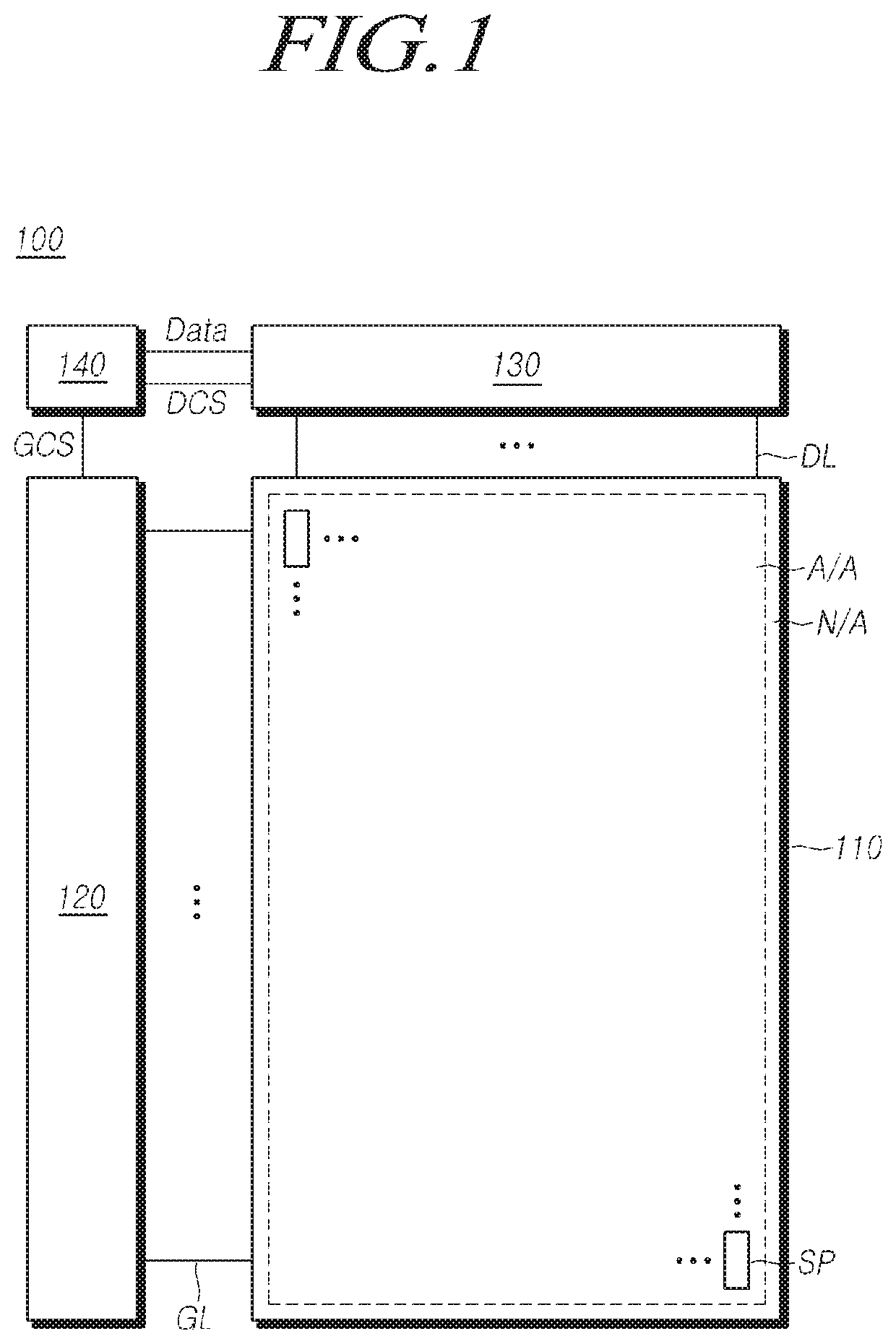

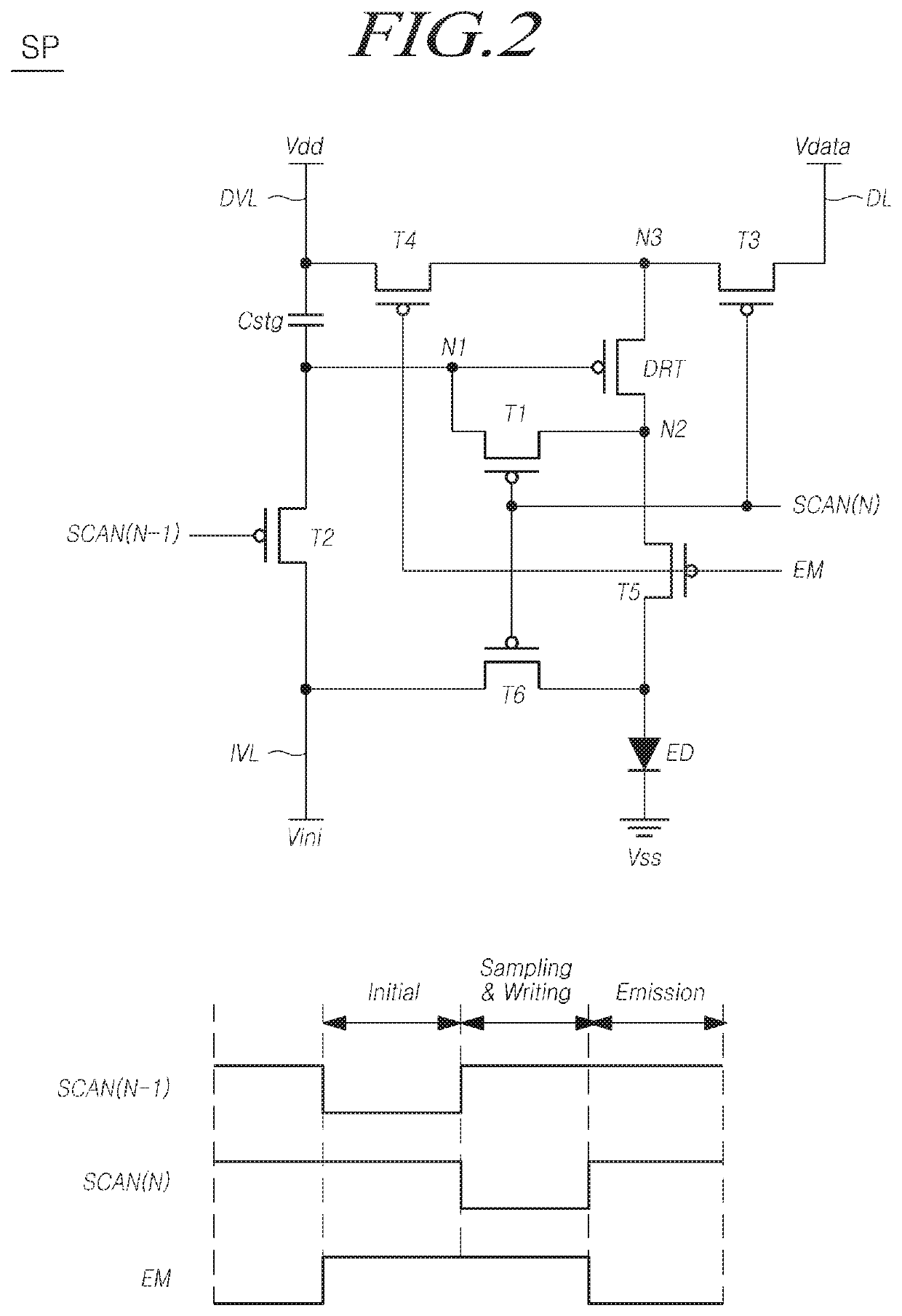

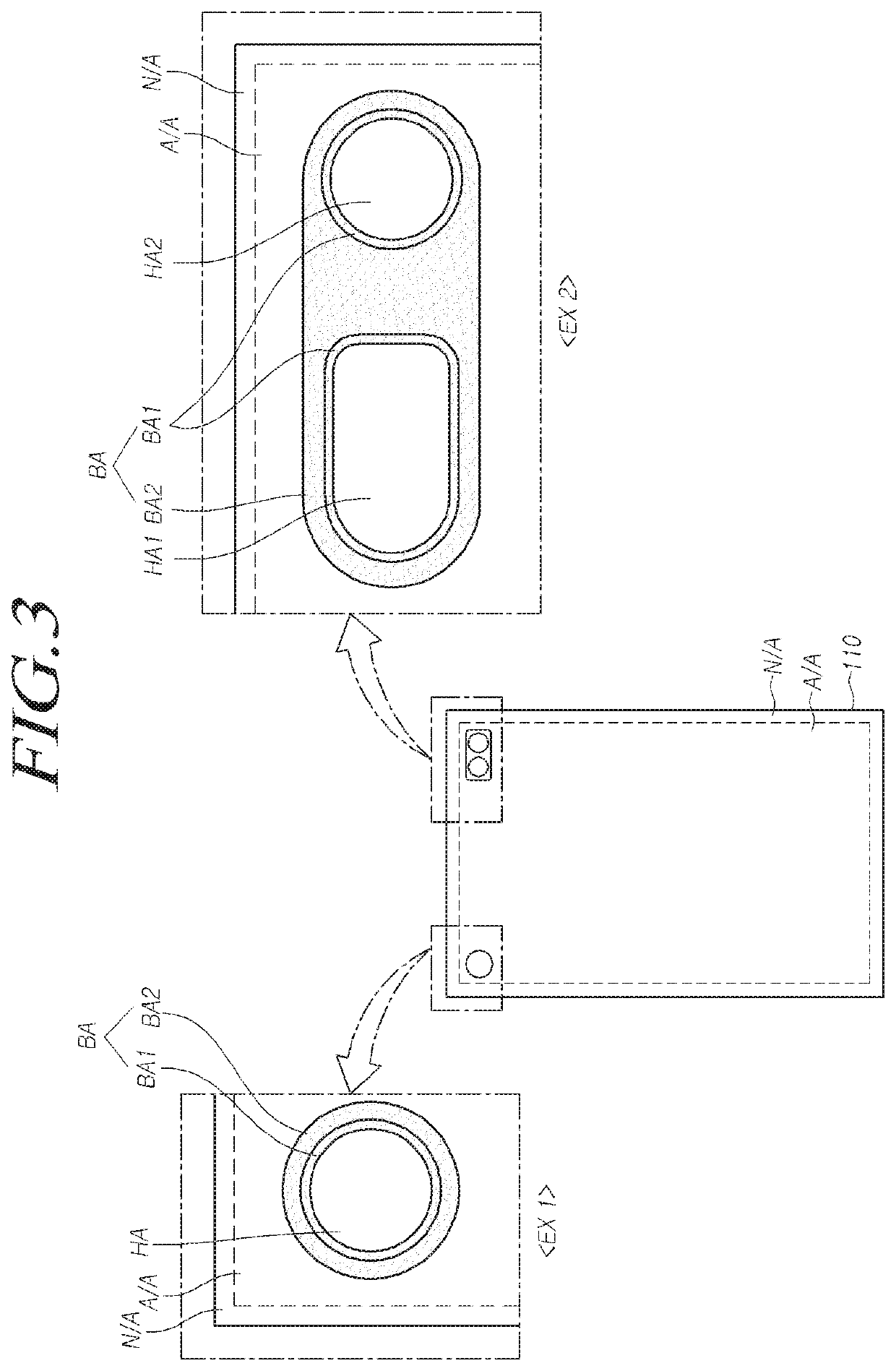

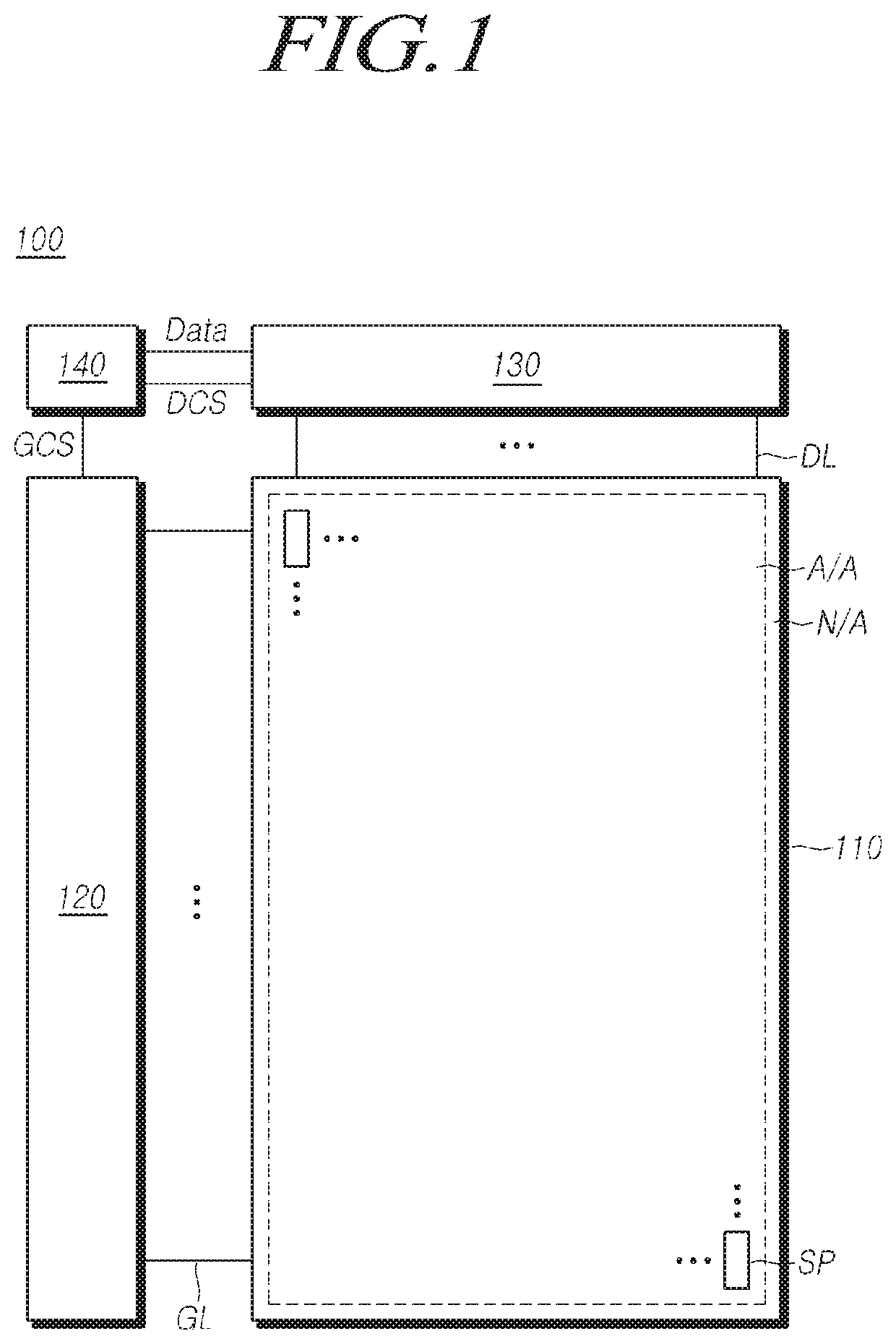

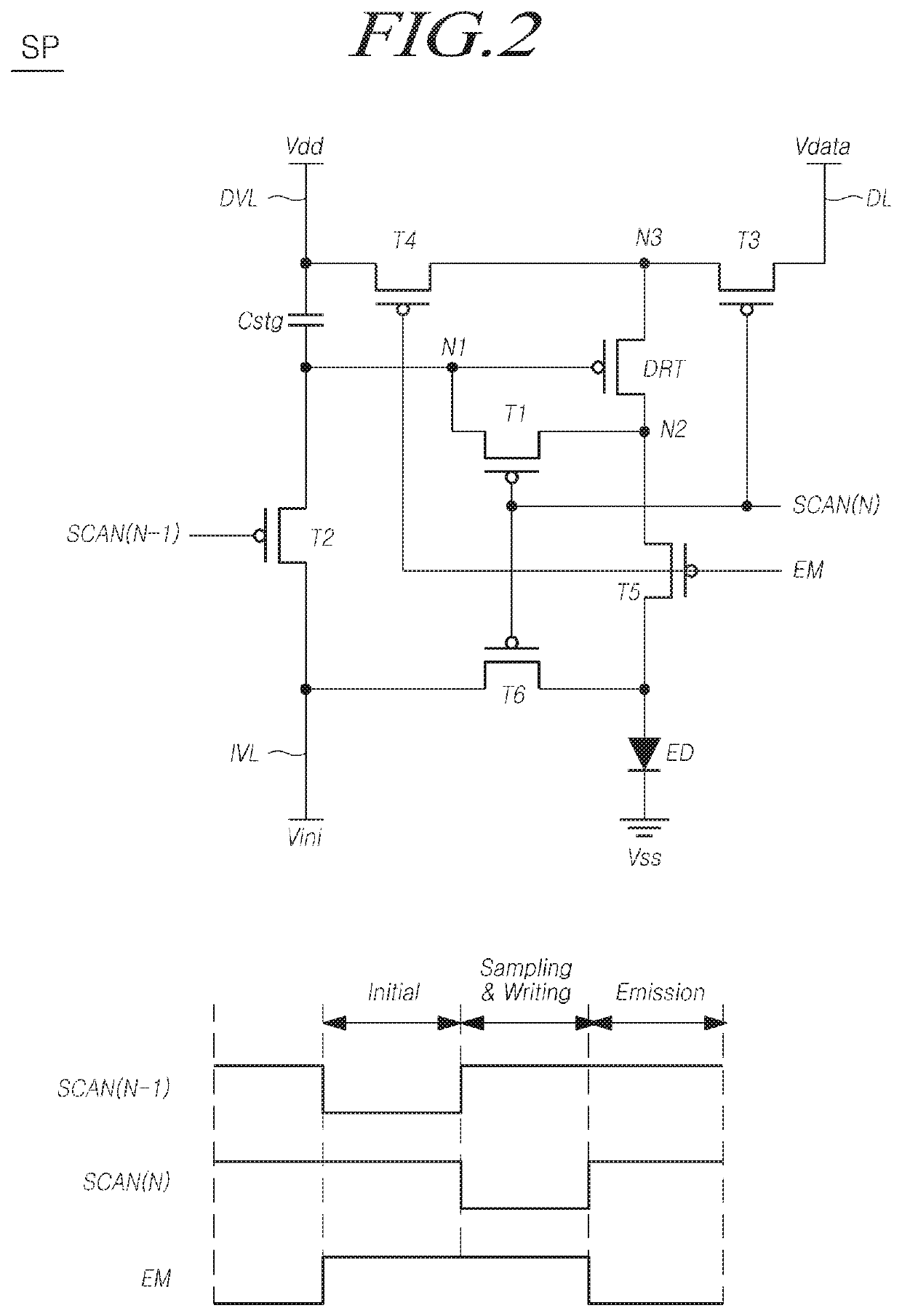

Electronic device including optical sensor module

PendingUS20210026419A1Reduce and preventImprove Sensing PerformanceDigital data processing detailsPrinted circuit aspectsFlexible electronicsPrinted circuit board

In embodiments, an electronic device may include a housing, a display panel, and an optical sensor module. The display panel is disposed in an inner space of the housing and is at least partially visible from an outside through the housing, the display including a display area, a first non-display area disposed adjacent to at least a peripheral portion of the display area, and a second non-display area disposed adjacent to at least a peripheral portion of the first non-display area. The optical sensor module is disposed in the inner space at least partially overlapping the display panel, and includes a flexible printed circuit board (FPCB), a light emitting structure disposed on the FPCB at least partially overlapping the first non-display area when the display panel is viewed from above, and a light receiving structure disposed on the FPCB at least partially overlapping the display area when the display panel is viewed from above. The display area has a first transmittance, and the first non-display area has a second transmittance greater than the first transmittance.

