Combined type glue coating machine and use method thereof

A coating machine, combined technology, applied in the direction of electrical components, circuits, manufacturing wiring harnesses, etc., can solve the problems of fatigue, unergonomic, different quality of coating, etc., to achieve the effect of fast and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

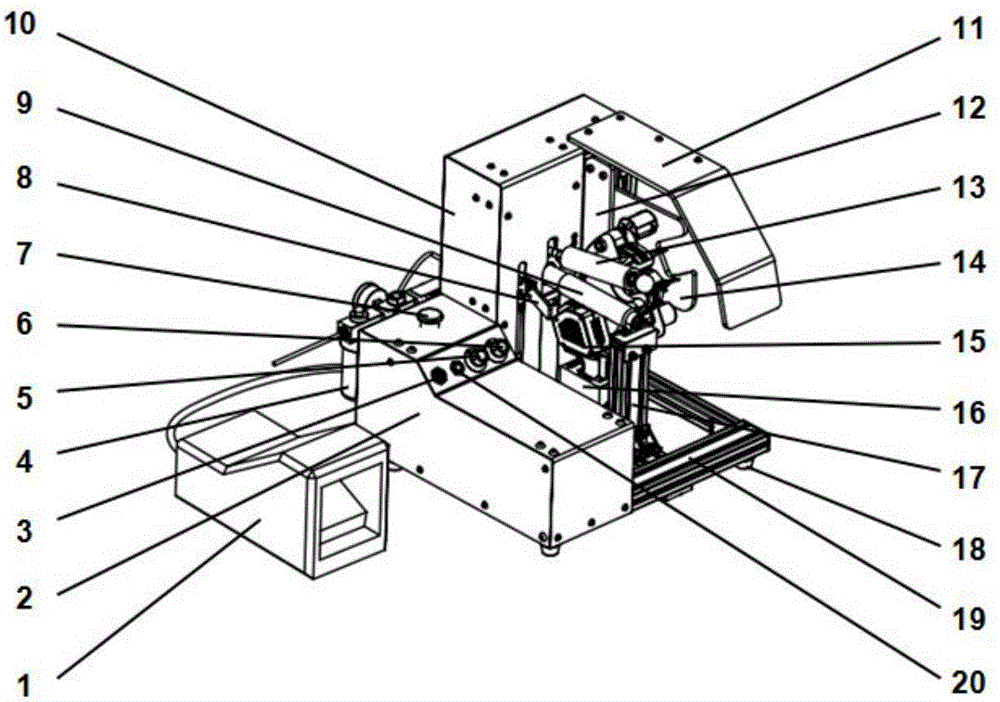

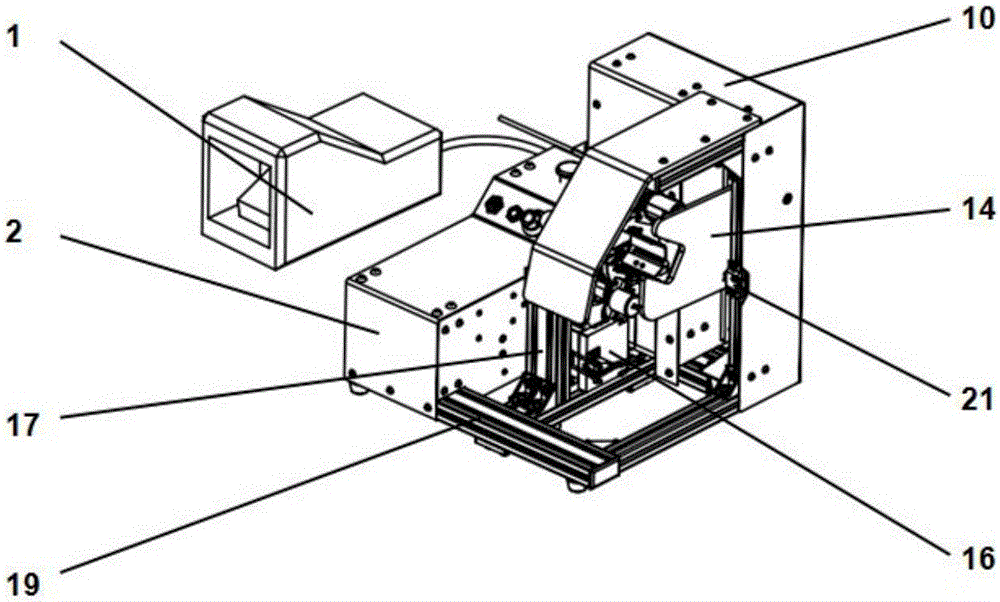

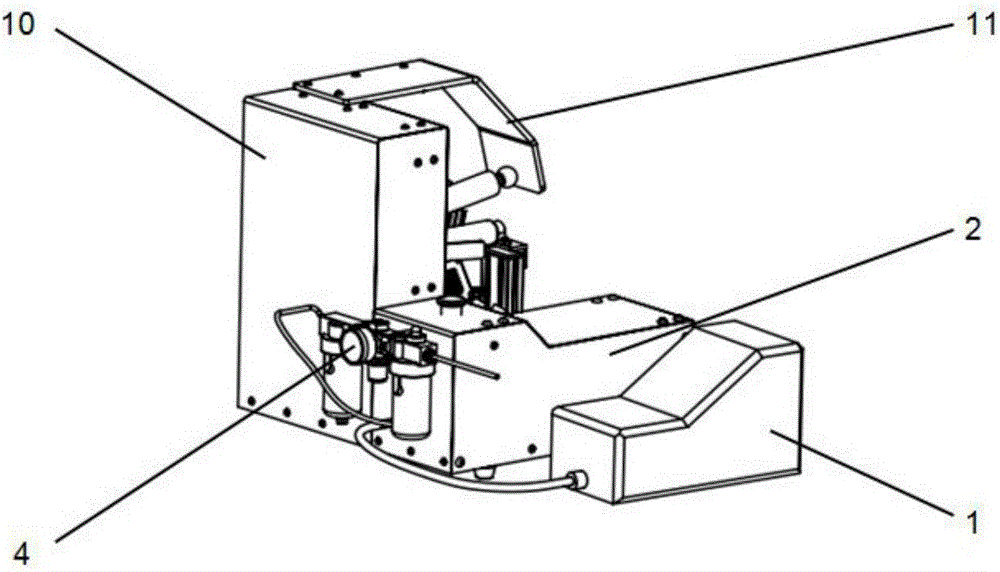

[0033] Such as figure 1 As shown, a combined rubber encapsulation machine includes a foot switch 1, a first control box 2, an air source triple piece 4, a lower roller 9, a second control box 10, a safety protection cover 11, an upper roller 13, and a support frame 14. Glue wrapping machine 15, glue wrapping machine fixture 16, support bar with bearing 17, base 19, support frame fixing lock 21. The safety protection cover is fixedly connected to the top surface of the second control box 10, and is used to cover the upper roller 13, the lower roller 9 and the support frame 14;

[0034] A plurality of pads 18 are installed on the lower surface of the base 19, and the first control box 2, the second control box 10, the rubber encapsulation machine clamp 16, the band bearing support bar 17 and the support frame fixed lock 21 are installed on the upper surface; the encapsulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com