Automatic efficient melt electrostatic spinning device

A melt electrospinning and spinning device technology, applied in textiles and papermaking, filament/thread forming, melting of filament raw materials, etc., can solve problems such as unstable structures, endangering human health, pollution, etc., and achieve structural Simple, efficiency-enhancing, and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

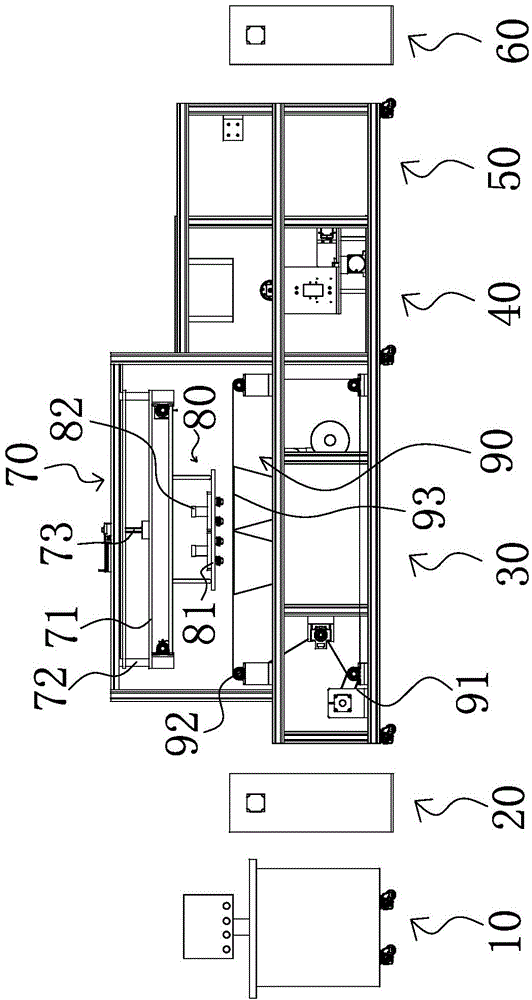

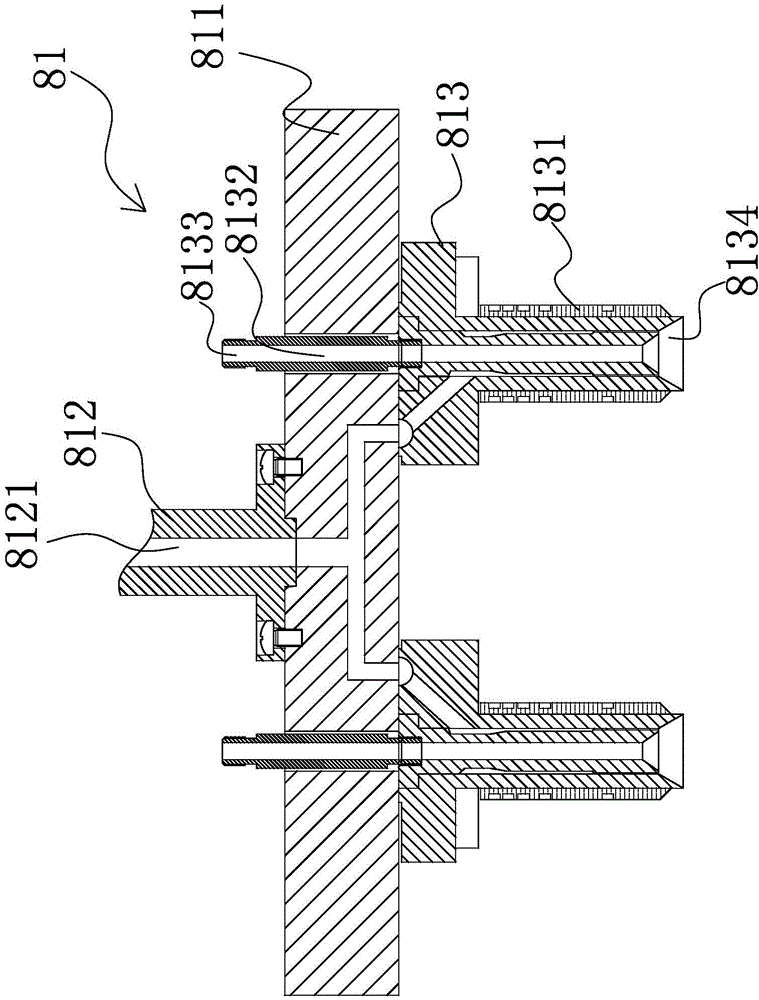

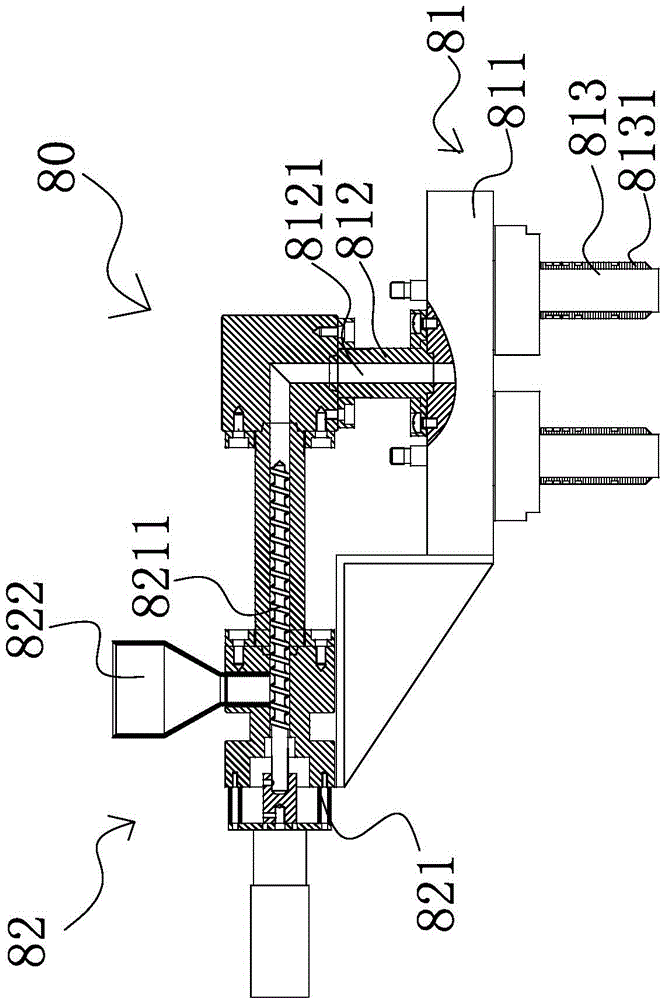

[0021] Such as figure 1 and figure 2 As shown, the automatic high-efficiency melt electrospinning device includes a circuit control device 10, an unwinding device 20, a spinning device 30, a composite device 40, a calendering device 50 and a winding device 60, and the spinning device 30 includes a vertically movable The spinning device 70, the spinning mechanism 80 installed on the moving device 70 and the receiving device 90 that is positioned right below the spinning mechanism 80 and can move left and right. The feeding mechanism 82 on the silk machine 81, the spinning machine 81 includes a splitter plate 811, a main nozzle 812 installed on the upper end surface of the splitter plate 811, and a plurality of heating noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com