Owner:SAMSUNG ELECTRONICS CO LTD

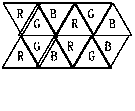

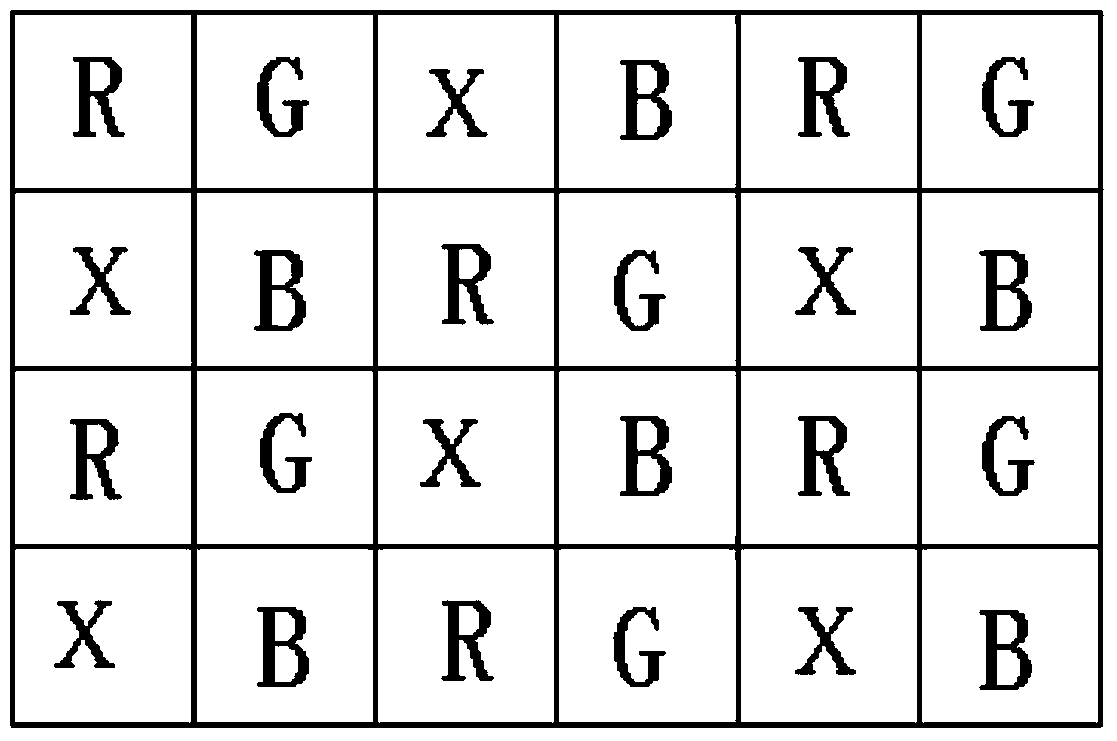

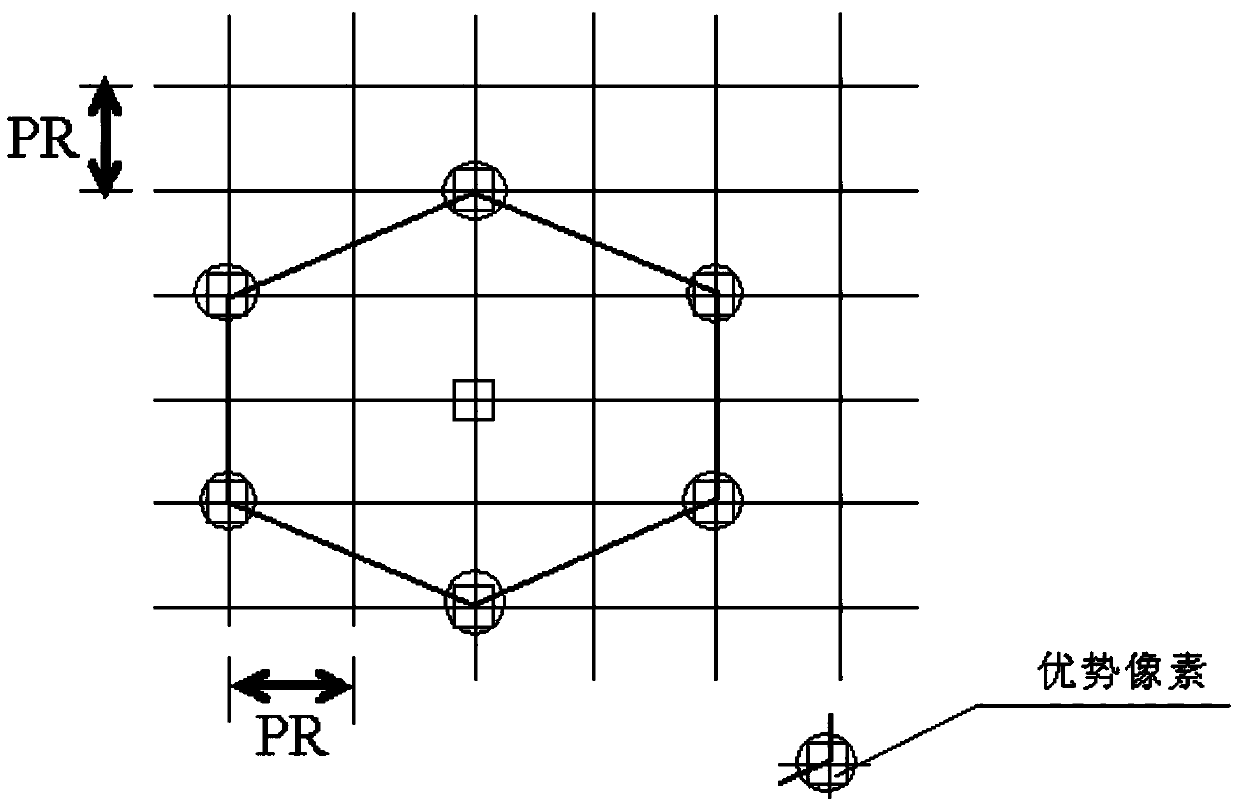

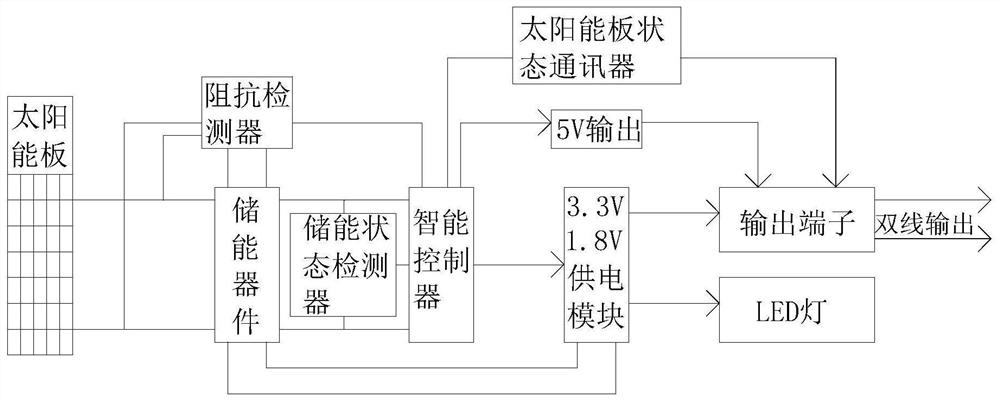

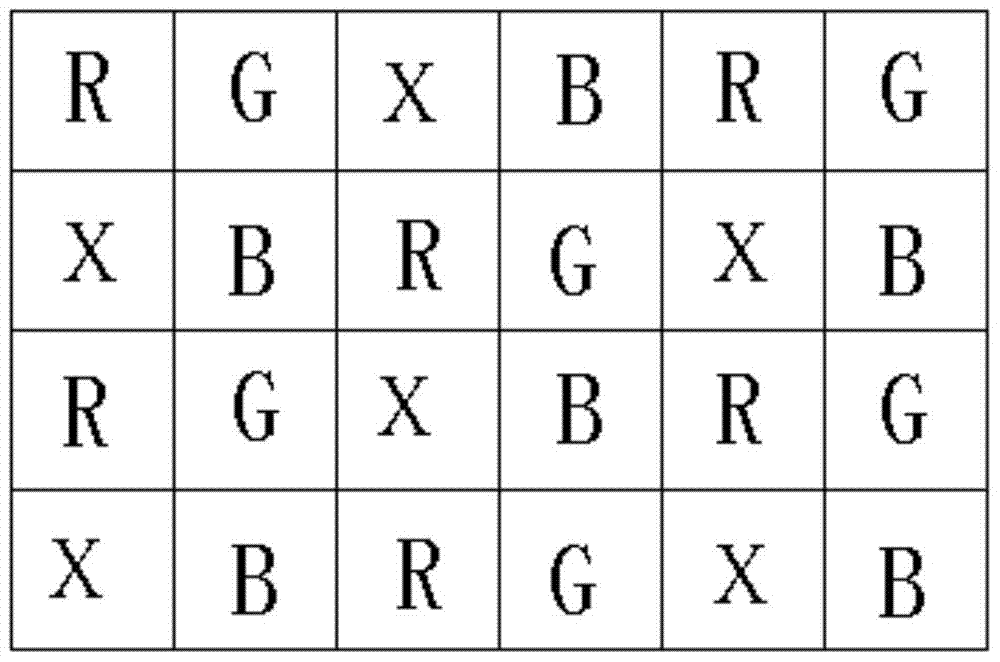

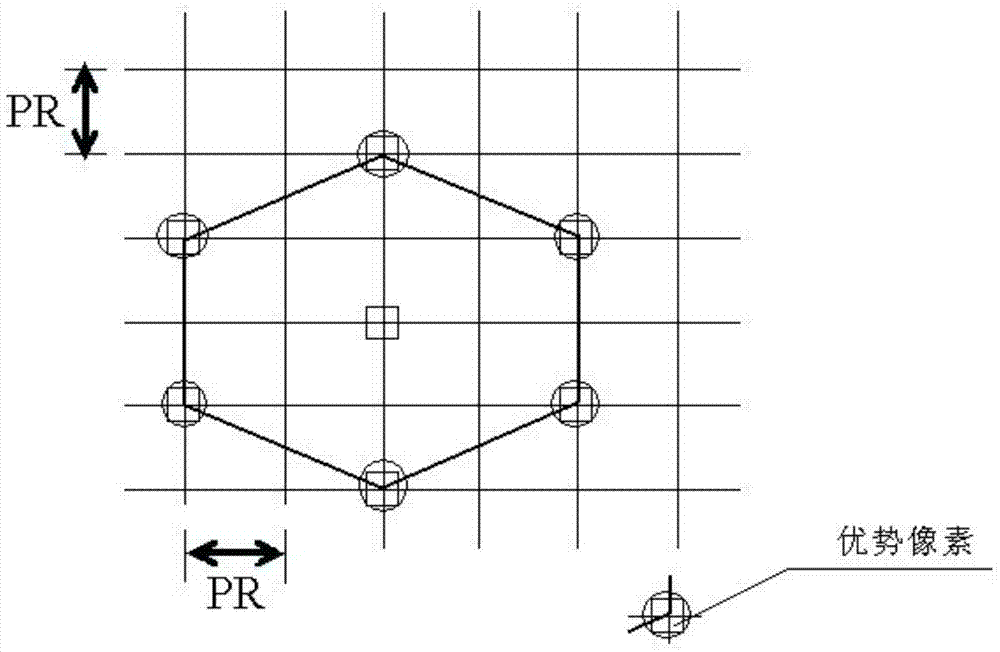

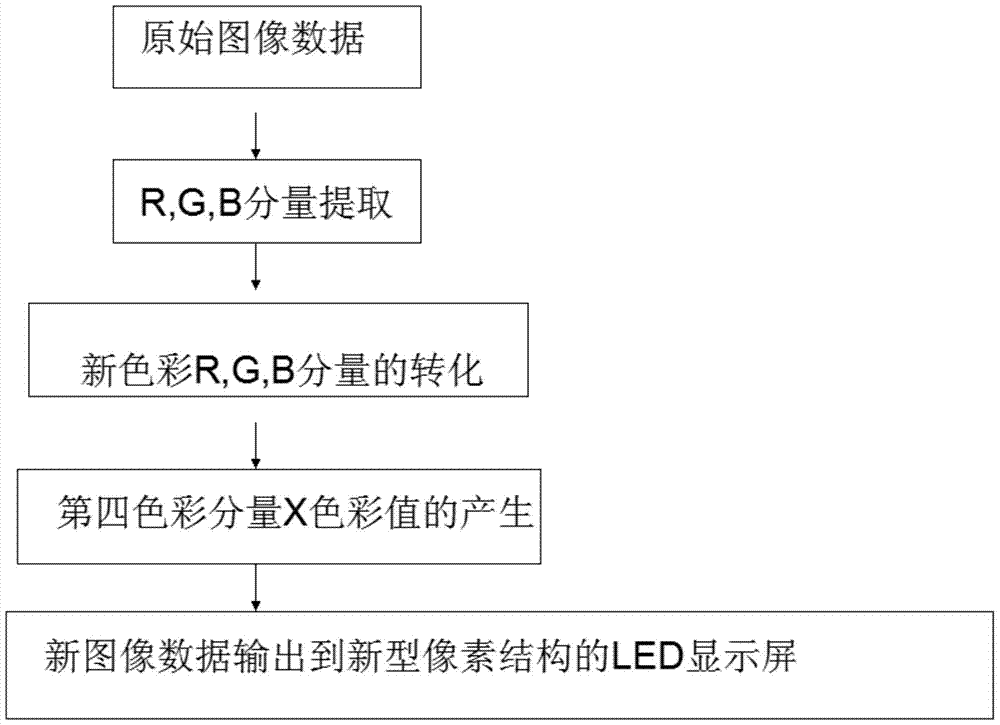

Computing method for improving visual resolution and optimum pixel arraying structure module

InactiveCN103474001AEnhance sensory effectArrangement structure optimizationStatic indicating devicesIdentification meansStiphra robustaVisual resolution

Disclosed is a computing method of a pixel arraying structure for improving visual resolution. The computing method includes the steps: connecting middle points of neighboring physical pixels different in color with straight lines so as to allow all the middle points of the abstract pixels to fall on a grid formed by the straight lines; extracting physical pixel Xs, in any color, with the middle points D of the same falling on the grid, taking a middle point D of an any pixel as a center pixel, and searching a most widespread polygon formed by the middle point Ds of the other pixels around the middle point D; defining an average value of the distance from advantaged pixels to the center pixels and naming the average value as visual resolution (VR). The invention further provides a pixel array structure obtained by the above computing method. By the pixel arraying structure, image resolution synthesized by a display is greatly improved, and a sensory effect of human eyes upon the display is improved. Meanwhile, image brightness of the display is uniform, and intense stimulation and damage to the human eyes are avoided.

