Super-porous polysaccharide microsphere and preparation method thereof

A technology of ultra-large pores and polysaccharides, applied in the field of biochemical industry, can solve problems such as low mass transfer efficiency, small pores, and slow separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: Preparation of small molecule glucomannan

[0058] In a 1L beaker, mix 25ml of 0.1M HCl and 200g of deionized water evenly, pour 50g of konjac glucomannan powder into the mixture, stir evenly, and it will become jelly after swelling for 10min. Put it into a high-pressure reactor and degrade it at 120°C for 40min. After the degradation was complete, the reactor was taken out and allowed to cool to room temperature. Add 125g of 40% NaOH solution, stir to dissolve the jelly-like substance, and filter the impurities to obtain a clarified aqueous solution of konjac glucomannan of the desired concentration. The same method can prepare konjac glucomannan aqueous solution with solid content of 0.1%, 4%, 15%, 20%, 40% and so on for future use.

Embodiment 2

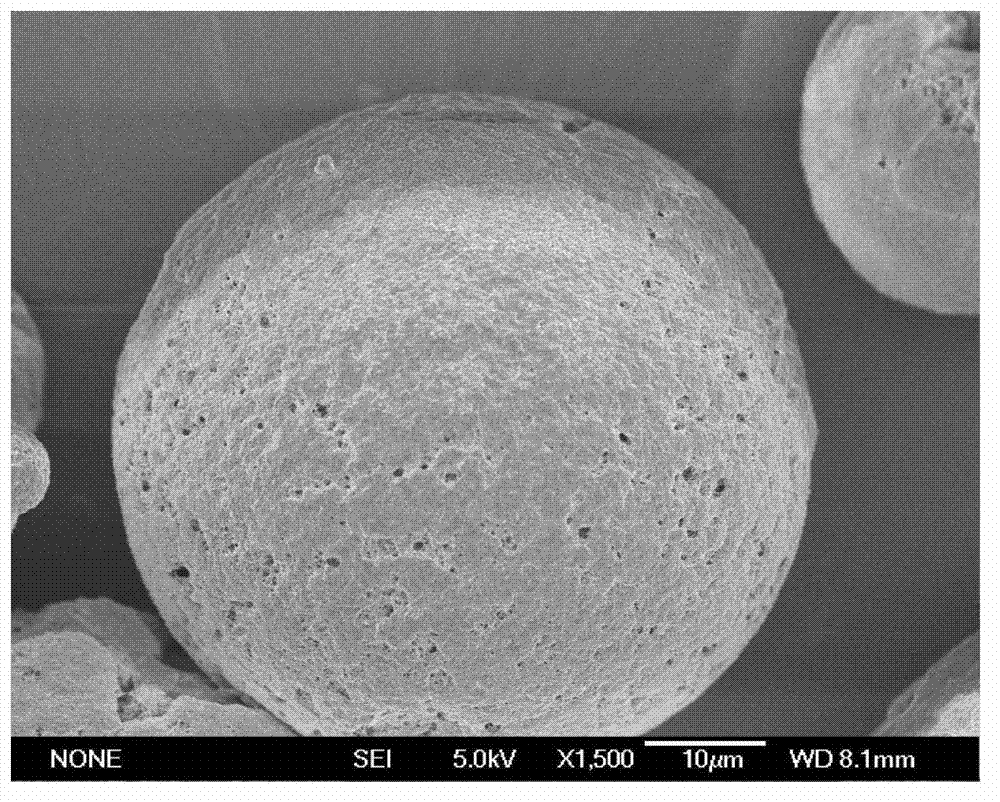

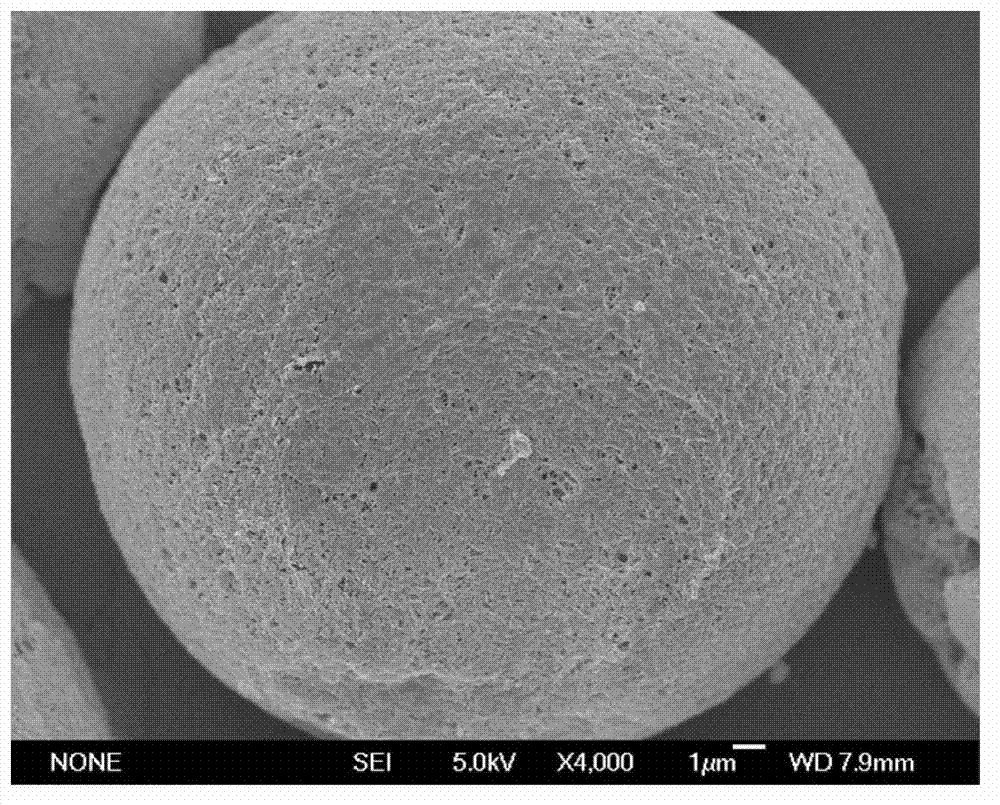

[0060] Accurately take by weighing 30g concentration be the konjac glucomannan (molecular weight is 50,000) aqueous solution of 0.05wt%, in aqueous solution, add the polyoxyethylene sorbitan monooleate that quality is 6g and 2g sodium lauryl sulfate in In a beaker, stir and mix for 1 h at 50°C in a constant temperature water bath. Accurately weigh 20g of polyglycerol fatty acid ester, 15g of dichloromethane and 45g of kerosene in a three-necked flask as the oil