Gap-adjustable electrostatic-spinning nozzle and array-type spinning system

An electrospinning, gap technology, applied in electrospinning, textile and papermaking, filament/thread forming, etc., can solve the problems of difficult processing, high cost, easy blockage, etc., to increase the spinning rate and avoid high costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

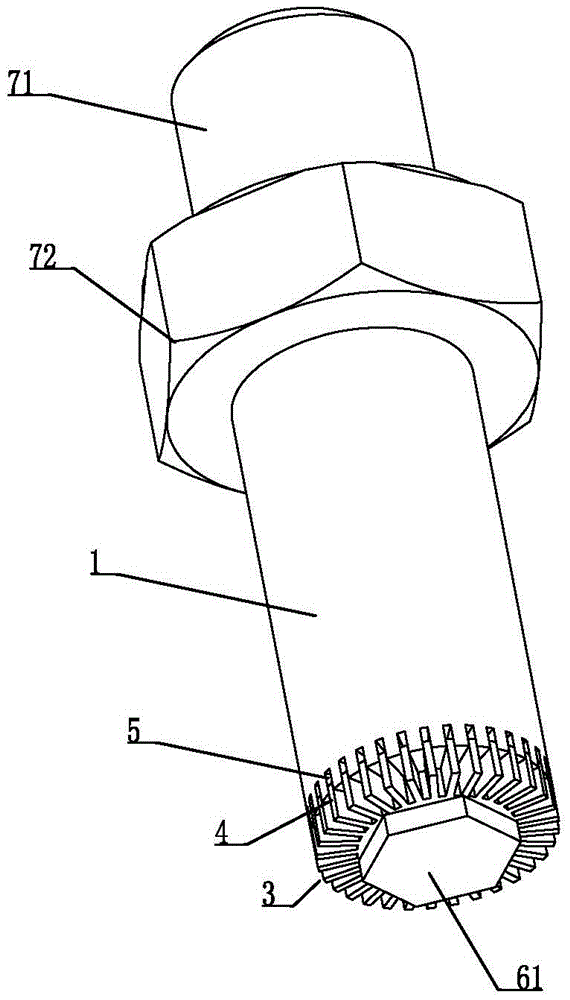

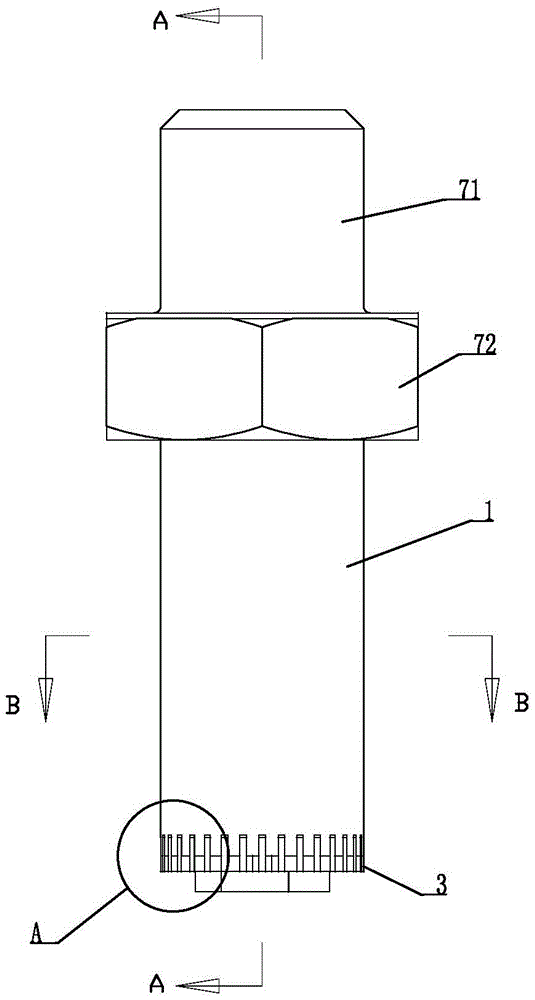

[0031] Such as figure 1 , figure 2 with Figure 8 The illustrated electrospinning nozzle with adjustable gap includes a liquid inlet pipe 1, an end cover 3 and a regulator.

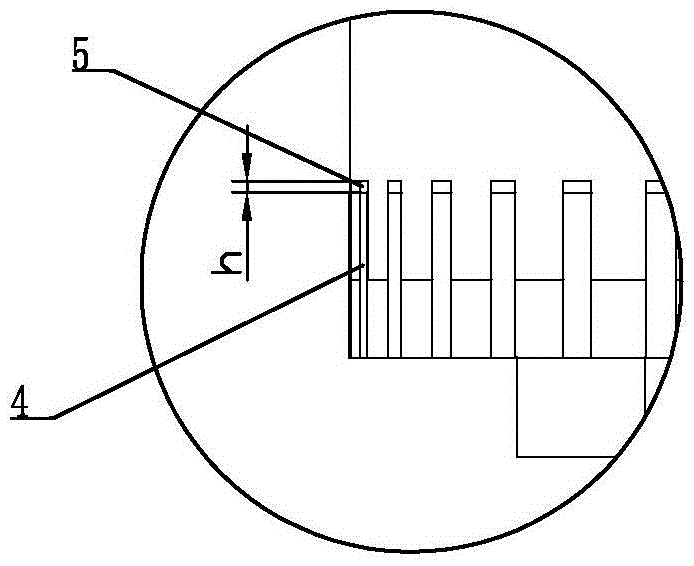

[0032] The liquid inlet pipe 1 has a hollow cylindrical shape, and the annular array at the bottom end has a number of microgrooves 2 which penetrate the inner and outer walls of the liquid inlet pipe 1 to connect the liquid inlet channel inside the liquid inlet pipe 1 and the outside.

[0033] The annular array on the end cap 3 has a plurality of convex ribs 4, and each convex rib 4 is filled into the micro groove 2 one by one, that is, each micro groove 2 is filled with a convex rib 4. The filling means that the rib 4 enters the micro groove 2 and is accommodated, and does not necessarily fill the entire micro groove 2, that is, there may also be a gap between the micro groove 2 and the rib 4. The above-mentioned rib 4 is the same thickness as the micro groove 2. When the rib 4 is filled with the micro groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com