Automatic polishing system for cylindrical workpiece

An automatic polishing, cylindrical technology, applied in the direction of grinding workpiece supports, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of unstable polishing quality and low degree of automation, achieve stable and good polishing quality, and improve the level of automation , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

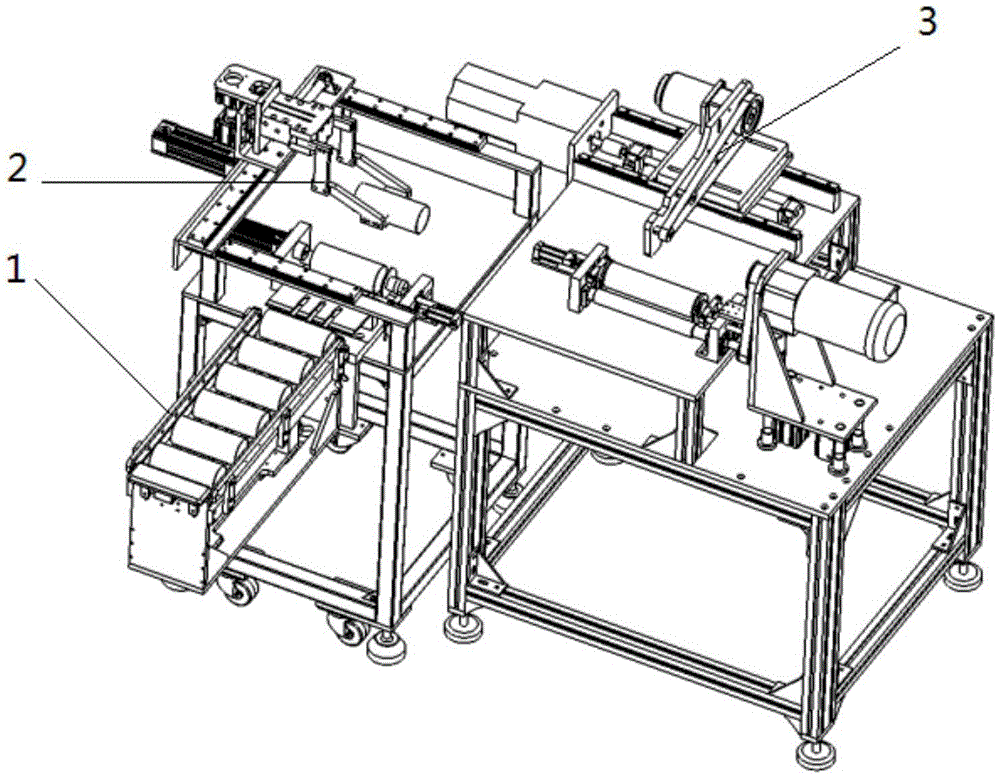

[0047] Such as Figure 1-7 As shown, the present invention provides an automatic polishing system for cylindrical workpieces, including a feeding mechanism 1 , a feeding mechanism 2 and an outer circle polishing mechanism 3 . In this embodiment, the cylindrical workpiece is a stainless steel cup as an example for illustration. Of course, the automatic polishing system of the present invention can also be used for other cylindrical workpieces except stainless steel water cups.