Owner:湖州大业科技有限公司

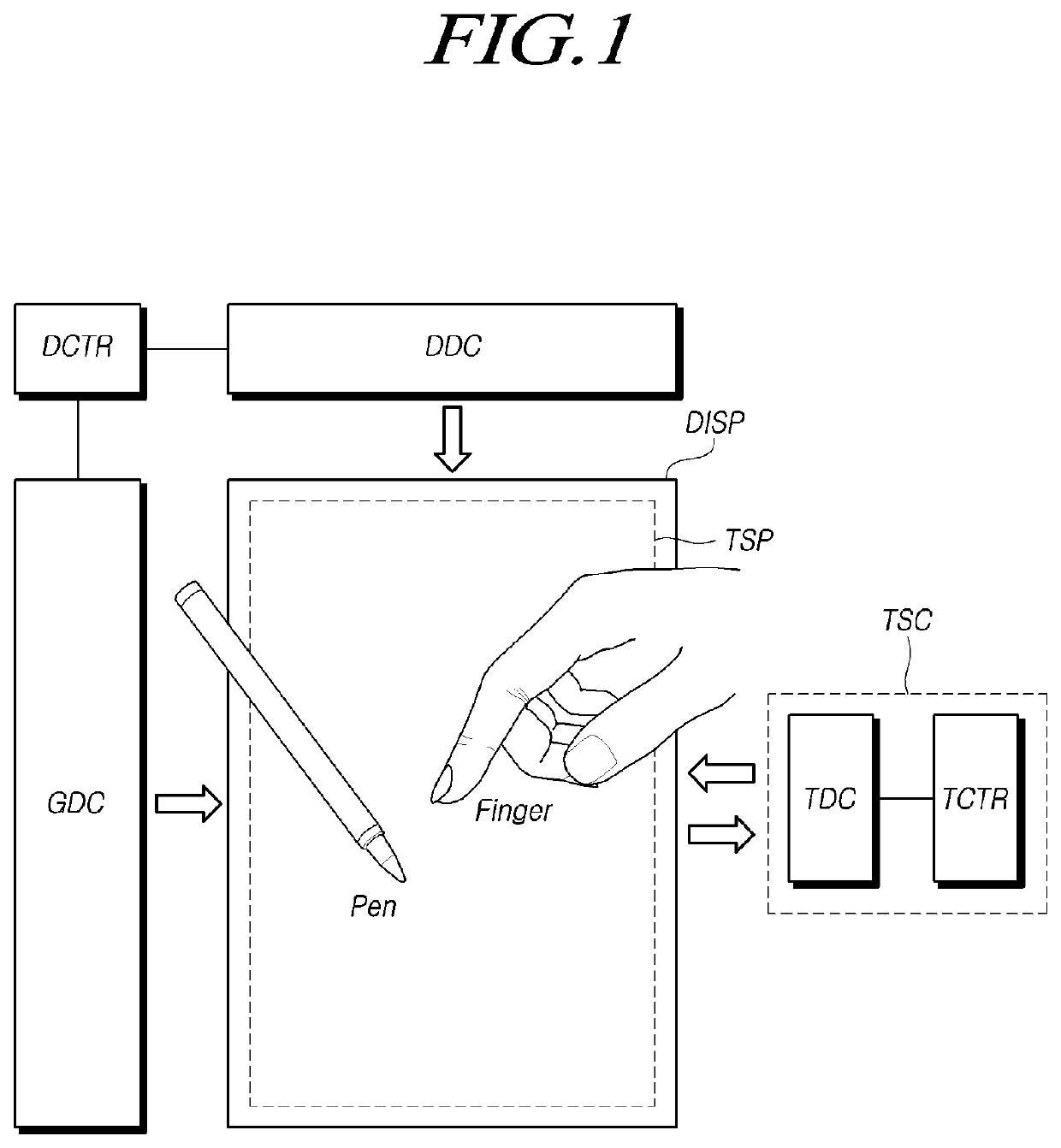

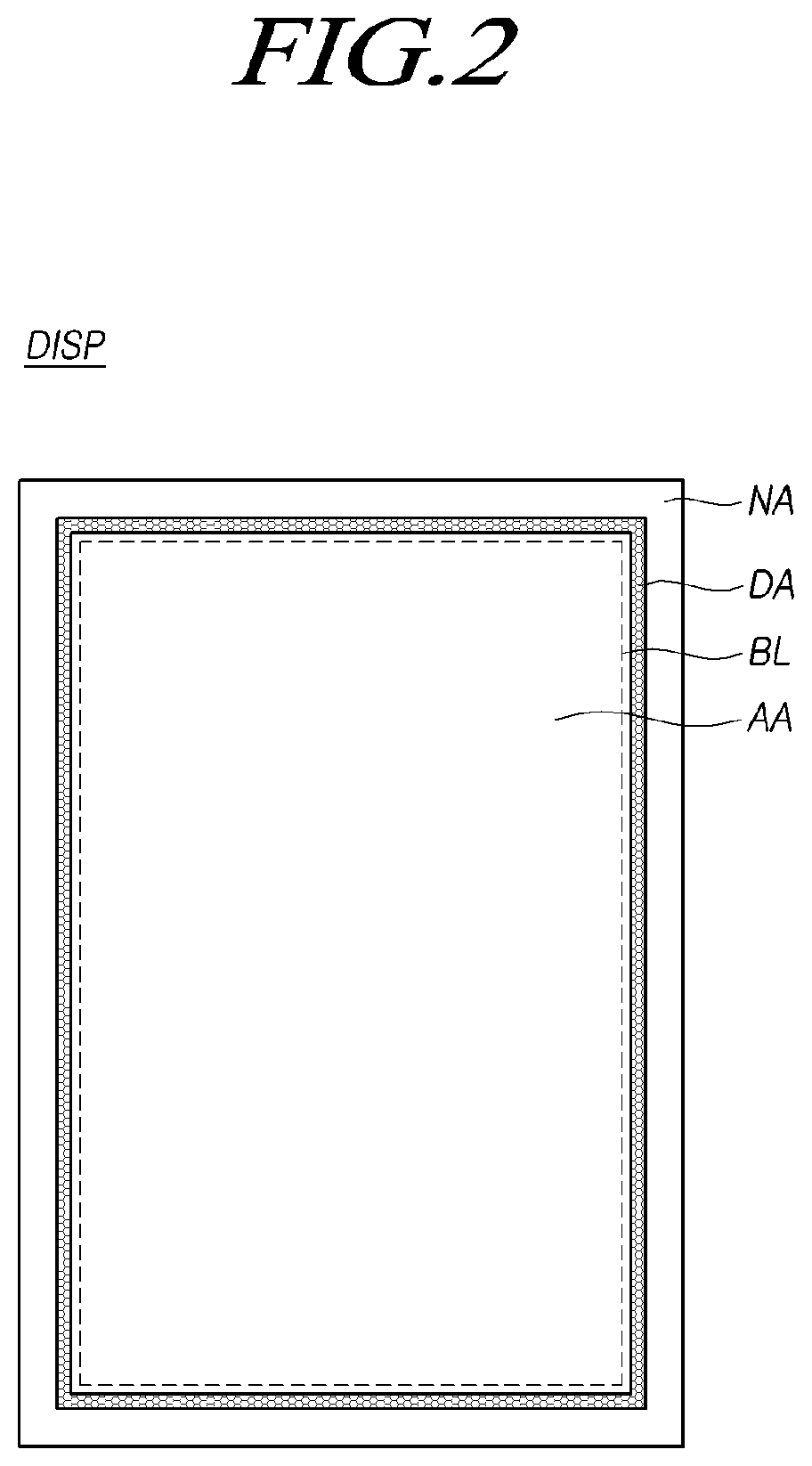

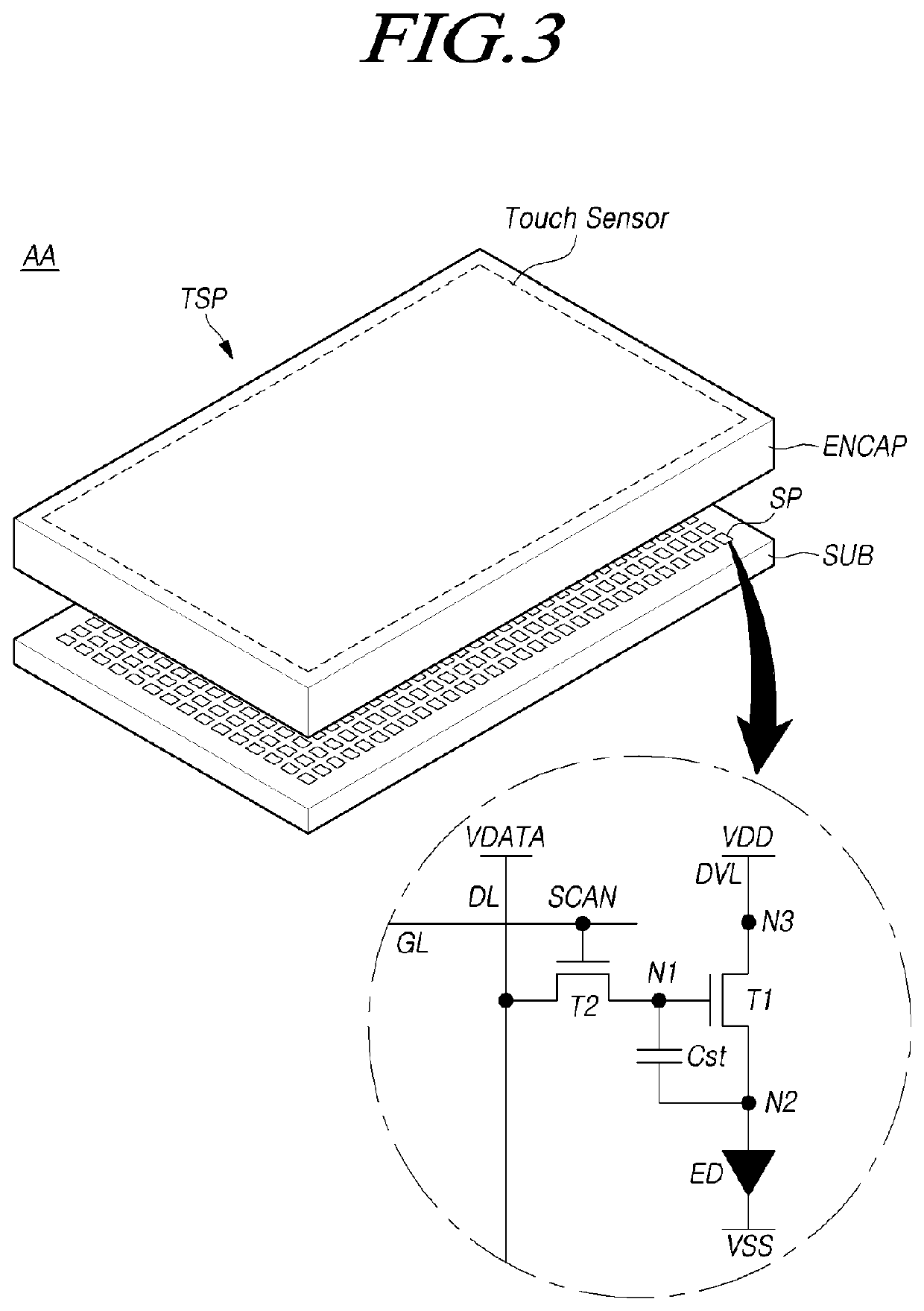

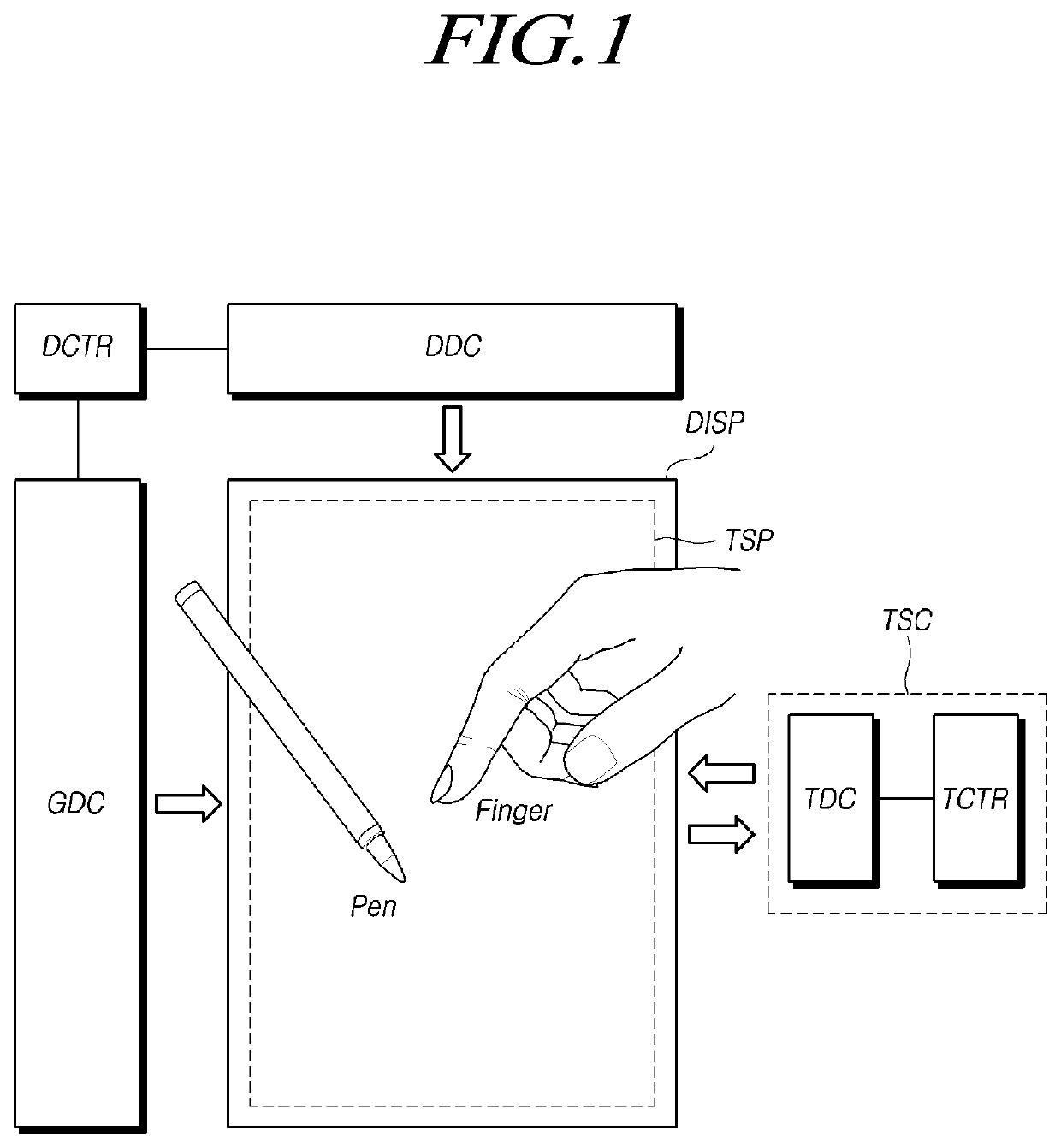

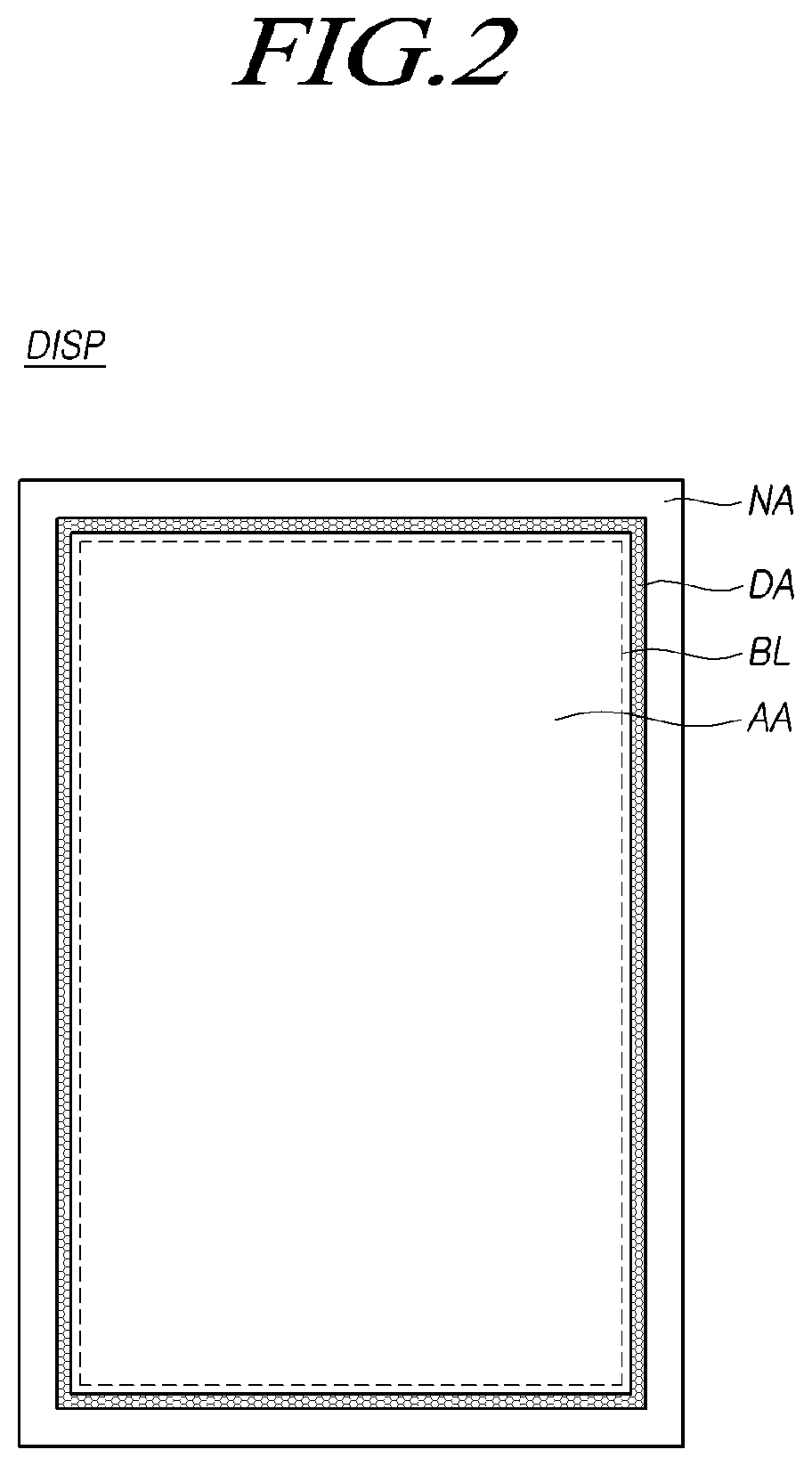

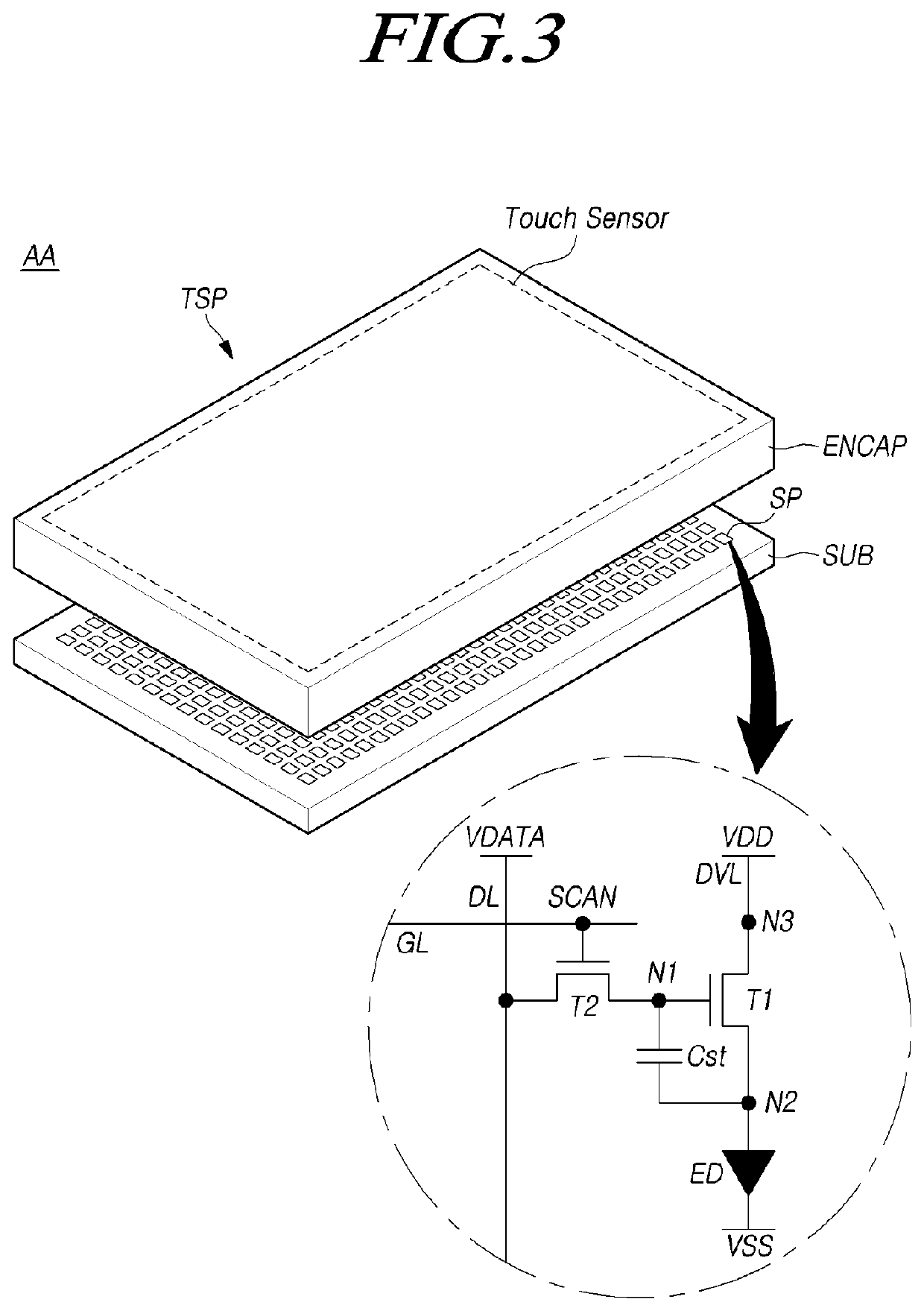

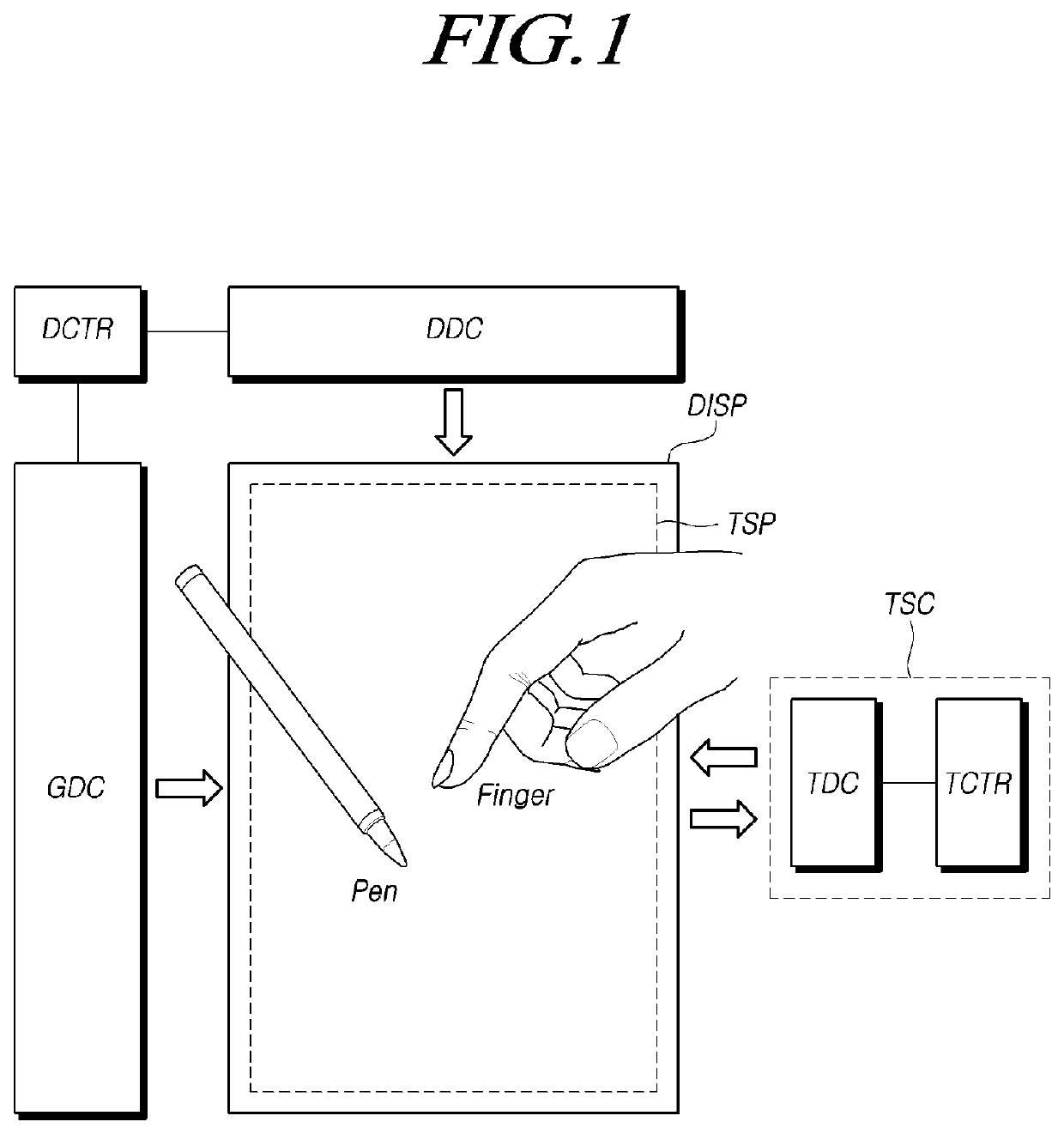

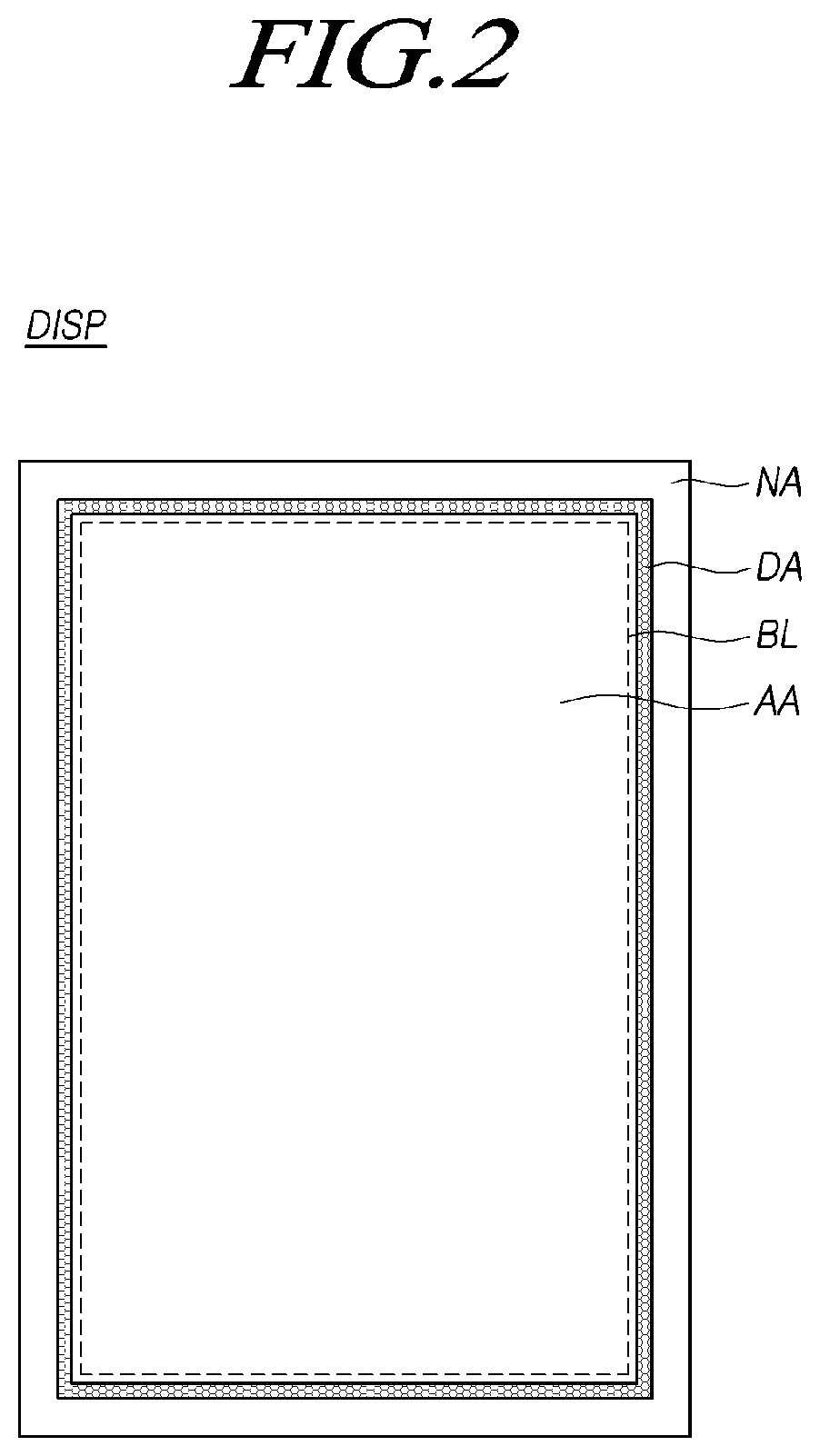

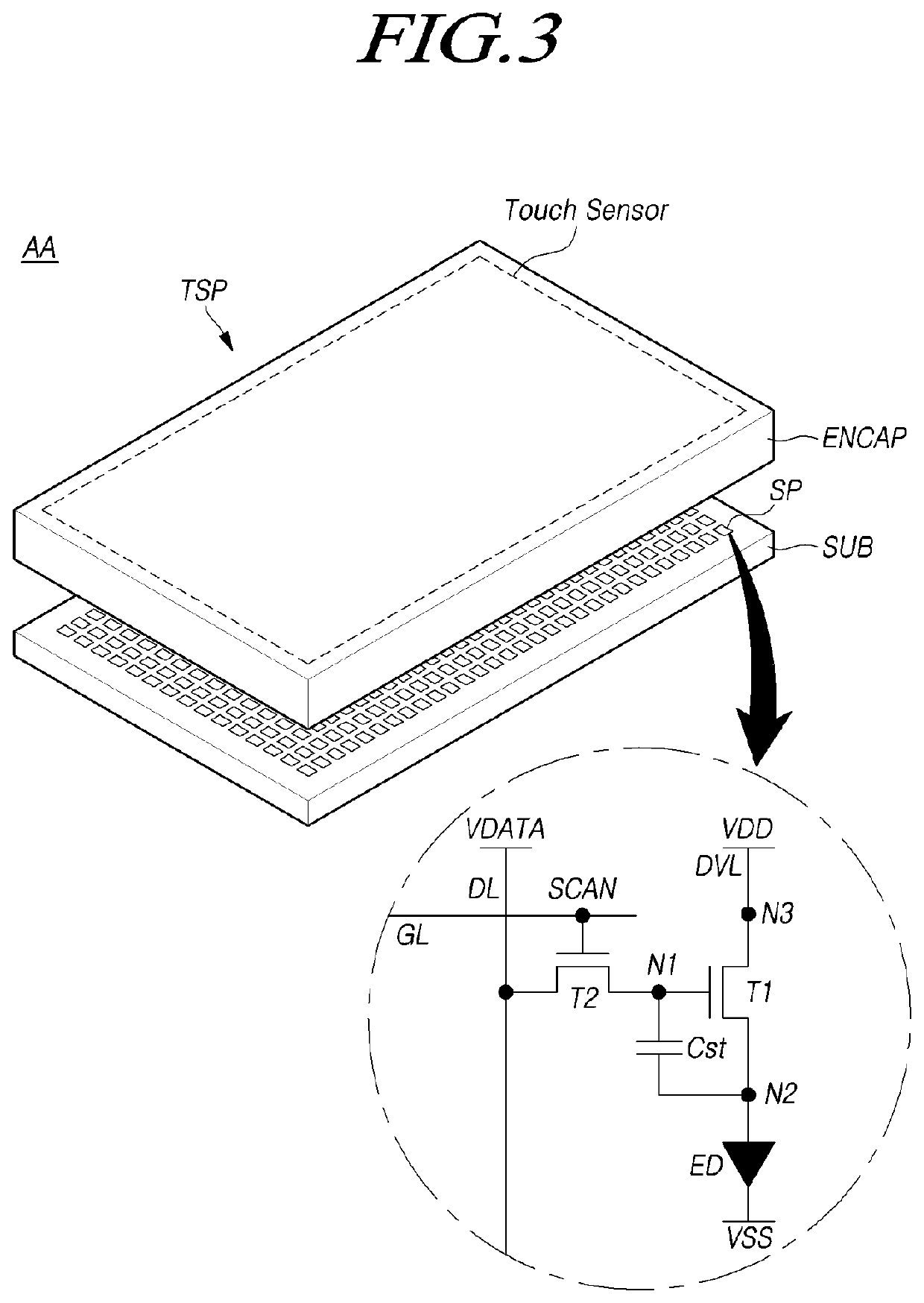

Touch display device

ActiveUS20210026477A1Reduce border sizeAvoid Parasitic CapacitanceStatic indicating devicesSolid-state devicesComputer hardwareMedicine

Embodiments of the present disclosure relate to a touch display device, and more particularly, to a touch display device which can have a small bezel size even when touch routing lines connecting a touch sensor to a touch sensing circuit are disposed in a non-display area and which can improve touch sensitivity by preventing or minimizing the formation of parasitic capacitance that can be caused by the touch routing lines.

Owner:LG DISPLAY CO LTD

Touch display device

ActiveUS11194414B2Reduce border sizeSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingComputer hardwareMedicine

