Low-adhesion spinning melt pipeline

A melt-pipe, low-adhesion technology for spinneret assemblies, textiles, and paper making that solves the problems of time and cost consumption, impact, and production disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

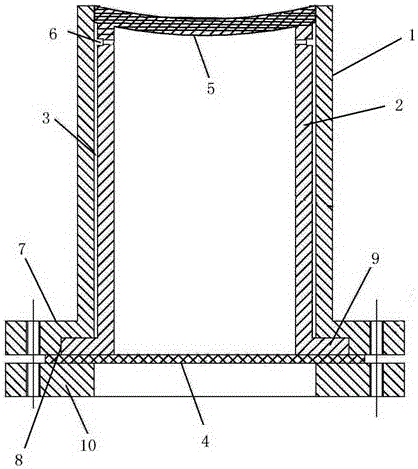

[0035] A low-adhesion spinning melt pipe, the melt pipe includes a melt pipe outer cylinder 1 and a melt pipe liner 2, and the melt pipe liner 2 is located inside the melt pipe outer cylinder 1; the melt Both the pipe outer cylinder 1 and the melt pipe liner 2 have an open head end and a tail end, and an inner cavity is formed in the melt pipe liner 2, and the wall of the melt pipe liner 2 and the melt pipe outer cylinder There is a gap 3 between the wall of the 1 cylinder, and a sealing structure is provided between the wall of the tail end and the head end of the opening of the melt pipe liner 2 and the wall of the outer cylinder 1 of the melt pipe, and the melt pipe liner The head end and tail end of the opening of 2 are respectively sealed and installed with a head end filter device 4 and a tail end filter device 5; a concave-convex anti-adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com