Novel straight-strut electrostatic spinning spray nozzle

An electrospinning and one-frame technology, applied in the direction of spinneret assemblies, textiles and papermaking, filament/thread forming, etc., can solve unfavorable spinning fiber collection, processing and manufacturing, capillary single filament output, spinning Difficult to carry out and other problems, to achieve the effect of optimizing the arrangement structure, improving spinning efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

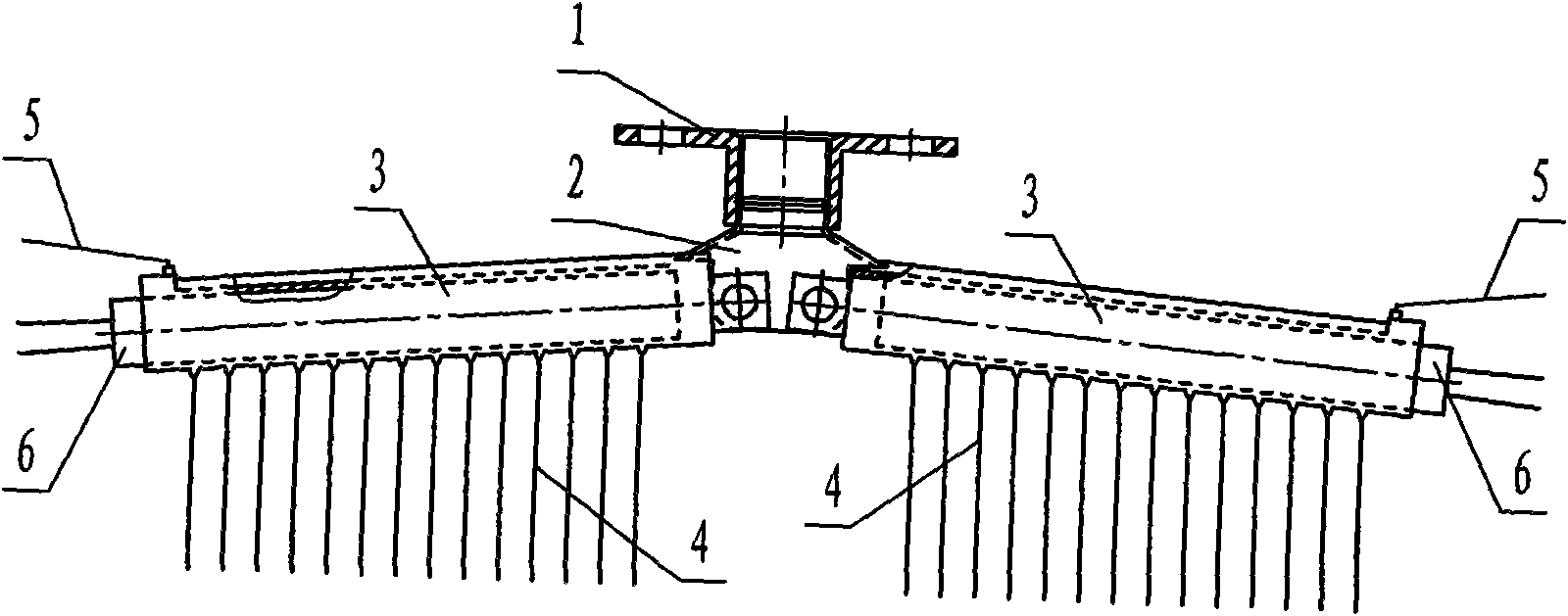

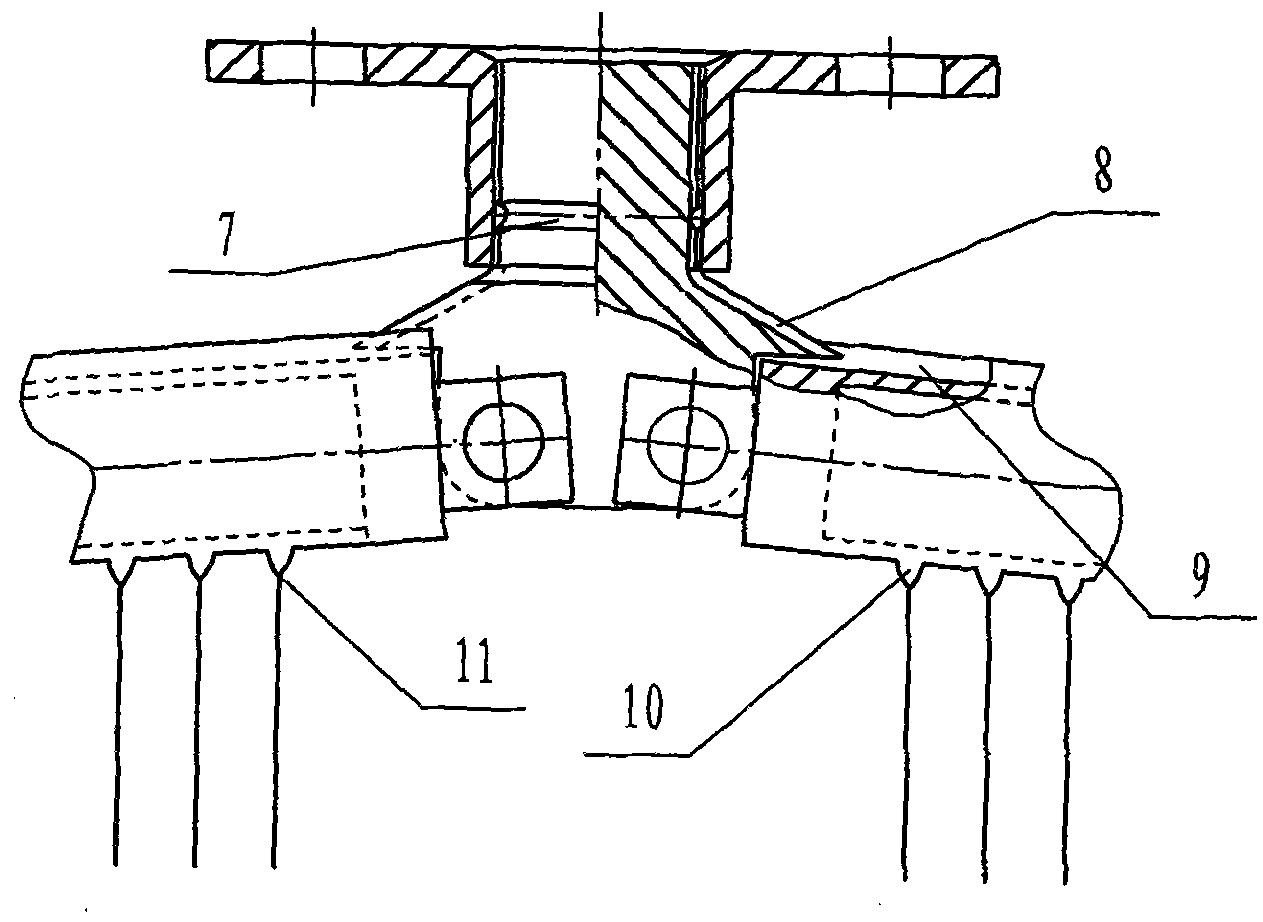

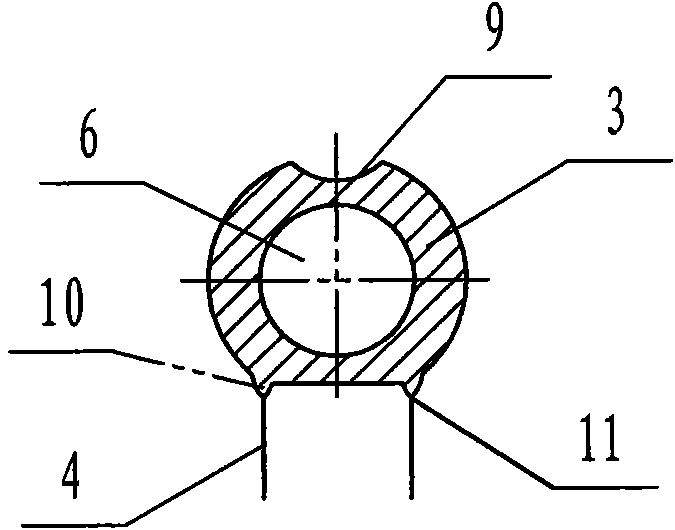

[0017] The present invention, a novel one-frame electrospinning nozzle, adopts such as figure 1 The schematic diagram of the device shown mainly includes a connector 1 and a drainage core 2 for guiding materials. The redistributed annular balance groove 7, the straight frame 3 directly connected with the drainage core 2 by screws, the flat groove surface 9 on the straight frame 3 for material flow, and the heating for the straight frame 3 Rods 6 and temperature sensors 5 for determining the temperature of the material on the nozzle, protrusions 10 for distributing the melt or solution, and tips 11 for forming the filaments.

[0018] The spinning solution or melt flows from the drainage groove 8 to the straight frame 3. When the solution or melt is evenly distributed on the protrusion 10, after the electrostatic field is applied, multiple jet streams 4 will be formed on the tip 11.

[0019] figure 1 and figure 2 Among them, the radius of the drainage groove 8 is 1.5mm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com