Hydraulic excavator flow rate control method and control loop

A technology of flow control and circuit, which is applied in the direction of earth mover/shovel, mechanical equipment, servo meter circuit, etc., can solve the problems of reducing the service life of the motor, occupying the installation space of the whole machine, and increasing the system flow, so as to prolong the life of the motor. Longevity, reduced maintenance cost, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

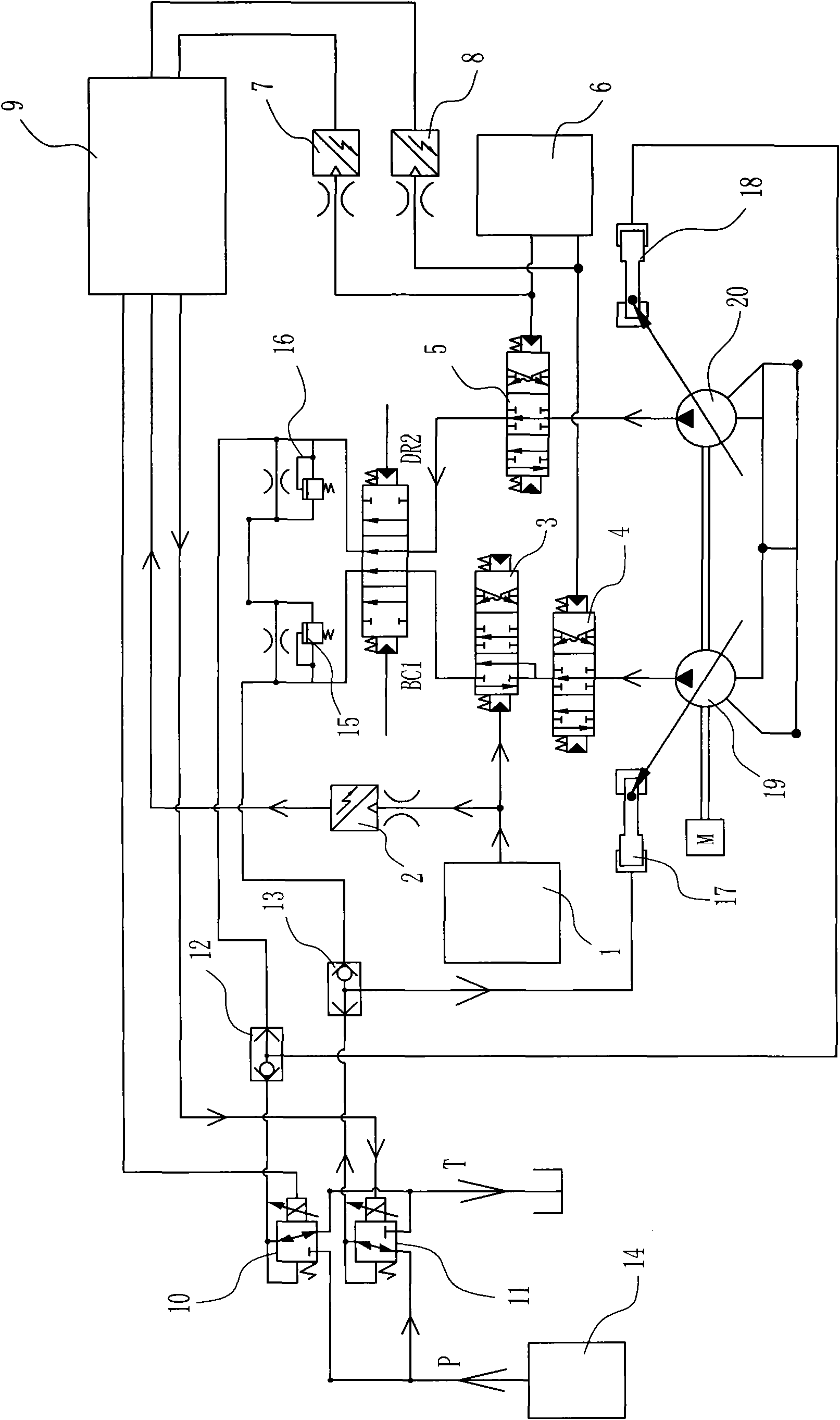

