Equipment and method for controlling rotating speed of synchronous magnetic motor

A technology of synchronous reluctance motor and rotation speed, which is applied in the direction of controlling generators, controlling electromechanical brakes, controlling electromechanical transmissions, etc., and can solve problems such as increased costs, inability to achieve speed control, and difficulty in handling Hall sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Description of preferred embodiments

[0026] Preferred embodiments of the invention will now be described in detail, which are illustrated in the accompanying drawings.

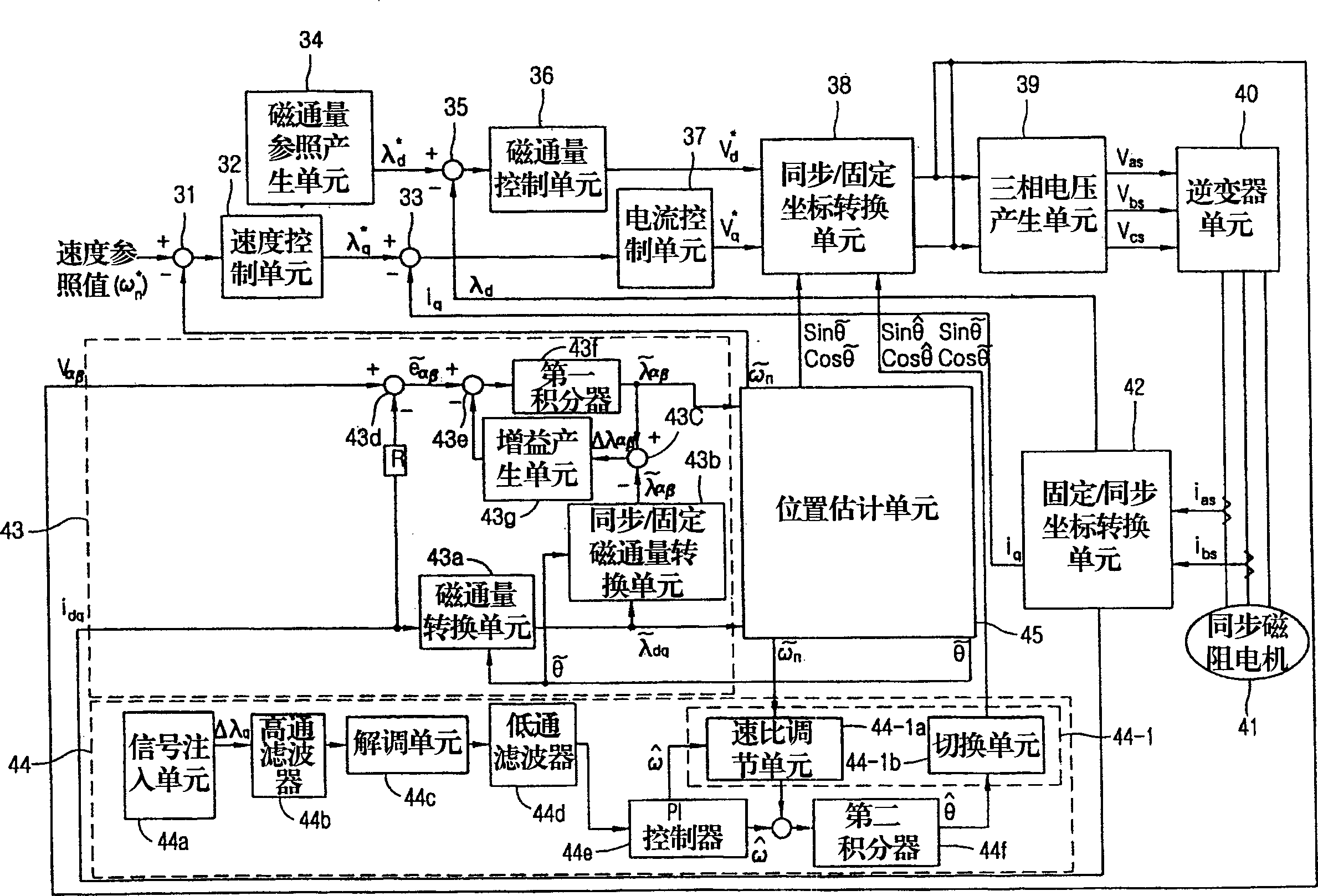

[0027] Below, refer to figure 2 Describe in detail a preferred embodiment of an apparatus for controlling the rotational speed of a synchronous reluctance motor, which does not use hall sensors or encoders to detect the speed and position of the synchronous reluctance motor, but can be controlled separately according to changes in load Low-speed zone and high-speed zone to maintain the accuracy of speed control, in the case where it is difficult to detect the position of the rotor such as in the compressor of refrigerators and air conditioners, it can linearly control the induction variable according to the change of current, thereby accurately controlling the rotation speed of the motor .

[0028] figure 2 It is a structural block diagram of the synchronous reluctance motor of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com