Differential melt-electrospinning jet head

A technology of electrospinning and melt differentiation, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as difficult mass production, high cost, and insufficient number of filaments for industrial applications. , to achieve the effect of reducing processing difficulty, improving efficiency, and ensuring the uniformity of annular distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

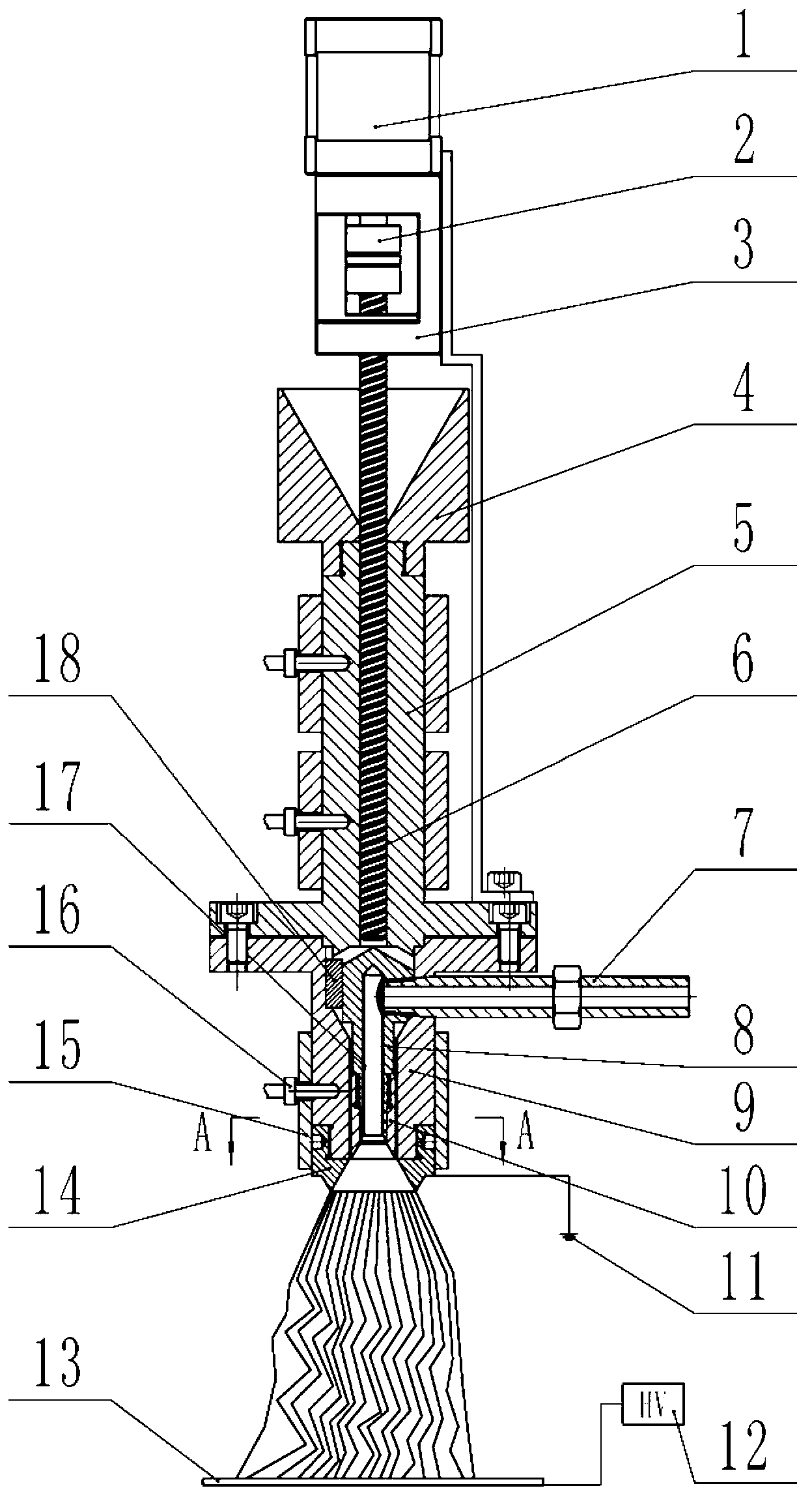

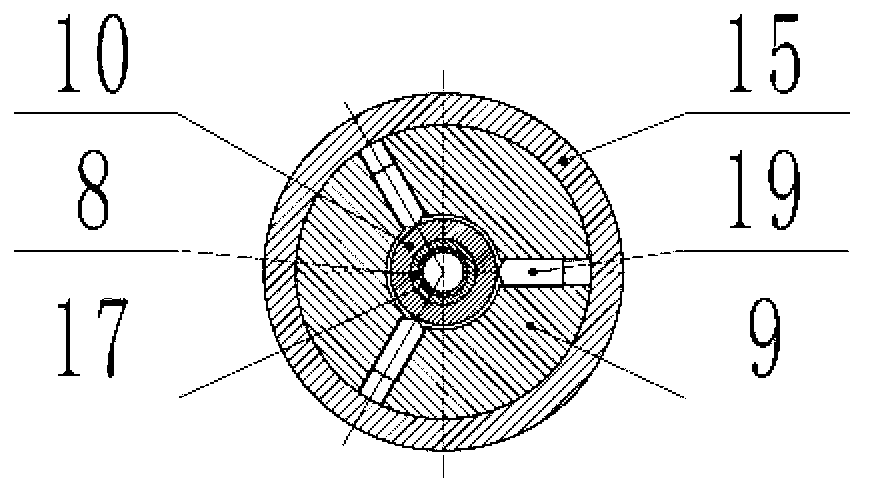

[0019] Such as figure 1 and figure 2 As shown, a melt differential electrospinning nozzle of the present invention mainly includes a hopper 4, a barrel 5, a nozzle body 9, an inner cone nozzle 14, an air inlet pipe 7, an air passage vertical pipe 8, and an air passage partition Thermal layer 17, nozzle inner body 10, key 18, top wire 19, heating device 15, temperature sensor 16, screw 6, coupling 2, servo motor 1, motor bracket 3, ground electrode 11, receiving electrode plate 13, high voltage The electrostatic generator 12, the air flow vertical pipe 8 and the nozzle inner body 10 are connected by threads, and are installed in the nozzle body 9, and the key 18 is installed between the air flow vertical pipe 8 and the nozzle body 9, so that the air flow vertical pipe 8 and the nozzle Positioning between body 9 prevents air flow channel vertical pipe 8 from rotating and misalignment. Air flow channel air inlet pipe 7 passes through nozzle body 9 and air channel vertical pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com