Embodiments of the present disclosure relate to a touch display device, and more particularly, to a touch display device which can have a small bezel size even when touch routing lines connecting a touch sensor to a touch sensing circuit are disposed in a non-display area and which can improve touch sensitivity by preventing or minimizing the formation of parasitic capacitance that can be caused by the touch routing lines.

Owner:LG DISPLAY CO LTD

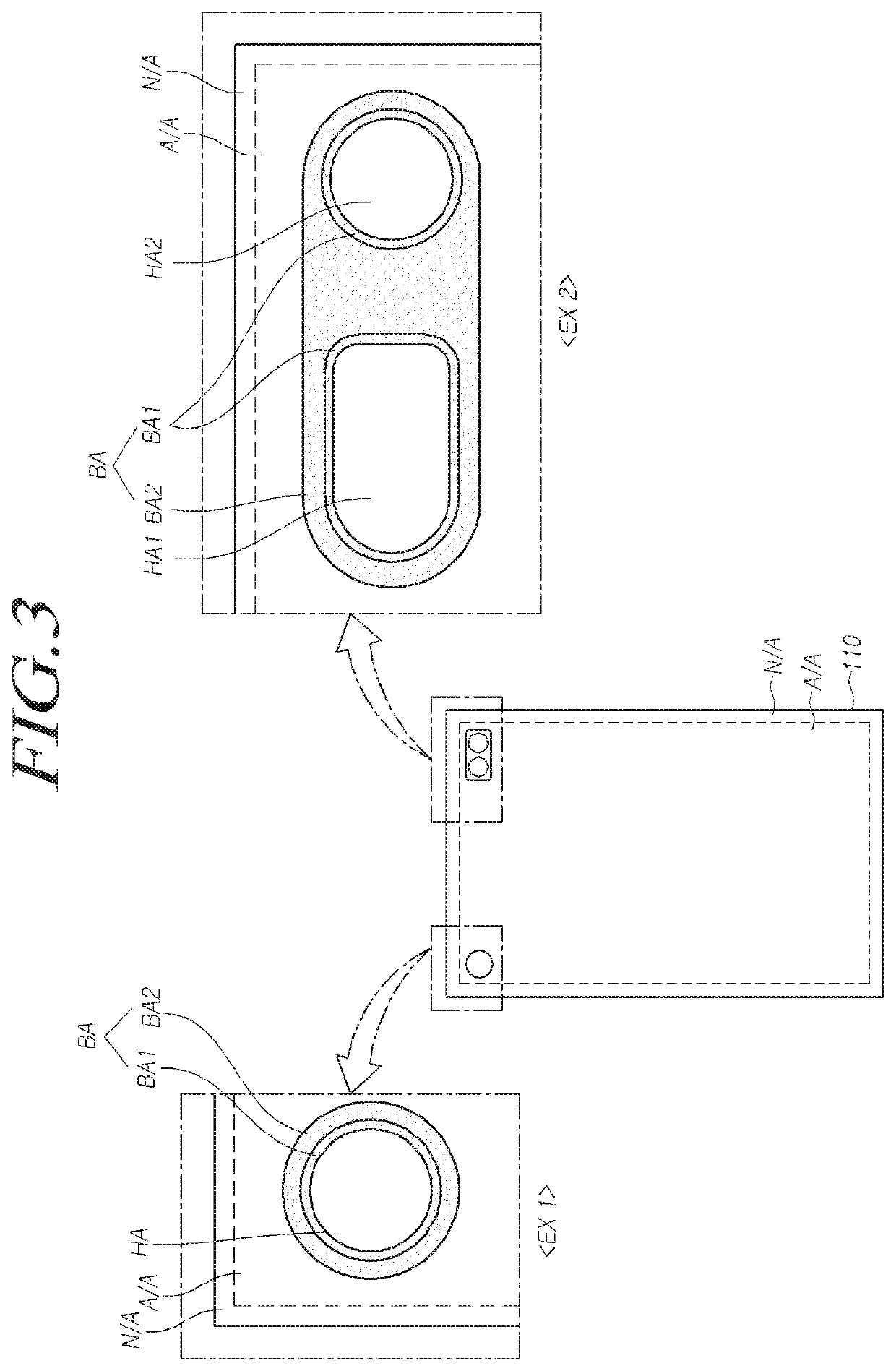

Display device

ActiveUS11367383B2Arrangement structure optimizationImprove uniformityStatic indicating devicesDigital data processing detailsComputer hardwareMedicine

Provided is a display device having a structure in which a hole area in which camera sensors or the like are disposed is included in an active area of a display panel. Data lines among a plurality of data lines bypassing the hole area are disposed on different layers to prevent an increase in the load of data lines, through which green subpixels are driven. Degradations in the luminance of subpixels disposed around the hole area and driven through the data lines bypassing the hole area are prevented. The uniformity of luminance around the hole area is improved.

Owner:LG DISPLAY CO LTD

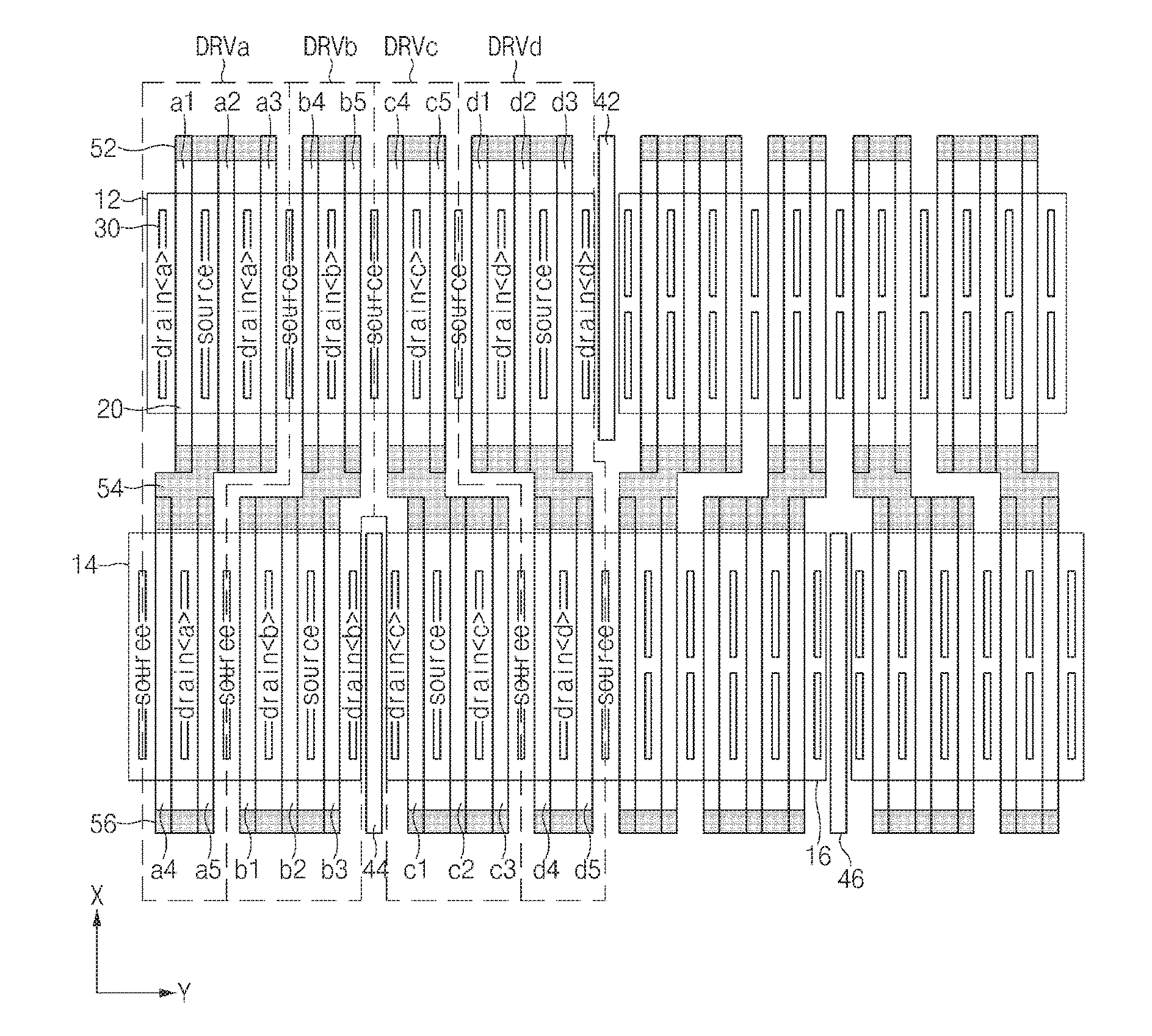

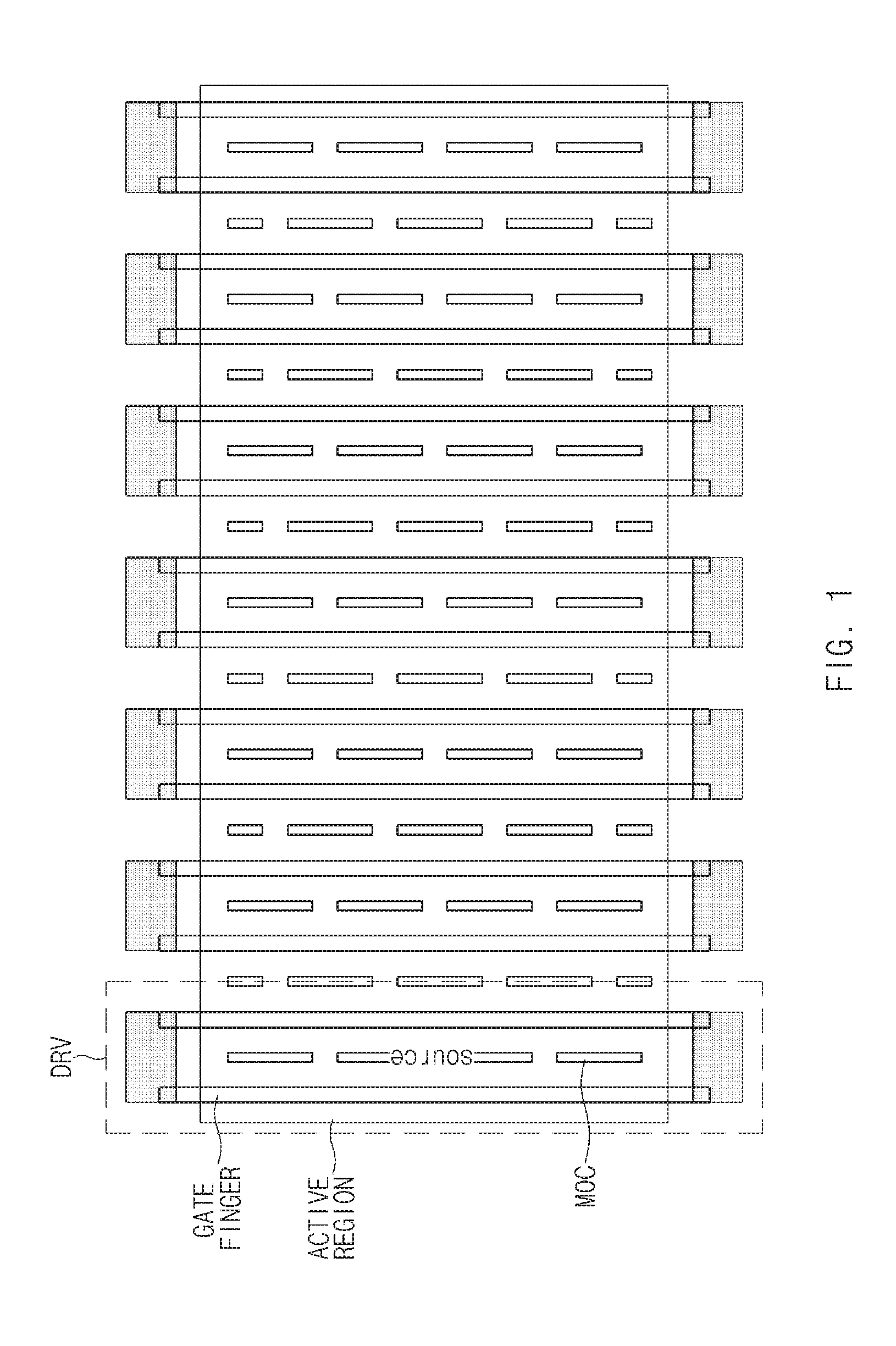

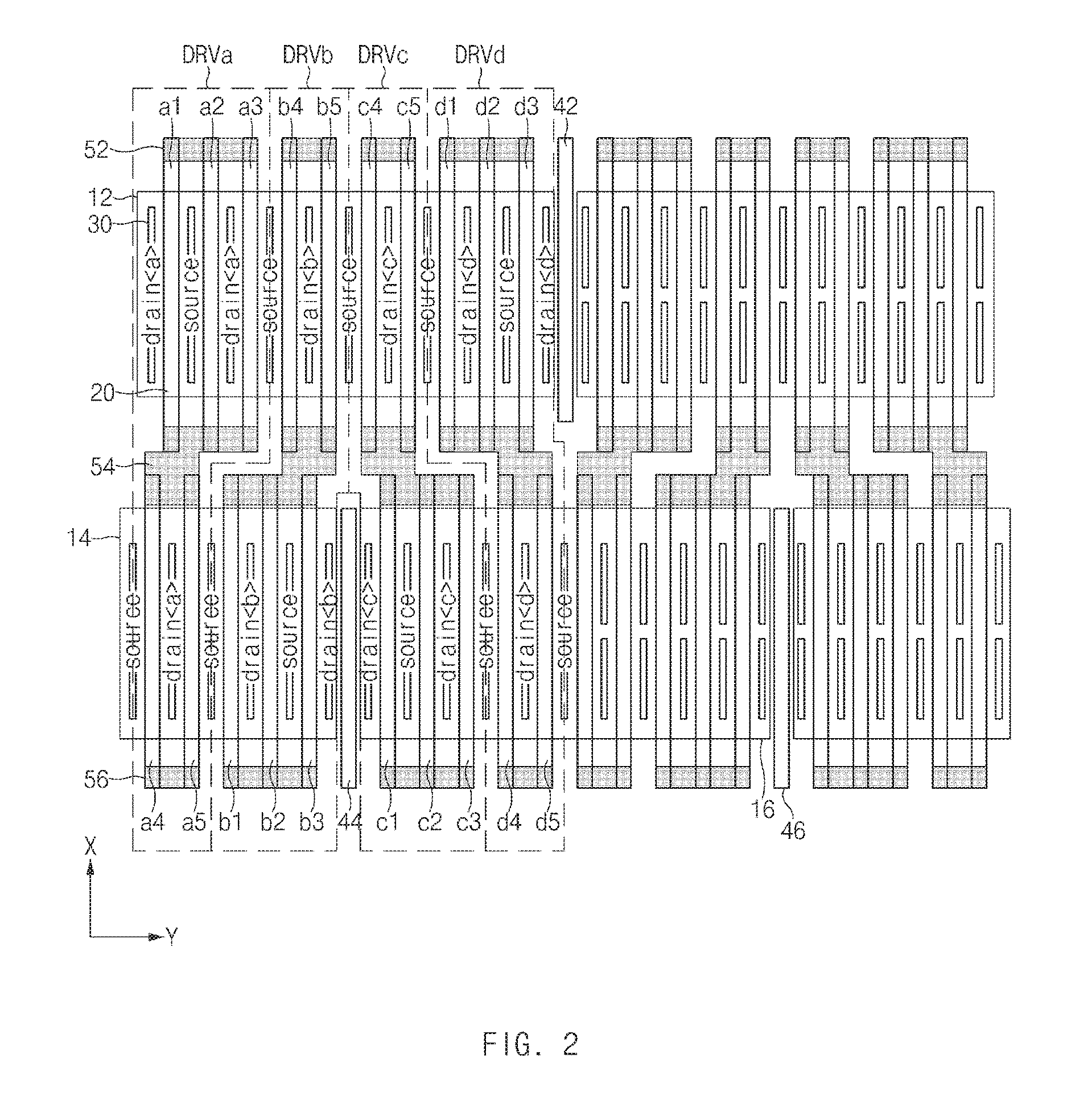

Semiconductor device including drivers

ActiveUS20170062402A1Maximizing abilityArrangement structure optimizationTransistorSolid-state devicesEngineeringSemiconductor

