Patents

Literature

134results about How to "Reduce speed fluctuations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

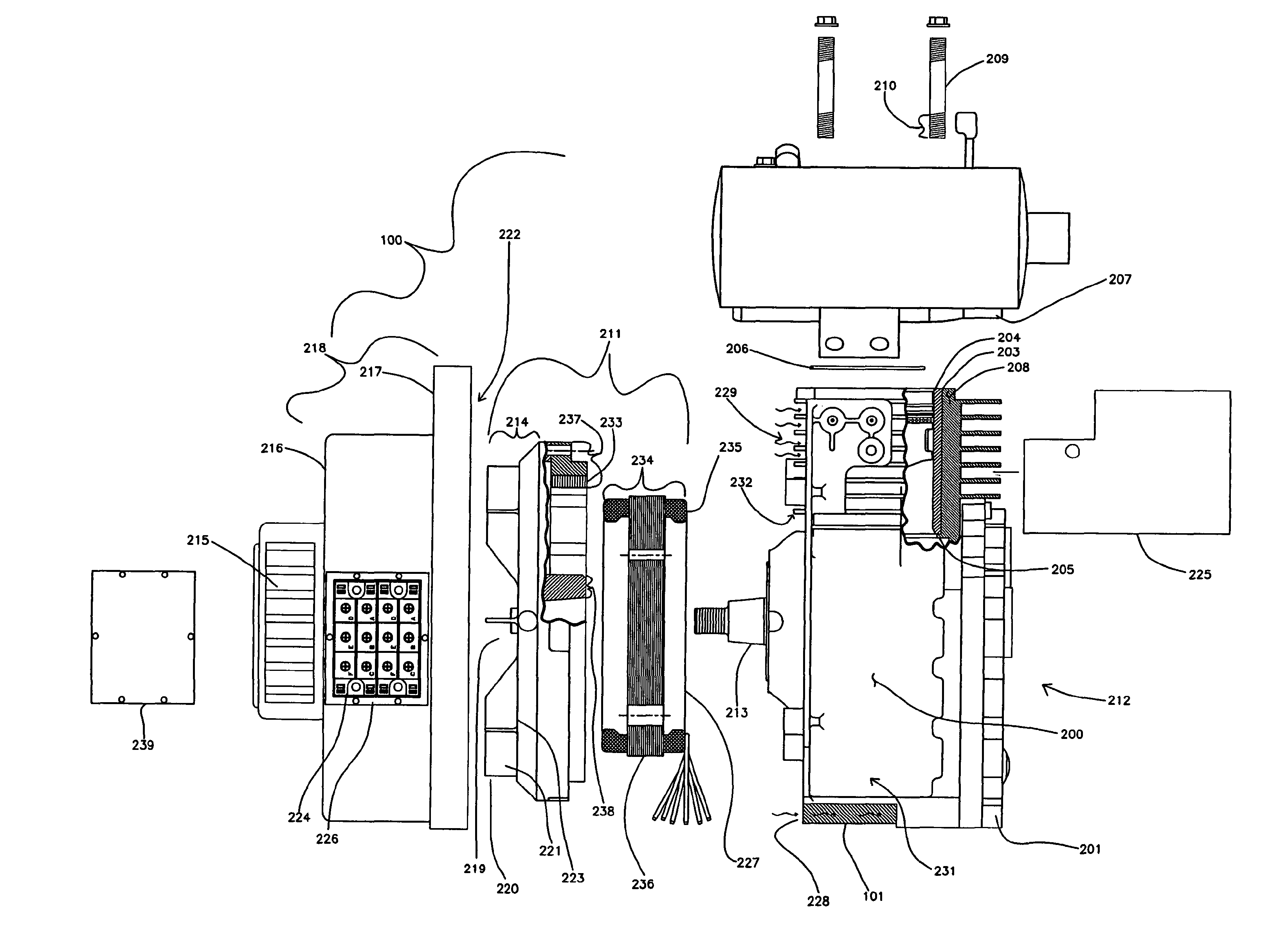

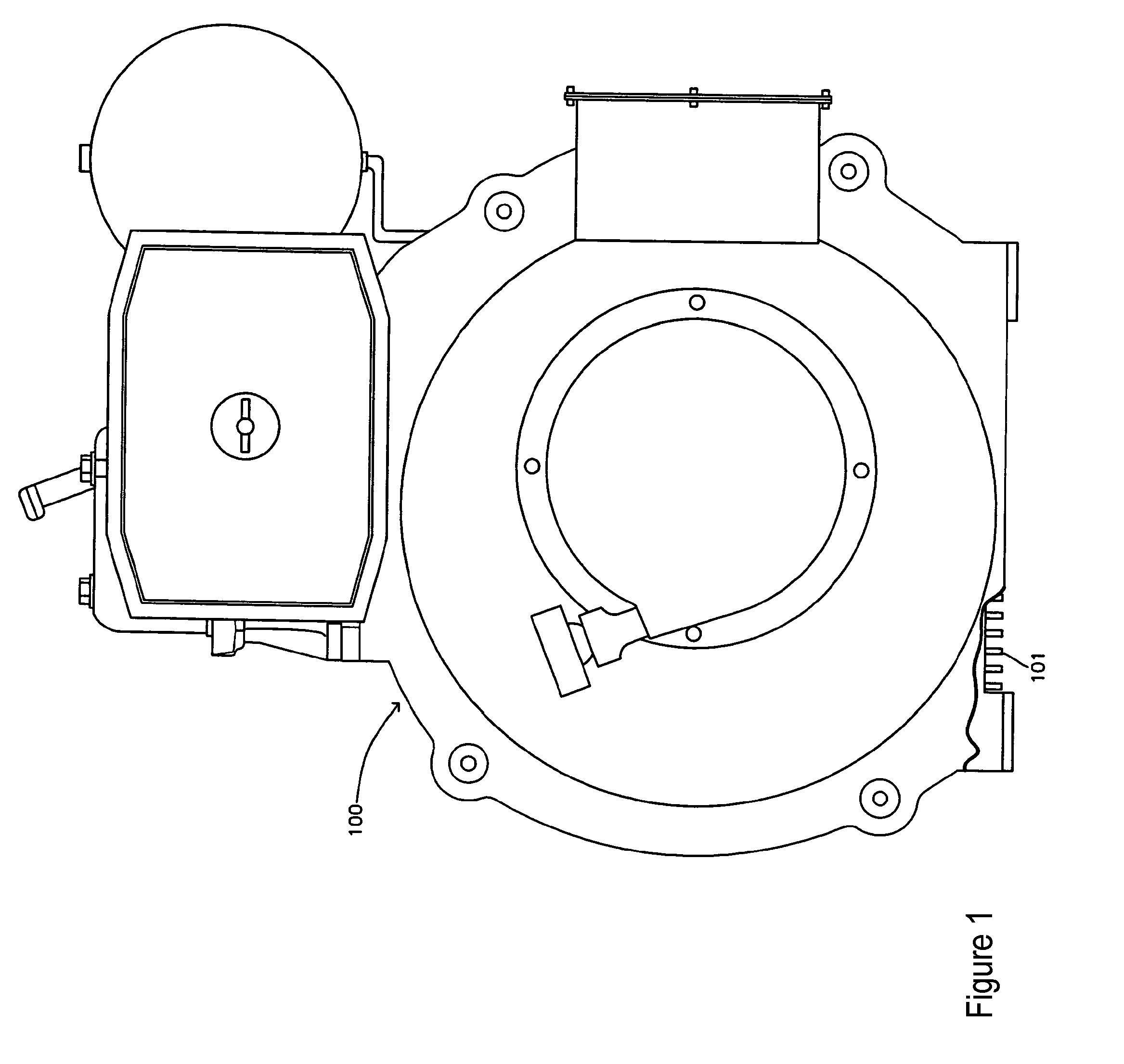

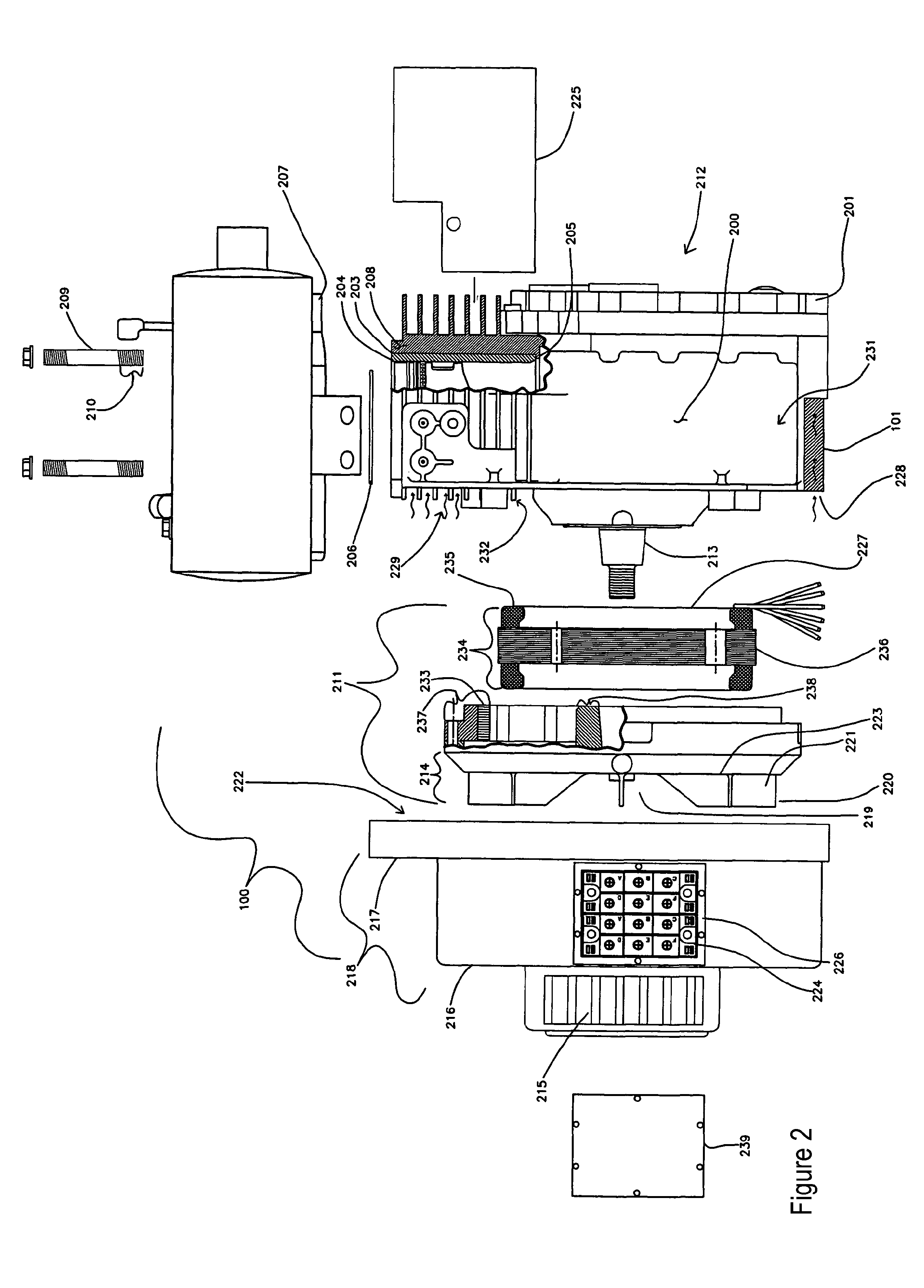

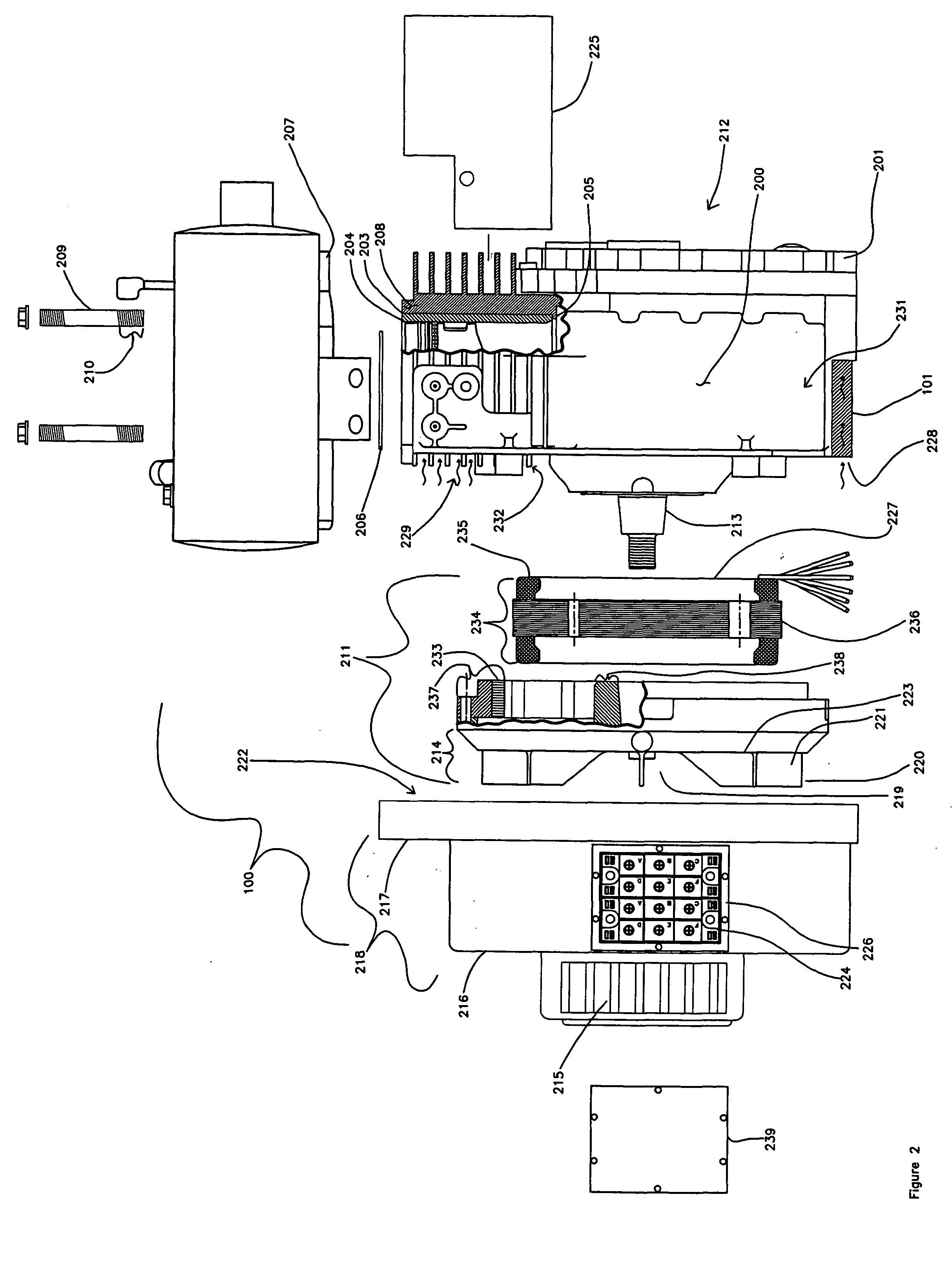

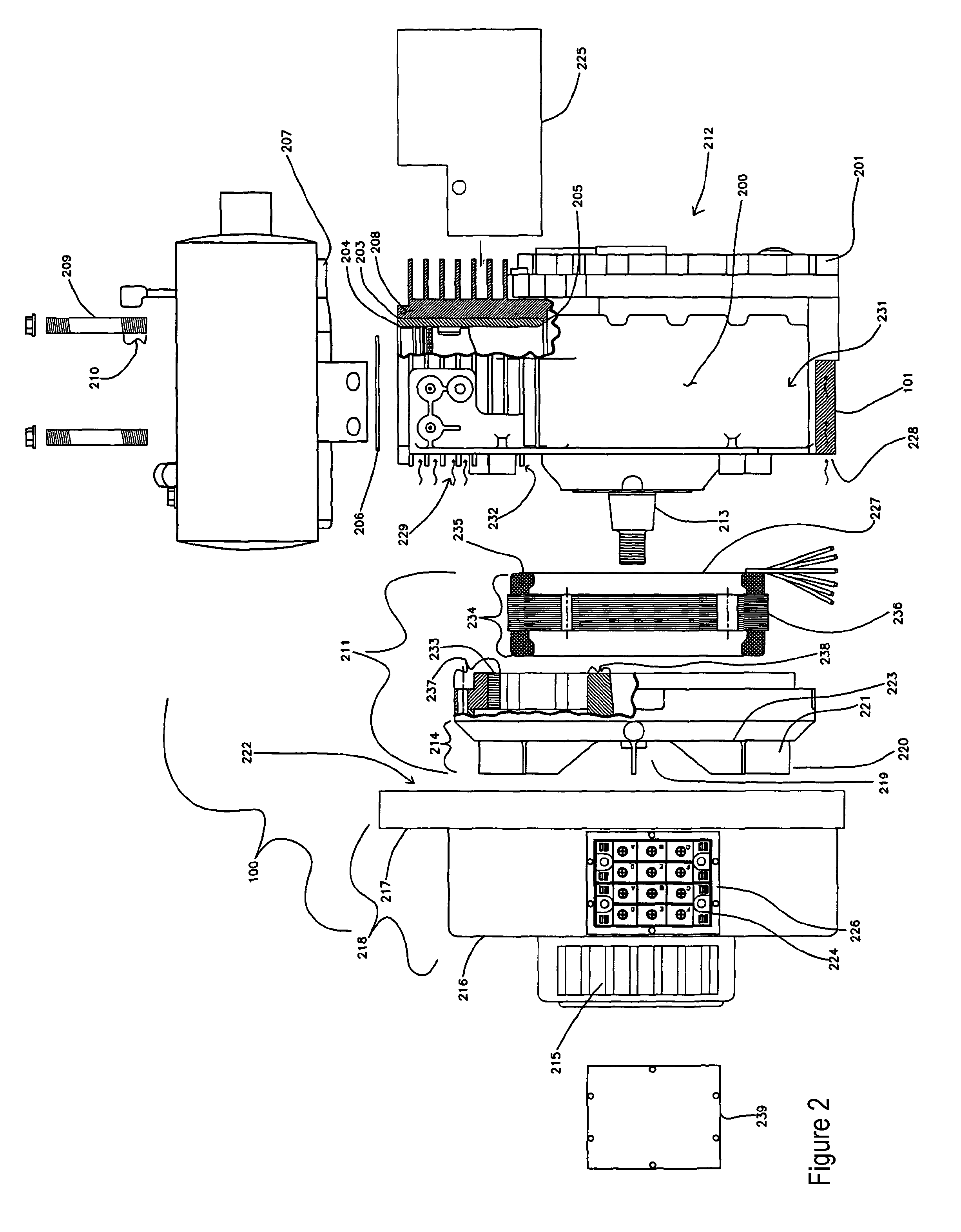

Lightweight Portable Electric Generator with Integrated Starter/Alternator

ActiveUS20070227470A1Improve torque performanceLow costMagnetic circuit rotating partsAir coolingAlternatorFuel efficiency

A compact and lightweight electric generator for portable power applications employs a new engine design and integration approach for reducing engine, generator, and starter weight. A unique flywheel alternator / starter configuration that generates electrical power, rotates the engine for starting, provides inertia for smooth engine operation, pressurized air for cooling, and inertia for the alternator. An engine cowling provides rotating component protection, a fan shroud mechanism, cooling air ducts, and a cooling mechanism for handling large quantities of heat produced by rectified power conversion. An electrical hook up that allows the generator to provide transient surge capacity for starting inductive loads, or improved load leveling and fuel efficiency.