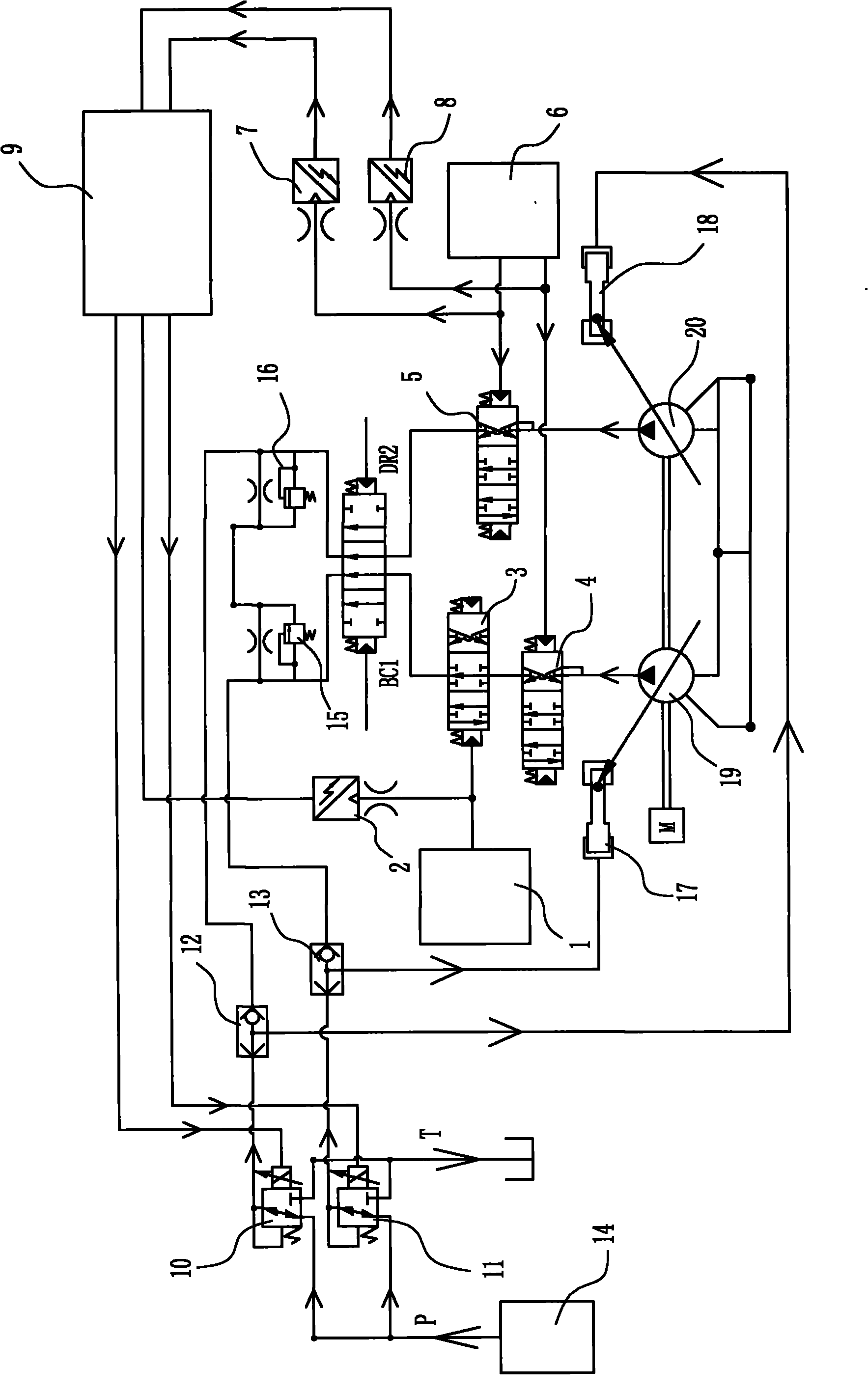

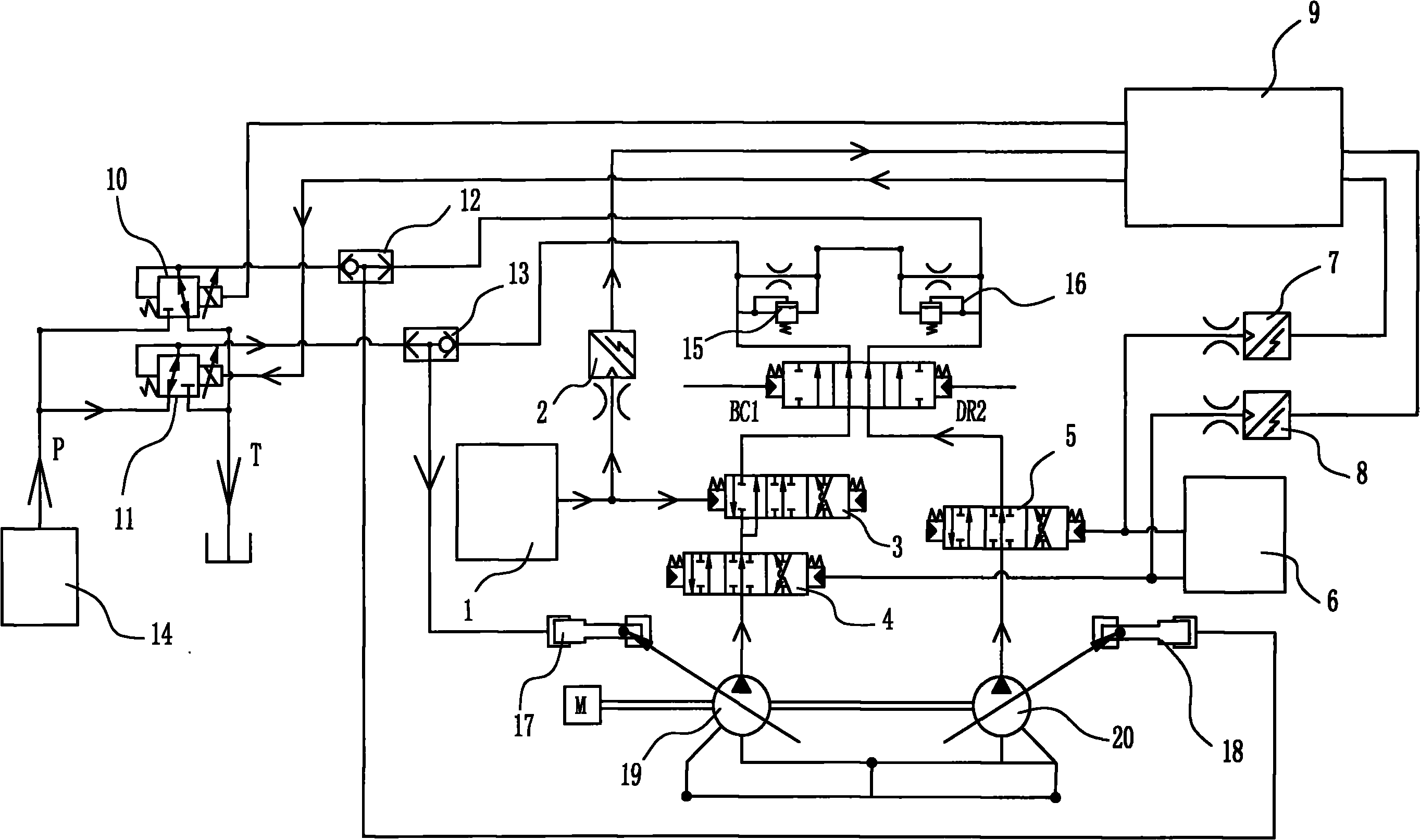

[0021] Embodiment one: see figure 1 , 2 As shown, a hydraulic excavator flow control circuit includes the first and second electromagnetic proportional valves and the first and second two OR-type three-way shuttle valves, the first and second electromagnetic proportional valves The input ends are respectively connected to the output port of the pilot gear 14 of the excavator, the output end of the first electromagnetic proportional valve 10 is connected to the P1 input port of the first or gate type three-way shuttle valve 12, and the second electromagnetic proportional valve 11 The output end is connected to the P1 input port of the second OR gate type three-way shuttle valve 13; the P2 input port of the first OR gate type three-way shuttle valve 12 is connected to the negative feedback spool 16 behind the excavator, and its A output port It is connected with the corresponding rear negative feedback regulator 18, the P2 input port of the second or gate type three-way shuttle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com