A semiconductor device including drivers is disclosed, which can maximize driving ability of a plurality of drivers installed in a given region when the plurality of drivers is arranged in an array shape. The semiconductor device includes: a first active region; a second active region spaced apart from the first active region a predetermined distance in a first direction; a first gate finger group located in the first active region, and configured to include an odd number of gate fingers; and a second gate finger group located in the second active region, and configured to include an even number of gate fingers electrically coupled to the gate fingers of the first gate finger group.

Owner:SK HYNIX INC

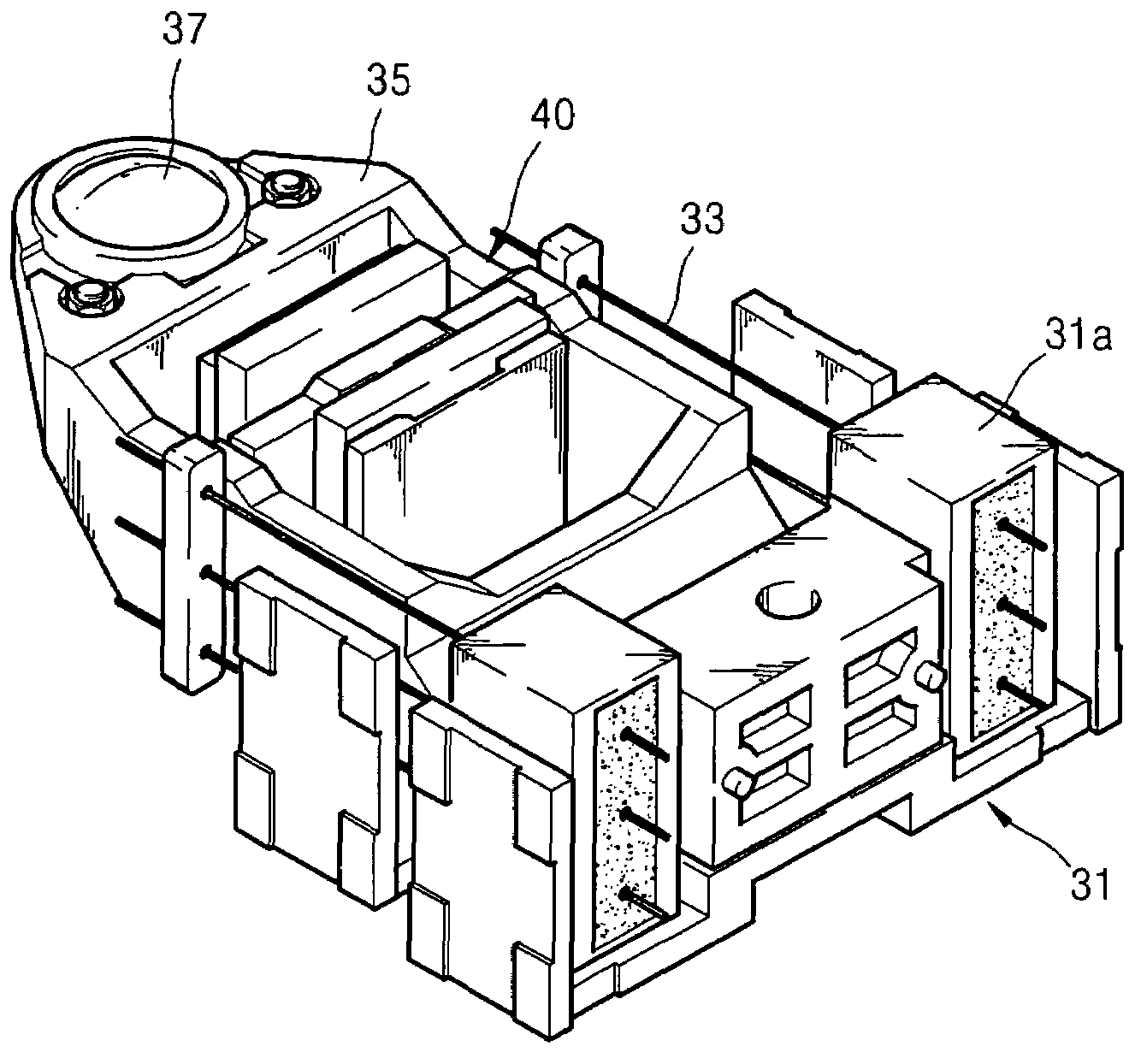

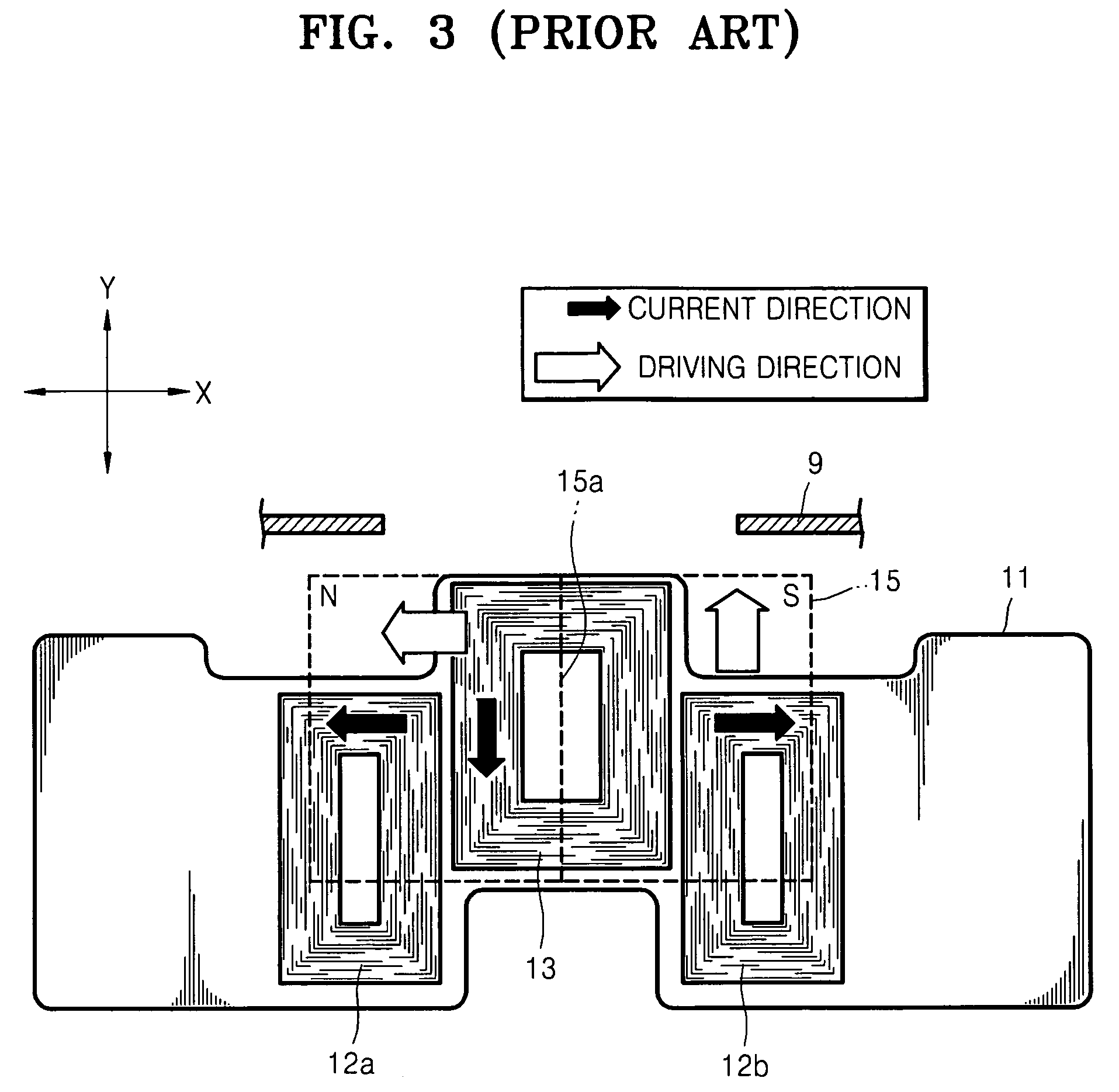

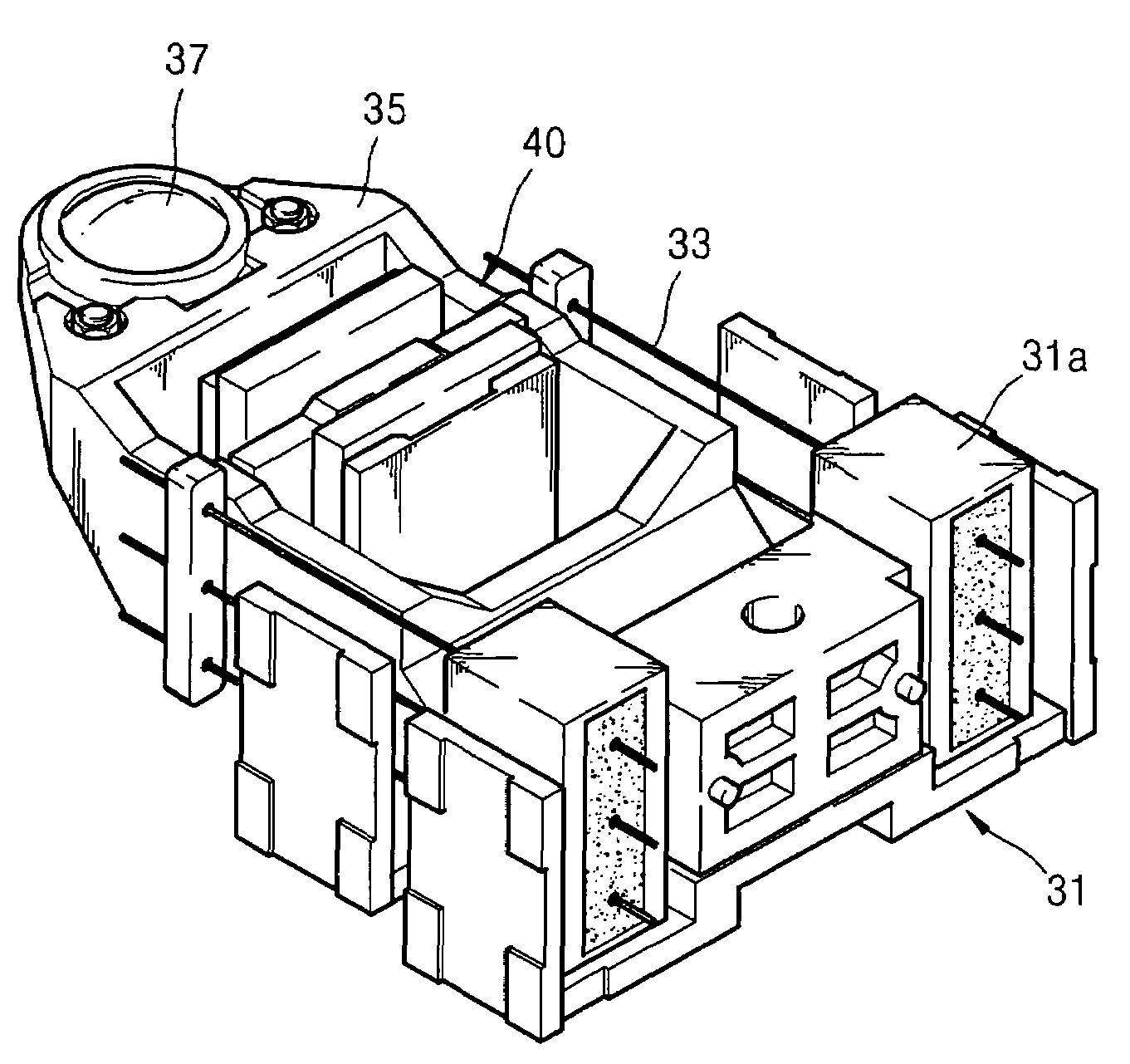

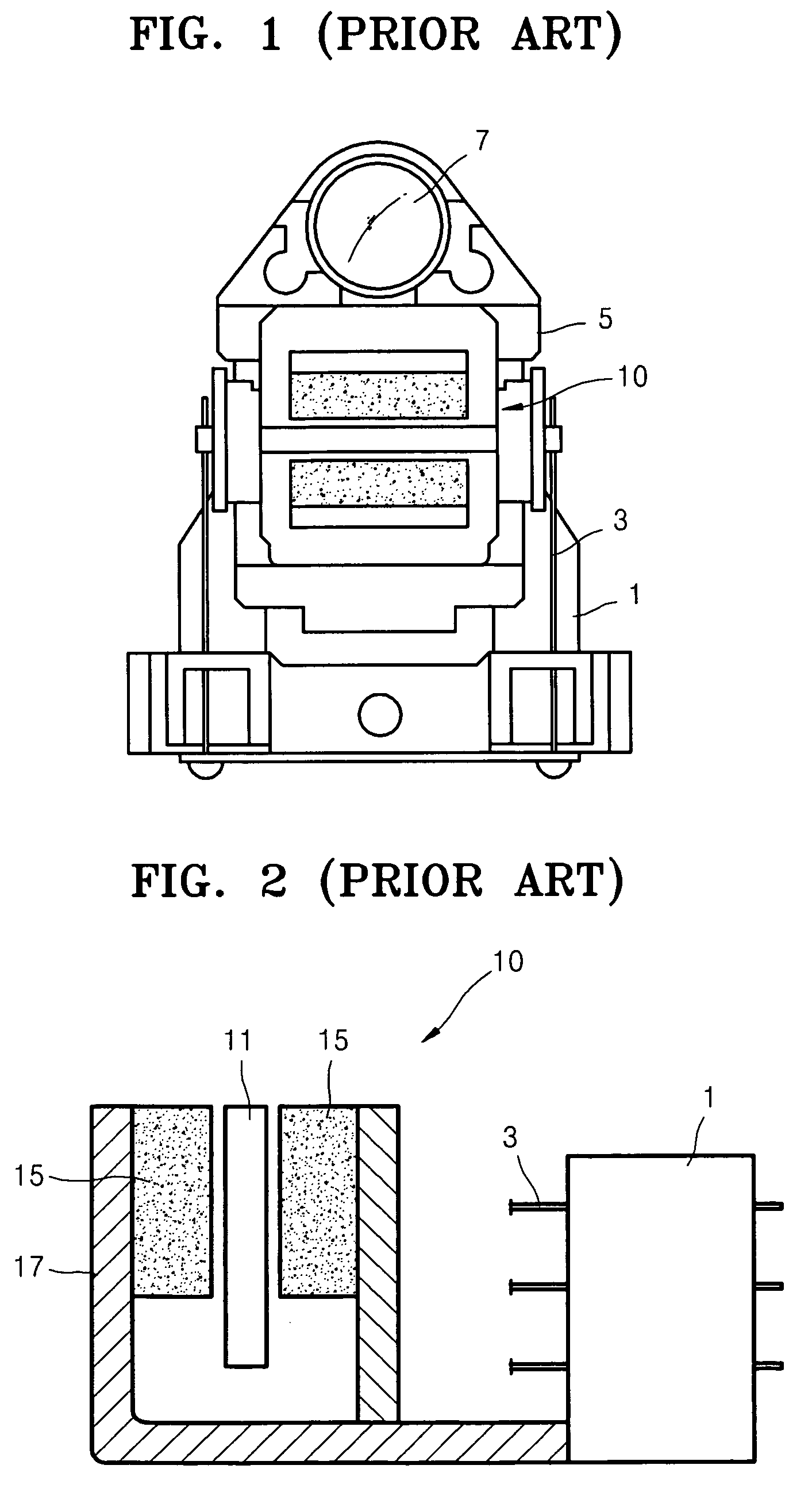

Optical pickup actuator

InactiveUS20070201323A1Increases magnetic driving forceArrangement structure optimizationRecord information storageBusesOptical pickupEngineering

An optical pickup actuator which includes a base, a blade having an objective lens mounted thereon, a plurality of suspensions supporting the blade to be movable with respect to the base and forming an electroconductive path, and a magnetic circuit driving the blade according to a driving signal applied through the respective suspensions. The magnetic circuit includes a magnet fixed to the base, and a fine pattern coil installed on the blade at a position facing the magnet and having a track pattern coil, a focus pattern coil, and a tilt pattern coil independently driven by current applied through the suspensions and providing driving forces in a track direction, a focus direction, and a tilt direction of the blade.

