Melt electrostatic spinning device and method based on calculus cascade

A melt electrospinning and calculus technology, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as few electrospinning melt processing, and achieve the effect of simple structure and principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

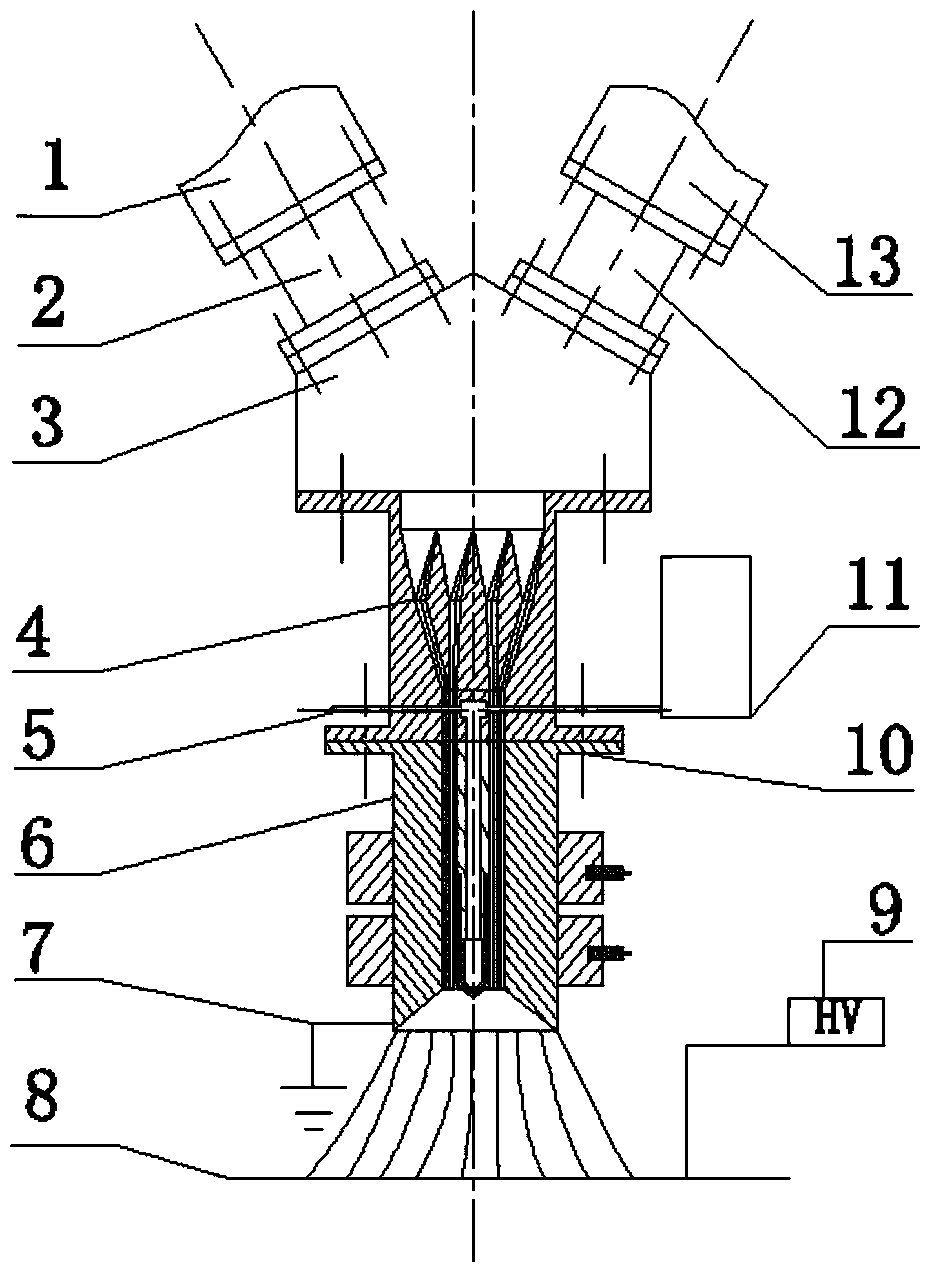

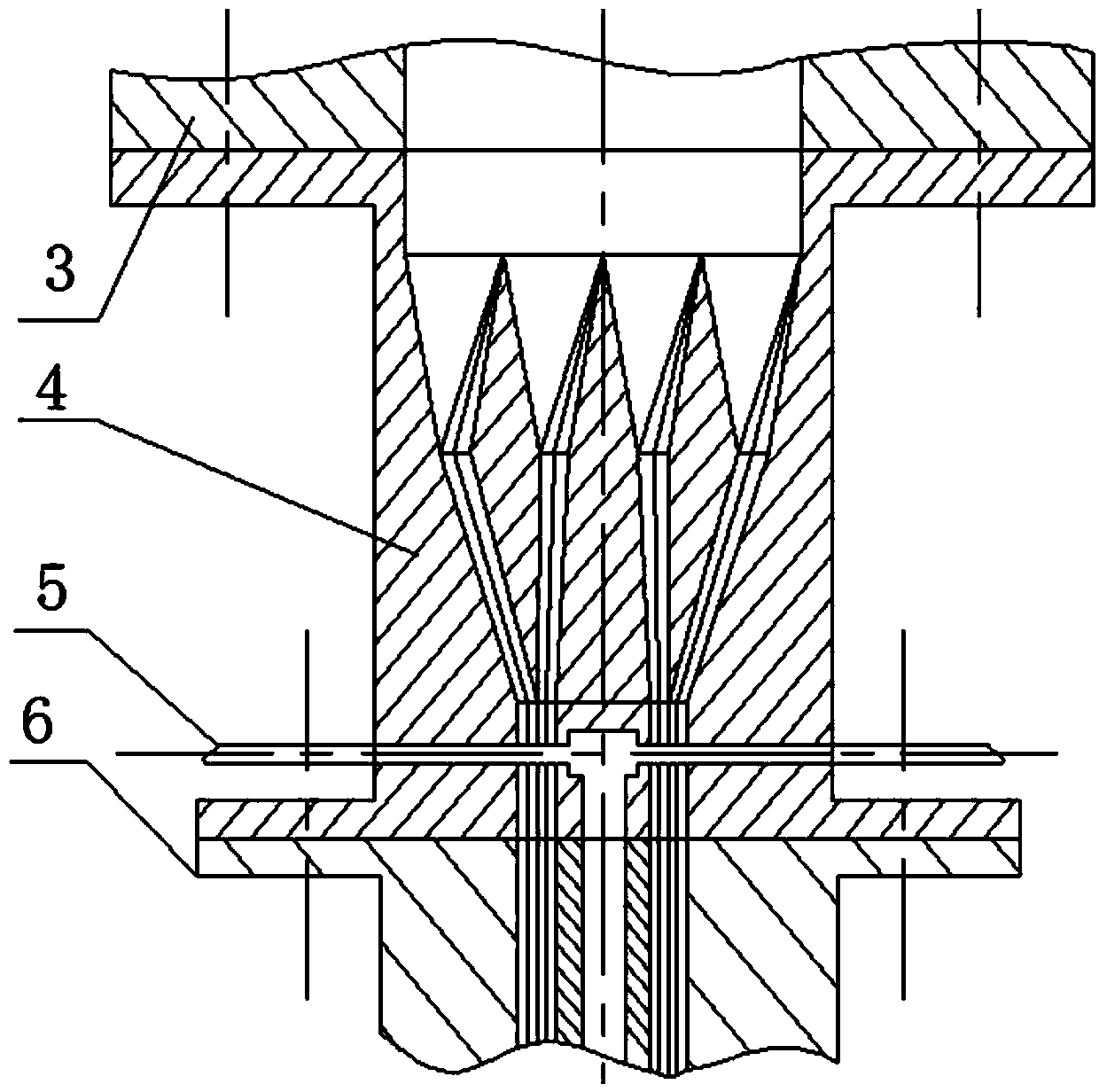

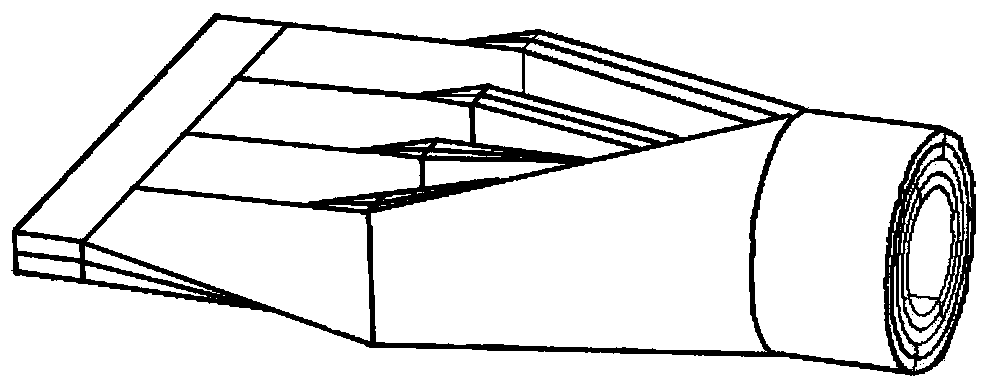

[0021] The present invention is a melt electrospinning device based on calculus lamination, such as figure 1 and figure 2 As shown, it includes melt conveying device 1, connecting flange 2, confluence 3, laminator 4, gas inlet thin tube 5, inner cone split nozzle 6, ground electrode 7, base cloth 8, high-voltage electrostatic generator 9. Connecting screw 10, air heating system 11, connecting flange 2 12 and melt conveying device 2 13, melt conveying device 1 and melt conveying device 2 13 are confluent through connecting flange 1 2 and connecting flange 2 12 The inlet of the confluence device 3 is connected, the outlet of the confluence device 3 is connected with the melt inlet of the laminator 4, the outlet of the laminator 4 is connected to the inner cone diverting nozzle 6, and the base cloth 8 is directly under the inner cone diverting nozzle 6 to continuously transport the fibers, and the melting The composite fiber bundle formed by the body through the nozzle 6 is soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com