Owner:MAINSTREAM ENG

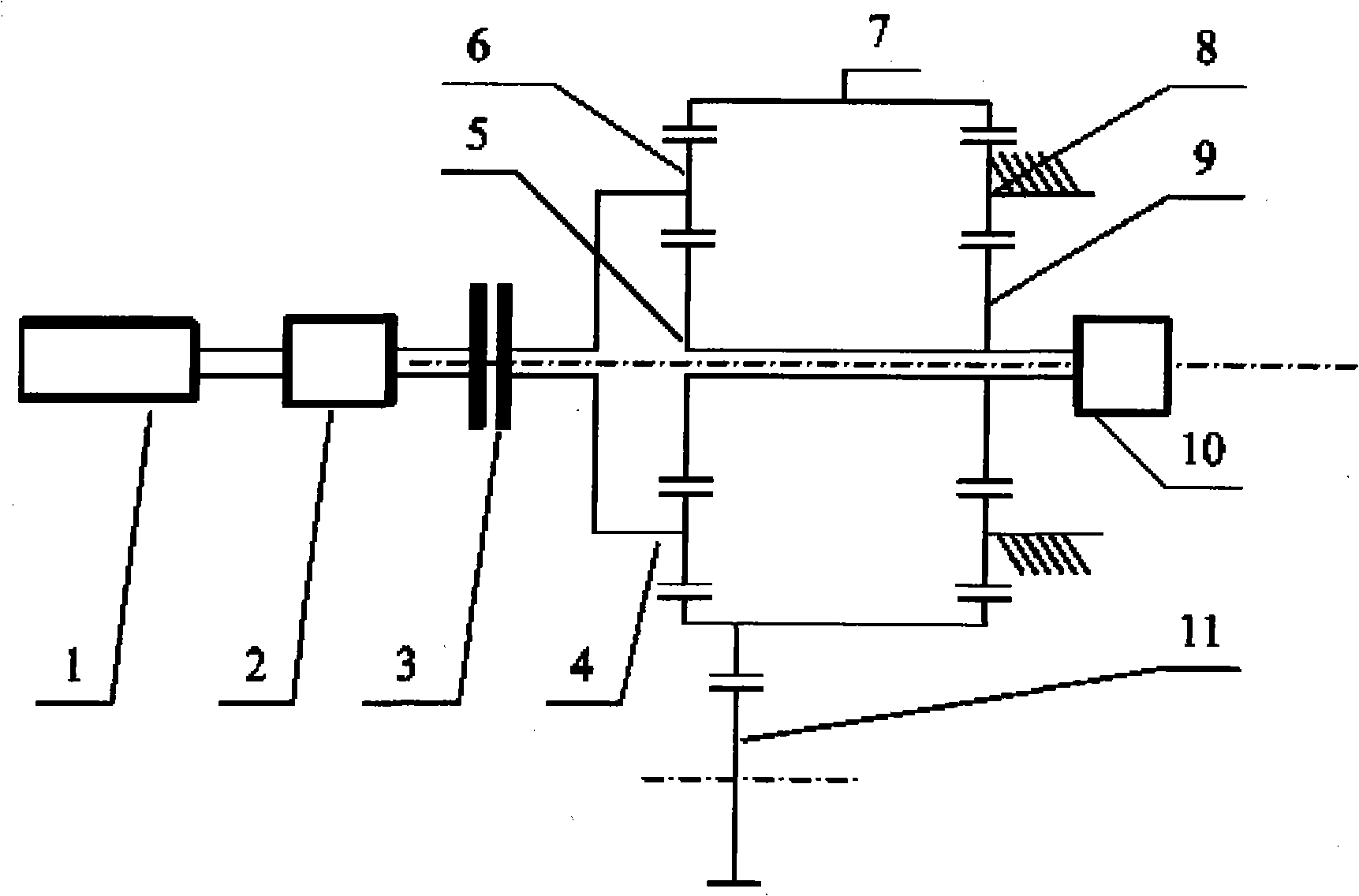

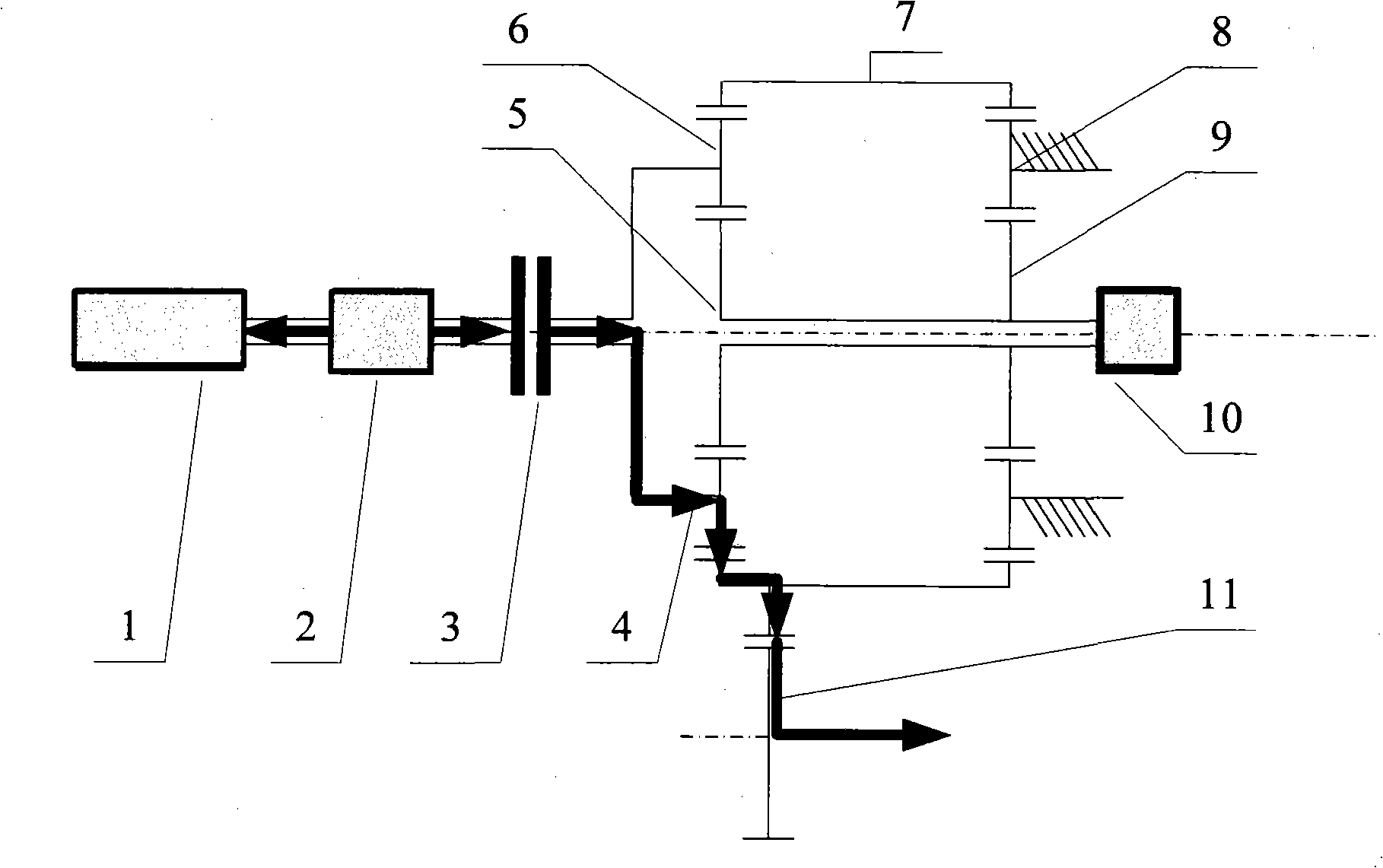

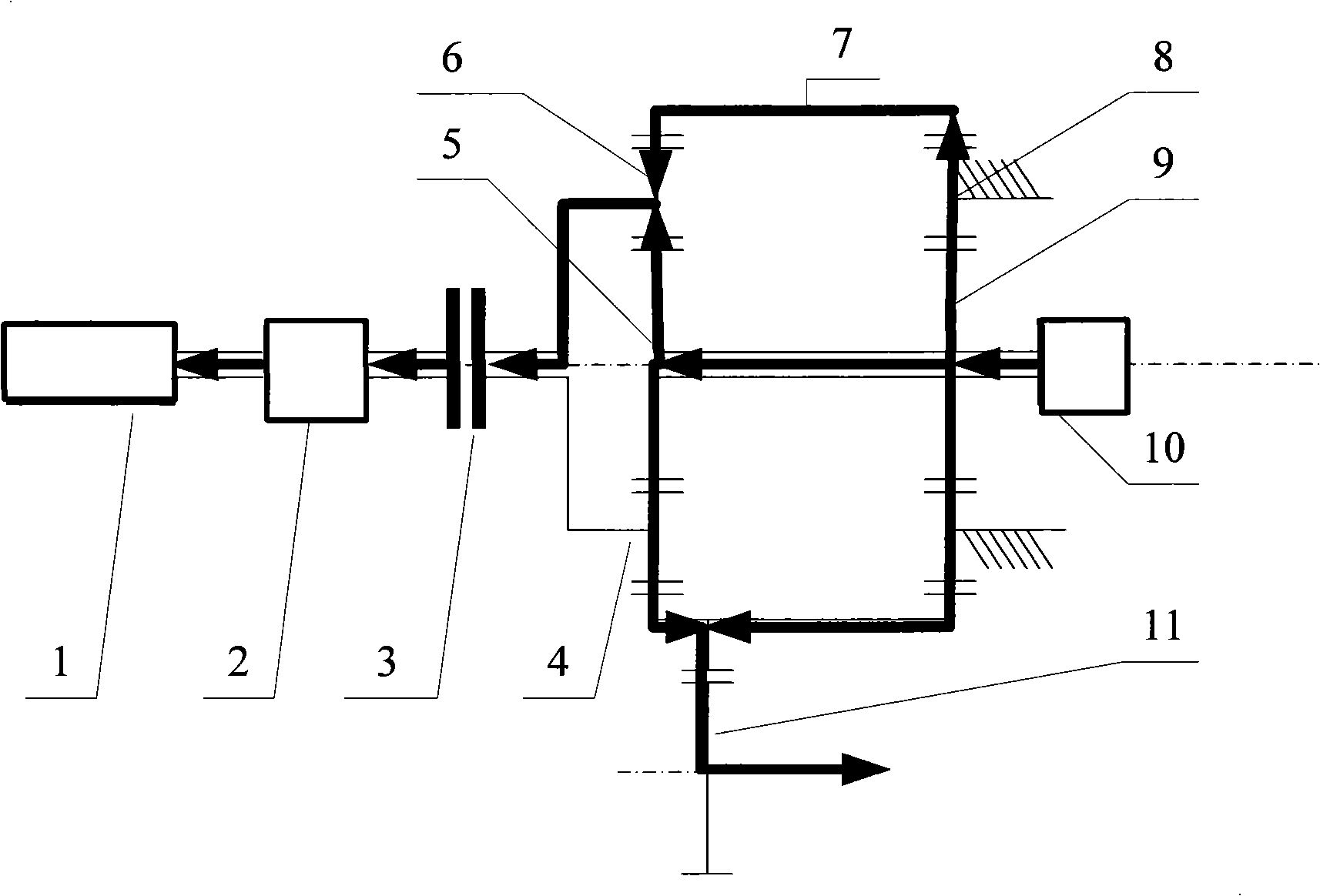

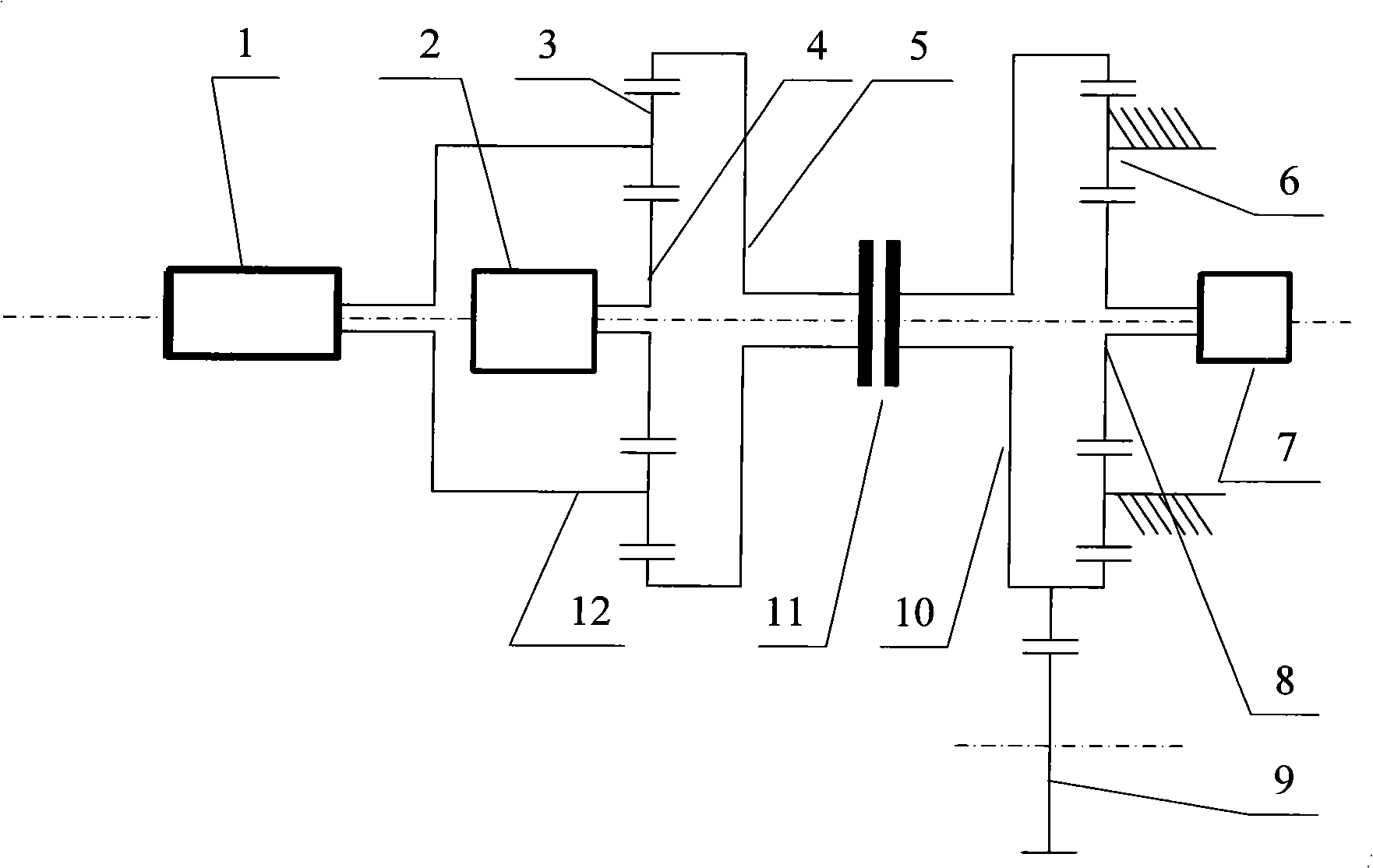

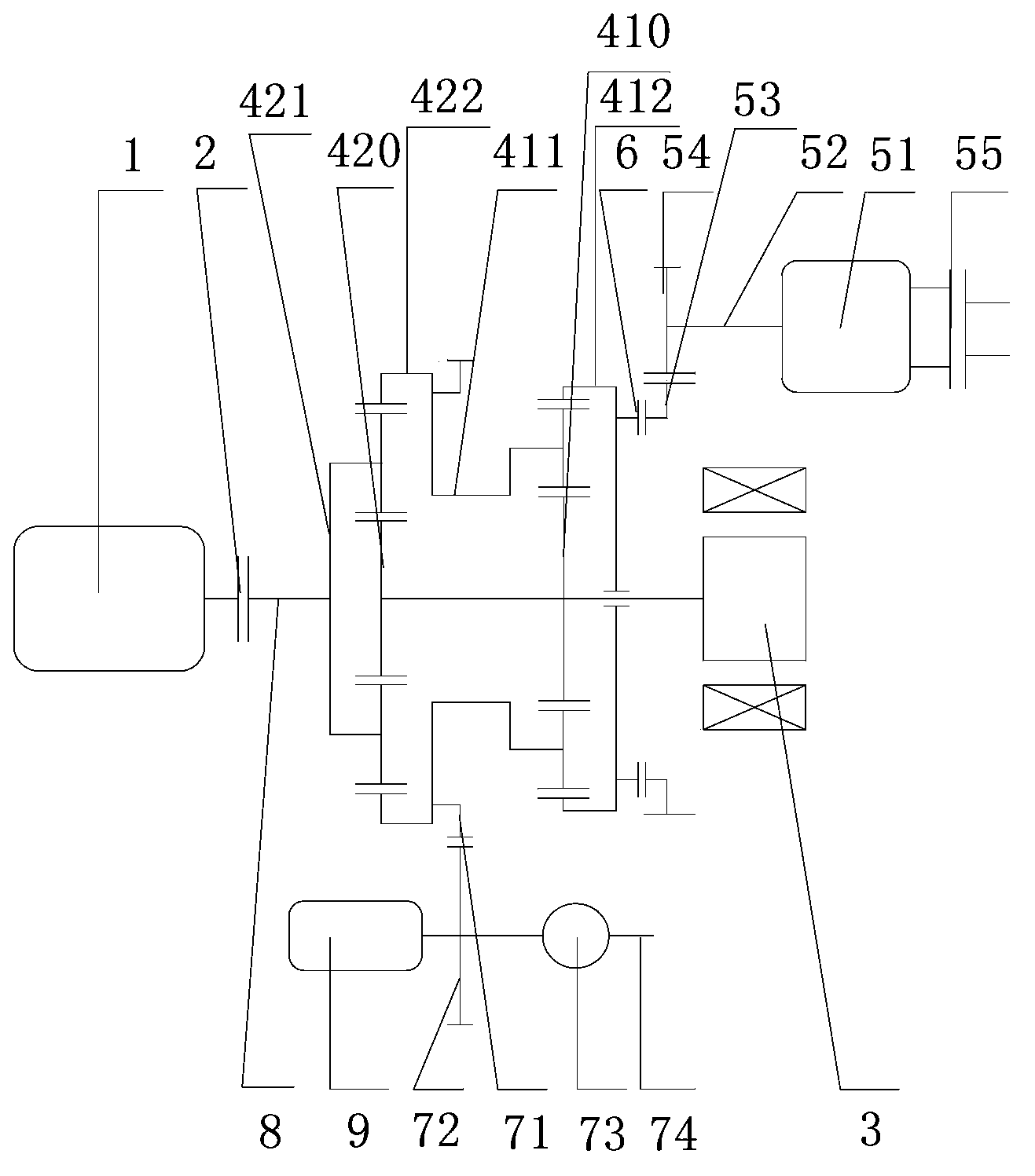

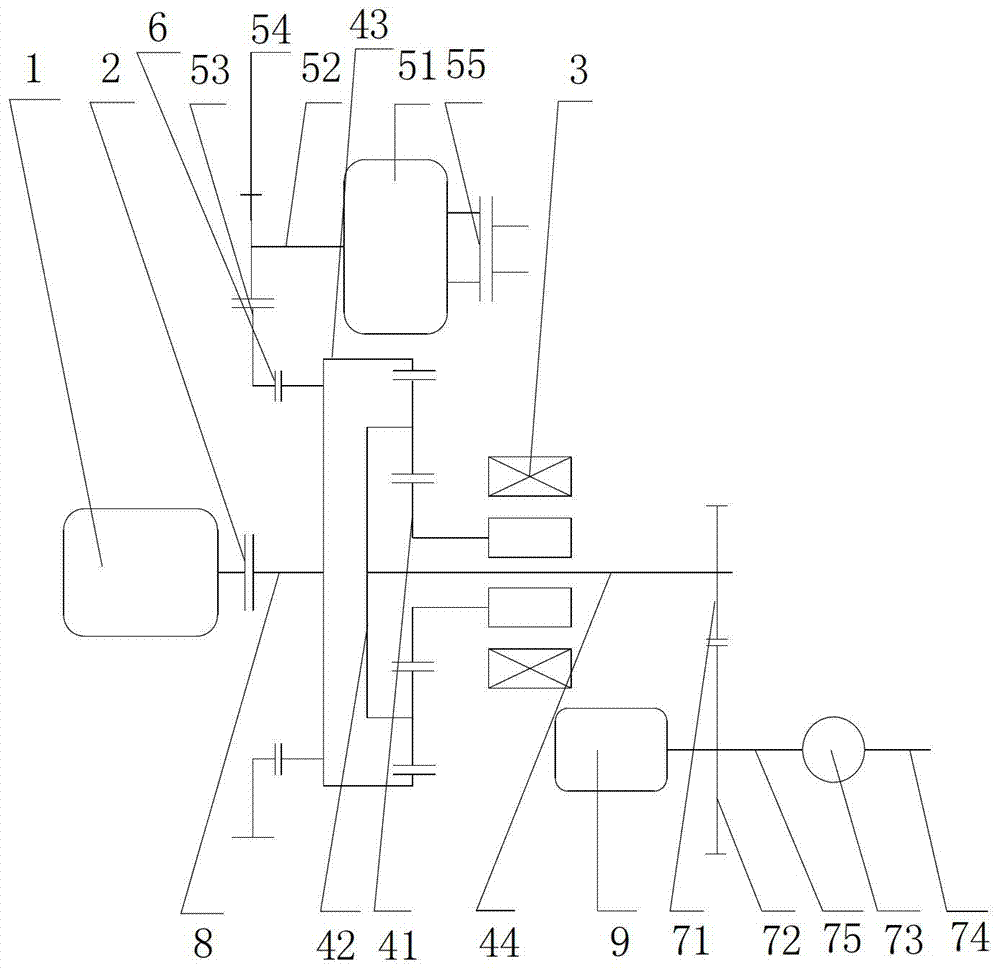

Hybrid power vehicle double electric machine double row planetary gear single clutch drive apparatus

InactiveCN101323243ALower requirementIncrease profitHybrid vehiclesGas pressure propulsion mountingStarter generatorVehicle frame

The invention discloses a twin-motor two-planet-row and single clutch driving device of a hybrid vehicle in the technical field of machinery. The device is provided with a front planet row and a back planet row; the front planet row is provided with a front planet row planet wheel and a front planet row sun gear; the back planet row is provided with a back planet row planet wheel and a back planet row sun gear; the front planet row and the back planet row share a gear ring. The output shaft of an engine is connected with the input end of an integrated starter generator; the output end of the integrated starter generator is connected with the driving disk of the clutch; the driven disk of the clutch is connected with the planet wheel of the front planet row through a planet carrier; the sun gear of the front planet row is connected with a drive motor; the planet carrier of the planet wheel of the back planet row is arranged fixedly on a car frame; the sun gear of the back planet row is also connected with the drive motor; the outside gear of the gear ring is normally engaged with a power take-off gear. The twin-motor two-planet-row and single clutch driving device of the hybrid vehicle has the advantages of compact structure, large transmission ratio, large load support capability, stable driving, and high transmission efficiency, thereby realizing power dividing and infinite variable speed at the same time.

