Circumferential seam single-pass electro-gas welding machine

A gas-electric vertical welding machine, single-pass technology, applied in arc welding equipment, electrode characteristics, welding equipment, etc., can solve the problem of low efficiency, improve efficiency, ensure internal and external quality requirements, and meet the effect of forming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

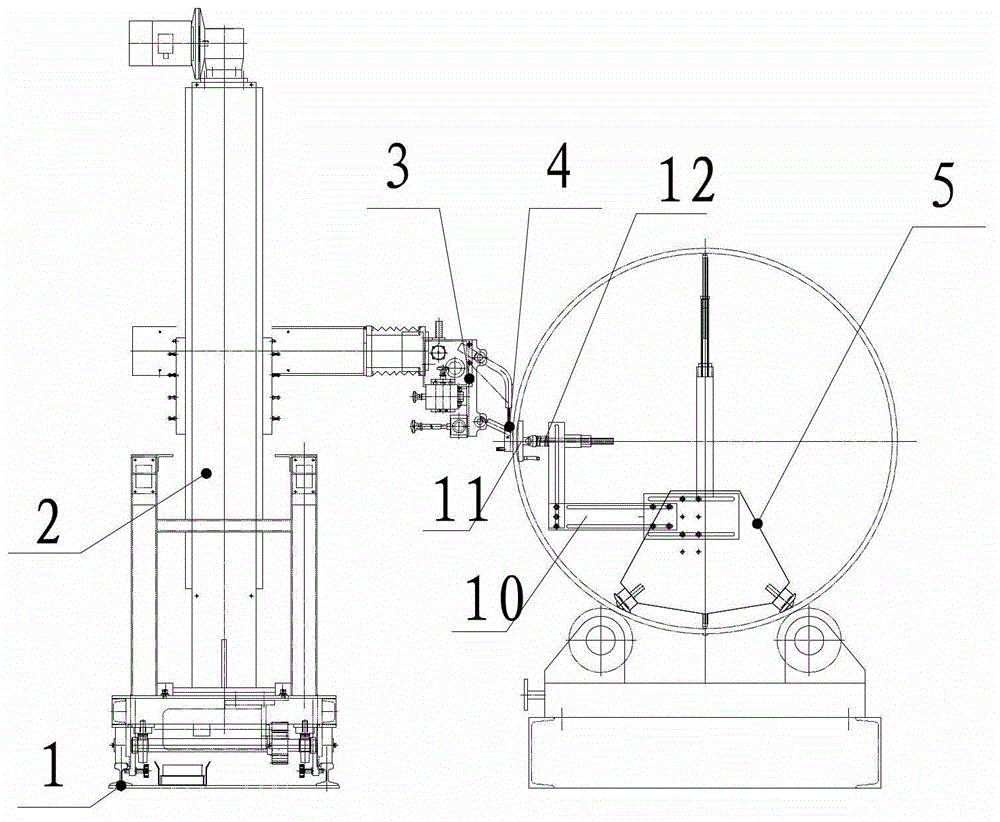

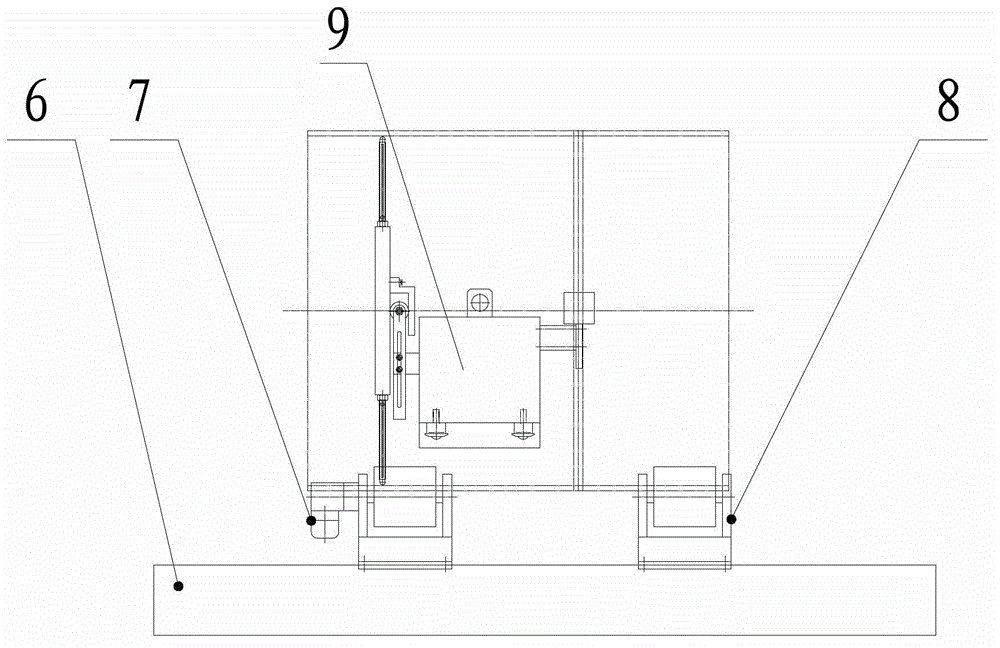

[0014] A kind of circular seam single channel gas electric vertical welding machine provided by the present embodiment, such as figure 1 and figure 2 As shown, it is mainly composed of walking track 1, cantilever welding machine 2, gas-electric welding head 3, front water-cooled slider 4, back forming device 5, roller frame base 6, driving roller frame 7, driven roller frame 8 and other components . The cantilever welding machine 2 is installed on the walking track 1; the gas-electric welding head 3 and the front water-cooled slider 4 are integrated and installed on the cantilever welding machine 2; the active roller frame 7 and the driven roller frame 8 are installed on the roller frame base 6, The active roller frame 7 is driven by a servo motor to meet the precise control of the rotation speed of the welding cylinder; the cylinder to be welded is placed on the roller frame; during welding, the back forming device 5 is installed inside the cylinder. The cantilever welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com