Mechanical damping passive pay-off unit

A pay-off device and mechanical damping technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material handling, etc., can solve the problems that the cable is easy to move back and forth, affects the stability of the pay-off, and affects the work of the pay-off, etc. Achieve safe and convenient use, reduce friction and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

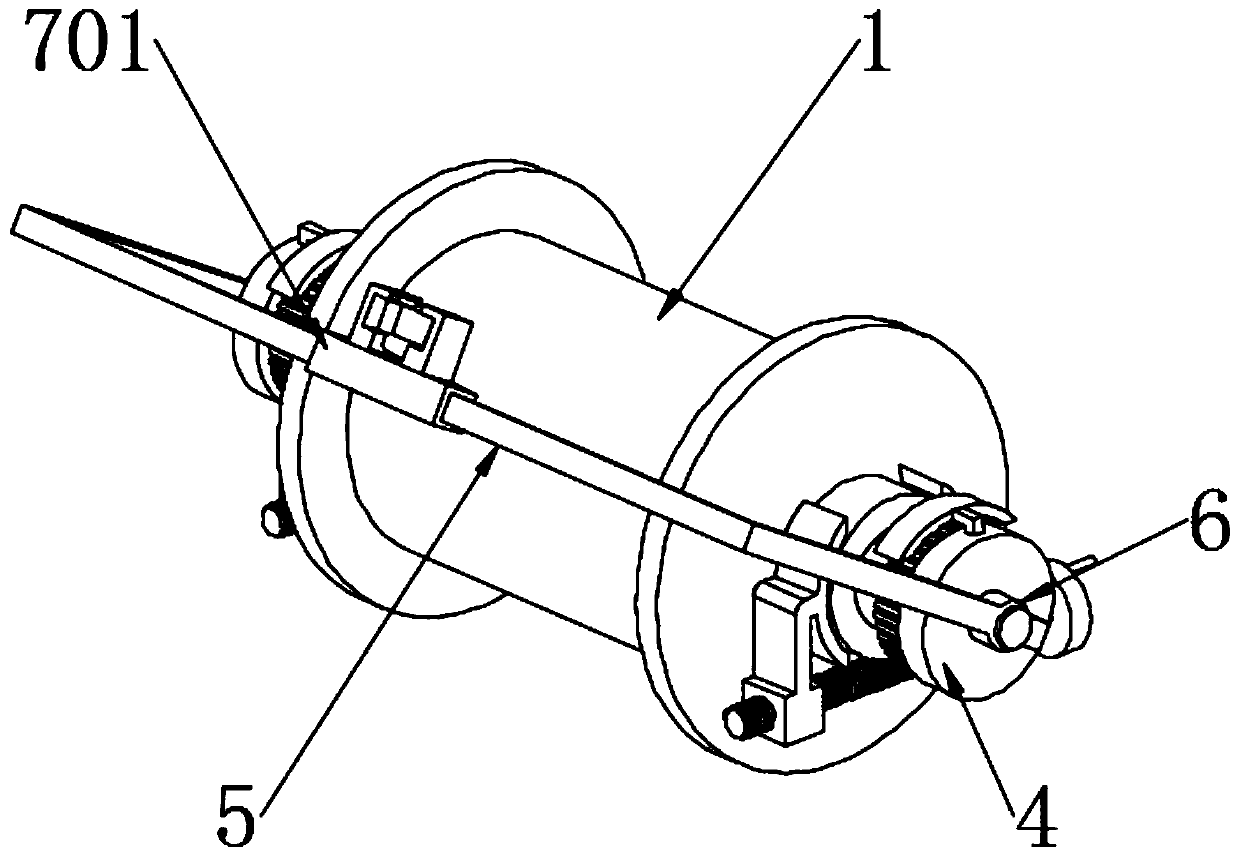

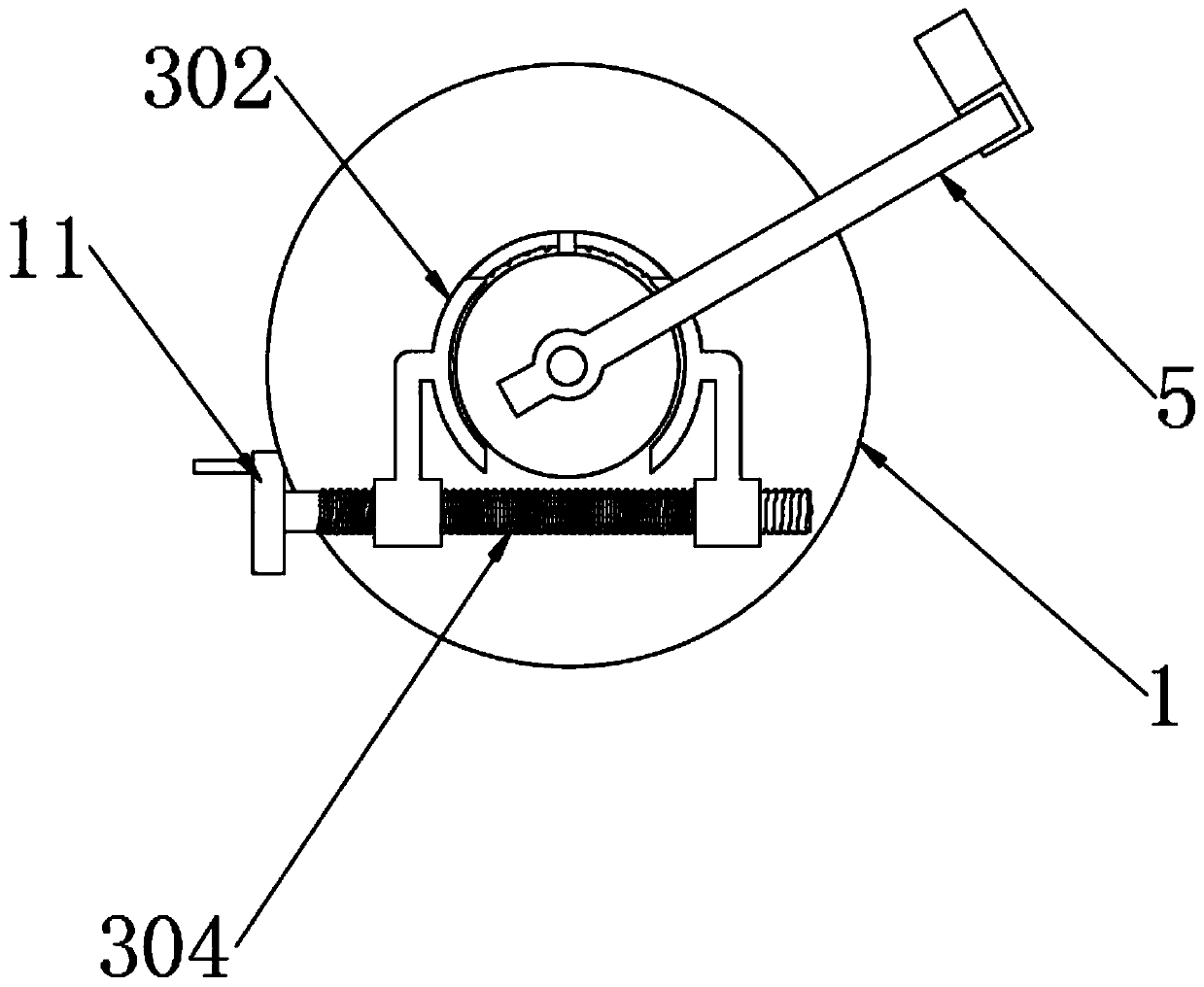

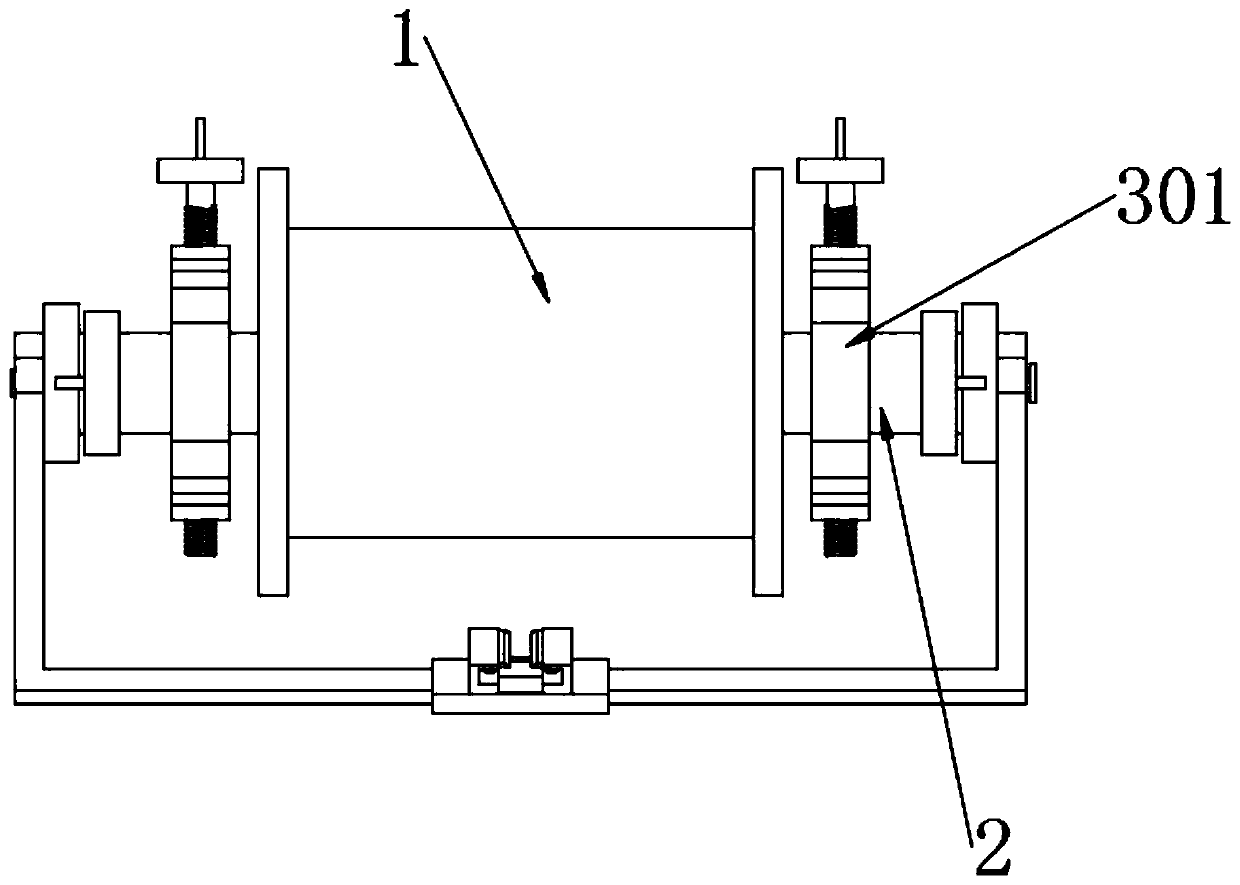

[0031] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a mechanical damping passive pay-off device, comprising a pay-off wheel 1 and a central axis 2 located at the center of the pay-off wheel 1 and passing through the pay-off wheel 1, both sides of the central axis 2 are A damping mechanism 3 is provided, and the damping mechanism 3 includes a turntable 301, a damping plate 302, a connecting rod 303, a screw rod 304, and a screw nut 305. Both ends of the central shaft 2 are sleeved with a turntable 301 near the end surface of the pay-off wheel 1, and the turntable Both sides of 301 are provided with damping sheet 302, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com