Production device of liquid nitrogen ice cream and making technology thereof

A production device and production process technology, applied in the field of dairy product production and processing, can solve the problems such as the inability to accurately control the amount of liquid nitrogen added, the inability to change the amount of liquid nitrogen added, and the inability to reduce the stirring rate of milk, so as to achieve a unique taste. , Improve the taste and mix well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

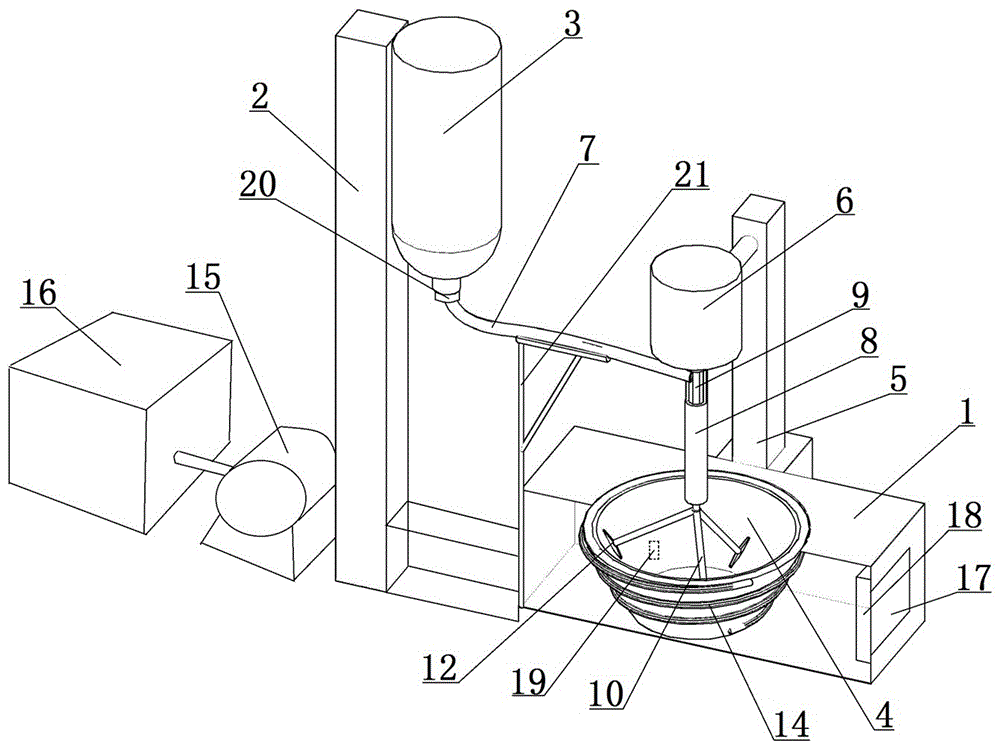

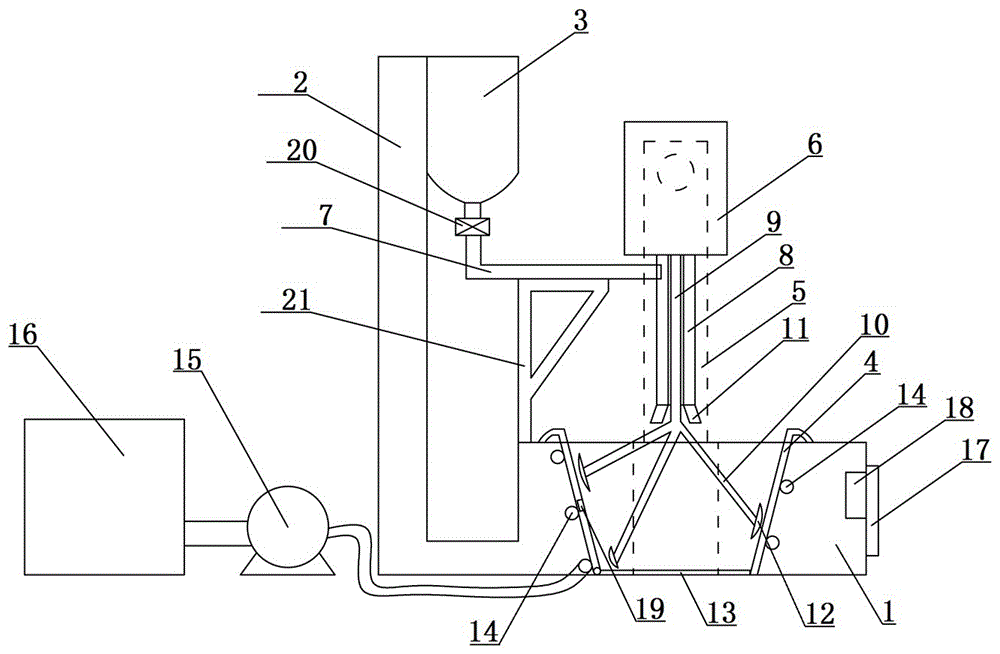

[0033] A manufacturing process of liquid nitrogen ice cream, the manufacturing process comprises the following manufacturing steps:

[0034] a. Put 100 parts by weight of sterilized milk into the stirring container 4, and add additives, including 10 parts by weight of sucrose, 1 part by weight of sodium hydroxymethyl cellulose, 0.2 parts by weight of sodium citrate, 0.2 parts by weight low-fat pectin, 0.2 parts by weight of sodium tripolyphosphate, and add 0.2 parts by weight of taro essence and 2 parts by weight of fruit juice;

[0035] b. Turn on the water pump 15, inject cold water into the circulating water pipe 14, cool the milk temperature to below 6°C, and turn off the water pump 15;

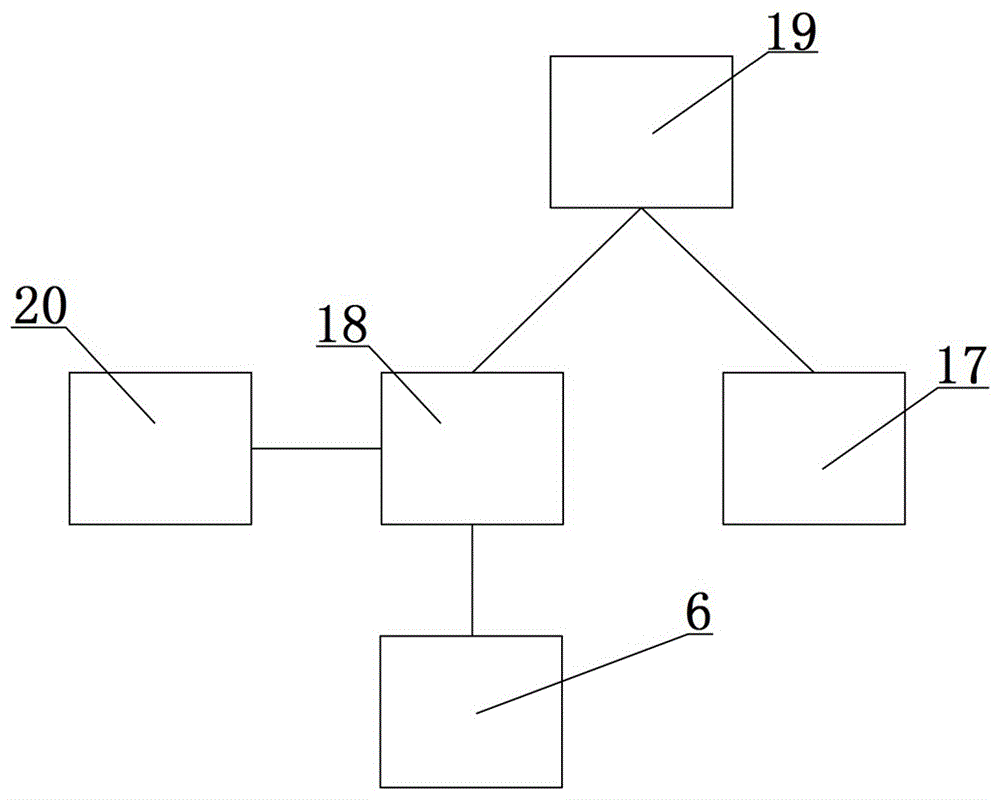

[0036] c. The solenoid valve 20 is opened through the PLC control module 18, nitrogen is introduced into the stirring shell 8 through the conduit 7, and is introduced into the stirring container 4 from the gas outlet 11, and the liquid nitrogen in the liquid nitrogen tank 3 at -196 ° C...

Embodiment 2

[0040] A manufacturing process of liquid nitrogen ice cream, the manufacturing process comprises the following manufacturing steps:

[0041] a. Put 100 parts of weight of milk through high-temperature sterilization into the stirring container 4, and add additives, 12 parts of sucrose by weight, sodium hydroxymethylcellulose of 1.5 parts by weight, sodium citrate of 0.3 parts by weight, sodium citrate of 0.3 parts by weight Low-fat pectin, 0.3 parts by weight of sodium tripolyphosphate, and add 0.3 parts by weight of caramel coloring and 5 parts by weight of cocoa powder;

[0042] b. Turn on the water pump 15, inject cold water into the circulating water pipe 14, cool the milk temperature to below 4°C, and turn off the water pump 15;

[0043] c. The solenoid valve 20 is opened through the PLC control module 18, nitrogen is introduced into the stirring shell 8 through the conduit 7, and is introduced into the stirring container 4 from the gas outlet 11, and the liquid nitroge...

Embodiment 3

[0047] A manufacturing process of liquid nitrogen ice cream, the manufacturing process comprises the following manufacturing steps:

[0048] a. 100 parts by weight of sterilized milk are put into the stirring container 4, and additives are added, including 15 parts by weight of sucrose, 2 parts by weight of sodium hydroxymethyl cellulose, 0.5 parts by weight of sodium citrate, 0.5 parts by weight of low-fat pectin, 0.5 parts by weight of sodium tripolyphosphate, and add 5 parts by weight of mango fruit;

[0049] b. Turn on the water pump 15, inject cold water into the circulating water pipe 14, cool the milk temperature to below 6°C, and turn off the water pump 15;

[0050] c. The solenoid valve 20 is opened through the PLC control module 18, nitrogen is introduced into the stirring shell 8 through the conduit 7, and is introduced into the stirring container 4 from the gas outlet 11, and the liquid nitrogen in the liquid nitrogen tank 3 at -196 ° C and 1.2 atmospheres is un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com