Owner:TOSHIBA SAMSUNG STORAGE TECH KOREA CORP

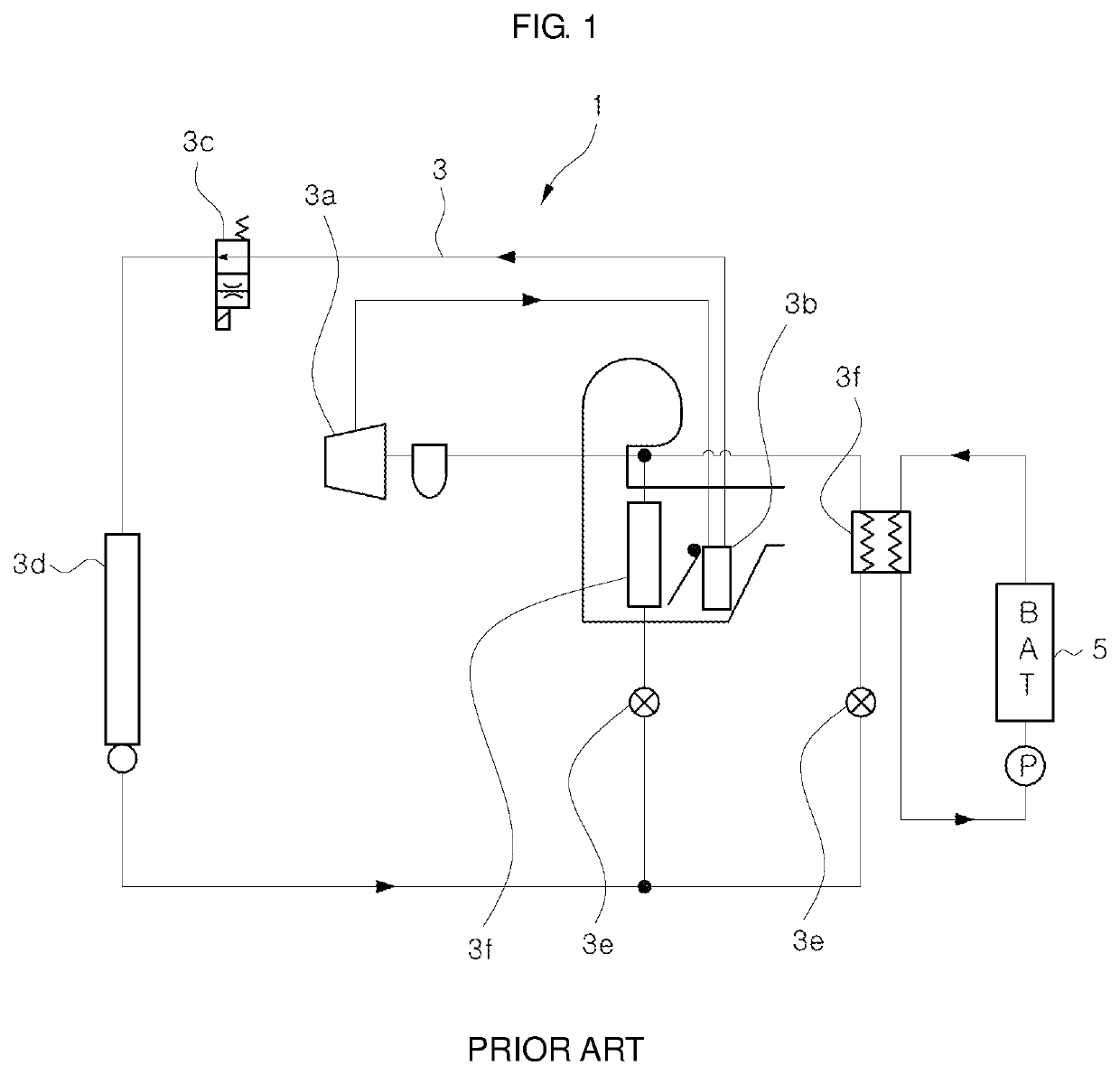

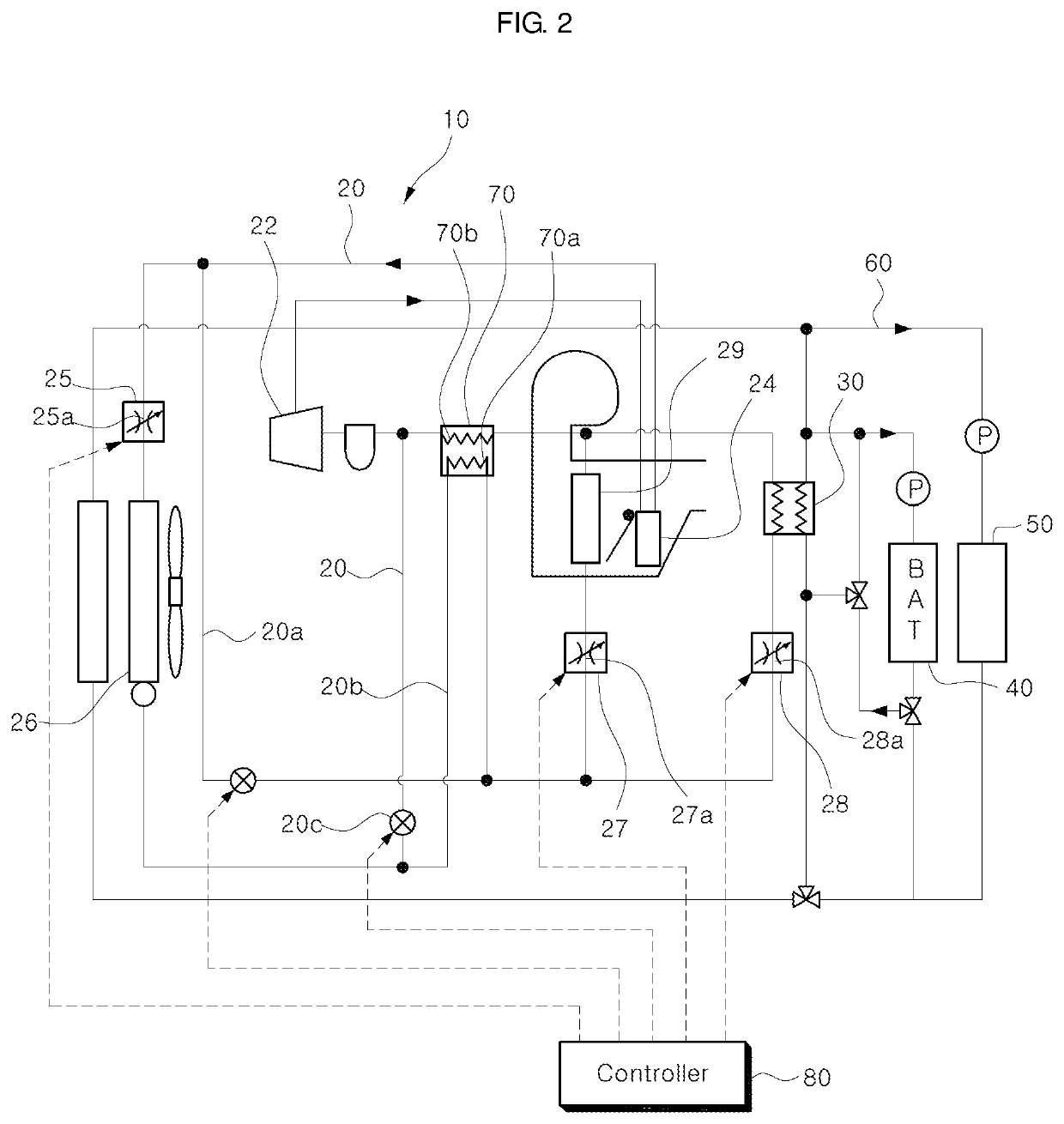

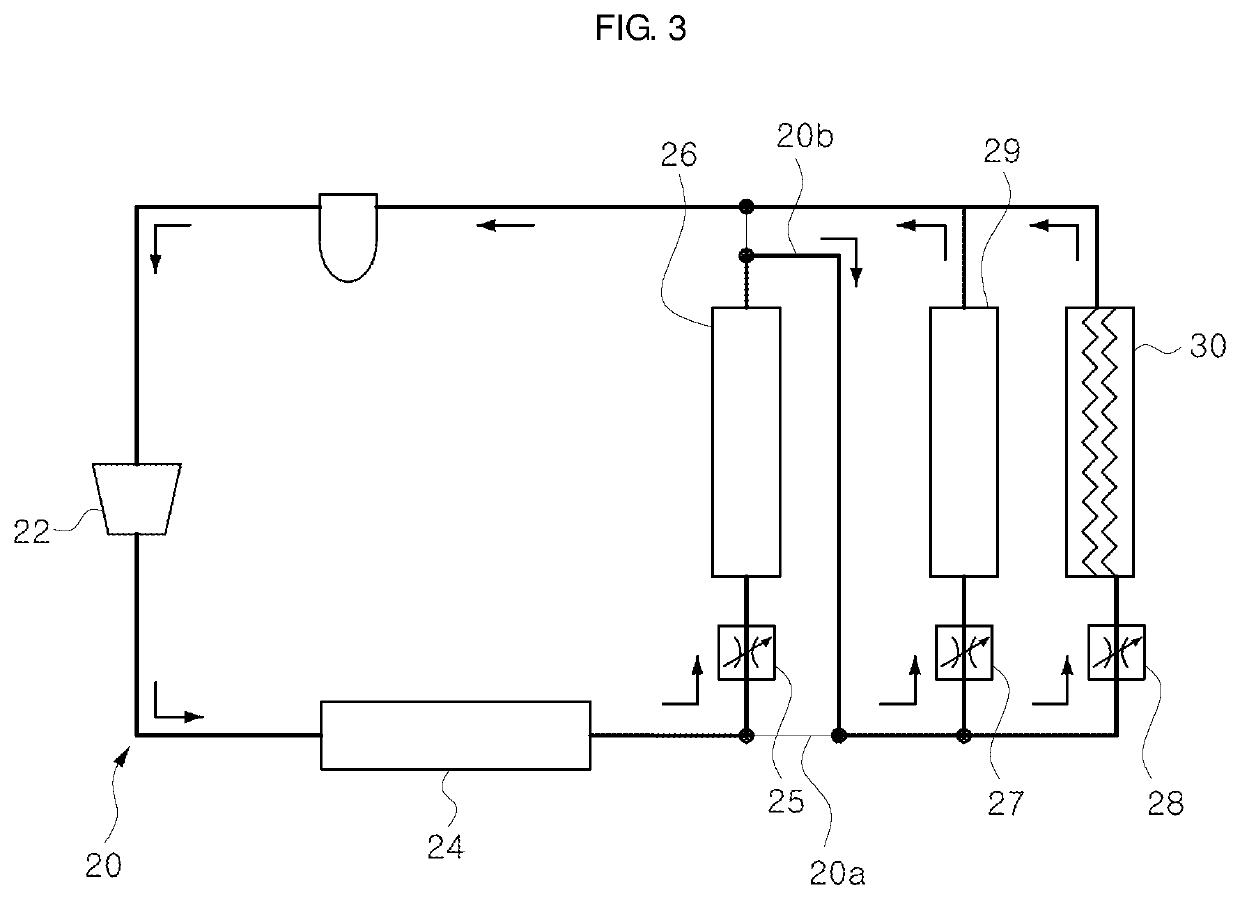

Vehicular heat management system

PendingUS20220176776A1High trafficImproved cooling/heating performanceAir-treating devicesMechanical apparatusCold airHeat management

A vehicular heat management system is provided with a heat pump type refrigerant circulation line that cools and heats specific air conditioning regions by generating a hot air or a cold air depending on a flow direction of a refrigerant. The system includes a compressor configured to suck, compress and discharge the refrigerant, a high-pressure side heat exchanger configured to dissipate heat of the refrigerant discharged from the compressor, an outdoor heat exchanger configured to allow the refrigerant to exchange heat with an air outside the vehicle, an expansion valve configured to depressurize the refrigerant flowing out of the high-pressure side heat exchanger or the outdoor heat exchanger, and one or more low-pressure side heat exchangers configured to evaporate the depressurized refrigerant. The outdoor heat exchanger and the low-pressure side heat exchangers are connected in series or in parallel depending on an air conditioning mode.

Owner:HANON SYST

Display device

ActiveUS20210090490A1Easy loadingDegradation in luminanceStatic indicating devicesDigital data processing detailsComputer hardwareMedicine

Provided is a display device having a structure in which a hole area in which camera sensors or the like are disposed is included in an active area of a display panel. Data lines among a plurality of data lines bypassing the hole area are disposed on different layers to prevent an increase in the load of data lines, through which green subpixels are driven. Degradations in the luminance of subpixels disposed around the hole area and driven through the data lines bypassing the hole area are prevented. The uniformity of luminance around the hole area is improved.

Owner:LG DISPLAY CO LTD

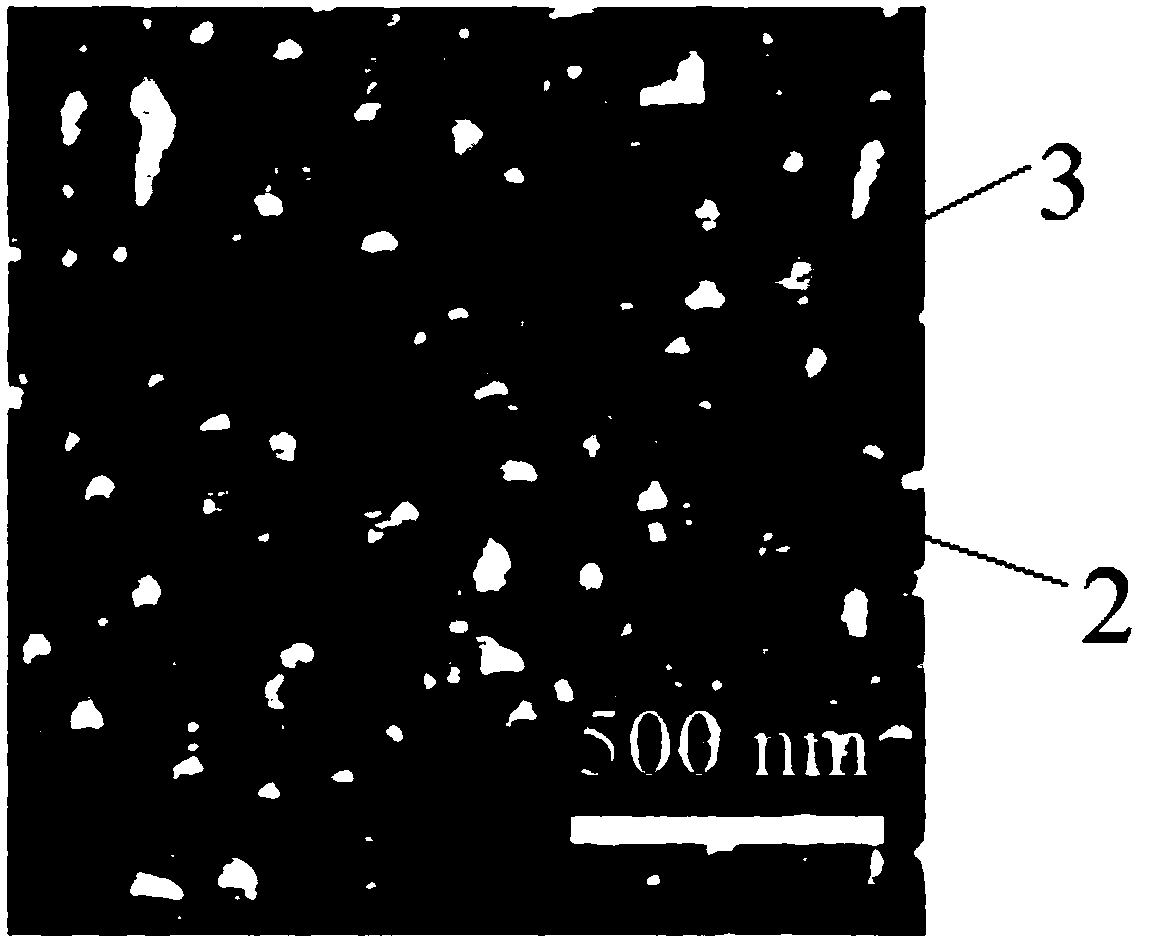

Iodine-doped graphene thin film with high thermal stability and method for preparing iodine-doped graphene thin film

InactiveCN108423671AEnhance interactionNot easy to escape and volatilizeGrapheneCvd grapheneOptoelectronics

The invention discloses an iodine-doped graphene thin film with high thermal stability. The iodine-doped graphene thin film comprises multilayer graphene nanoplatelets mixed with iodine dopants. The multilayer graphene nanoplatelets are randomly stacked along the directions of planes of the multilayer graphene nanoplatelets. The invention further discloses a method for preparing the iodine-doped graphene thin film with the high thermal stability. The method includes depositing graphene nanoplatelets on substrates to form graphene thin films; depositing the iodine dopants on the graphene thin films to obtain the iodine-doped graphene thin film. The iodine-doped graphene thin film and the method have the advantages that the multilayer graphene nanoplatelets are stacked to form compact structures of the iodine-doped graphene thin film, acting force between the graphene nanoplatelets and the iodine dopants can be enhanced, the steric hindrance of the iodine dopants can be enlarged, the iodine dopants are difficult to escape or volatile, and accordingly the thermal stability of the iodine-doped graphene thin film can be improved; array structures of graphene and the iodine dopants are improved by the aid of step-by-step deposition processes, accordingly, the iodine-doped graphene thin film prepared by the aid of the method is still thermally stable even under the condition of the high temperatures of 500 DEG C, obvious effects can be realized, and the iodine-doped graphene thin film and the method are suitable for popularization.

Owner:NORTHWEST UNIV

Touch display device

ActiveUS11314349B2Reduce border sizeSmall sizeStatic indicating devicesSolid-state devicesComputer hardwareMedicine

