Electrostatic melt spinning device

A melt electrospinning, nozzle body technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as unfavorable production, influence of properties of spinning properties, and influences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

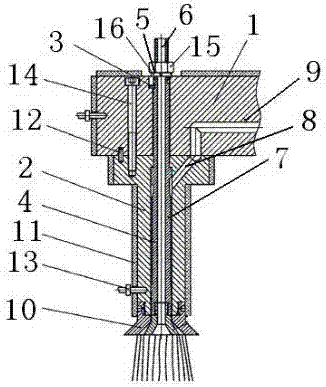

[0038] A melt electrospinning device, comprising an upper nozzle body 1 and a lower nozzle body 2, the upper nozzle body 1 is provided with an upper nozzle inner cylinder 3, the lower nozzle body 2 is provided with a lower nozzle inner cylinder 4, and the upper nozzle inner cylinder 3 and the lower nozzle inner cylinder 4 are set correspondingly and the axes coincide; the top of the upper nozzle body 1 is provided with a socket 5, and the core liquid pipe 6 is inserted through the socket 5 through the upper nozzle body 1 and the lower nozzle body 2, and the core liquid pipe 6 is located at The axes of the upper nozzle inner cylinder 3 and the lower nozzle inner cylinder 4 coincide; the core fluid pipeline 6 has a core fluid cavity inside, and the outer wall of the core fluid pipeline 6 is sealed with the inner walls of the upper nozzle inner cylinder 3 and the lower nozzle inner cylinder 4 The skin liquid chamber 7, the upper part of the lower nozzle body 2 is provided with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com