Owner:SHANGHAI JIAO TONG UNIV

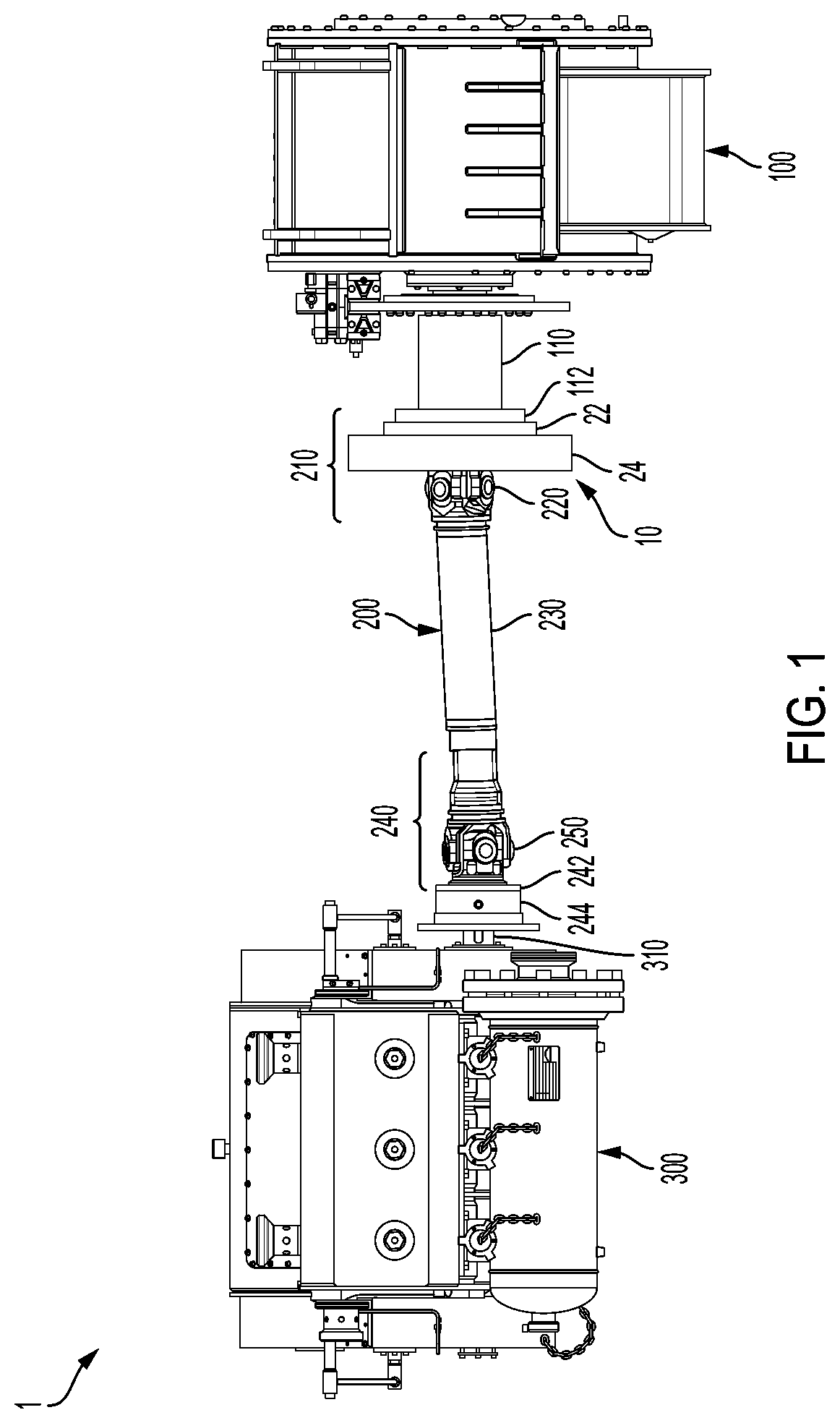

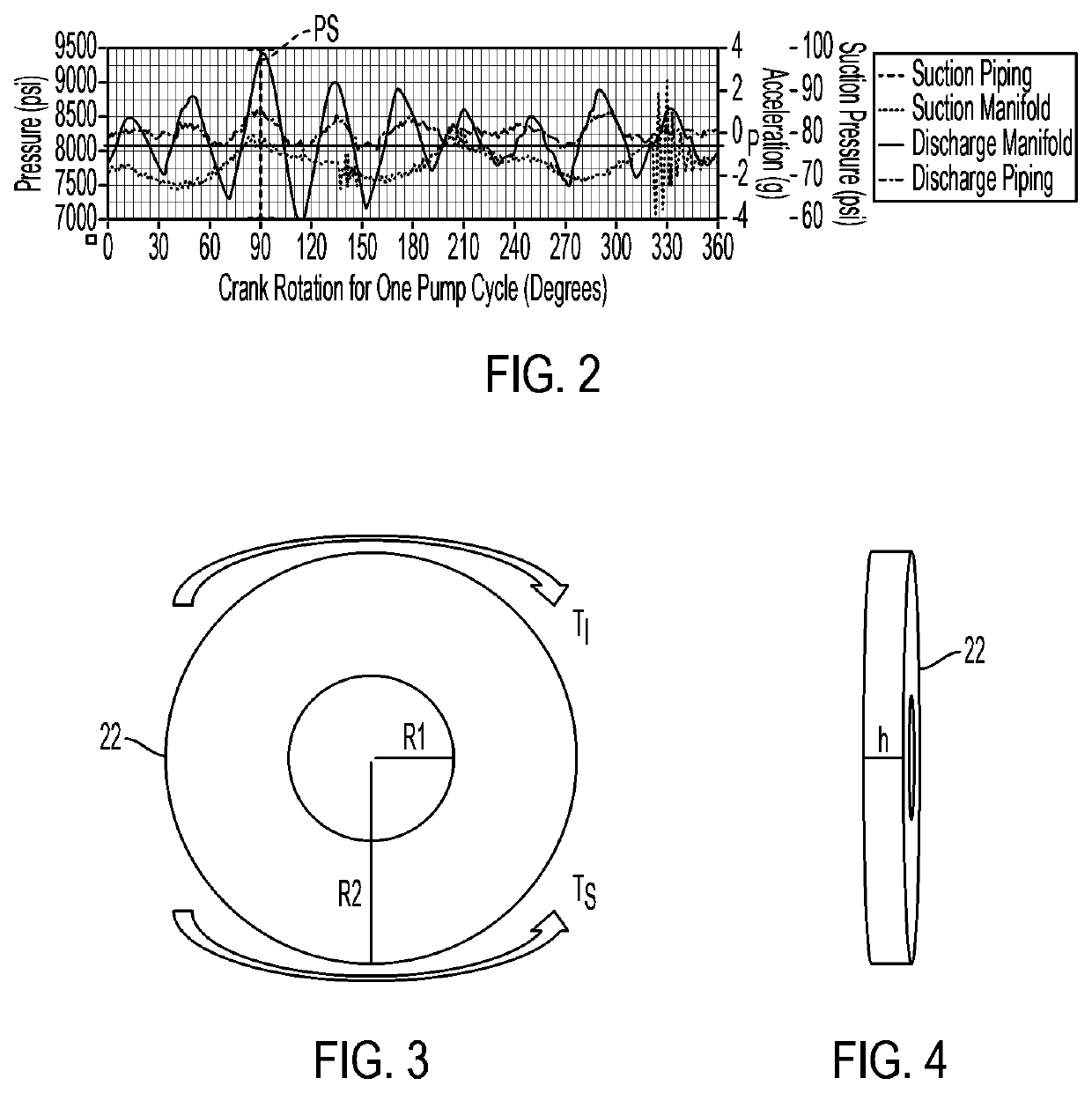

Systems and method for use of single mass flywheel alongside torsional vibration damper assembly for single acting reciprocating pump

ActiveUS11015594B2Reduce and eliminate shock loadingDampen torsional resonanceRotating vibration suppressionSpringsRotary pumpClassical mechanics

A pump system may include a pump, a driveshaft, driving equipment, and a vibration dampening assembly configured to reduce pump-imposed high frequency / low amplitude and low frequency / high amplitude torsional vibrations. The pump may have an input shaft connected to the driveshaft. The driving equipment may include an output shaft having an output flange connected to the driveshaft. The driving equipment may be configured to rotate the driveshaft to rotate the input shaft of the pump therewith. The vibration dampening assembly may include one or more flywheels operably connected to the input shaft and configured to rotate therewith.

Owner:BJ ENERGY SOLUTIONS LLC

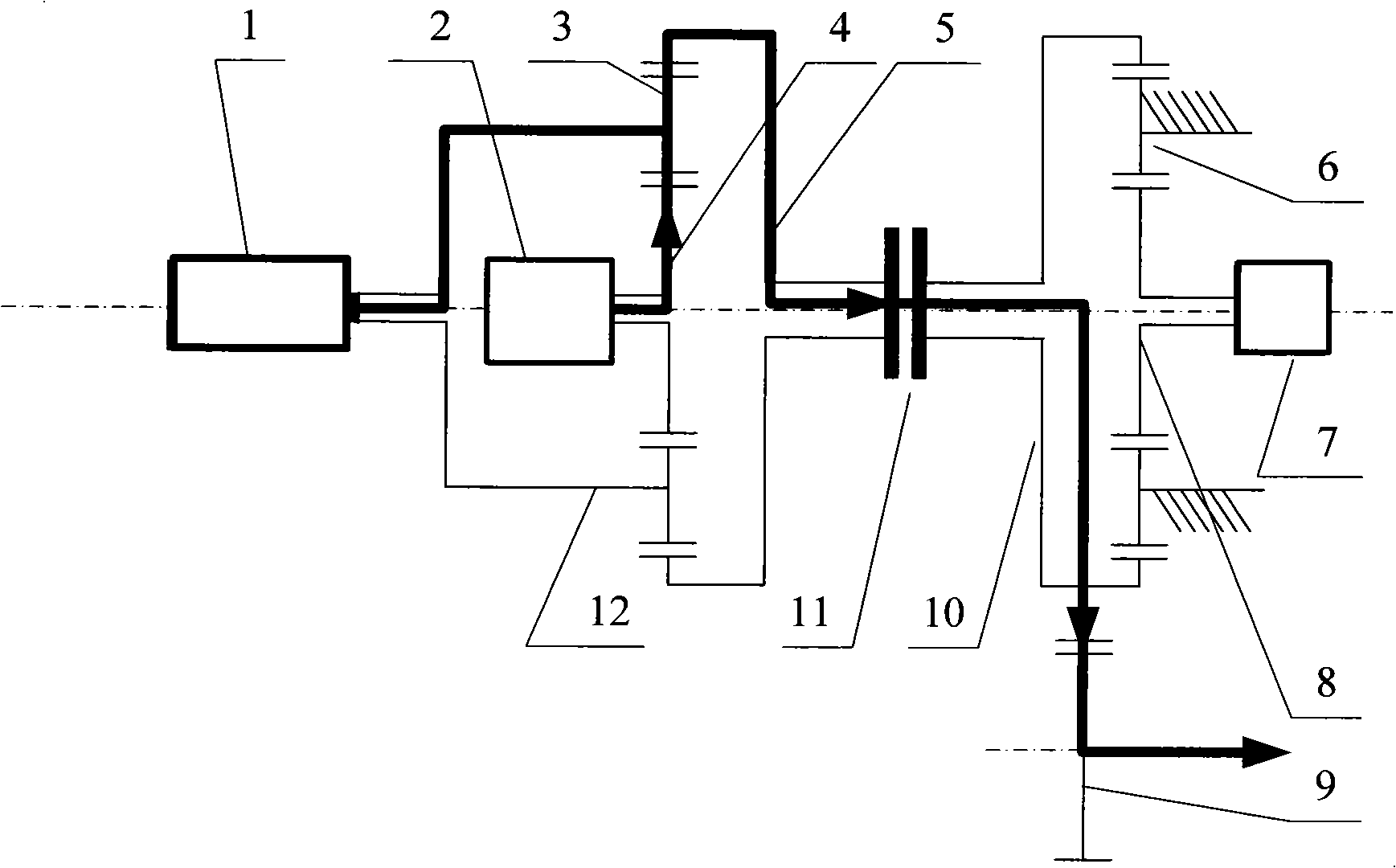

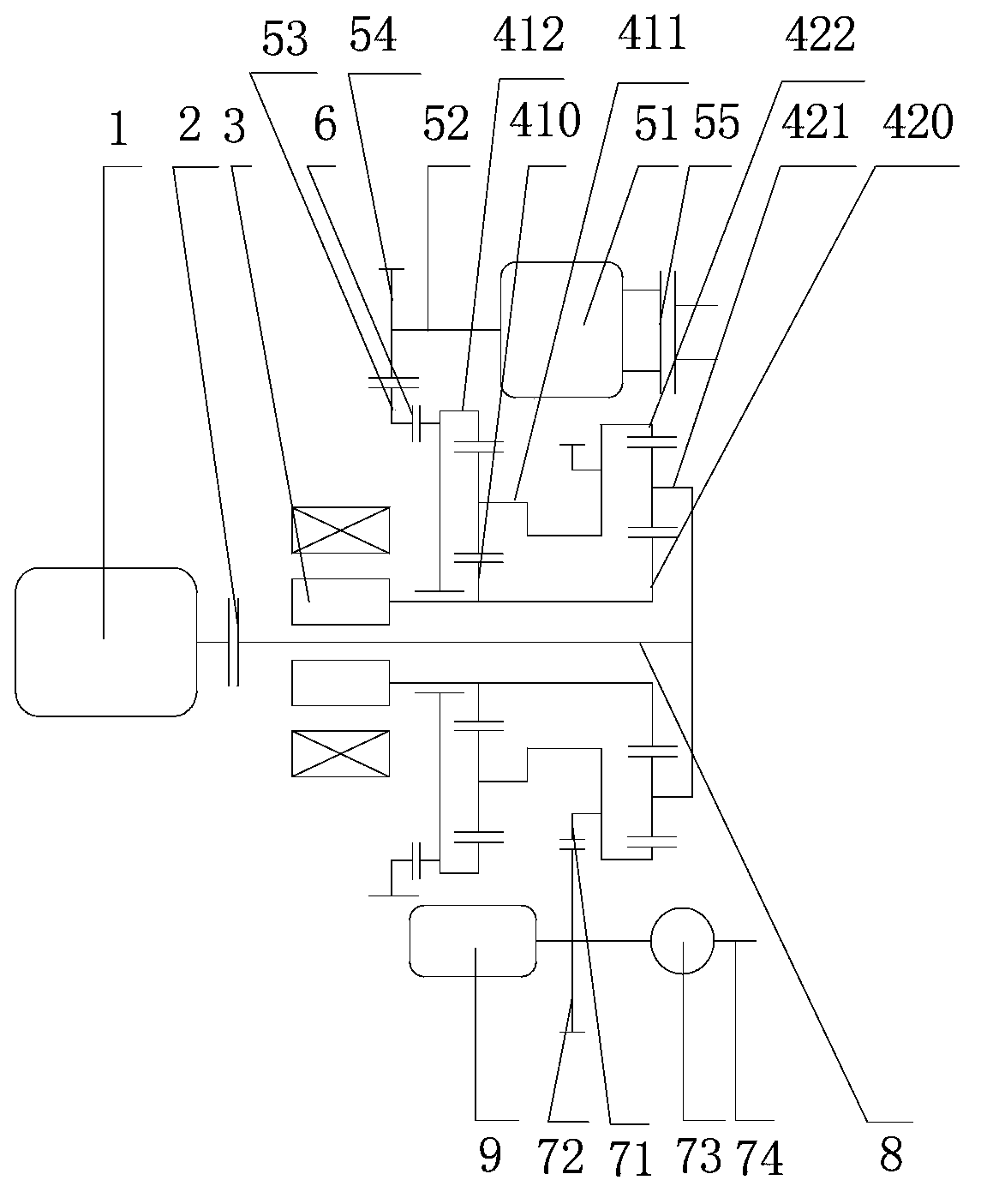

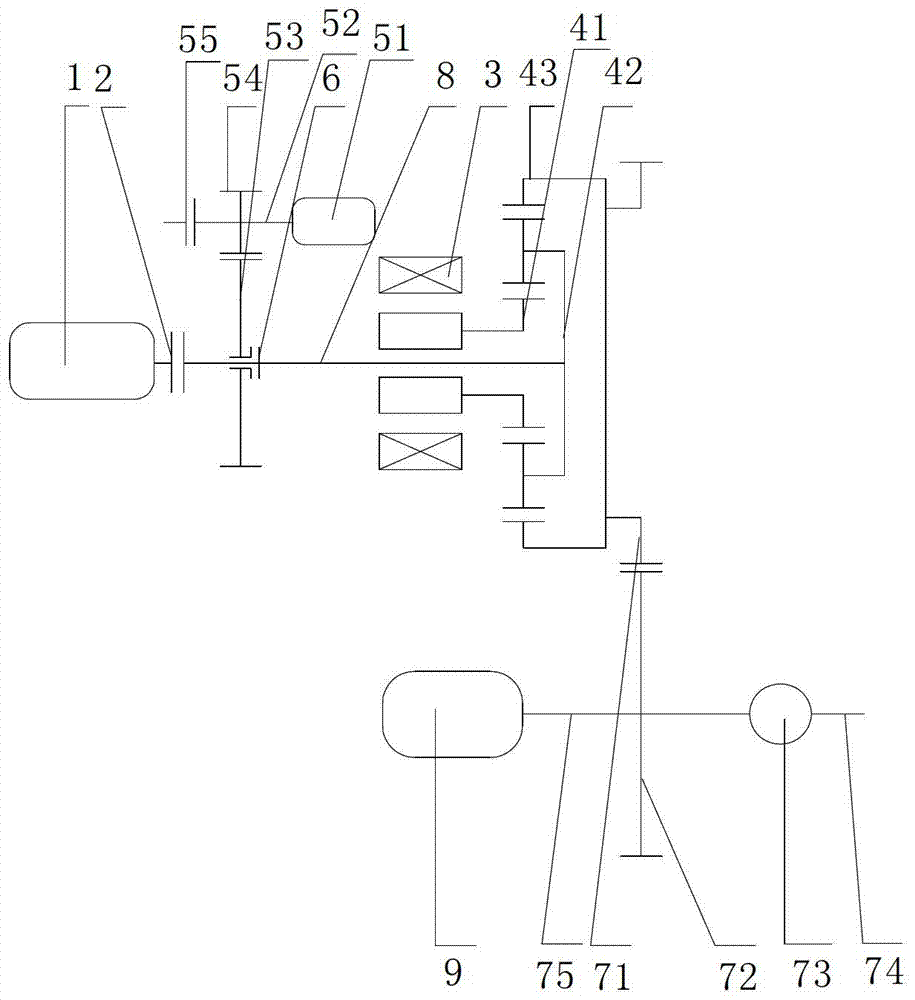

Hybrid power vehicle double row planetary gear electromechanical coupling driving mechanism

InactiveCN101323242AEasy to control independentlyLower requirementHybrid vehiclesGas pressure propulsion mountingVehicle frameGear wheel

The invention discloses a two-planet-row electromechanical coupling driving device of a hybrid vehicle in the technical field of machinery. The device is provided with a front planet row and a back planet row; each of the two planet rows is provided with a planet wheel, a sun gear and a row gear ring; the two planet row gear rings are connected with each other by a clutch. An engine is connected with the planet wheel of the front planet row; an ISG motor is connected with the sun gear of the front planet row; the gear ring of the front planet row is connected with the driving disk of the clutch; the driven disk of the clutch is connected with the gear ring of the back planet row; the planet carrier of the planet wheel of the back planet row is arranged fixedly on a car frame; the sun gear of the back planet row is connected with a drive motor; the outside gear of the gear ring of the back planet row is normally engaged with a power take-off gear. The two-planet-row electromechanical coupling driving device of the hybrid vehicle has the advantages of compact structure, large transmission ratio, large load support capability, stable driving, and high transmission efficiency, thereby realizing power dividing and infinite variable speed at the same time.

