Manufacturing method of magnetic control bionic film microstructure

A manufacturing method and microstructure technology, applied in the direction of photolithography process, microlithography exposure equipment, photoplate process coating equipment, etc., can solve the problems of friction performance and application of materials without micro-scale MRE, and achieve Simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

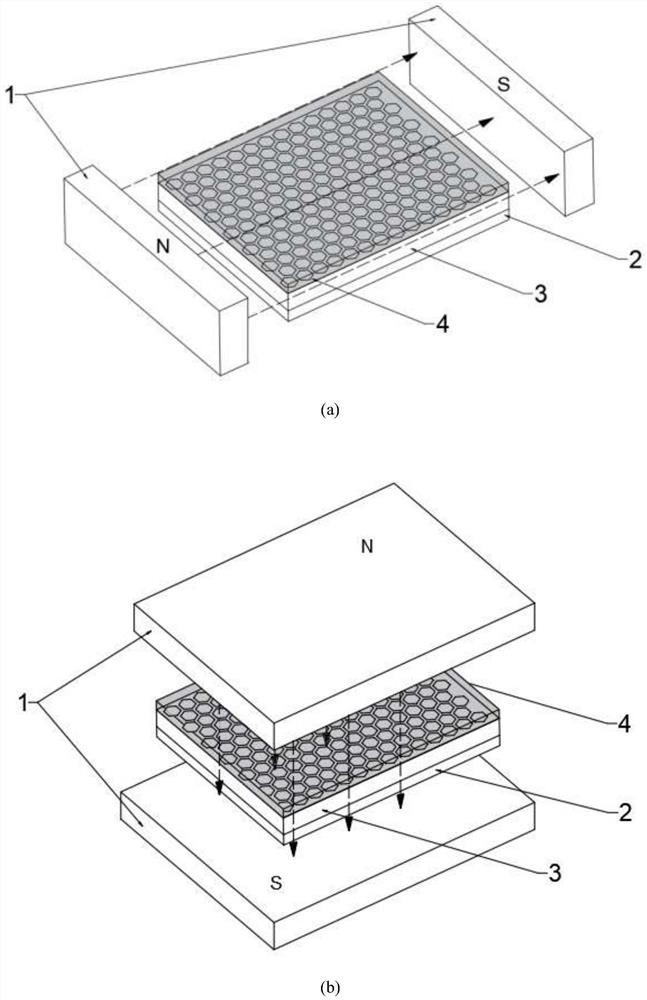

[0029] Embodiment 1: Manufacturing method of magnetron biomimetic thin film microstructure with parallel anisotropic microstructure

[0030] S1. Spin-coat the negative photoresist SU-8 2050 (MicroChem) evenly on the cleaned silicon substrate;

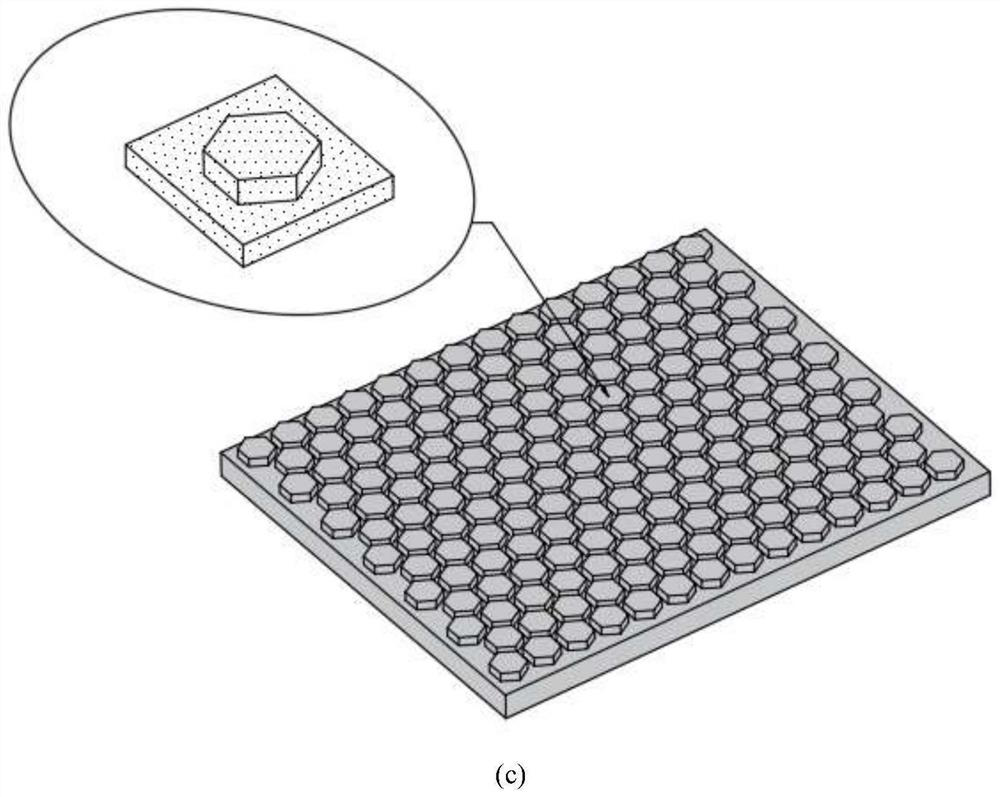

[0031] S2. Forming a micron-scale regular hexagonal groove array, i.e. a concave template, on the negative photoresist obtained in step S1 by photolithography;

