Deformed elliptic gear speed change mechanism for paper transport transmission

A technology of deformed elliptical gear and speed change mechanism, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of different speed of the separation head, damage to the transmission structure, unstable paper feeding, etc., to achieve accurate paper delivery, The effect of reducing shock and vibration, reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

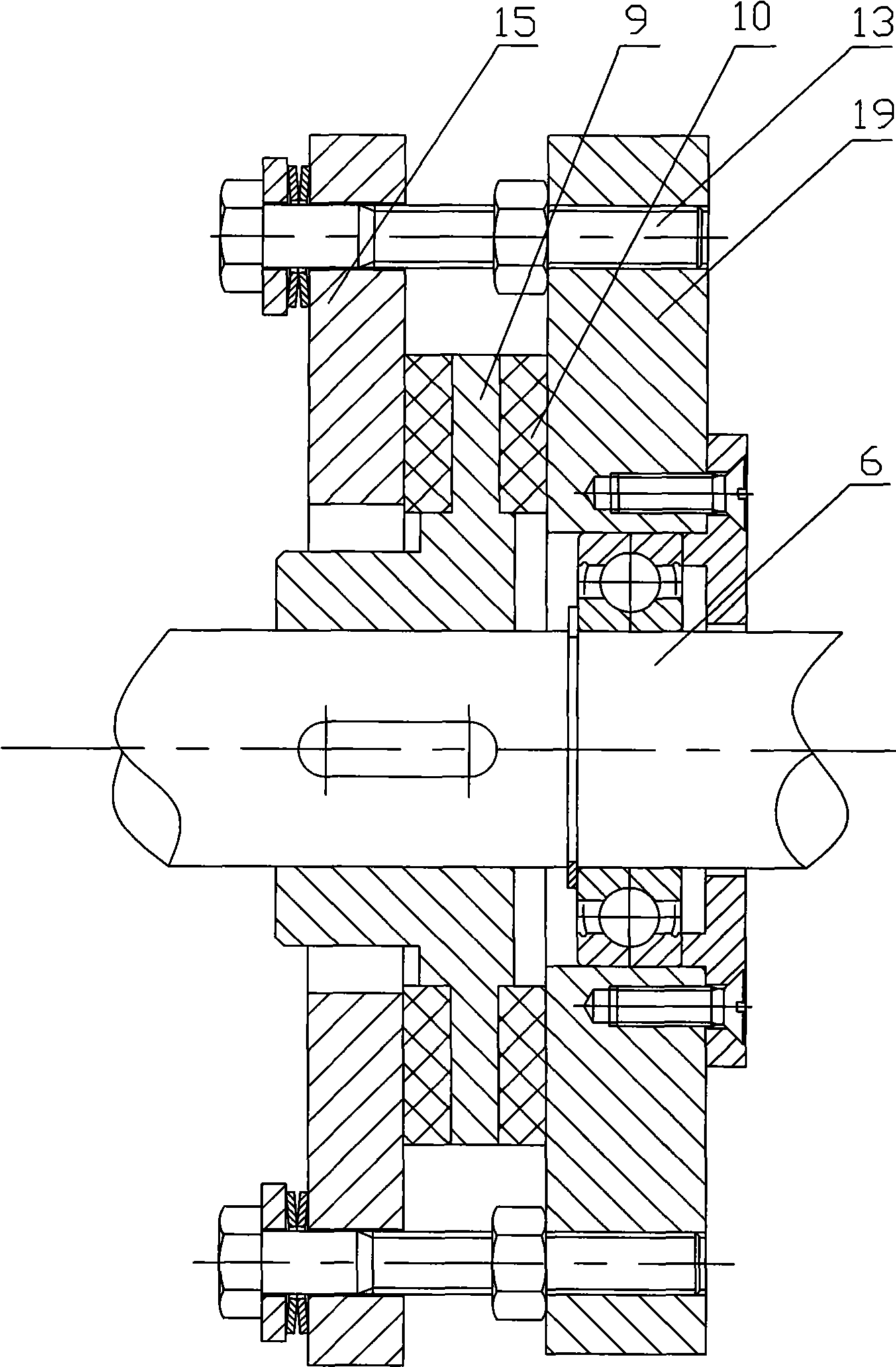

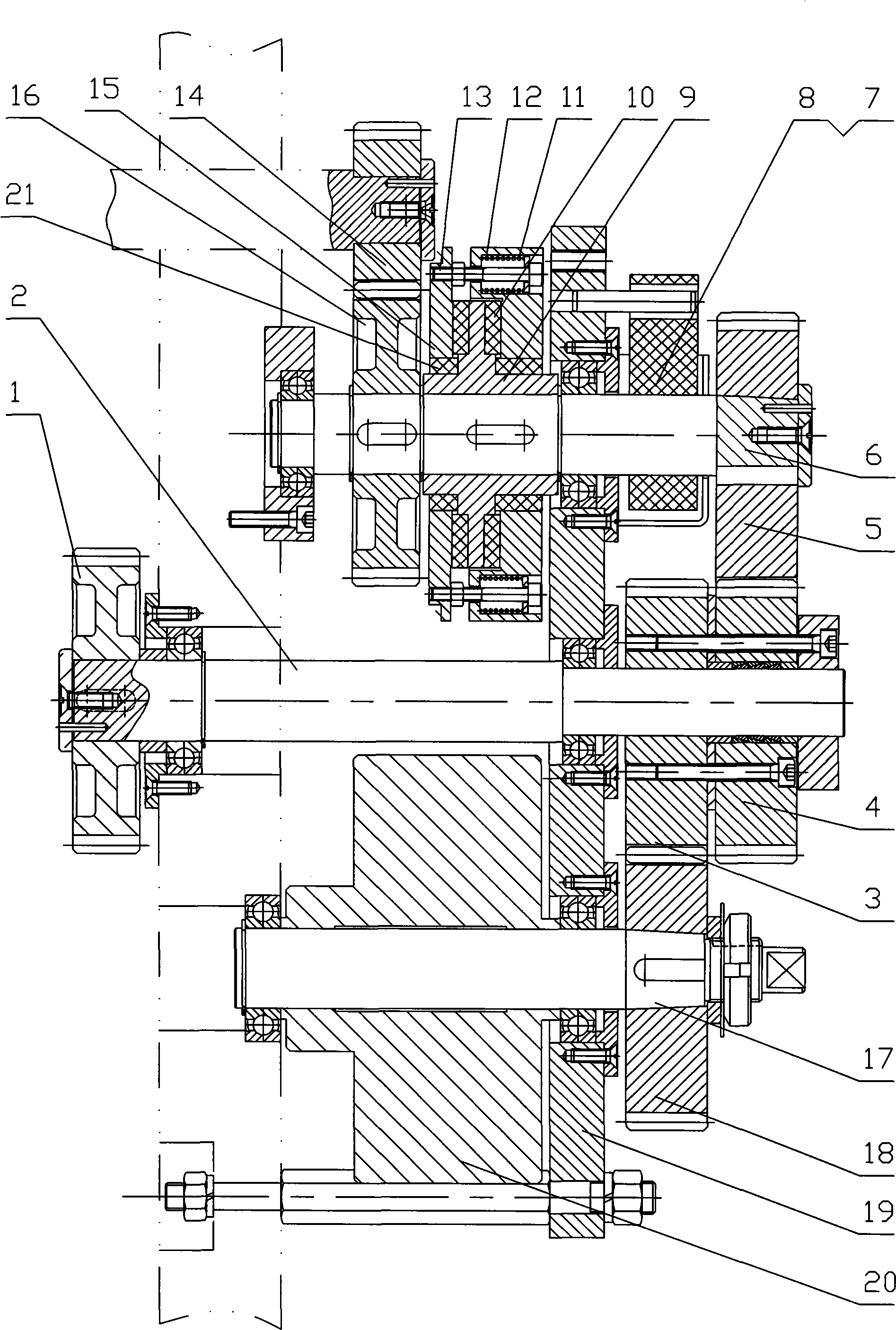

[0028] like figure 2As shown, the input gear 1, the third deformed oval gear 3 and the first deformed oval gear 4 are sequentially installed on the input shaft 2; the inertia flywheel 20 and the fourth deformed oval gear 18 are sequentially installed on the flywheel shaft 17; gear 16, power The damping disc 9, the half-piece damping blocks 7 and 8 arranged on the outer side of the box body 19 and the second deformed oval gear 5 are sequentially installed on the transmission shaft 6, and the sliding bearing 21 and the damping friction plate 10 are installed on the dynamic damping disc 9 and clamped. The disc 15 and the damping flywheel 12 are pressed on the damping friction plate 10 by the spring 11 and the bolt 13; the box 19 and the damping blocks 7 and 8 are provided with a pair of positioning positions that cooperate with each other and make the damping blocks 7 and 8 circumferentially positioned. Pins and positioning holes, damping blocks 7 and 8 are composed of two first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com