Owner:SHANGHAI JIAO TONG UNIV

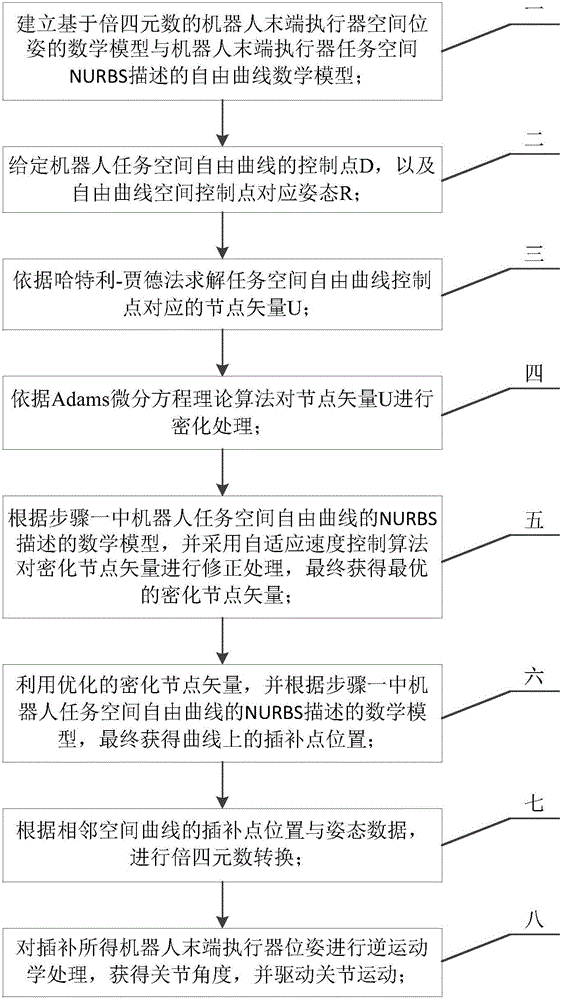

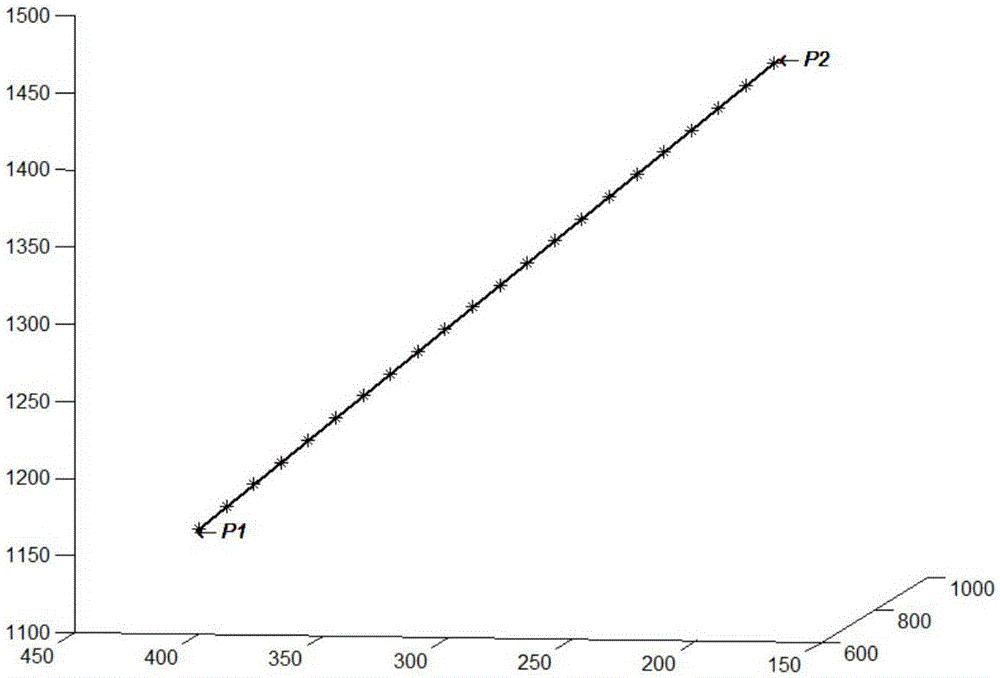

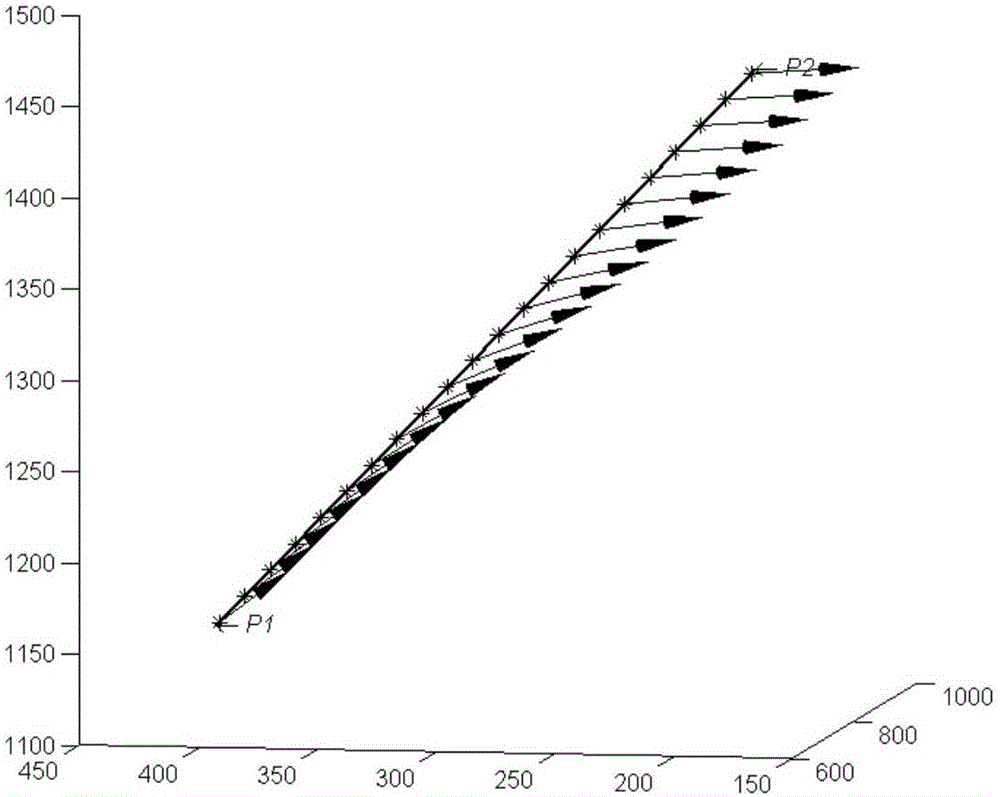

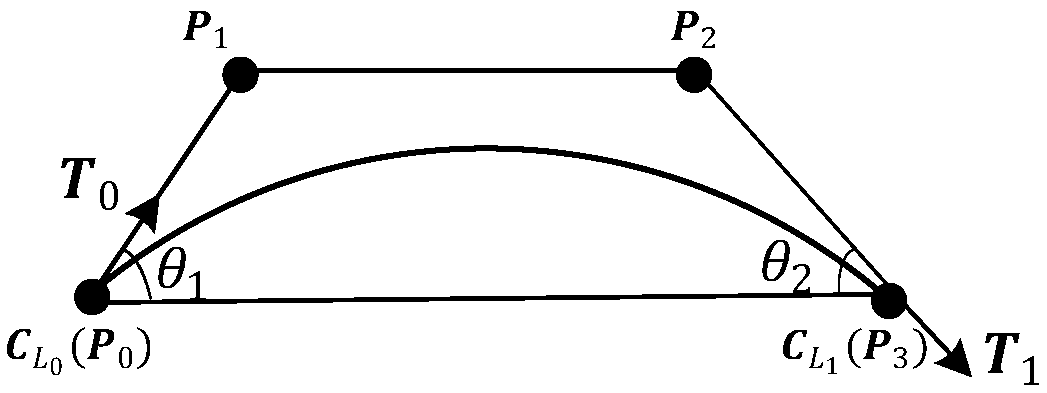

Track planning and control method of free curve of industrial robot based on double quaternions

InactiveCN105773620AImprove work efficiencyImprove the quality of workProgramme-controlled manipulatorQuaternionRobot position

The invention discloses a track planning and control method of a free curve of an industrial robot based on double quaternions. Control point data of the Cartesian space are adopted for describing the contour of the space free curve, and meanwhile an Adams differential equation is adopted for NURBS interpolation compacting calculation, and interpolation speed is adjusted in a self-adaption manner with the maximum contour error and maximum acceleration as constraint conditions; and then the position and posture of the robot in the Cartesian space are converted to a four-dimensional space through a short linear segment obtained through interpolation by adopting the double quaternions, the motion trail of the robot is subjected to spherical linear interpolation through hyperspherical rotation, and finally the track of the NURBS free curve of the industrial robot is planned.