[0032]S3. Mix PDMS prepolymer and curing agent (Dow Corning Sylgard 184) at a weight ratio of 10:1, stir evenly with a glass rod, and then put the PDMS mixture into an ultrasonic oscillator (Tianjin Autosaiens Instrument Co., Ltd. AS2060B) Oscillation, on the one hand, removes air bubbles, and on the other hand, promotes further mixing of the two components;

[0033] S4. Spherical Fe with a particle size of 20nm 3 o 4 Nanoparticles (Aladdin Chemistry Co., Ltd.) are mixed with the PDMS mixture obtained in step S3 at a weight percentage of 10%; the mixing method is: after full...

Embodiment 2

[0037] Embodiment 2: Manufacturing method of magnetron biomimetic thin film microstructure with perpendicular anisotropy microstructure

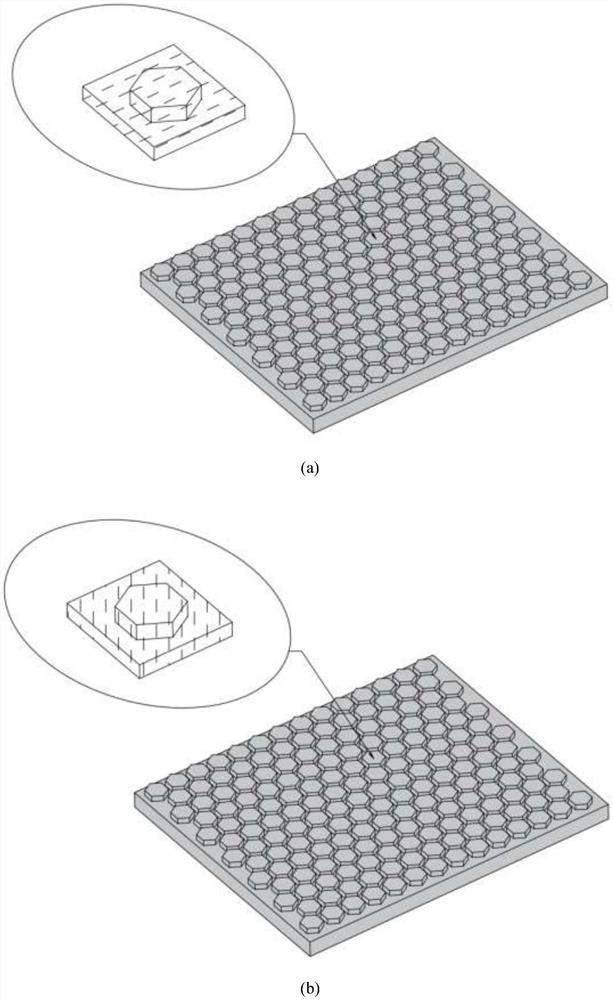

[0038] The difference between embodiment 2 and embodiment 1 is: in step S6, the applied magnetic field is perpendicular to the composite coating film surface ( figure 1 (b)), Fe under the action of magnetic field 3 o 4 The nanoparticles aggregated to form a columnar structure perpendicular to the surface of the film, making the composite coating film have a vertically anisotropic microstructure ( figure 2 Enlarged small picture in (b), obtain the magnetron biomimetic film microstructure with vertical anisotropic microstructure ( figure 2 (b)).

Embodiment 3

[0039] Embodiment 3: The manufacturing method of the magnetron biomimetic film microstructure with isotropic microstructure

[0040] The difference between embodiment 3 and embodiment 1 is that step S7 is directly executed after step S5 is completed, that is, no magnetic field is applied in the process of manufacturing the thin film microstructure, and a magnetron bionic with isotropic microstructure is obtained after step S7 is completed. Thin film microstructure ( figure 2 (c)), Fe 3 o 4 Nanoparticle aggregates are randomly distributed in the matrix ( figure 2 Enlarged small image in (c)).

[0041] PDMS-Fe 3 o 4 Mechanical characterization of composite films:

[0042] Under the action of a magnetic field, the Fe in the film 3 o 4 The magnetic particles tend to align along the direction of the magnetic field in the elastomeric PDMS, resulting in changes in the elastic modulus of the film, as well as the generation of magnetic stress and strain in the film. Microstr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com