Sulfuric acid delinting machine

A technology of sulfuric acid dehairing machine and motor motor, applied in the field of sulfuric acid dehairing machine, can solve problems such as easy failure, acid leakage, frequent replacement, etc., and achieve the effect of avoiding constant stirring, avoiding excessive speed, and not easy to fail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

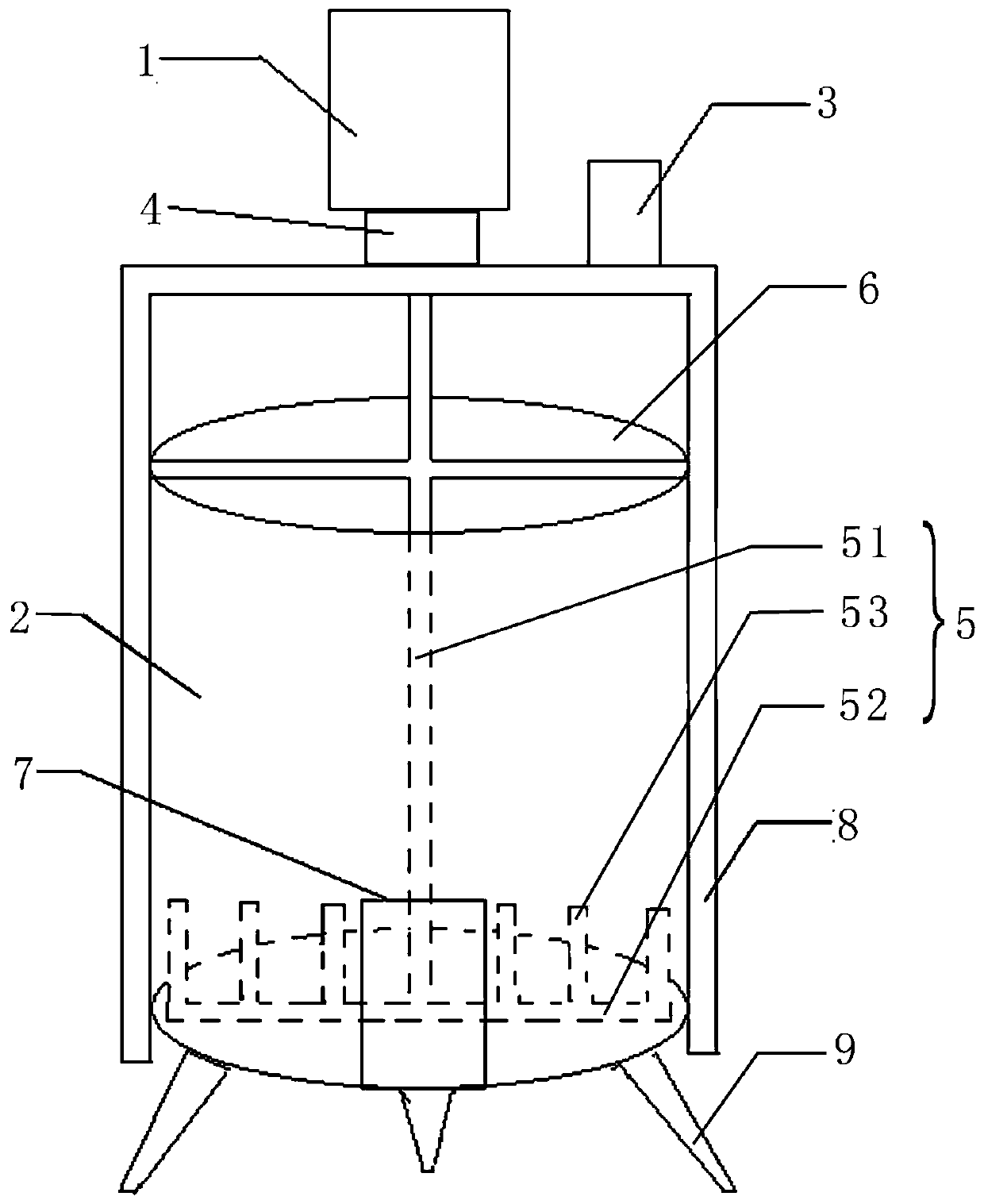

[0035] The following is based on figure 1 A sulfuric acid delinting machine according to an embodiment of the present invention is described in detail.

[0036] Such as figure 1 As shown, the embodiment of the present invention discloses a sulfuric acid delinting machine, which specifically includes: a motor 1 and a container 2 for holding materials.

[0037] The motor 1 is a forward and reverse motor, namely a three-phase AC asynchronous motor. The motor 1 is connected to a control device (not shown in the figure) through a wire, and the control device is connected to the reversing switch 3 and the power switch through a wire. The power switch is used to control the opening and closing of the motor 1 . The direction change switch 3 is used to control the direction in which the output shaft of the motor 1 rotates.

[0038] The output shaft gear of the motor 1 meshes with a reduction gear 4, and the reduction gear 4 drives the stirring rod 5 to rotate. The reduction gear 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com