Owner:LG DISPLAY CO LTD

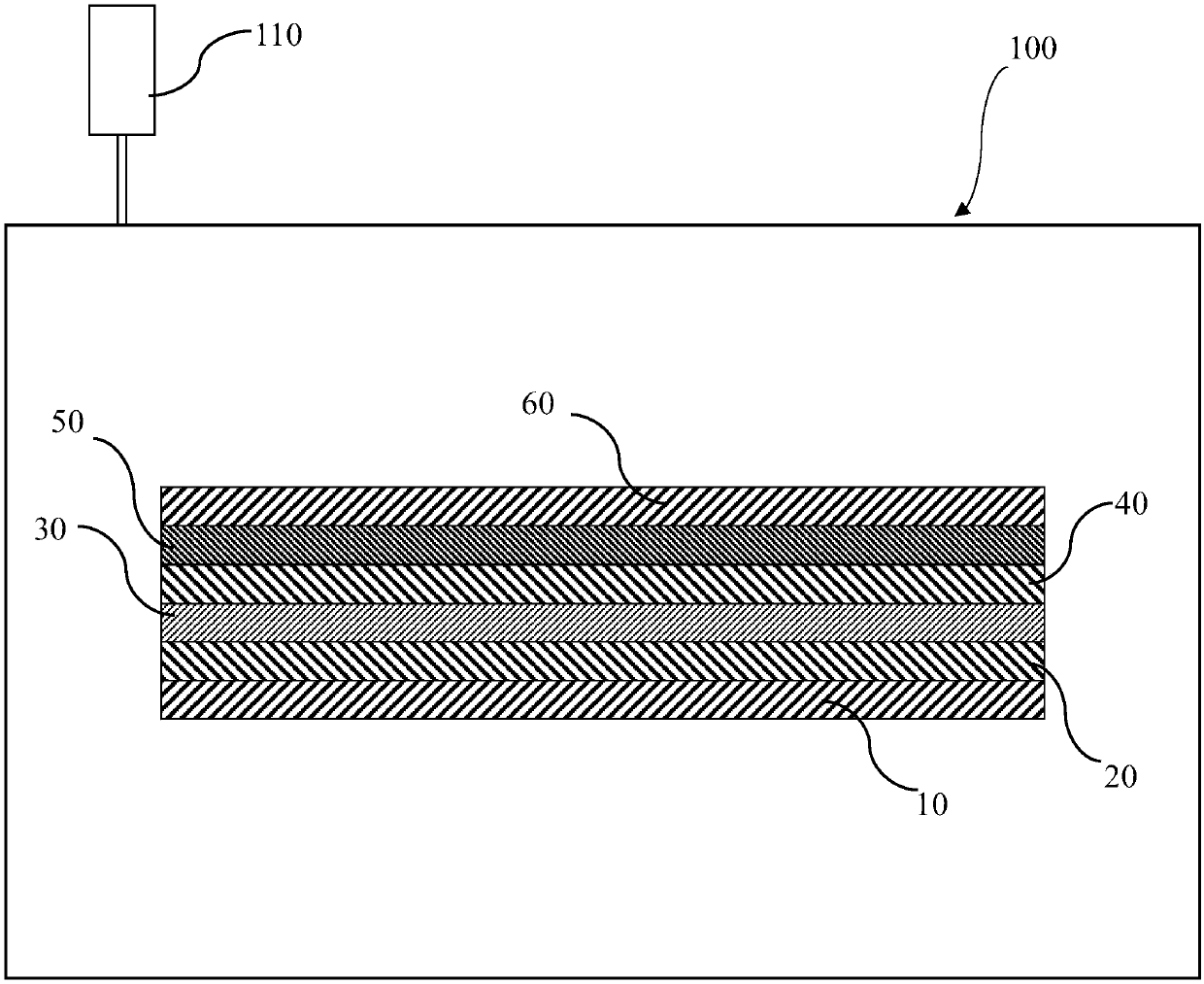

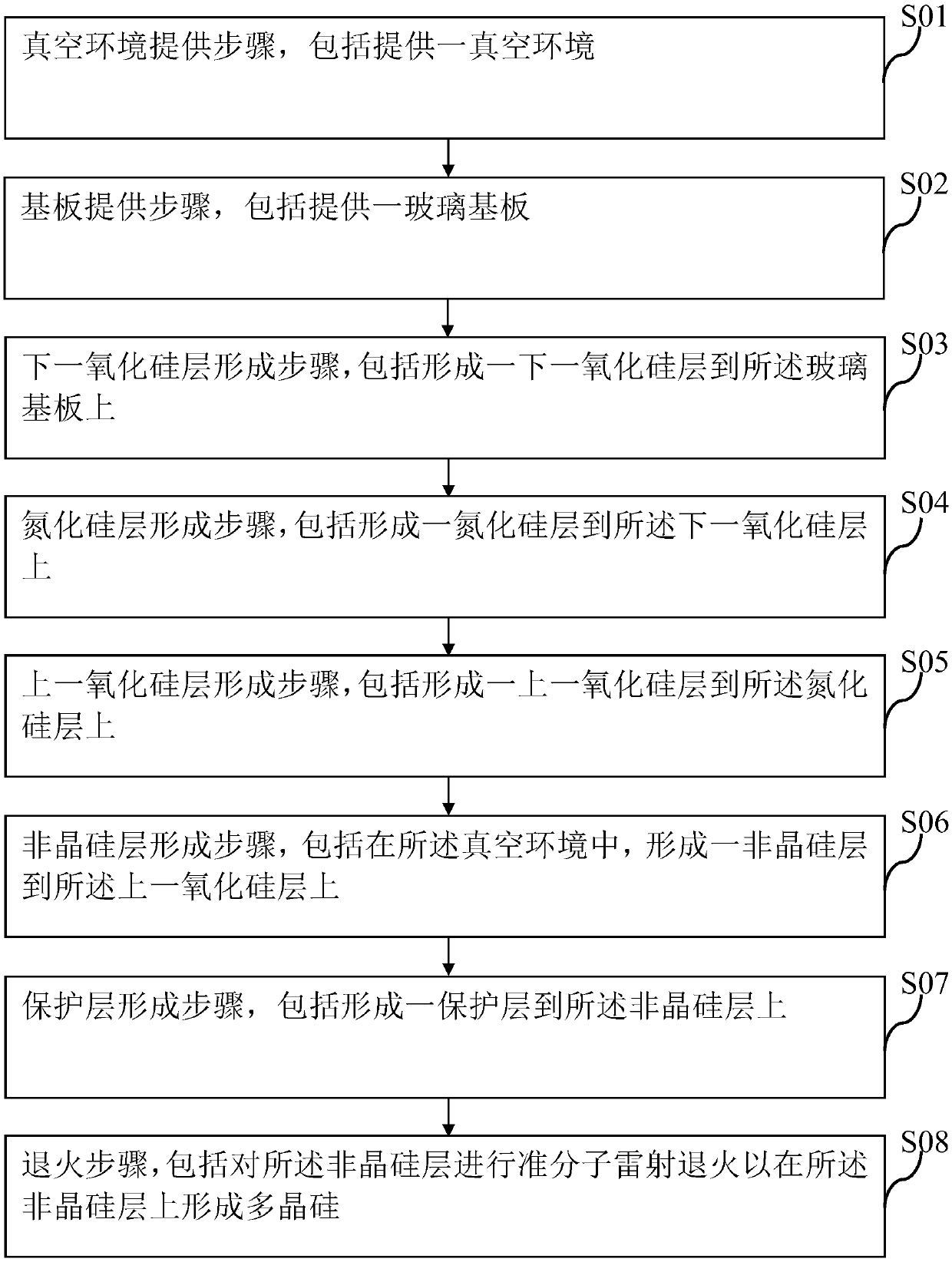

Method for manufacturing a low-temperature polysilicon display panel

InactiveCN109585366AImprove yieldImprove qualitySolid-state devicesSemiconductor/solid-state device manufacturingSilicon monoxideAmorphous silicon

The invention discloses a method for manufacturing a low-temperature polysilicon display panel. The method comprises the steps of: a vacuum environment providing step: providing a vacuum environment;a substrate providing step: providing a glass substrate; a step of forming a next silicon oxide layer: forming the next silicon oxide layer on the glass substrate; a step of forming a silicon nitridelayer: comprising forming a silicon nitride layer on the next silicon oxide layer; a step of forming of a last silicon monoxide layer: forming a last silicon monoxide layer on the silicon nitride layer; a noncrystalline silicon forming step: forming a noncrystalline silicon layer on the last silicon monoxide layer in the vacuum environment; a protection layer forming step: forming a protection layer on the noncrystalline silicon layer; and an annealing step: performing quasimolecule laser annealing for the noncrystalline silicon layer to form polycrystalline silicon on the noncrystalline silicon layer. The method for manufacturing a low-temperature polysilicon display panel avoids the problem that the generated polycrystalline silicon crystal lattice is defective due to residual airborne particles or metal ions on the amorphous silicon layer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

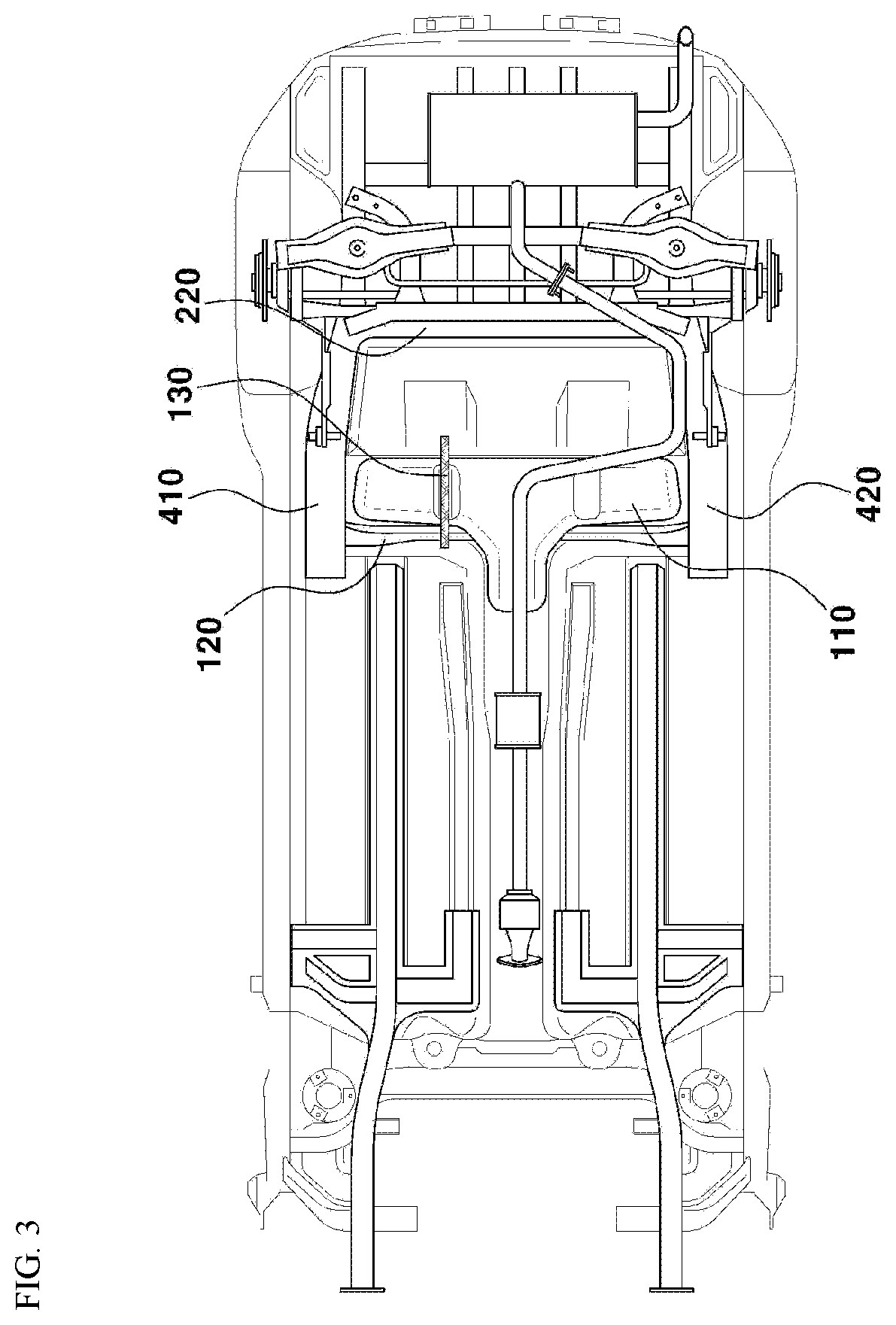

Hybrid vehicle having improved arrangement structure

ActiveUS20210023930A1Arrangement structure optimizationIncrease capacityElectric propulsion mountingGas pressure propulsion mountingFuel tankElectric drive

A hybrid vehicle having an improved arrangement structure is provided. The hybrid vehicle includes a fuel tank which provides fuel to an engine, and is disposed in a first area which is recessed upward from the under surface of the exterior of a vehicle body. A battery provides an electric driving force to a vehicle, and is disposed in a second area which is recessed downward between the bottom of the interior of the vehicle body and a rear seat. The first area is disposed further forward than the second area in a longitudinal direction of the vehicle body.

Owner:HYUNDAI MOTOR CO LTD +1

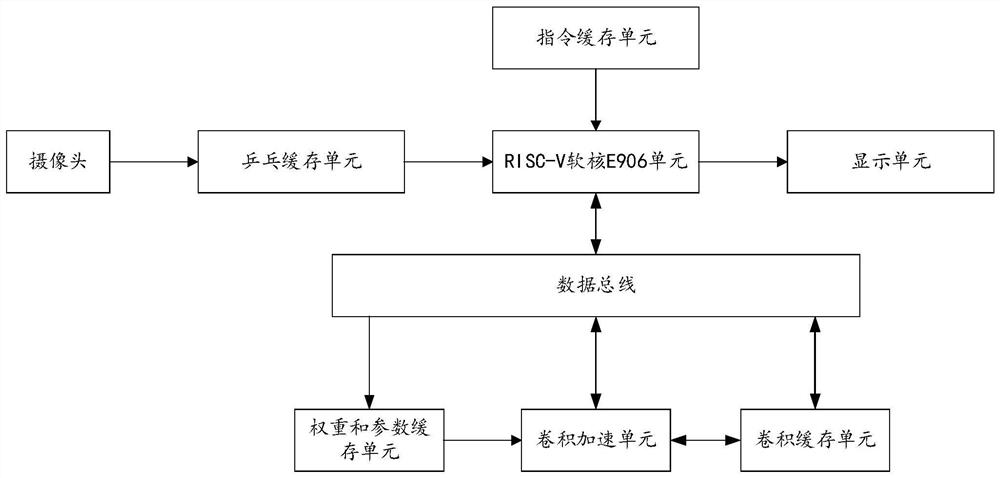

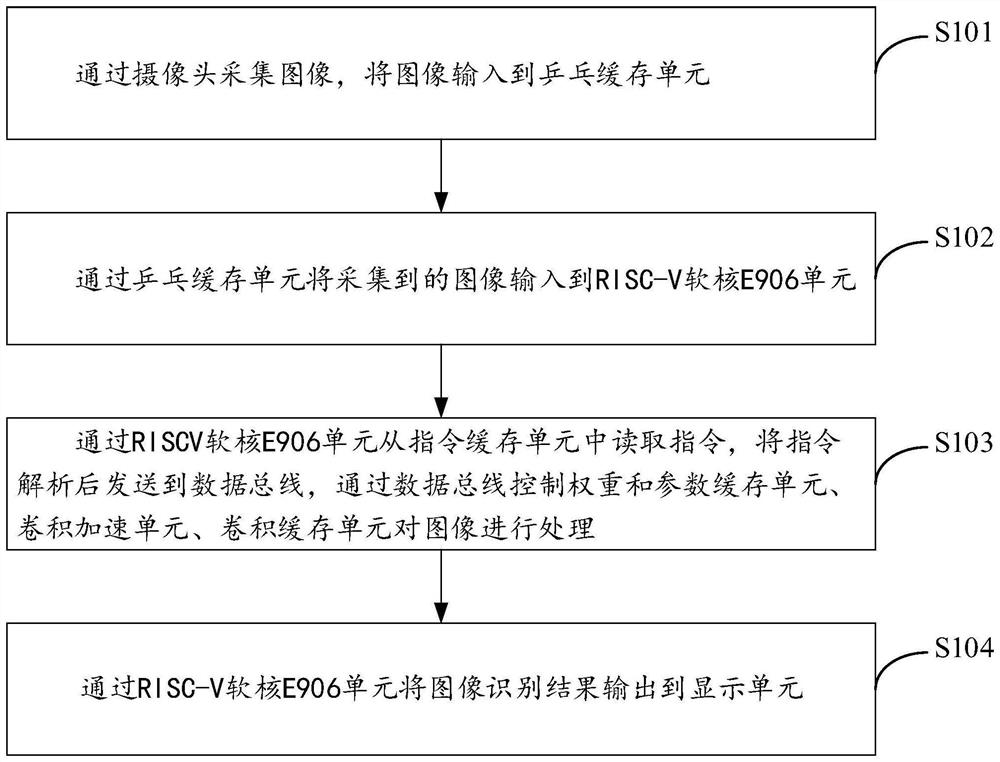

RISC-V-based TinyML target detection acceleration system and method, and storage medium

PendingCN114529797AThe design is completely autonomous and controllableArrangement structure optimizationCharacter and pattern recognitionEnergy efficient computingComputer hardwareComputer architecture

The invention discloses an RISC-V-based TinyML target detection acceleration system and method, and a storage medium, and the system comprises a ping-pong cache unit which is connected with a camera and an RISC-V soft core E906 unit, and is used for caching an image collected by the camera, and transmitting the image to the RISC-V soft core E906 unit; the RISC-V soft core E906 unit is connected with the ping-pong cache unit, the instruction cache unit and a data bus, and is used for reading and analyzing an instruction in the instruction cache unit, and controlling the weight and parameter cache unit, the convolution acceleration unit and the convolution cache unit to perform data processing through the data bus; and the convolution acceleration unit is connected with the data bus, the weight and parameter cache unit and the convolution cache unit, and is used for determining an image recognition result according to data in the weight and parameter cache unit and the convolution cache unit.

Owner:SHANDONG INSPUR SCI RES INST CO LTD

Optical pickup actuator for driving an objective lens

InactiveUS7663984B2Increase forceArrangement structure optimizationRecord information storageBus seatsOptical pickupEngineering

An optical pickup actuator which includes a base, a blade having an objective lens mounted thereon, a plurality of suspensions supporting the blade to be movable with respect to the base and forming an electroconductive path, and a magnetic circuit driving the blade according to a driving signal applied through the respective suspensions. The magnetic circuit includes a magnet fixed to the base, and a fine pattern coil installed on the blade at a position facing the magnet and having a track pattern coil, a focus pattern coil, and a tilt pattern coil independently driven by current applied through the suspensions and providing driving forces in a track direction, a focus direction, and a tilt direction of the blade.

Owner:TOSHIBA SAMSUNG STORAGE TECH KOREA CORP

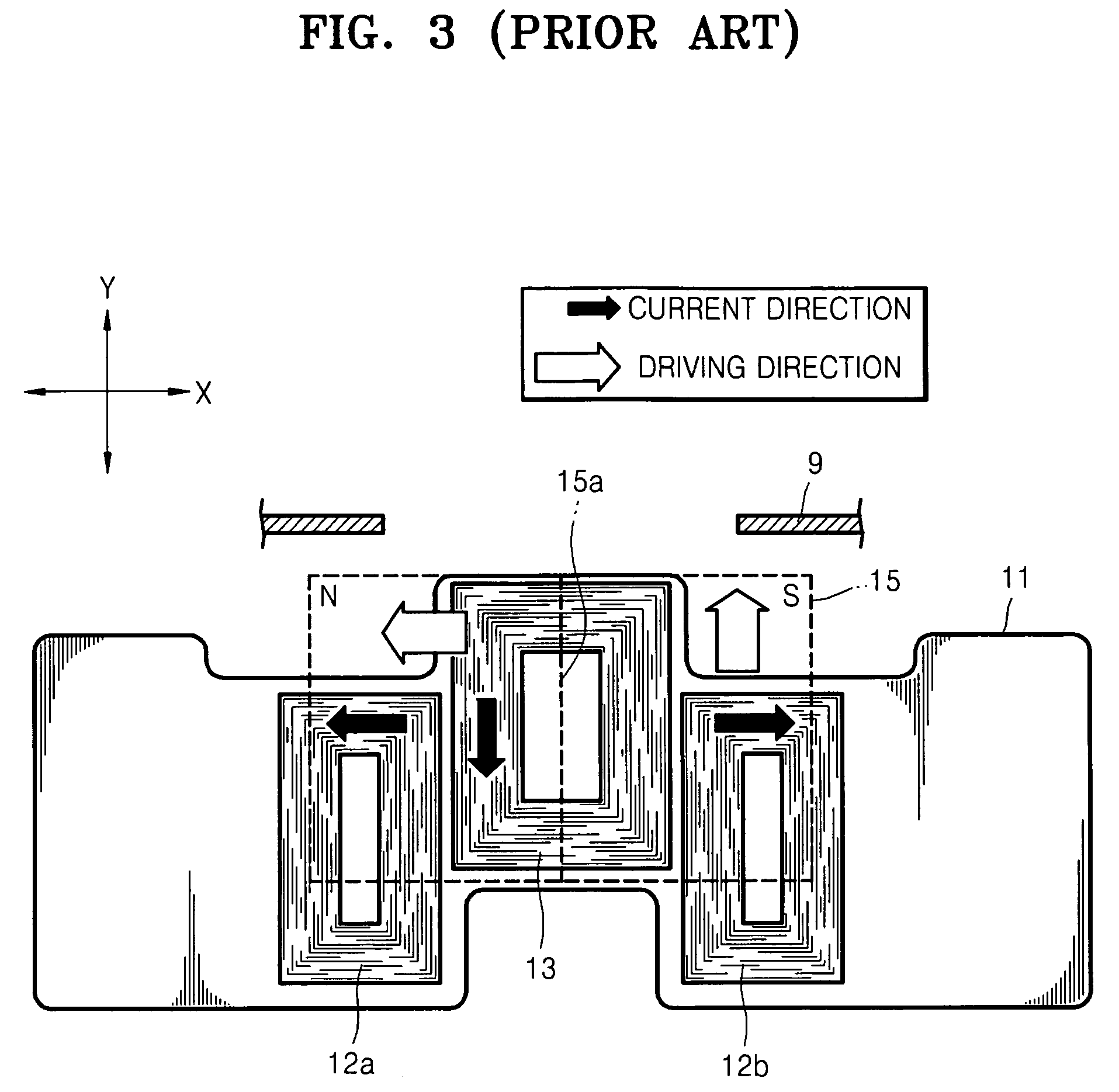

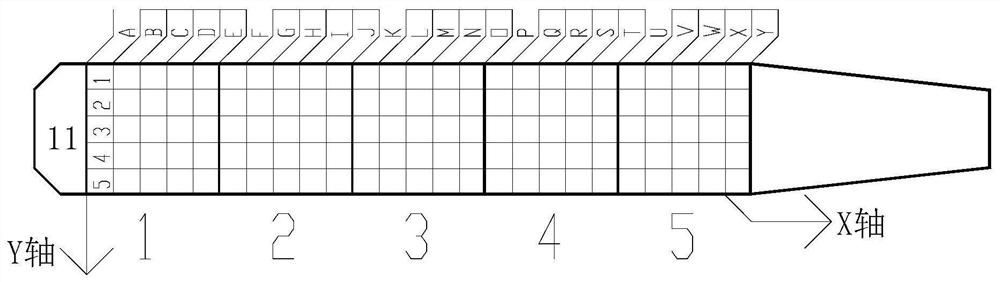

A waterproof combined power supply with flight mode solar panel structure optimization

ActiveCN108565946BArrangement structure optimizationImprove adaptabilityBatteries circuit arrangementsClimate change adaptationLight energyHemt circuits

The invention discloses a waterproof combined power supply with an optimized solar panel structure in flight mode, which relates to the technical field; a solar weak light intelligent conversion circuit is electrically connected with an optimized unit structure, and the optimized unit structure consists of five large independent large unit modules It is connected in parallel, and then five sub-units in each independent No. 1 large unit meet the voltage output and are connected in series. The arrangement of the small units is five groups, and the five independent sub-groups are connected in parallel to form a large unit. unit; the invention optimizes the solar panel unit arrangement structure, which is more suitable for portable products, more reliable and stable; improves the adaptability of solar panel power generation products; makes more intelligent and effective use of weak light power, and uses a power management method with lower loss.