Owner:NANJING INST OF TECH

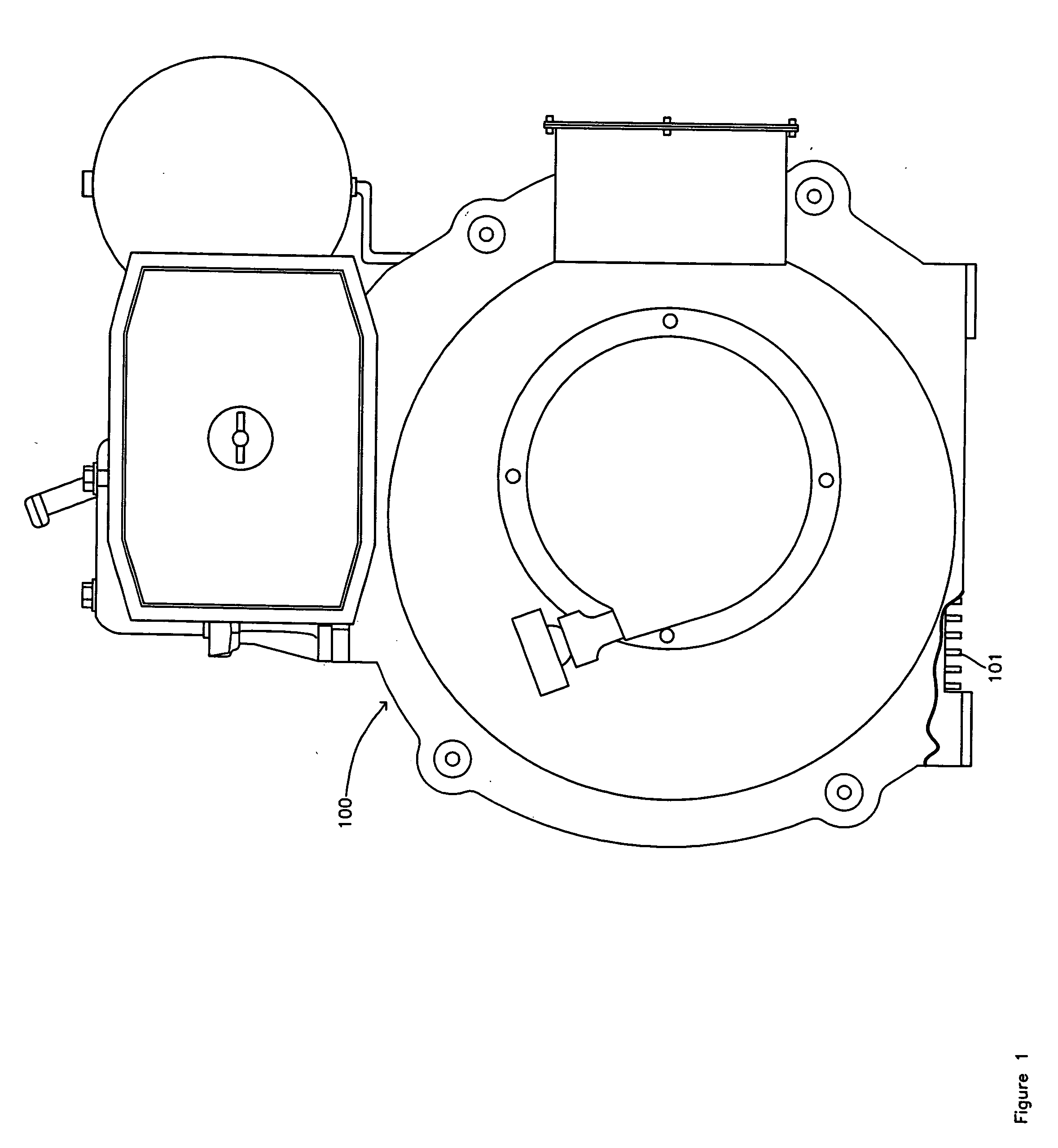

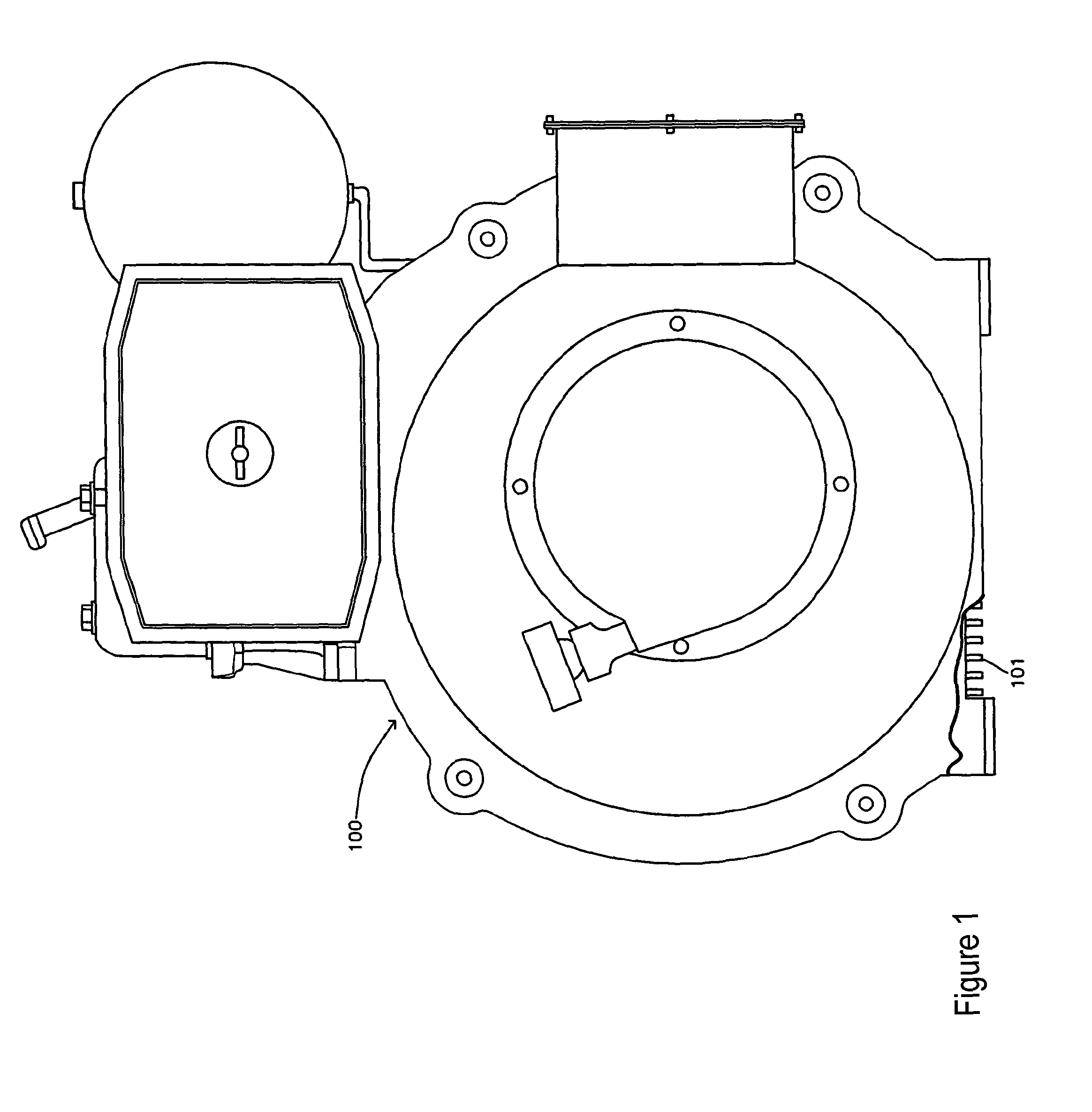

Lightweight portable electric generator

InactiveUS20050046191A1Eliminate excessive componentReduce weightMagnetic circuit rotating partsAir coolingAlternatorPortable power

A compact and lightweight electric generator for portable power applications employs a new engine design and integration approach for reducing engine and generator weight. A unique flywheel alternator generates electrical power and provides inertia for the engine, pressurized air for cooling, and inertia for the alternator. An engine cowling provides rotating component protection, a fan shroud mechanism, cooling air ducts, and a cooling mechanism for handling large quantities of heat produced by rectified power conversion.

Owner:MAINSTREAM ENG

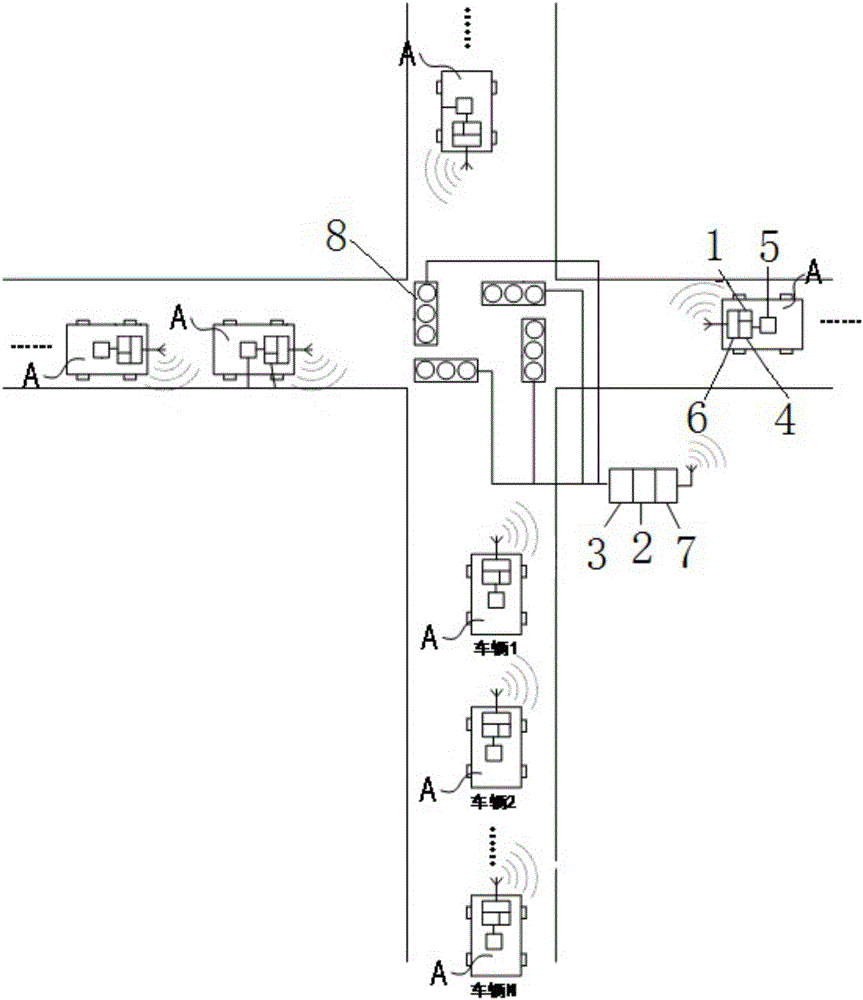

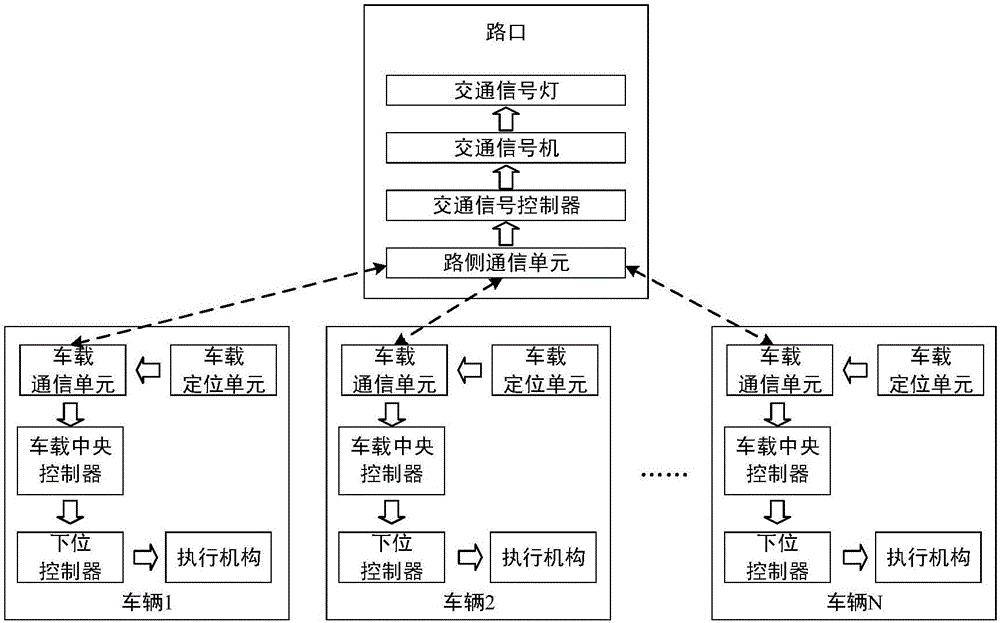

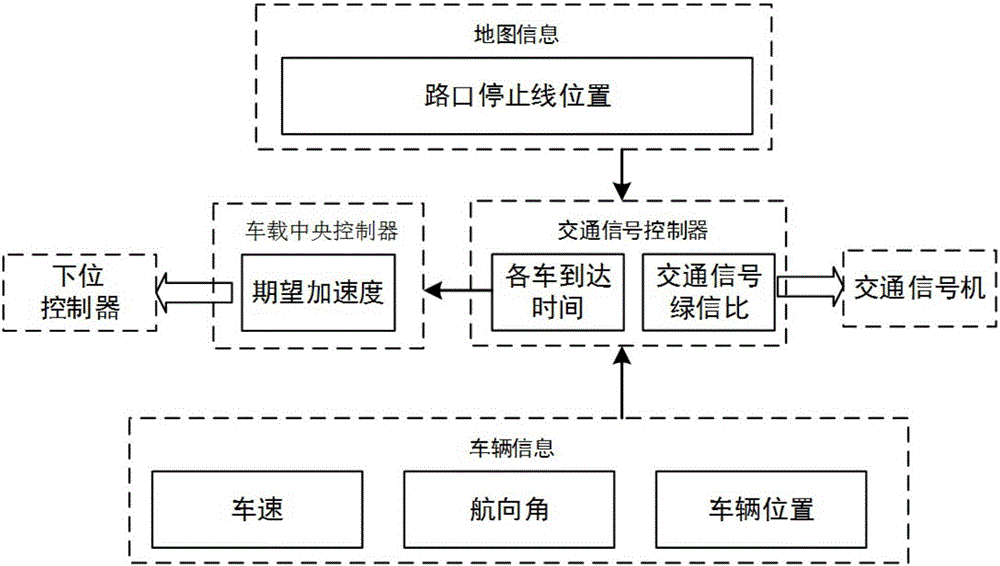

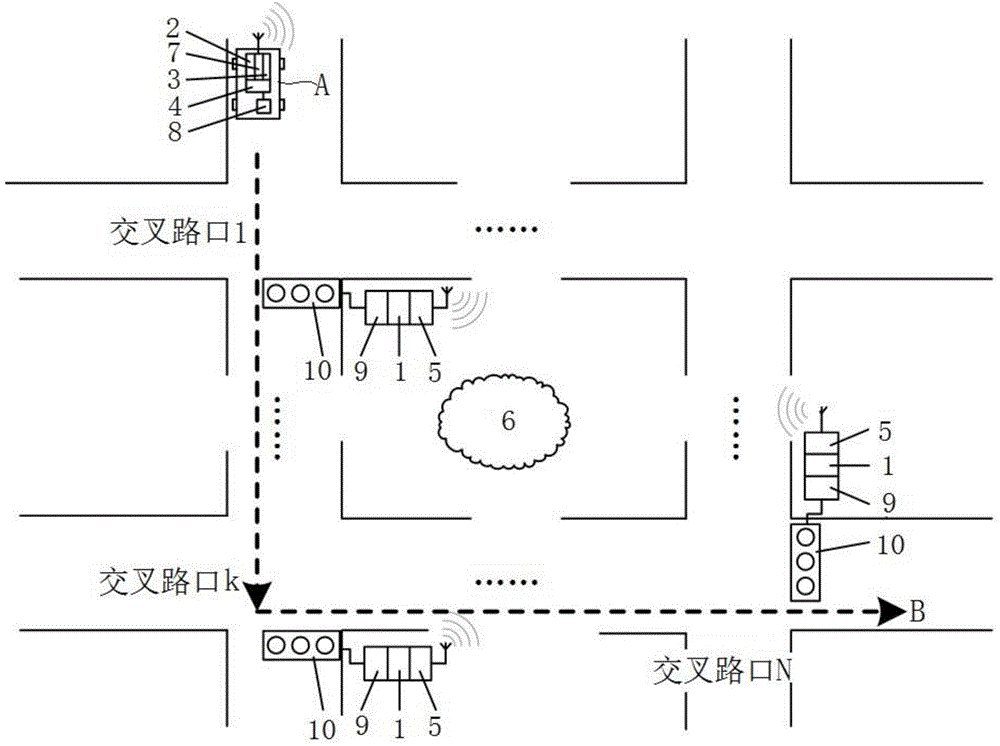

Traffic signal in crossroad and vehicle coordinated control method, device and vehicle

ActiveCN106448194AReduce forced brakingReduce blind acceleration and decelerationControlling traffic signalsTraffic signalEngineering

The invention discloses a traffic signal in crossroad and vehicle coordinated control method, device and vehicle. The method comprises the following steps: 1, based on the average traffic flow calculating the cycle of traffic signal lights, step 2, based on the positioning information of vehicles and the crossroad stop-line information calculating the signal split and the time used for various vehicles to arrive at the crossroad stop-line, step 3, based on the traffic signal cycle and signal split, controlling the switching of traffic signal lights of the crossroad, step 4, judging if all vehicles pass the crossroad, if the answer is negative, then entering step 5, if the answer is affirmative, entering step 6, step 5, sending the crossroad stop-line arrival time of all vehicles and the traffic signal light cycle to the corresponding vehicles for the calculation of the anticipated speeds of corresponding vehicles, step 6, checking whether the traffic signal light cycle is ended, if the answer is affirmative, returning to step 2, if the answer is negative, returning to step 4. The method can optimize the time distribution of crossroads and the speed and acceleration trajectory of the vehicles passing the crossroads, and control the traffic signals of the crossroads and the acceleration of the vehicles heading toward the crossroads.

