Fusion dynamic mixer

A technology for dynamic mixers and molten polymers, applied in the direction of mixers, mixers with rotating stirring devices, chemical instruments and methods, etc., can solve problems such as impact, unfavorable production, time and cost consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

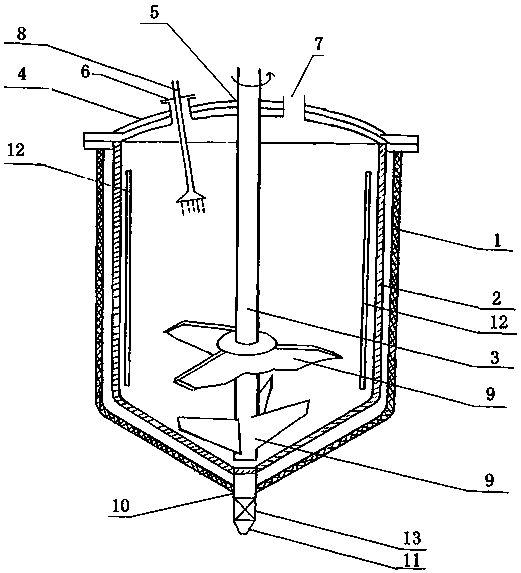

[0035] A melting dynamic mixer, comprising a shell 1, a filter layer 2, and a stirring shaft 3; a cover 4 is arranged on the upper part of the shell 1, and a stirring shaft hole 5, a monomer suction hole 6 and a feeding material are arranged on the cover 4 Hole 7, the stirring shaft 3 extends into the inside of the housing 1 through the stirring shaft hole 5, the monomer suction hole 6 is provided with a monomer suction device 8, and the feed hole 7 is connected with the external molten polymer supply device; the filter layer 2 It is set close to the inner wall of the shell 1, and there is a gap between it and the inner wall of the shell 1; several stirring blades 9 are set on the stirring shaft 3, and the stirring shaft 3 is connected with an external drive device; the bottom of the shell 1 is provided with a molten polymer discharge Port 10, the molten polymer discharge port 10 is connected to the discharge pipe 11; the surface of the stirring shaft 3, the stirring blade 9, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com