Stepping blade type robot joint

A robot joint and blade technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of complex drive structure, heavy load and high precision, and cannot be guaranteed at the same time, and achieves compact structure, high output power density, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

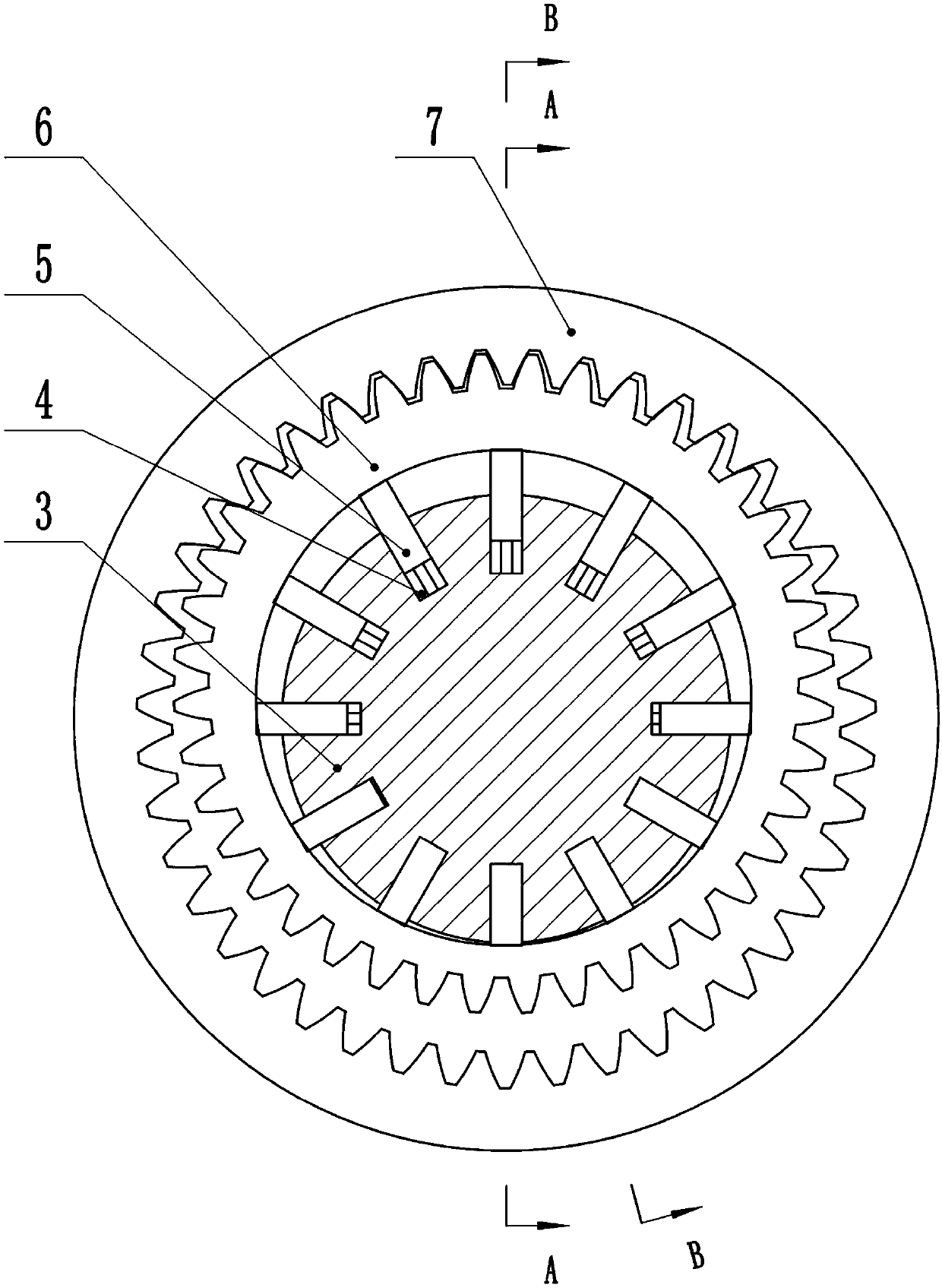

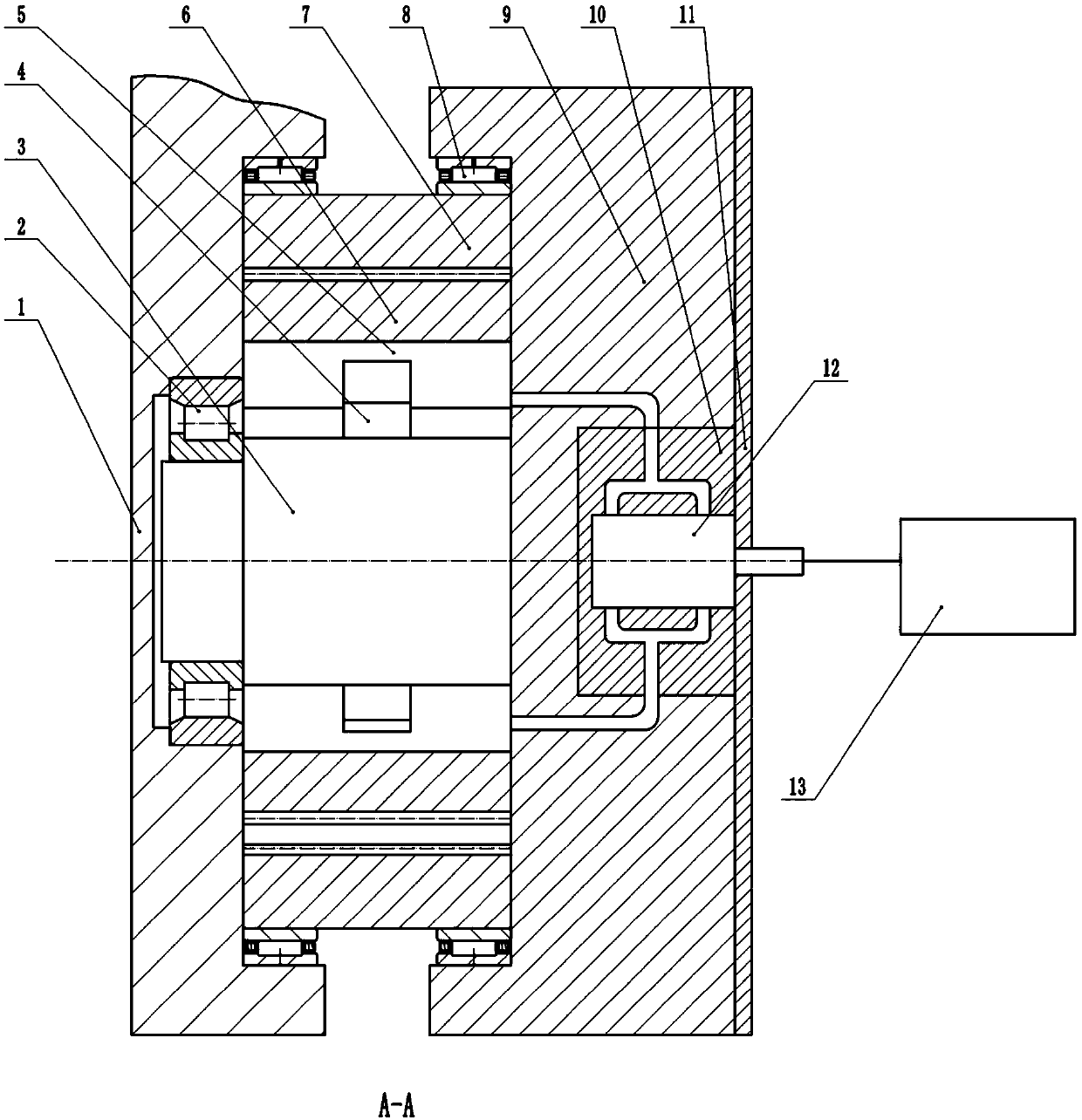

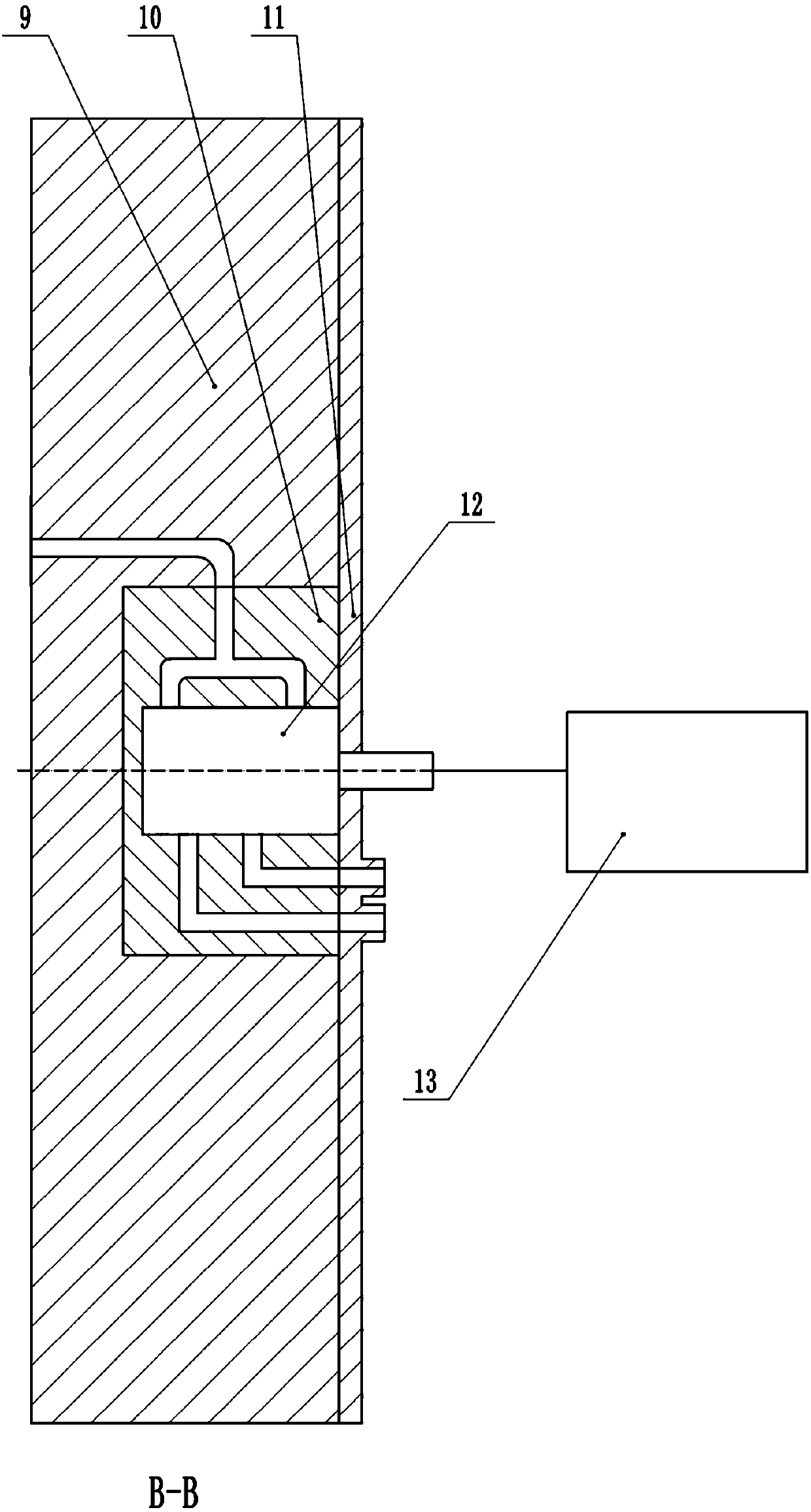

[0028] Such as figure 1 and figure 2 As shown, an external gear 6 and an internal gear 7 are arranged between the left end cover 1 and the right end cover 9, the outer ring of the external gear 6 is coaxially fitted with an internal gear 7, and the two sides of the outer ring of the internal gear 7 respectively pass through a needle bearing 8 is sleeved on the inner peripheral surface of the left end cap 1 and the right end cap 9. The inner ring of the internal gear 7 is a ring gear, and the outer ring 6 of the external gear is a ring gear. The internal teeth of the internal gear 7 are in contact with the external teeth of the external gear 6. The radial dimensions of the external gear 6 and the internal gear 7 are different. The modules of the external gear 6 and the internal gear 7 are equal and have a difference in the number of teeth, so that the teeth of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com