Owner:TSINGHUA UNIV +1

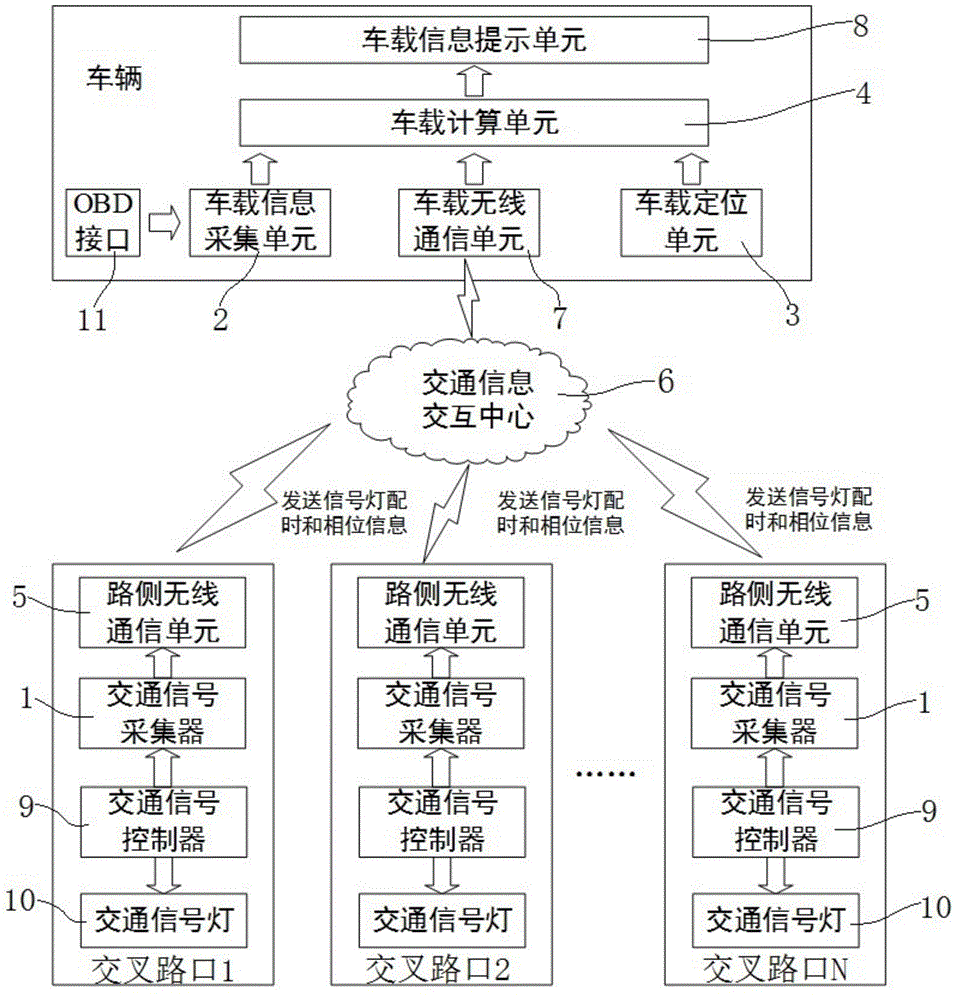

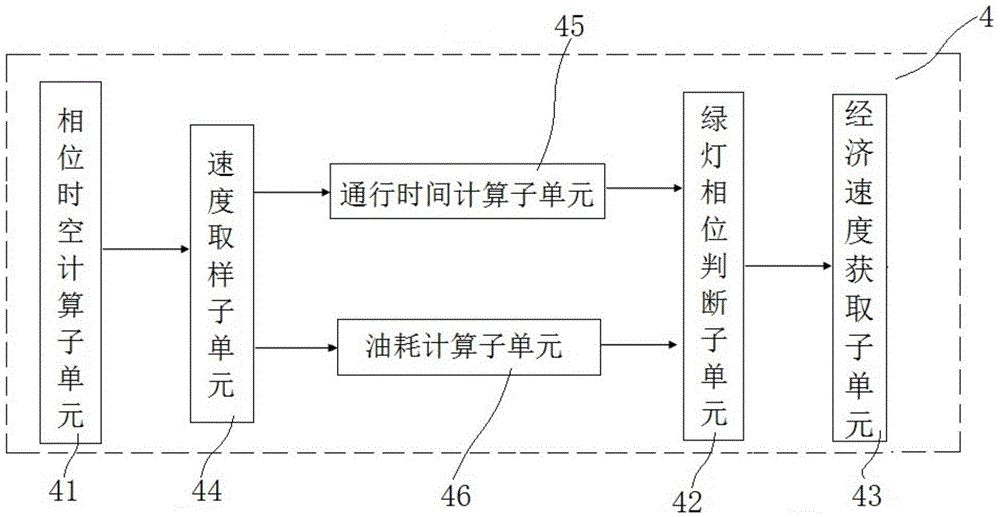

Continuous intersection traffic control method and device

ActiveCN104794915AImprove fuel economyReduce forced brakingRoad vehicles traffic controlDriver/operatorPhase space

The invention discloses a continuous intersection traffic control method and device. The continuous intersection traffic control method comprises: step 1, collecting signal lamp information and vehicle information on vehicle running route; step 2, calculating a phase space-time diagram of N signal lamps on the vehicle running route according to the information collected in the step 1) in combination with pre-loaded map information; step 3, setting a speed vk, wherein k is equal to 1, 2, ..., n, and n is a natural number; step 4, judging whether a passing time of passing by the ith signal lamp at the speed vk is within a green light phase in the phase space-time diagram, if so, the speed vk is an effective speed ui, and on the contrary, entering step 3; step 5, calculating multiple groups of effective speed combinations passing by N intersections, figuring out the total oil consumption of each group of effective speed combinations, using the effective speed combination with the lowest total oil consumption as an economic vehicle speed, and prompting the economic vehicle speed to drivers. The continuous intersection traffic control method disclosed by the invention can be used for achieving the aim of economic driving.

Owner:TSINGHUA UNIV

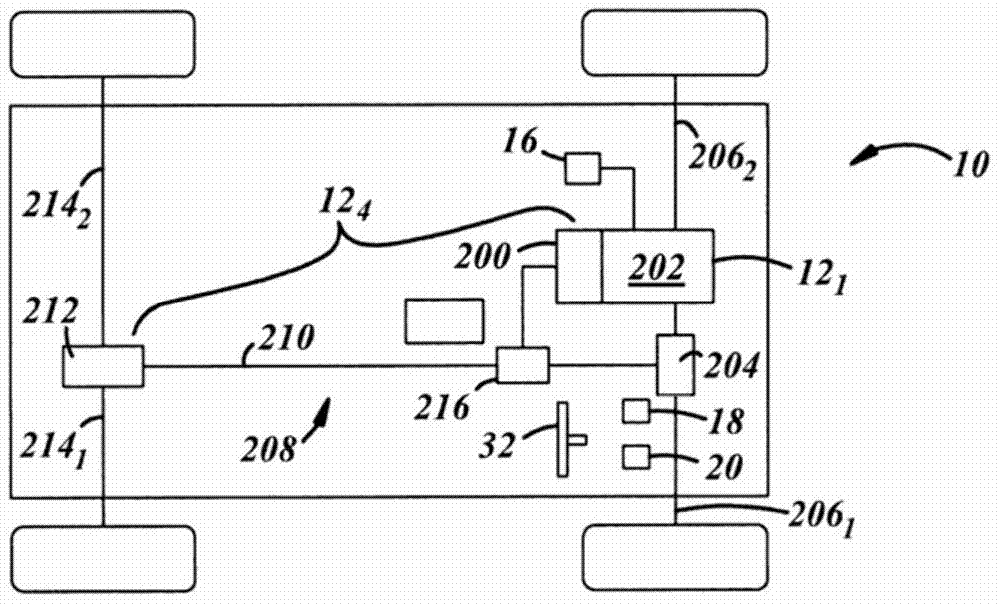

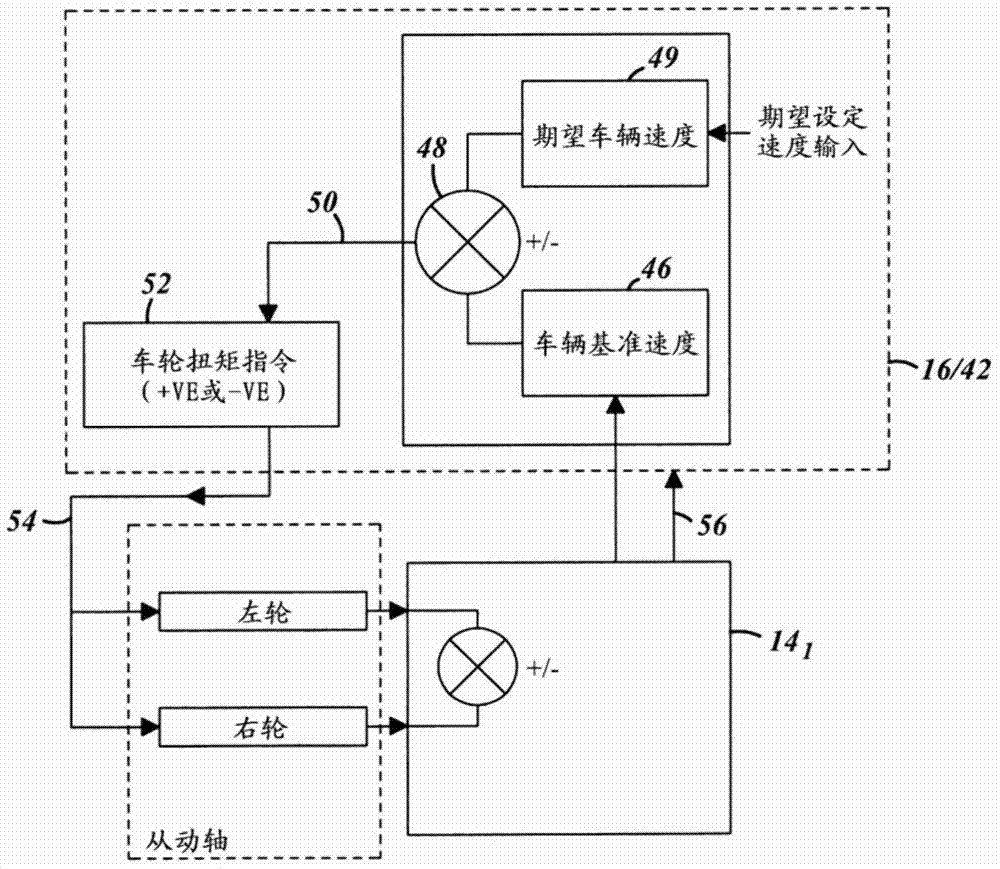

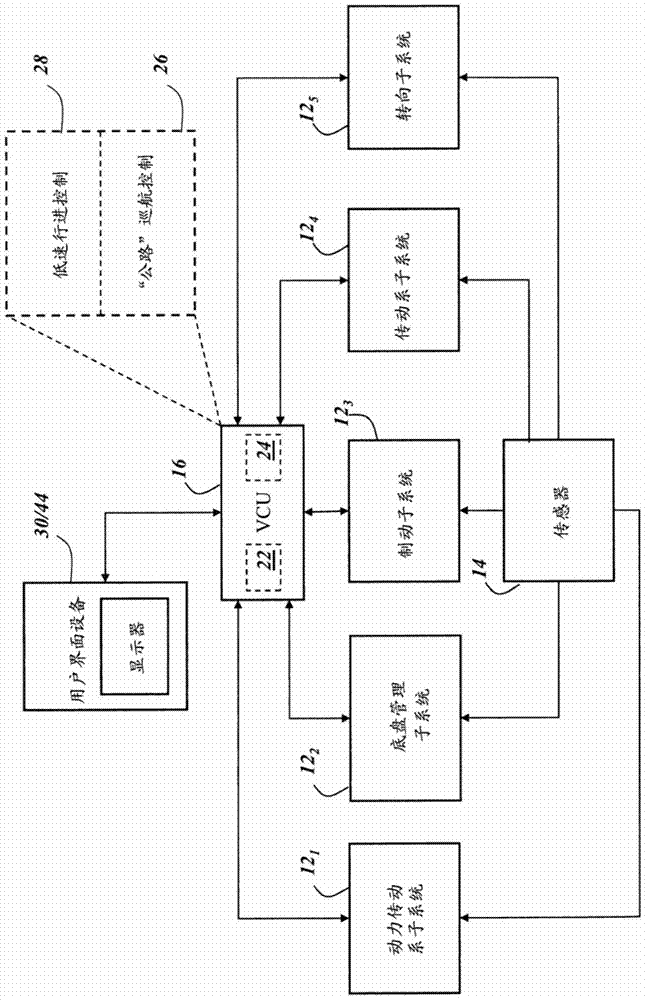

Vehicle speed control system and method employing torque balancing

ActiveCN104718113AGuaranteed stabilityImprove stabilityVehicle fittingsBrake system interactionsSpeed control systemControl system

A method for operating a speed control system of a vehicle having a plurality of wheels is provided. The method comprises receiving one or more electrical signals representative of vehicle-related information. The method further comprises determining, based on the one or more electrical signals representative of vehicle-related information, that one or more of the wheels of the vehicle have overcome an obstacle or are about to overcome an obstacle and that therefore a reduction in an applied drive torque to one or more of the wheels of the vehicle by a powertrain subsystem (applied drive torque) will be required to maintain the speed of the vehicle at a target set-speed of the speed control system. The method still further comprises automatically commanding the application of a retarding torque to one or more of the wheels of the vehicle to counteract the effect of an overrun condition in the powertrain subsystem from increasing the speed of the vehicle. A system for controlling the speed of a vehicle comprising an electronic control unit configured to perform the above- described methodology is also provided.