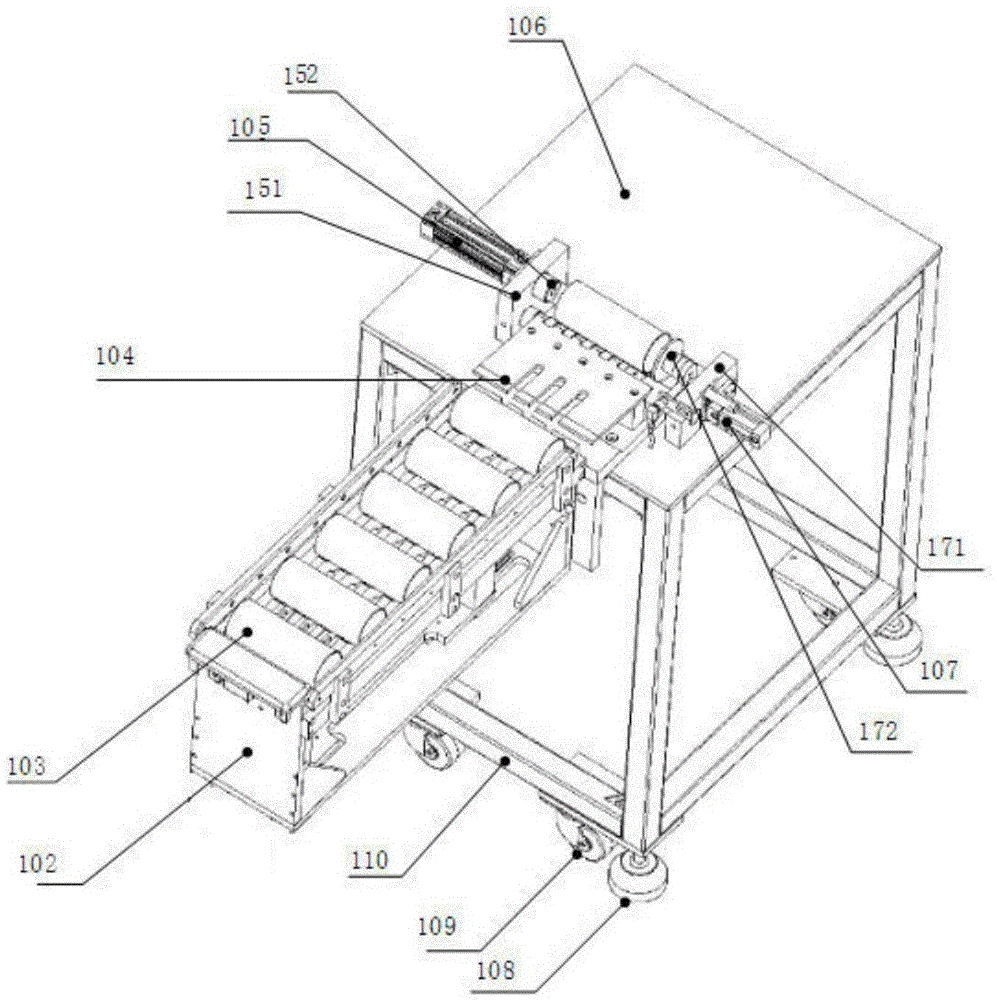

[0048] The feeding mechanism 1 includes a feeding frame, and a conveying table unit and a pressing unit installed on the feeding frame.

[0049] The feeding frame is composed of a profile support frame 110, a bracket panel 106 is arranged on the top, and a plurality of feet 108 and a plurality of rollers 109 are arranged in the bottom.

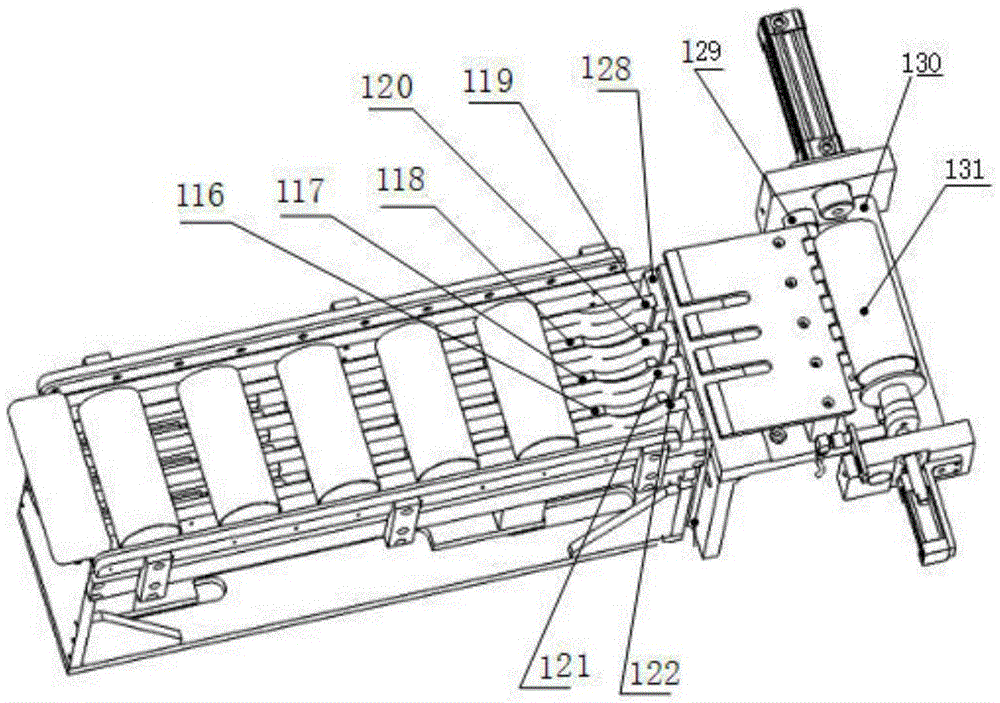

[0050] The conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com