phase, stir in a constant temperature water bath at 50°C, and adjust an appropriate speed. Add the mixed water phase to the oil phase, disperse and emulsify for 40 minutes, then weigh 15g of epichlorohydrin crosslinking agent, and add it dropwise to the mixing system. Link 6h. After the reaction is finished, filter, wash the product several times with industrial ethanol and distilled water, and wash away components such as dichloromethane, kerosene, and surfactant to obtain the product. The appearance of the obtained ...

Embodiment 3

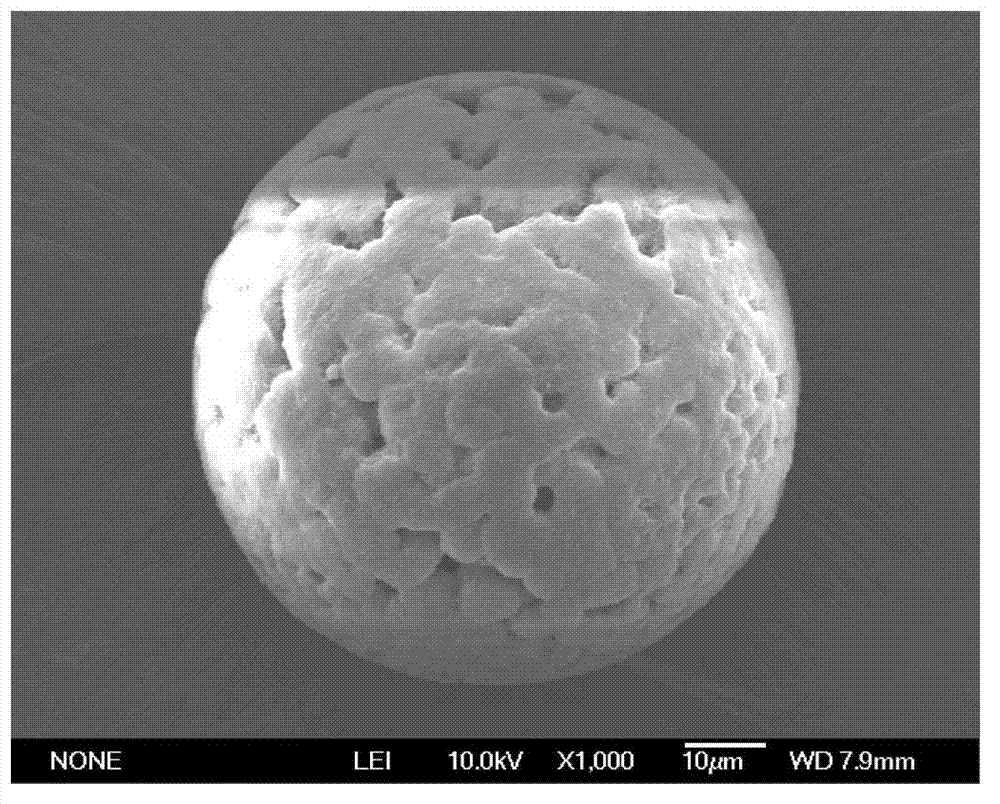

[0062]Accurately weigh 20 g of a 20% aqueous solution of konjac glucomannan (molecular weight: 150,000) and 2 g of polyoxyethylene sorbitan tristearate in a beaker, and stir and mix for 1 h in a constant temperature water bath at 30°C. Accurately weigh 15g of polyoxyethylene fatty acid ester, 50g of petroleum ether and 200g of turbine oil in a three-necked flask as the oil phase, stir in a constant temperature water bath at 30°C, and adjust the appropriate speed. Add the mixed water phase to the oil phase, disperse and emulsify for 1 hour, then weigh 30g of epichlorohydrin crosslinking agent, and add it dropwise to the mixing system. Joint curing 10h. After the reaction, filter, wash the product several times with industrial ethanol and distilled water, wash petroleum ether, turbine oil, surfactant and other components, and dry to obtain the product. The electron micrographs of the obtained microspheres are as follows: figure 2 shown. The average particle size of the micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com