Telescopic transmission shaft

A technology of drive shaft and telescopic shaft, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve the problems that the pick-and-place mechanism cannot pick and place low-chassis vehicles, the underground garage is inconvenient, and the car is taken out, and the structure is simple. Simplification, increased reliability, and good synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

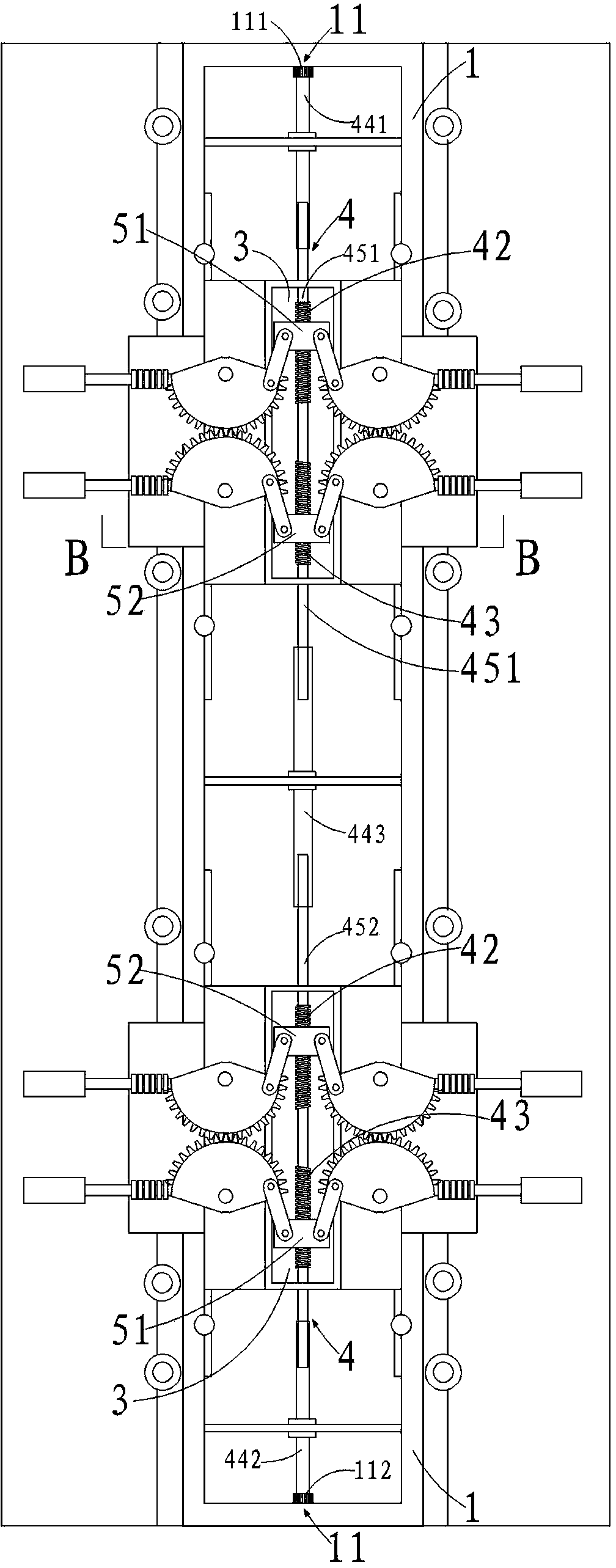

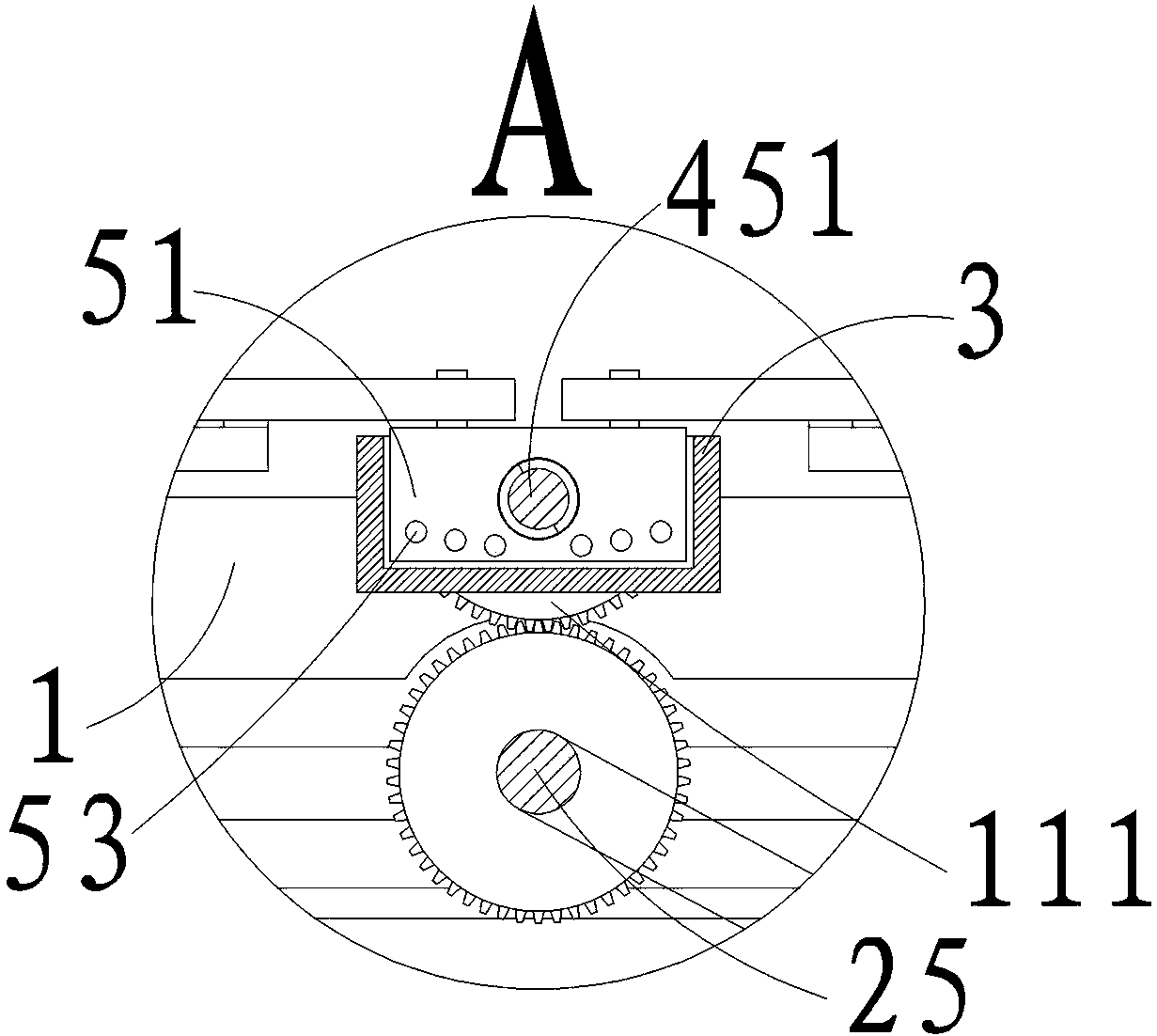

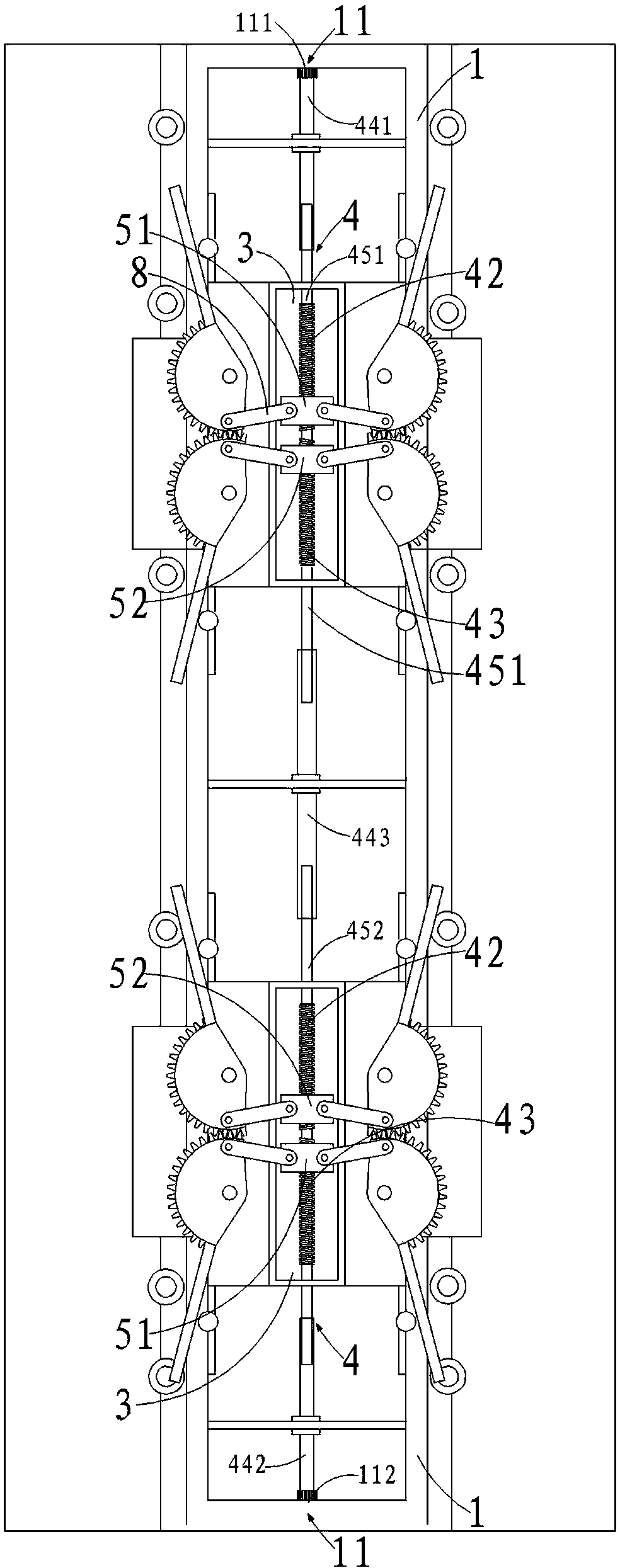

[0021] See attached Figures 1 to 5 , a telescopic transmission shaft in this embodiment includes an upper ring beam 1 and a telescopic shaft 4 that runs through the left and right ends of the upper ring beam 1. The telescopic shaft 4 sequentially includes: a first end gear 111, a first shaft sleeve 441, A threaded screw 451, a series shaft sleeve 443, a second screw 452, a second shaft sleeve 442, and a second end gear 112, the first end gear 111 is fixedly connected with the first shaft sleeve 441, and the second shaft The sleeve 442 is fixedly connected with the second end gear 112, the first shaft sleeve 441 is inserted into the first lead screw 451, and the first lead screw 451 and the second lead screw 452 are inserted into the two ends of the serial shaft sleeve 443 respectively. Then, the serial bushing 443 is fixedly arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com