Owner:深圳市遨捷智能科技有限公司

Calculation method for improving visual resolution and optimal pixel arrangement structure module

InactiveCN103474001BEnhance sensory effectArrangement structure optimizationStatic indicating devicesIdentification meansStiphra robustaVisual resolution

A calculation method for improving the pixel arrangement structure of visual resolution, comprising the following steps: at the physical pixel points of each color; connecting the center points of adjacent physical pixel points with straight lines, so that the center points of abstract pixel points are uniform Fall on the grid composed of straight lines; extract physical pixel points X of any color, and the midpoints of these pixels fall on the grid, take any pixel point X as the central pixel point, and find a surrounding pixel point consisting of The polygon with the largest area formed by the center of other pixel points; the average value of the distance from the dominant pixel to the center pixel is defined, which is called visual resolution VR; the present invention also provides a pixel arrangement structure obtained according to the above calculation method. This kind of arrangement structure greatly increases the resolution of the image synthesized by the display, and improves the sensory effect of the human eye on the display; at the same time, the imaging brightness of the display is uniform, and will not cause strong stimulation and damage to the human eye.

Owner:湖州大业科技有限公司

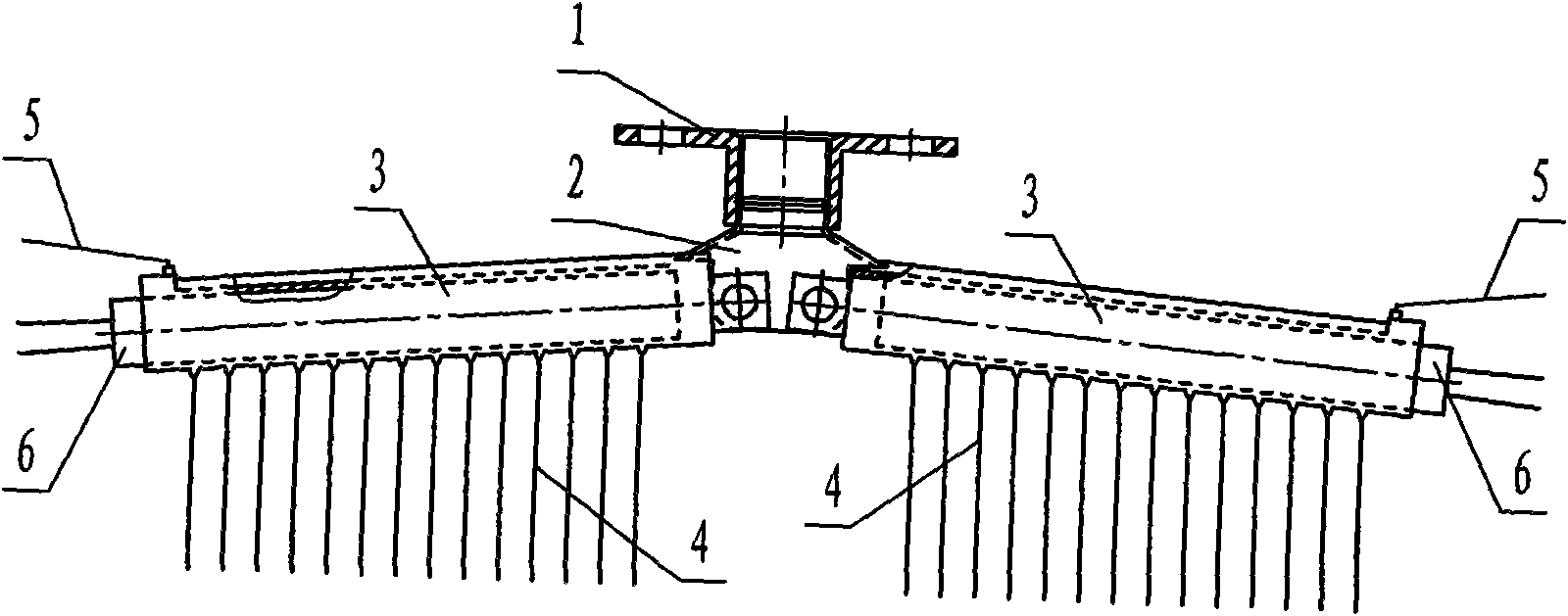

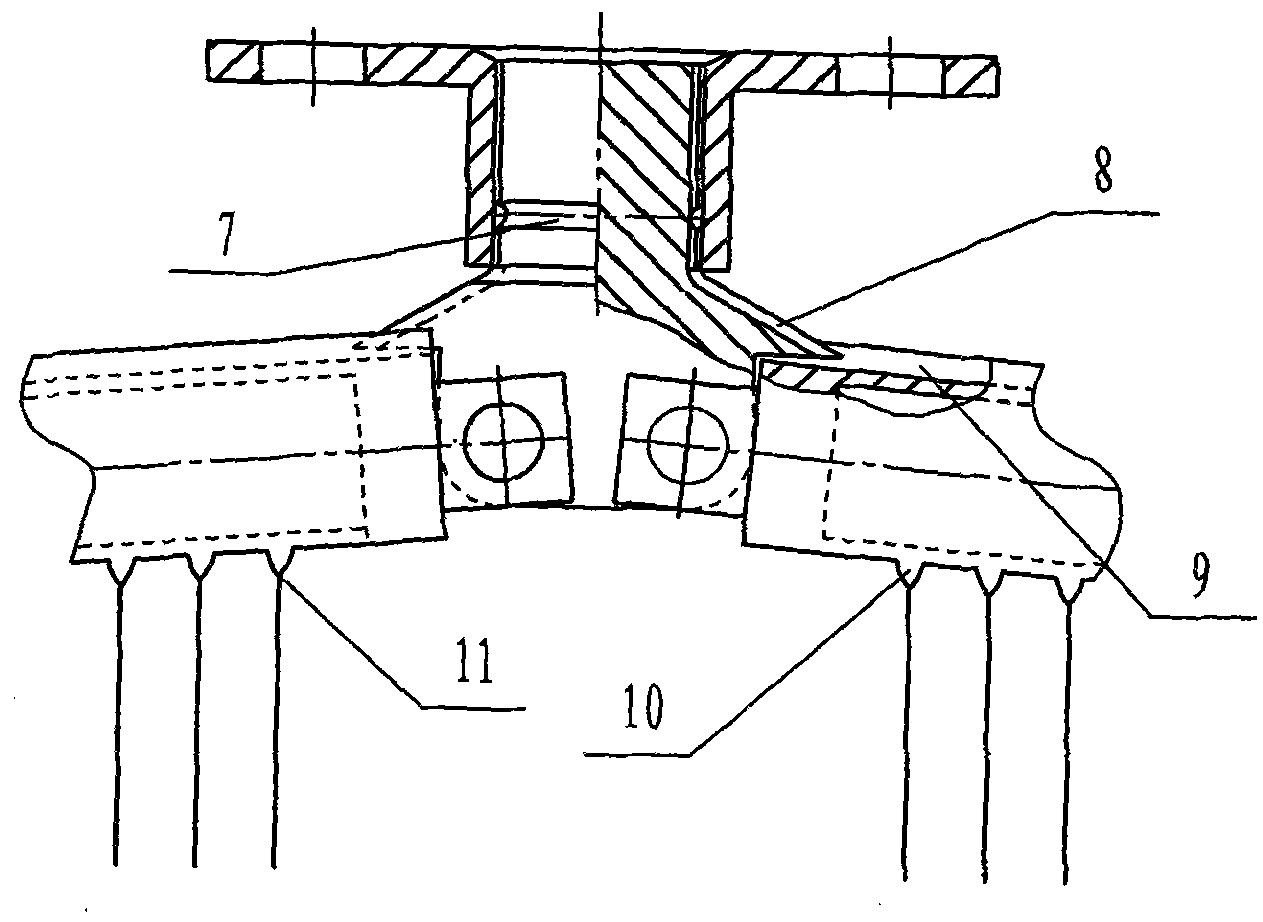

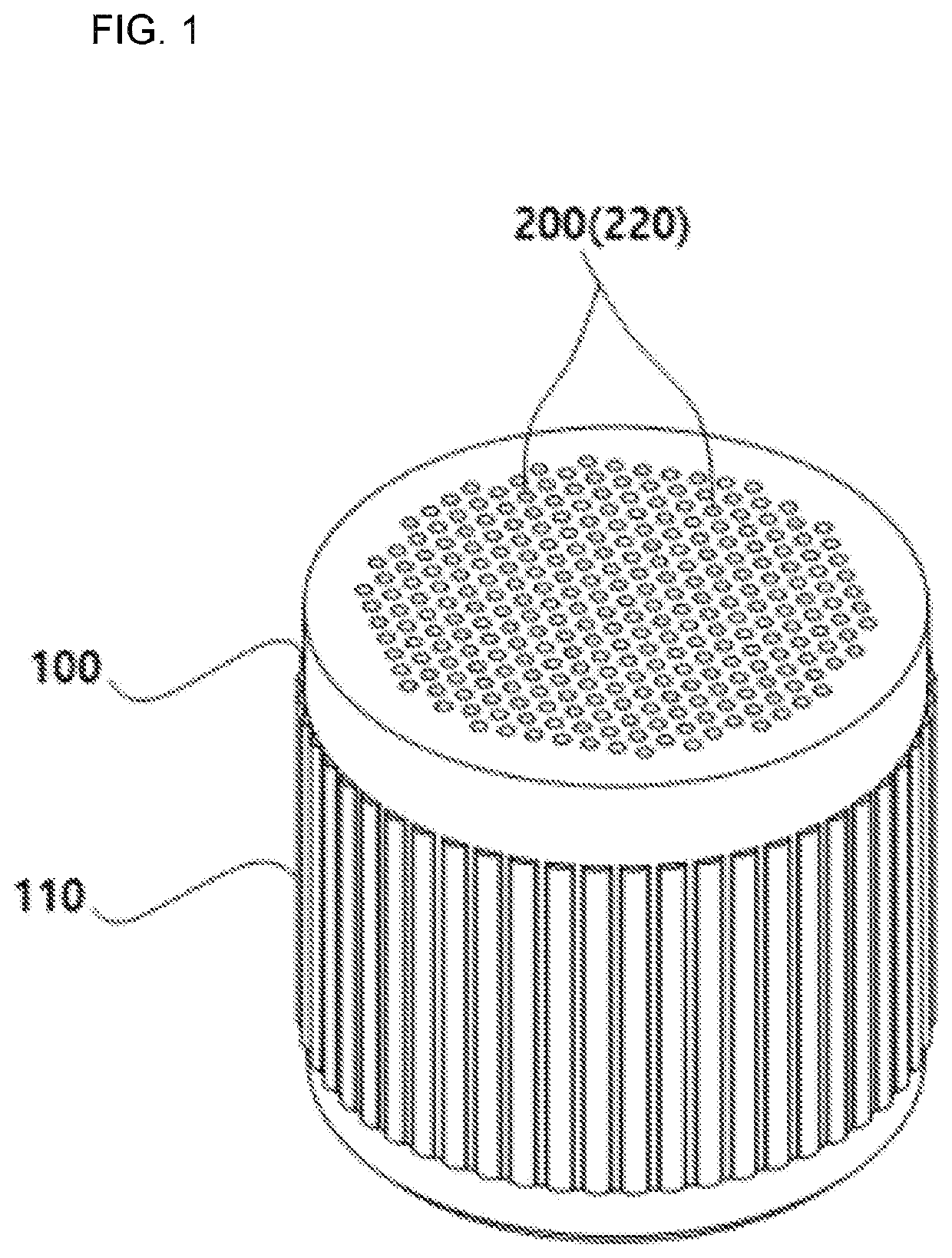

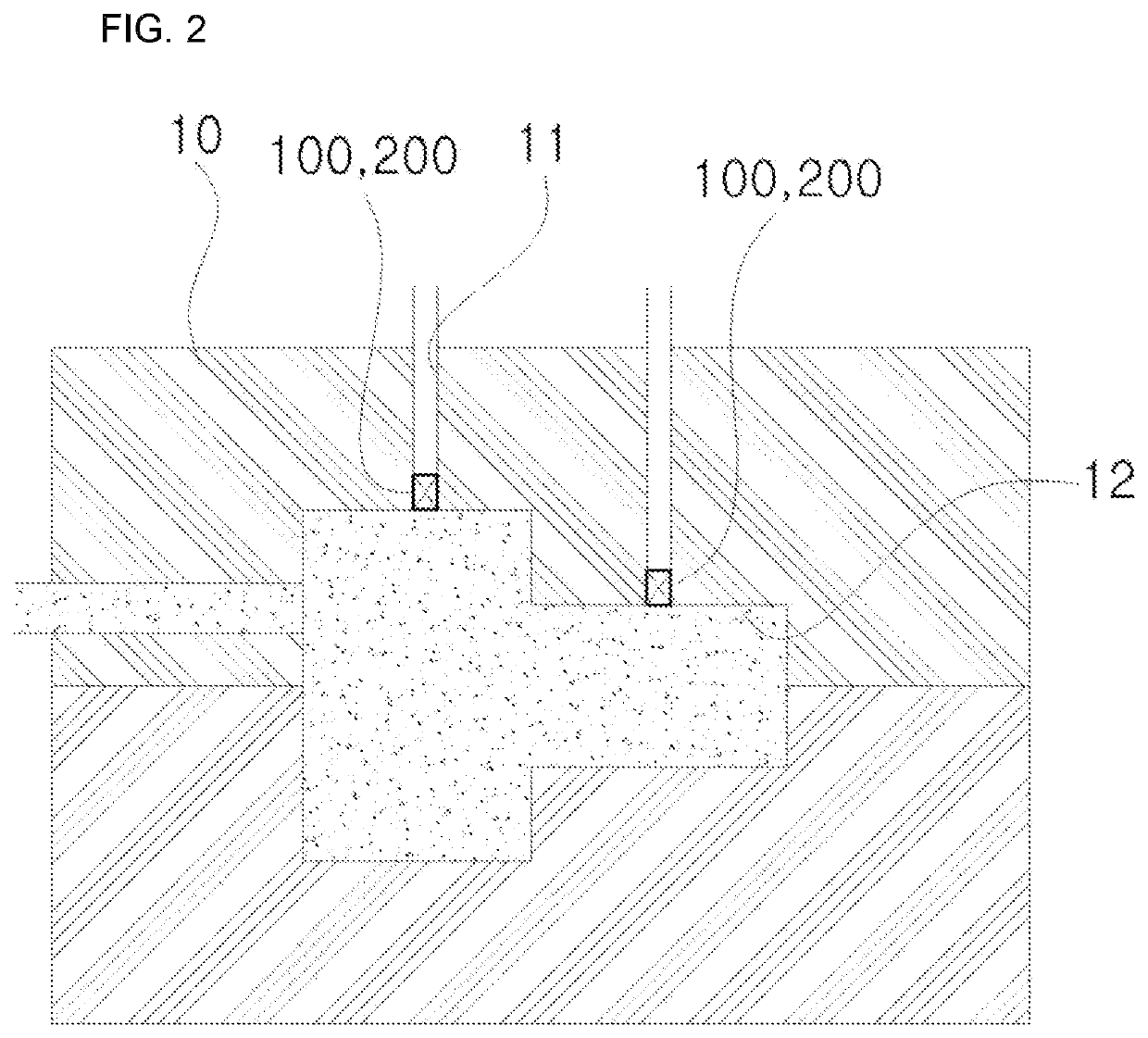

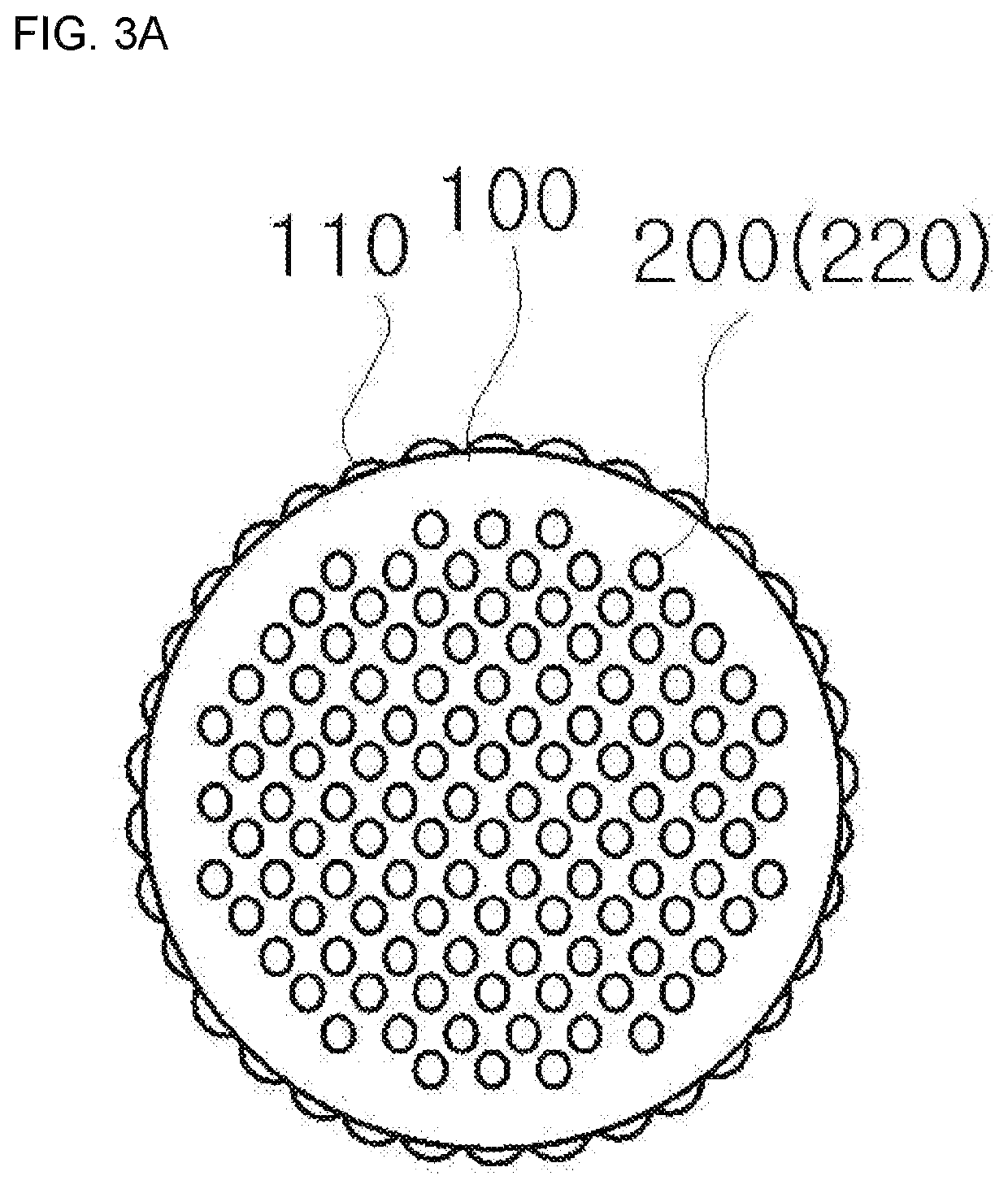

Ventilator for casting mold

ActiveUS11484937B2Inhibit transformationImprove emission efficiencyFoundry mouldsFoundry coresEngineeringCasting mold

A ventilator for a casting mold is mounted on an exhaust pipe (11) of a mold (10) to emit gas generated when melt is injected into a molding space (12). The ventilator for a casting mold has exhaust holes which are improved in arrangement structure and are shorter than a cylindrical body part so as to enhance gas emission efficiency and prevent transformation of the exhaust holes, and has a buffering space part formed inside a cylindrical body part to spread and accept melt coming through the exhaust holes so as to effectively prevent a damage of a mold caused by external leakage of the melt. The ventilator for the casting mold includes a cylindrical body part (100) and a fixed type exhaust block (20).

Owner:PARK DAE GEUN

An Integrated Impedance Load Surface Acoustic Wave Gas Sensor

ActiveCN106841383BLow costSmall sizeAnalysing fluids using sonic/ultrasonic/infrasonic wavesInsulation layerSound wave

The invention discloses an integrated impedance-loaded sound surface wave gas sensor based on a Si (silicon) substrate. The integrated impedance-loaded sound surface wave gas sensor comprises a substrate, a piezoelectric layer, an input / output interdigital transducer, a reflective interdigital transducer, a sensitive interdigital electrode and a gas-sensitive thin film. The integrated impedance-loaded sound surface wave gas sensor has the advantages that by growing one thin SiO2 (silicon dioxide) insulation layer and one piezoelectric layer on the Si substrate, the good temperature characteristic is realized; the material of the Si substrate has the characteristics of low cost, large size and conductivity, and can be combined with the integrated circuit industry; the arrangement structure of the interdigital electrode is optimized, the sound wave reflection caused by the external sensor is reduced, and the parasitic effect caused by connecting wires is reduced; the interdigital transducer and the sensitive interdigital electrode are manufactured by one step, so that the simplicity in the manufacturing process is guaranteed, and the large-scale production is easily realized; the wireless passive measuring of the sensor is realized, the sensing part which is easily influenced by outside is separated from a signal sending part, and the application range of the sensor is widened.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com