Manufacturing method of porous nanofiber with controllable aperture

A nanofiber and pore size technology, which is applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems that are difficult to control the pore size uniformity and hole density of porous nanofibers, and achieve uniform size, enhanced conductivity, The effect of easy spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The manufacture method of the porous nanofiber of embodiment 1 controllable aperture

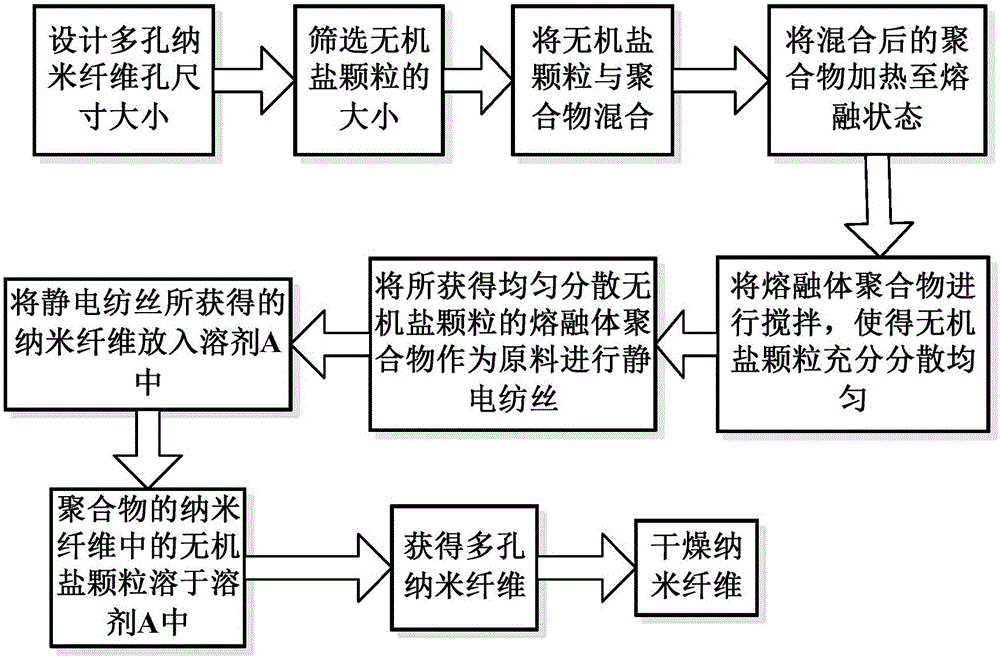

[0055] The flow chart of the method for manufacturing porous nanofibers with controllable pore size is as follows: figure 1 As shown, the specific operation steps are:

[0056] 1) Design the pore size of the porous nanofiber to be 10-800nm, and screen the inorganic salt with a particle size of 10-800nm according to the pore size of the designed nanofiber;

[0057] Described inorganic salt is selected from NaCl, KCl, LiCl, FeCl 3 , ZnCl 2 , CuCl 2 , AlCl 3 、NaNO 3 、KNO 3 、LiNO 3 , Fe(NO 3 ) 3 , Zn(NO 3 ) 2 , Cu(NO 3 ) 2 , Al(NO 3 ) 3 at least one of;

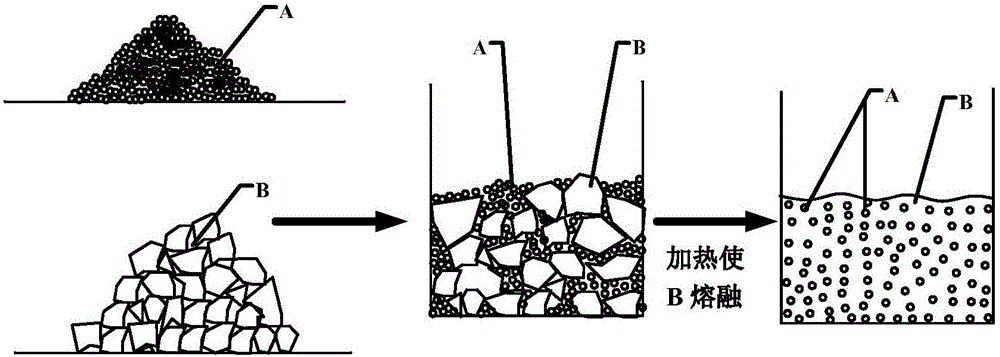

[0058] 2) Take the polymer as the raw material of the nanofiber, and mix it with the screened inorganic salt at a mass ratio of 100: (3-30) (the amount of the inorganic salt can be determined according to the designed porous nanofiber pore size and pore density), Heat at 60°C to 400°C for 10min to 2h. At this time, t...

Embodiment 2

[0064] The manufacture method of the porous nanofiber of embodiment 2 controllable aperture

[0065] 1) Design the pore size of the porous nanofiber to be 400-500nm, and screen the inorganic salt NaCl with a particle size of 400-500nm according to the pore size of the designed nanofiber;

[0066] 2) Take polyethylene as the raw material of nanofibers, mix it with the screened NaCl at a mass ratio of 100:20, and heat it at 200°C for 1 hour. At this time, the polyethylene is completely melted and NaCl will not melt. It is stirred and dispersed for 1 hour; at this time, NaCl ions are evenly dispersed in polyethylene, which enhances the conductivity of molten polyethylene;

[0067] 3) Electrospinning the molten material mixed in the previous step to obtain nanofibers, NaCl particles are evenly dispersed on the obtained nanofibers; the voltage of the electrospinning is 10kV;

[0068] 4) Soak the nanofibers obtained above in 10% v / v ethanol solution for 30 minutes, dissolve the N...

Embodiment 3

[0070] The manufacture method of the porous nanofiber of embodiment 3 controllable aperture

[0071] 1) Design the pore size of the porous nanofiber to be 10-100nm, and screen the inorganic salt KCl with a particle size of 10-100nm according to the pore size of the designed nanofiber;

[0072] 2) Take polyvinylidene fluoride as the raw material of nanofibers, mix it with screened KCl at a mass ratio of 100:30, and heat it at 200°C for 30 minutes. At this time, polyvinylidene fluoride is completely melted and KCl will not melt. Stir and disperse it with a magnetic stirrer for 20 minutes; at this time, KCl ions are uniformly dispersed in the polyvinylidene fluoride, which enhances the conductivity of the molten polyvinylidene fluoride;

[0073] 3) Electrospinning the molten material mixed in the previous step to obtain nanofibers, KCl particles are evenly dispersed on the obtained nanofibers; the electrospinning voltage is 1kV;

[0074] 4) Soak the nanofibers obtained above i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com