Handheld melt electrostatic spinning preparation device and method for applying same

A technology of melt electrospinning and preparation device, which is applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of complex heating system heat insulation and insulation system, and the inability to realize polymer melt, etc. To achieve the effect of simplifying the collection device, promoting application and development, and ensuring portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

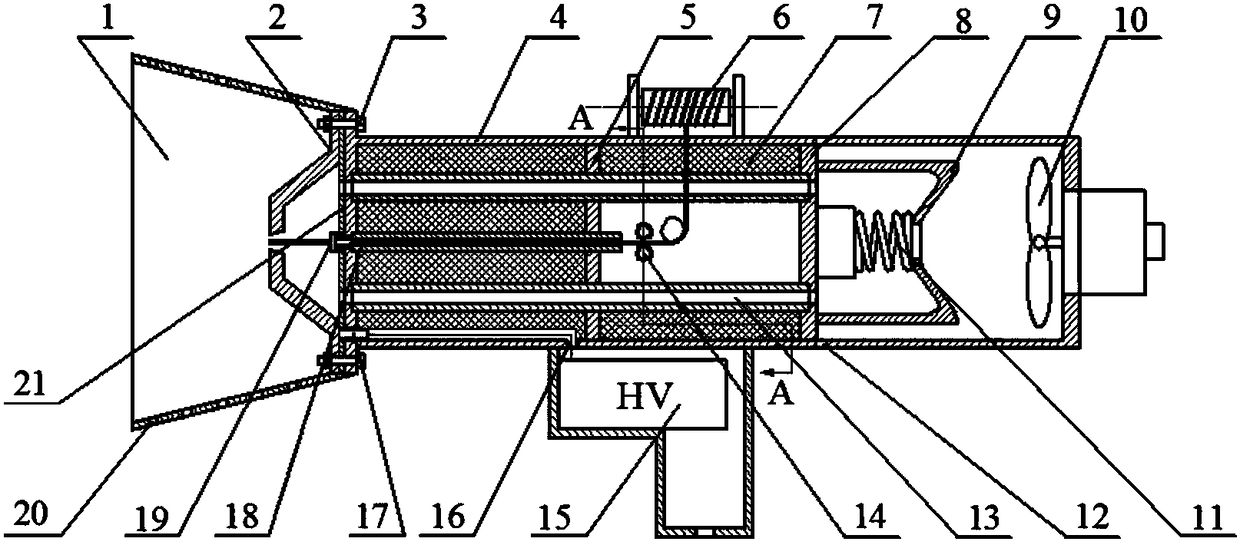

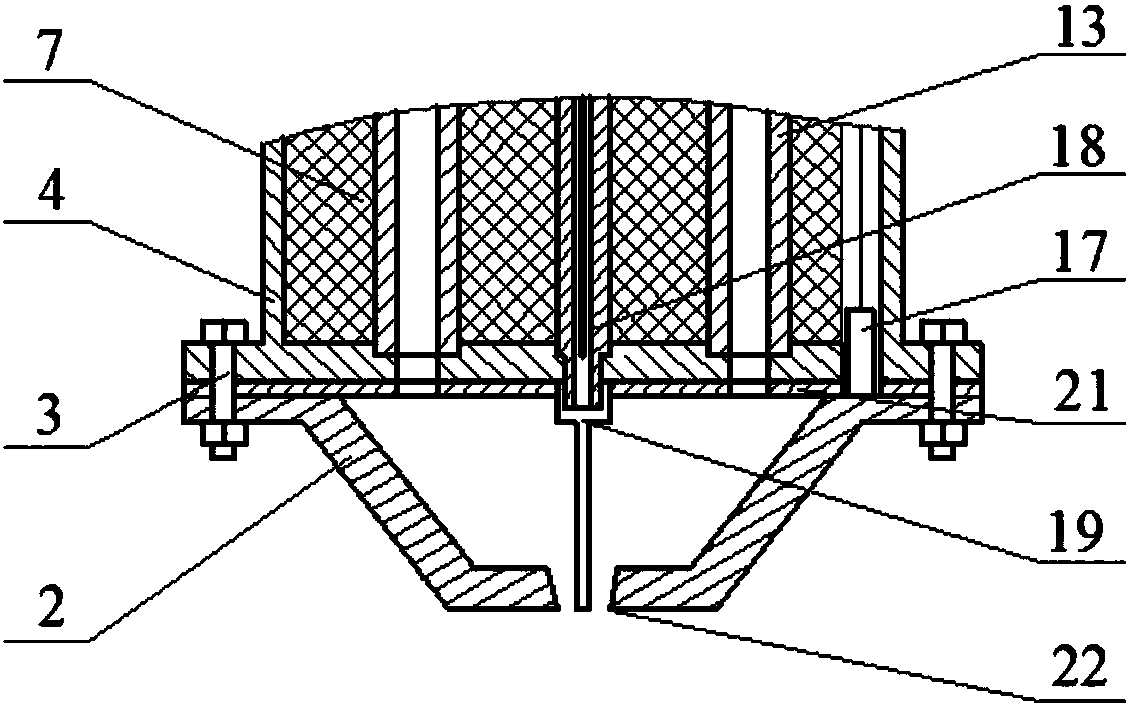

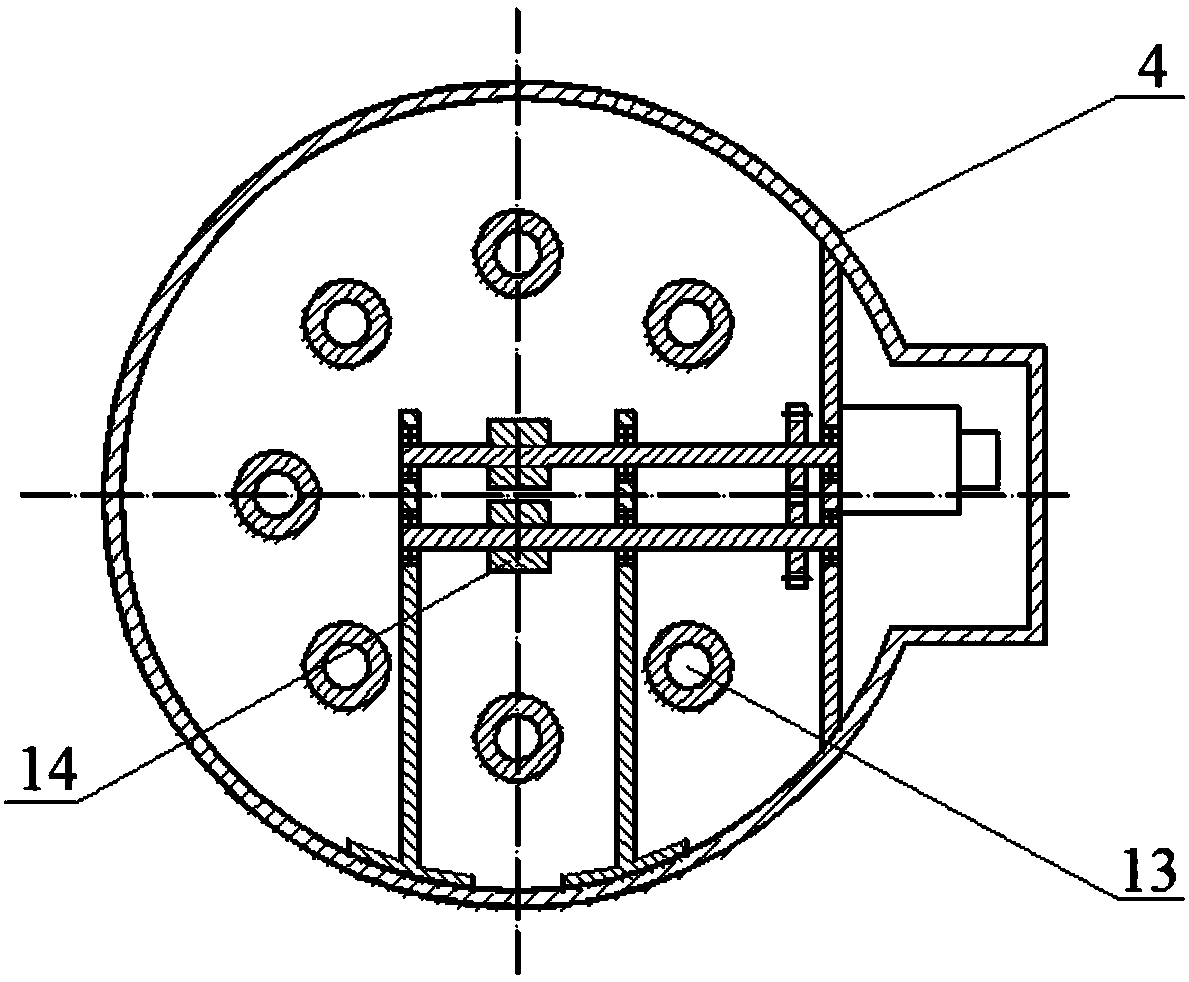

[0022] A kind of hand-held melt electrospinning preparation device of the present invention, such as figure 1 As shown, it mainly includes: safety cover 1, end cover 2, fastening screw 3, shell 4, support plate 5, roller 6, insulation cotton 7, partition 8, heating chamber shell 9, fan 10, resistance heating wire 11 , Vent 12, vent pipe 13, roller 14, miniature high-voltage electrostatic generator 15, wire hole 16, electrode joint 17, feeding tube 18, needle 19, vent 20 and metal gasket 21. This device utilizes silk feeding, and the silk is wound on the drum 6, and two rollers 14 form a roller pair to squeeze the silk and send it continuously into the feeding pipe 18, wherein the rollers 14 are connected to the motor, and the motor speed is adjustable, such as image 3 Shown; The inner diameter of feed pipe 18 is slightly larger than the wire material diameter, avoids the phenomenon that the wire material is bent and folded in feed pipe 18; Gas is brought into the device by fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com