Electromachining method with controllable tool electrode rotating speed for micro-holes and speed adjustment system

A tool electrode and rotation speed technology, which is applied in the field of micro-hole tool electrode rotation speed controllable electric machining method and speed regulation system, can solve the problems of reducing machining efficiency, high machining cost, increasing machining cumulative error, etc., so as to improve the machining surface. The effect of quality, reducing processing cost and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

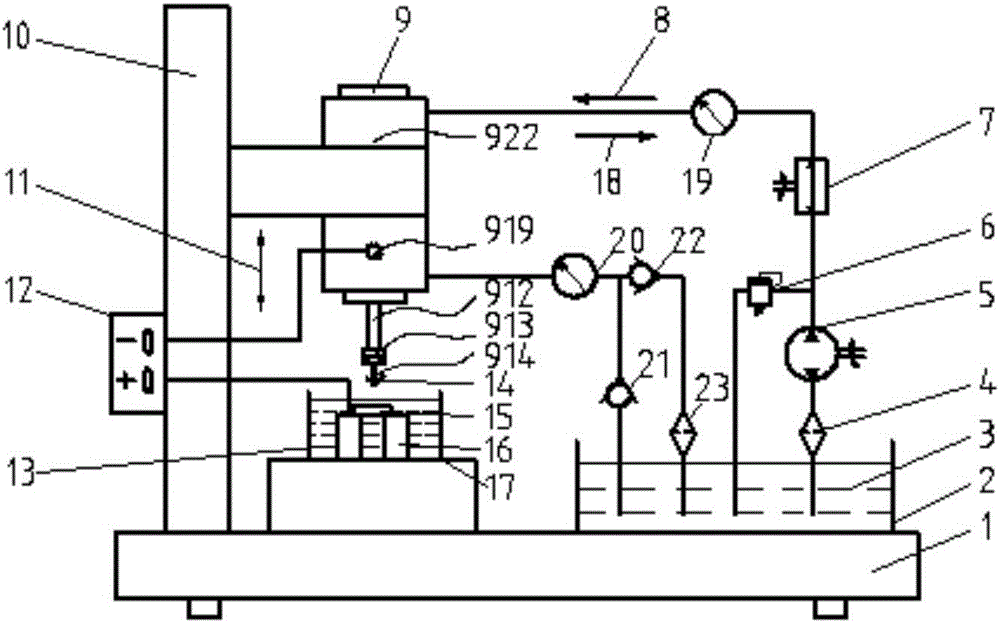

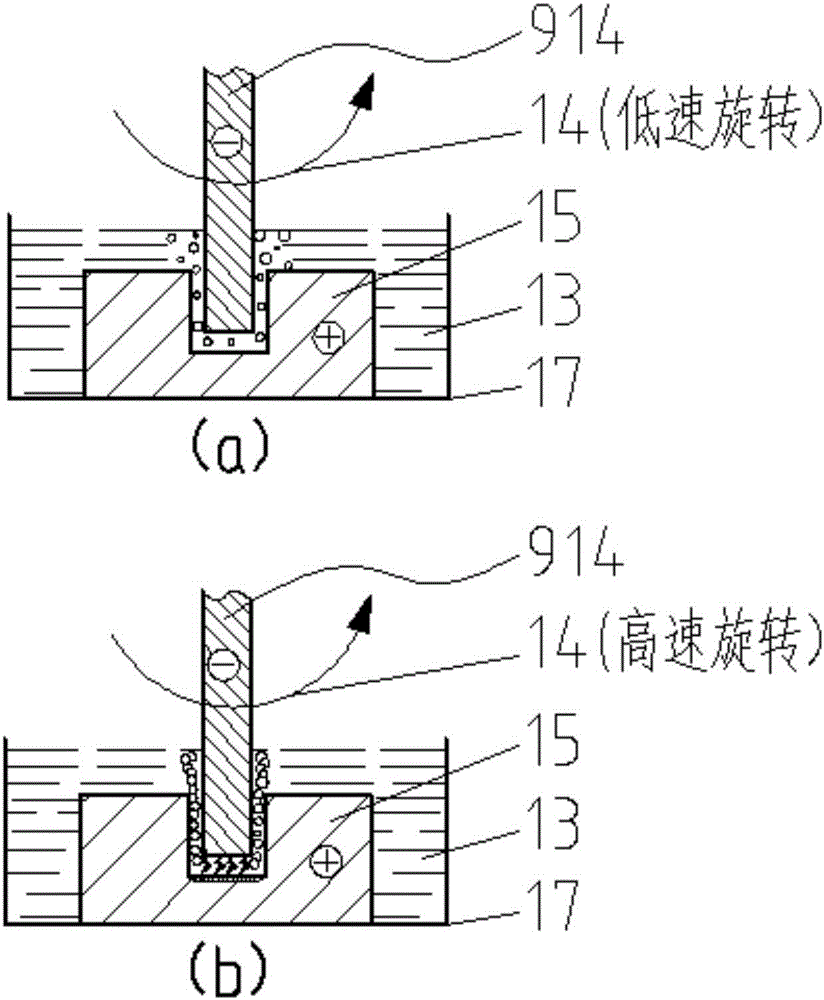

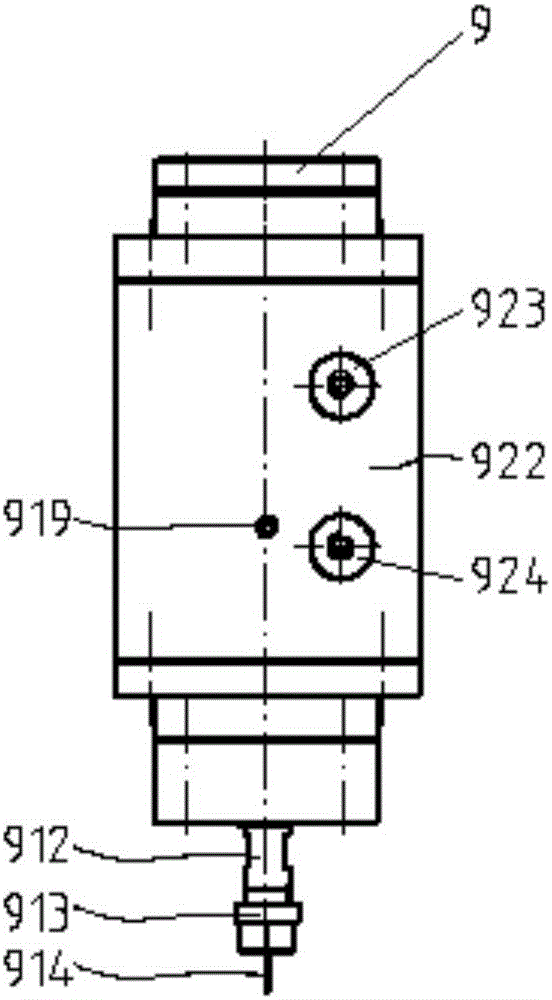

[0032] Such as figure 1 As shown, a microporous tool electrode rotation speed controllable electric machining method and speed regulating system, including a bed 1, a circulating working fluid tank 2, a working fluid 3, a filter 4, a two-way flow pump 5, an overflow valve 6, Two-way speed regulating throttle valve 7, positive flow of working fluid in the box 8, adjustable electrical processing device for tool electrode rotation speed 9 (rotary piece 906, rotary piece 907, rotating shaft 912, collet 913, tool electrode 914, lead Electric screw 919, box body 922, liquid port 923, liquid port 924), column 10, up and down feed motion 11, DC power supply 12, electrolyte 13, rotary motion 14, workpiece 15, pad 16, electrolyte Groove 17, box body working fluid reverse flow 18, flow meter 19, flow meter 20, check valve 21, check valve 22, filter 23. Wherein, the two-way speed reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com