Device for promoting electrostatic spinning of high-viscosity polymer melt by using rod-climbing effect

A technology of melt electrospinning and rod climbing effect, applied in the field of electrospinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

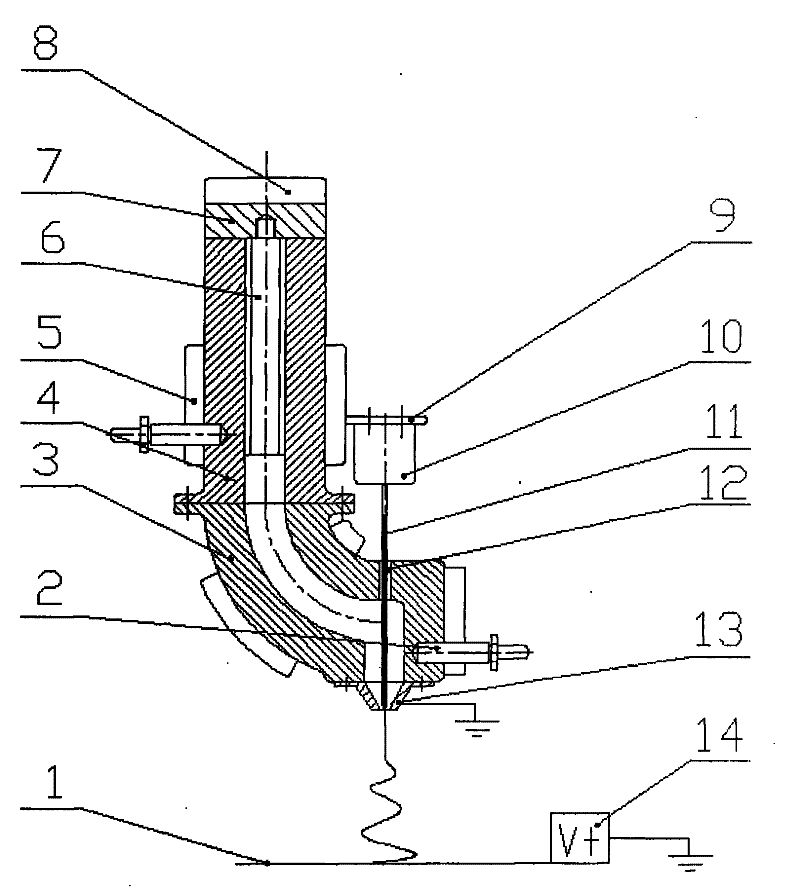

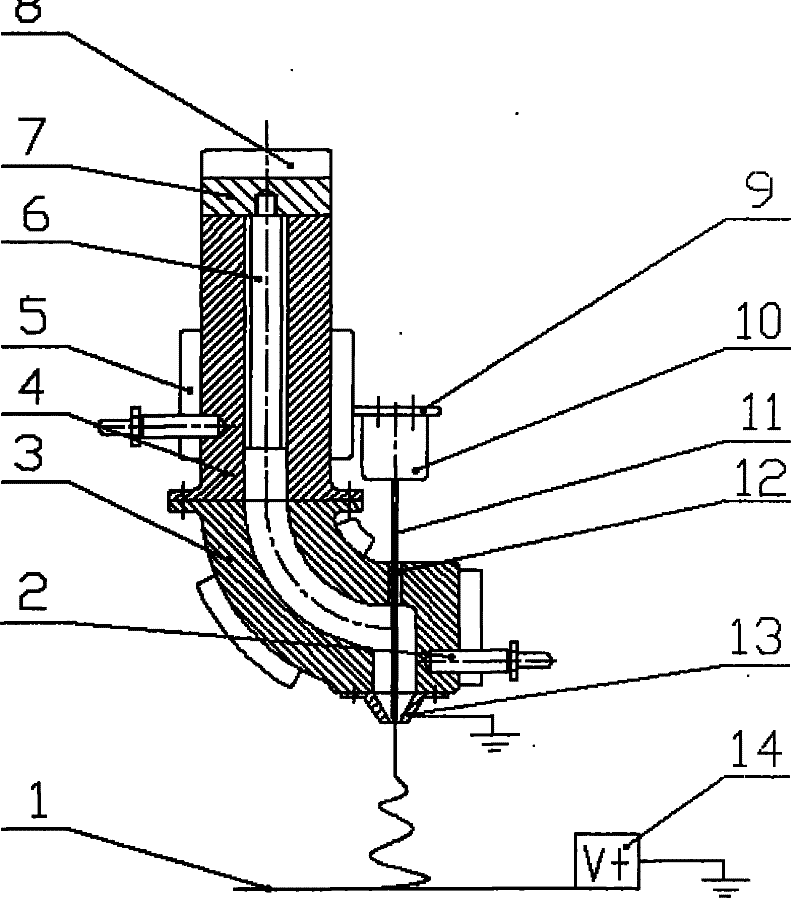

[0010] The invention proposes a device for promoting the electrospinning of high-viscosity polymer melt by using the pole-climbing effect. The schematic diagram of the device is as figure 1 As shown, it mainly includes a receiving device 1, a temperature sensor 2, a curved barrel 3, a straight barrel 4, a heating ring 5, a piston shaft 6, an end cover 7, a pressurizing device 8, a motor frame 9, a motor 10, and a rotating needle 11 , sealing ring 12, spinning head 13, and high-voltage electrostatic generator 14; the receiving device 1 is located directly below the spinning head, and the receiving device 1 is connected to the positive output end of the high-voltage electrostatic generator 14, and the other electrode of the high-voltage electrostatic generator 14 Grounding; the spinning head 13 and the outlet of the melt material channel in the curved barrel 3 adopt a tapered surface tight fit, and the spinning head 13 is grounded through the lead wire; the straight barrel 4 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com