An Integrated Impedance Load Surface Acoustic Wave Gas Sensor

A gas sensor and sensing technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze fluids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, instruments, etc. problem, to achieve the effect of reducing sound wave reflection, optimizing the arrangement structure, and ensuring simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

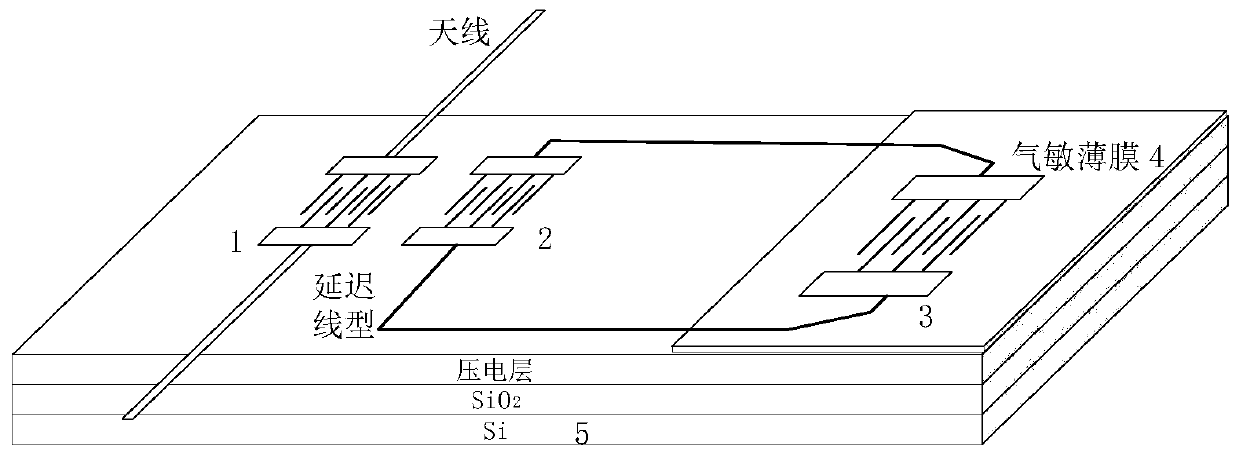

[0040] Such as figure 1 As shown, the piezoelectric layer is made of aluminum nitride film, the input / output IDT 1 and the reflective IDT 2 adopt a delay line structure, the electrodes are aluminum electrodes, and the reflective IDT 2 adopts a double-digital The electrode, the ratio of electrode height to electrode width is between 0.3-0.15, and the gas-sensitive film is made of SnO 2 Nanocrystalline thin film, together with sensitive interdigitated electrodes, constitutes a conductive gas sensing structure, and its resistance can be adjusted by doping Sb to change SnO 2 Resistivity of nanocrystalline thin films.

[0041] In this embodiment, a general-purpose double-digit electrode is selected, and an appropriate electrode aspect ratio is set, which can effectively reduce the inter-finger reflection, and the reflection coefficient is small when the double-digit electrode is short-circuited, and the characteristics of the change with the external impedance are realized. Measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com