Novel efficient linear nozzle for electrostatic spinning

A high-efficiency, electrospinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as small temperature adjustable range, equipment failure, and difficulties, so as to reduce processing difficulty and increase output , easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

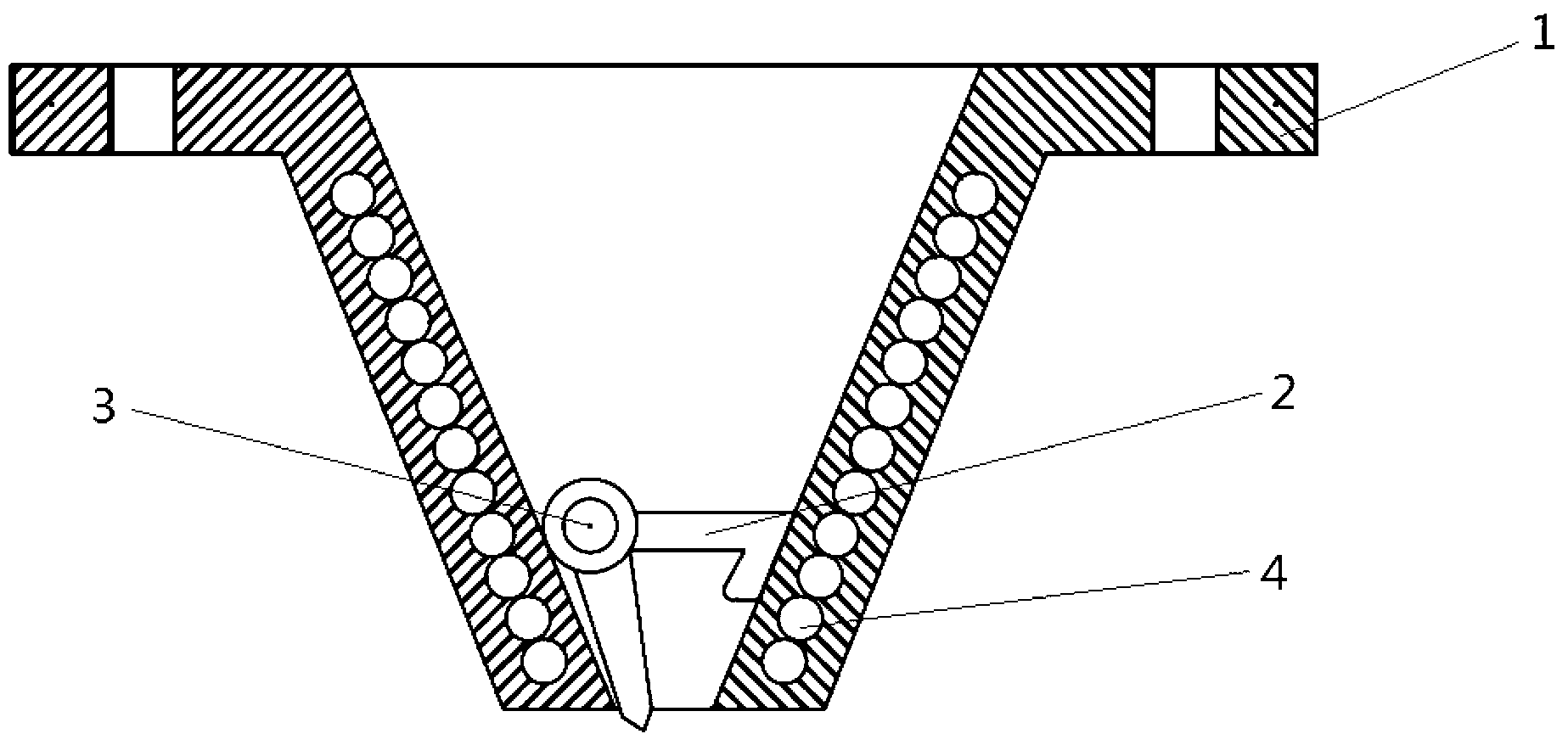

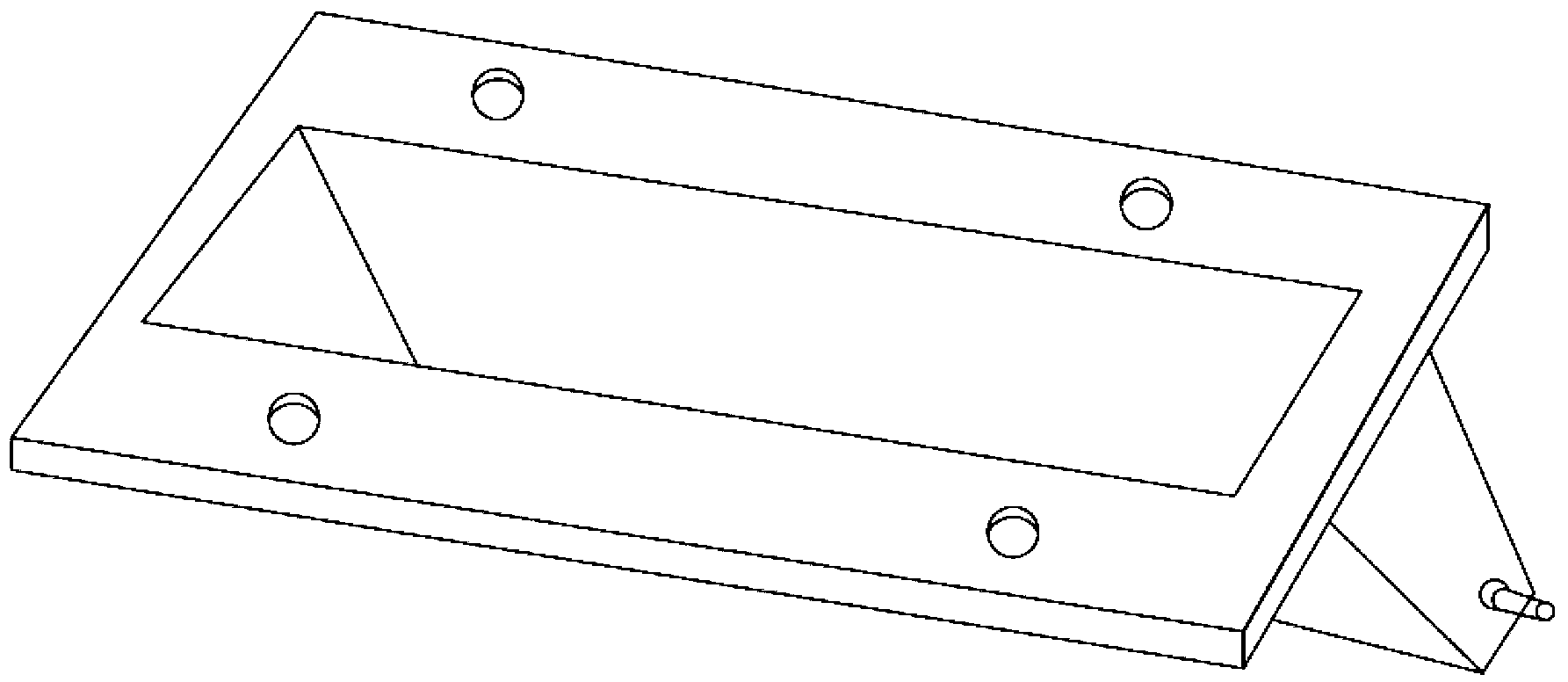

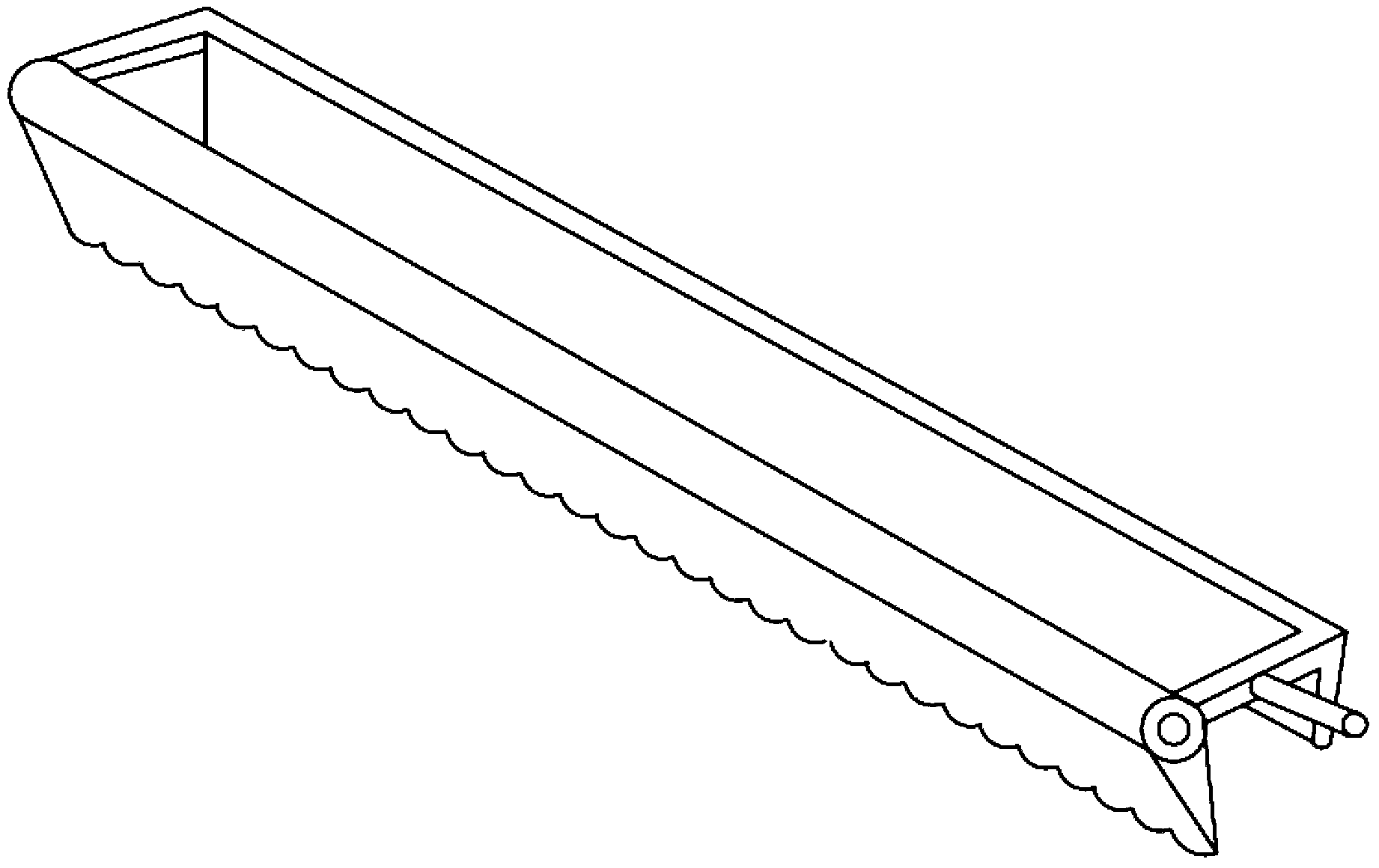

[0013] Such as figure 1 A new type of high-efficiency electrospinning linear nozzle is shown, which mainly includes two parts: a ceramic heat control device 1 and a metal folding fan conductive device 2; figure 2 The shown ceramic heat control device 1 is a one-time casting of ceramic castings, with a triangular prism-shaped cavity, embedded with metal heating copper wires and a temperature control sensor PT100, which is easy to control the overall temperature of the nozzle. The lower part of the cavity has a linear spout. Wherein the ceramic heat control device 1 is fixed on the barrel through a nut after being covered with a heat-resistant rubber gasket. Such as image 3 The shown metal folding fan current drainage conductive device 2 is hinged by a rectangular metal frame and a rectangular metal sheet, the rectangular metal sheet has a jagged uniform protrusion, and is stuck in the cavity of the ceramic heat control device 1 with the high voltage static voltage receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com