Owner:JAGUAR LAND ROVER LTD

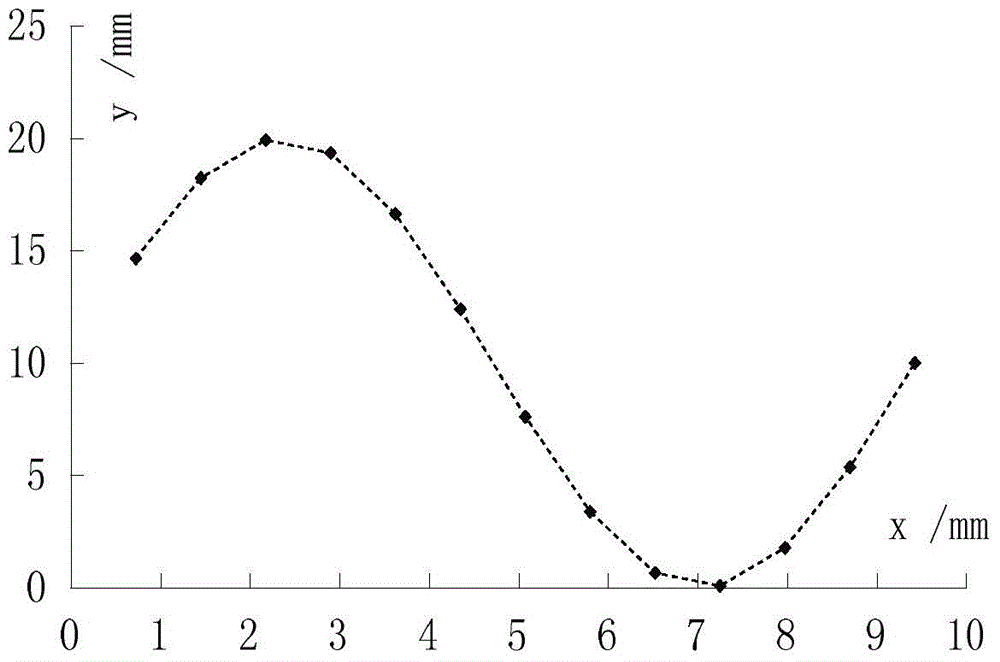

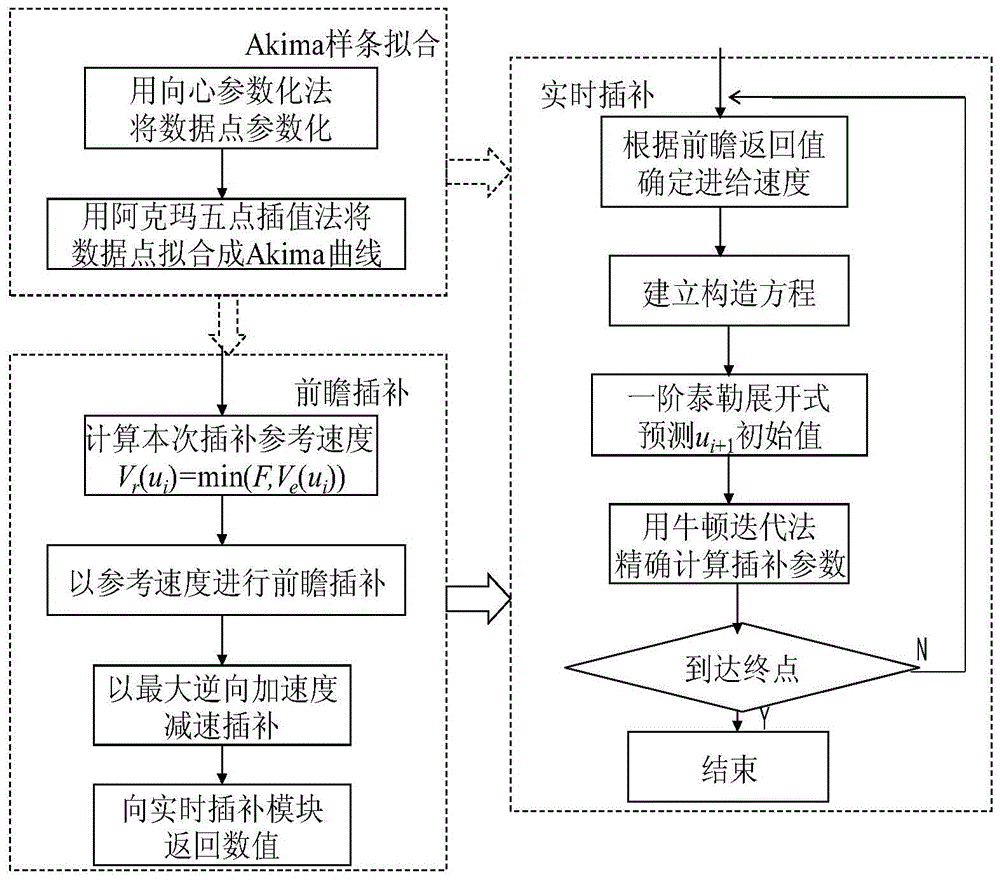

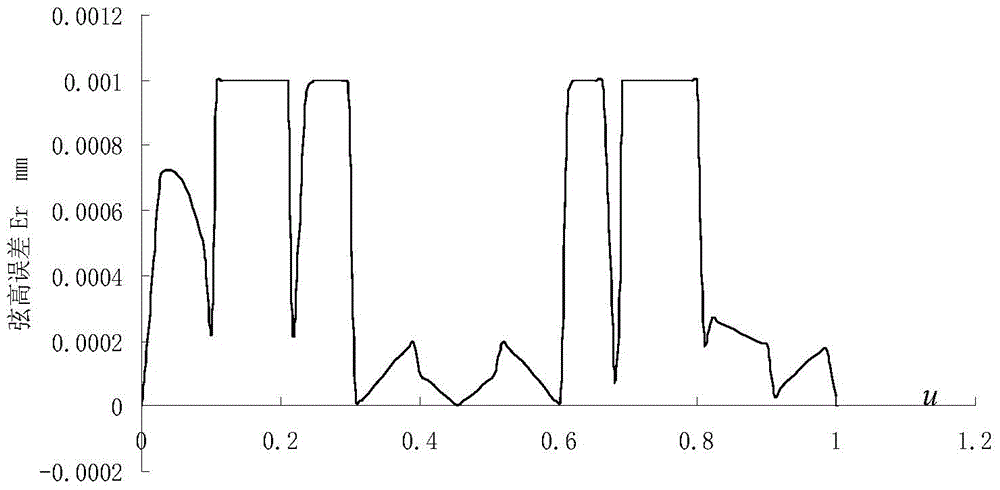

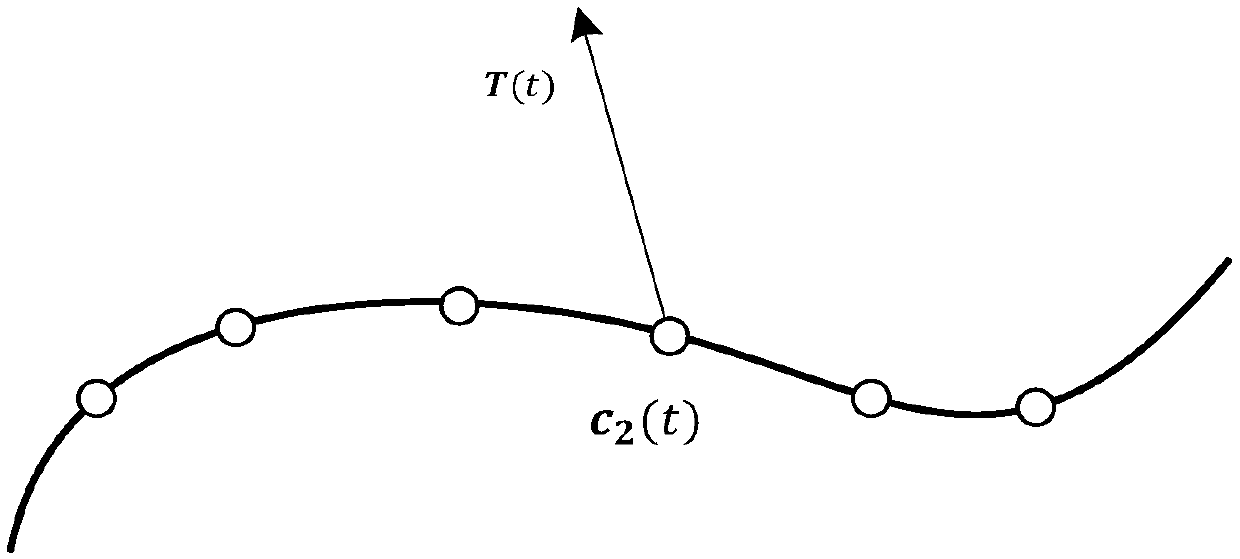

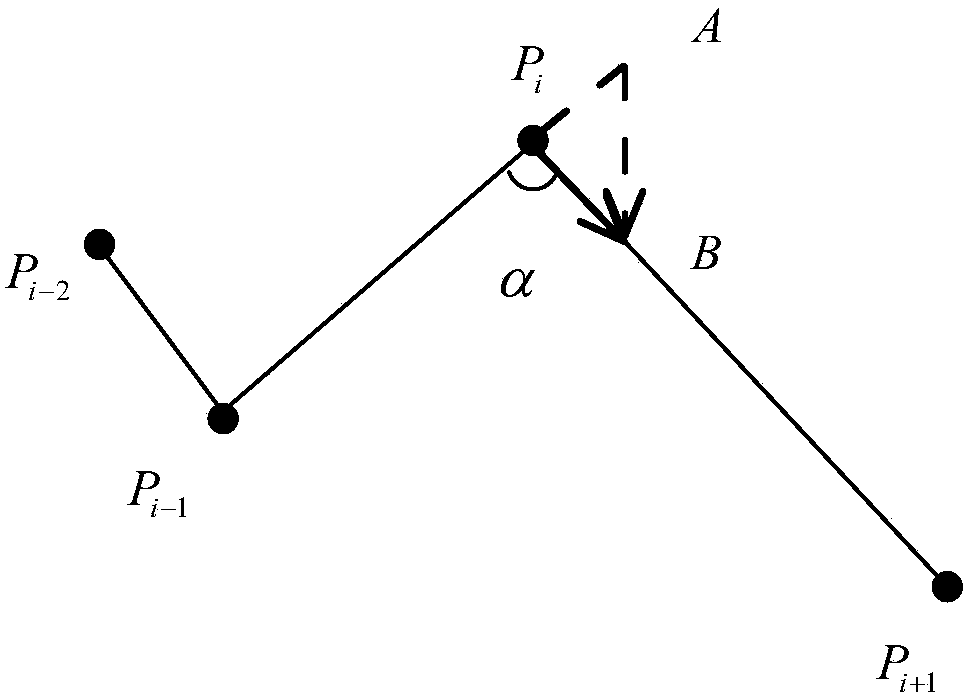

Akima spline fitting based look-ahead interpolation method

InactiveCN104597847APrecisely throughImprove fitting accuracyNumerical controlCurve fittingComputer science

The invention provides an Akima spline fitting based look-ahead interpolation method. The method is characterized in that the Akima spline fitting is that the parameters corresponding to each interpolation point are calculated by the centripetal parameterization method, and then the data points are fitted into a smooth Akima spline by the Akima five-point interpolation method; the look-ahead interpolation is that different values are returned for real-time interpolation by the look-ahead interpolation calculation according to the processing precision requirement, the programming speed of a numerical control system and the maximum speed information; the real-time interpolation is that the real-time feeding speed is adjusted according to the look-ahead interpolation returning value, then a structural equation is created according to the known Akima spline equation and interpolation cycle and other information, then the primary iteration value of the next interpolation method is predicated, and finally the interpolation parameters are accurately calculated by the newton iteration method. According to the method, the data points to be processed are fitted through the Akima spline, so that the actuating efficiency is increased, the smoothness is high, the fitting precision is improved while the interpolation real-time performance is ensured, the accuracy and flexibility are improved, and the actual state of a workpiece can be restored to the maximum.

Owner:中国科学院沈阳计算技术研究所有限公司

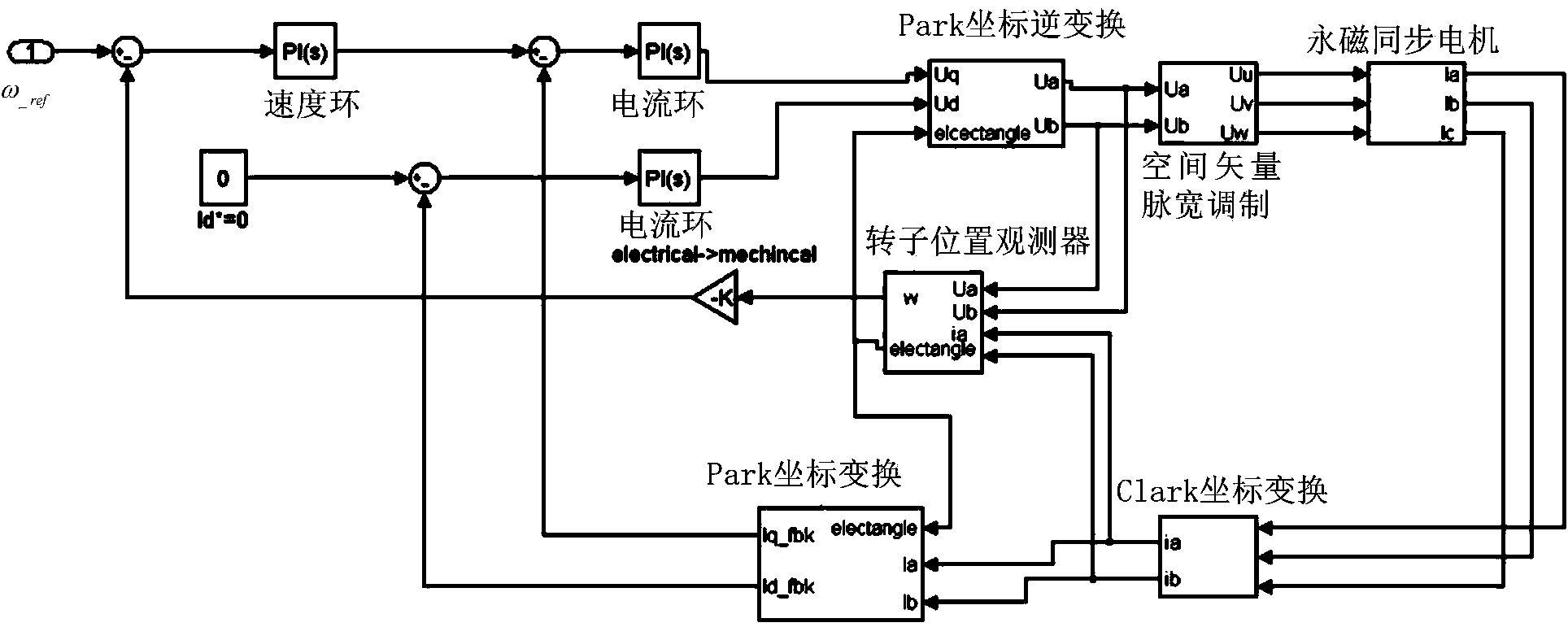

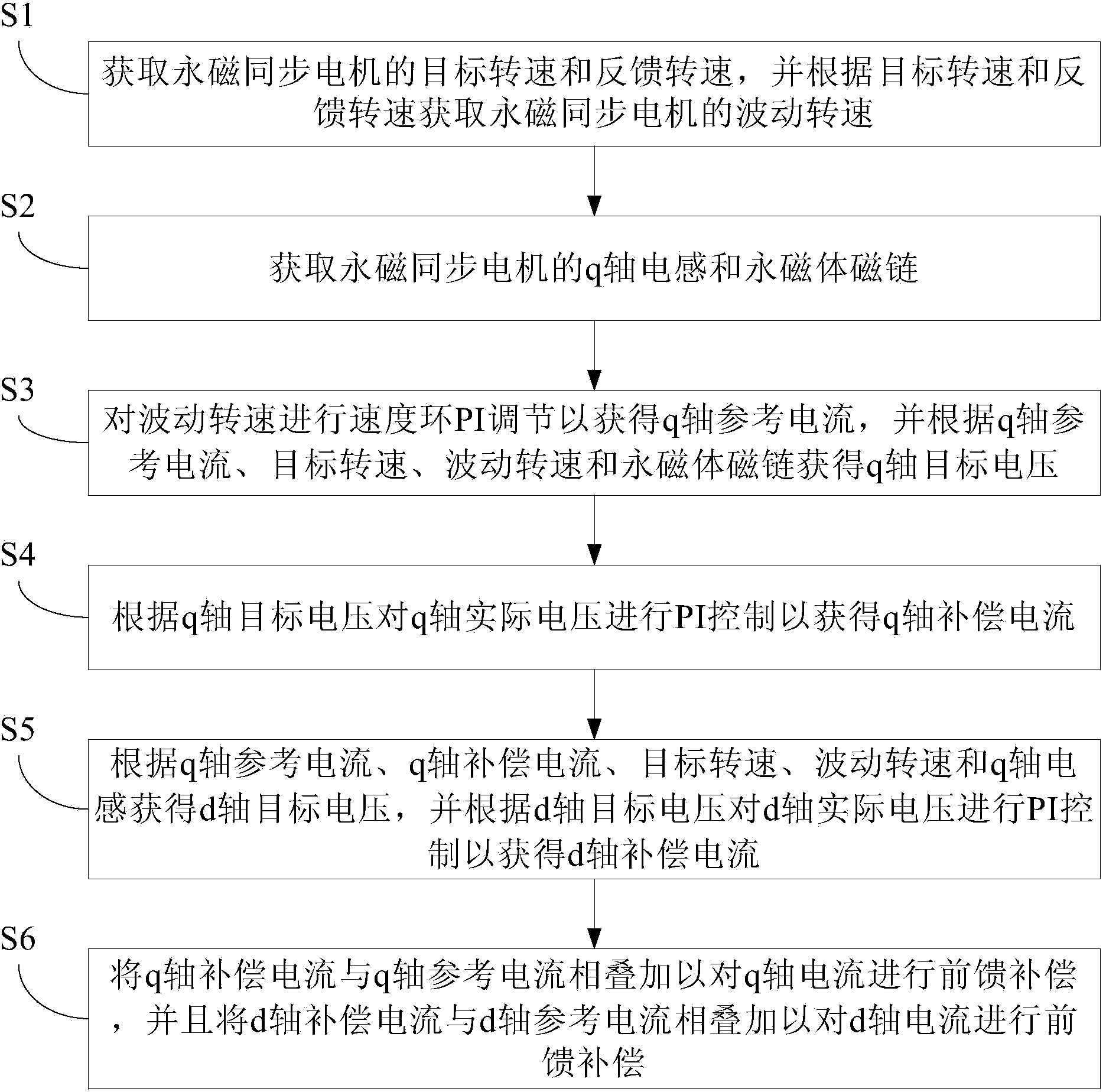

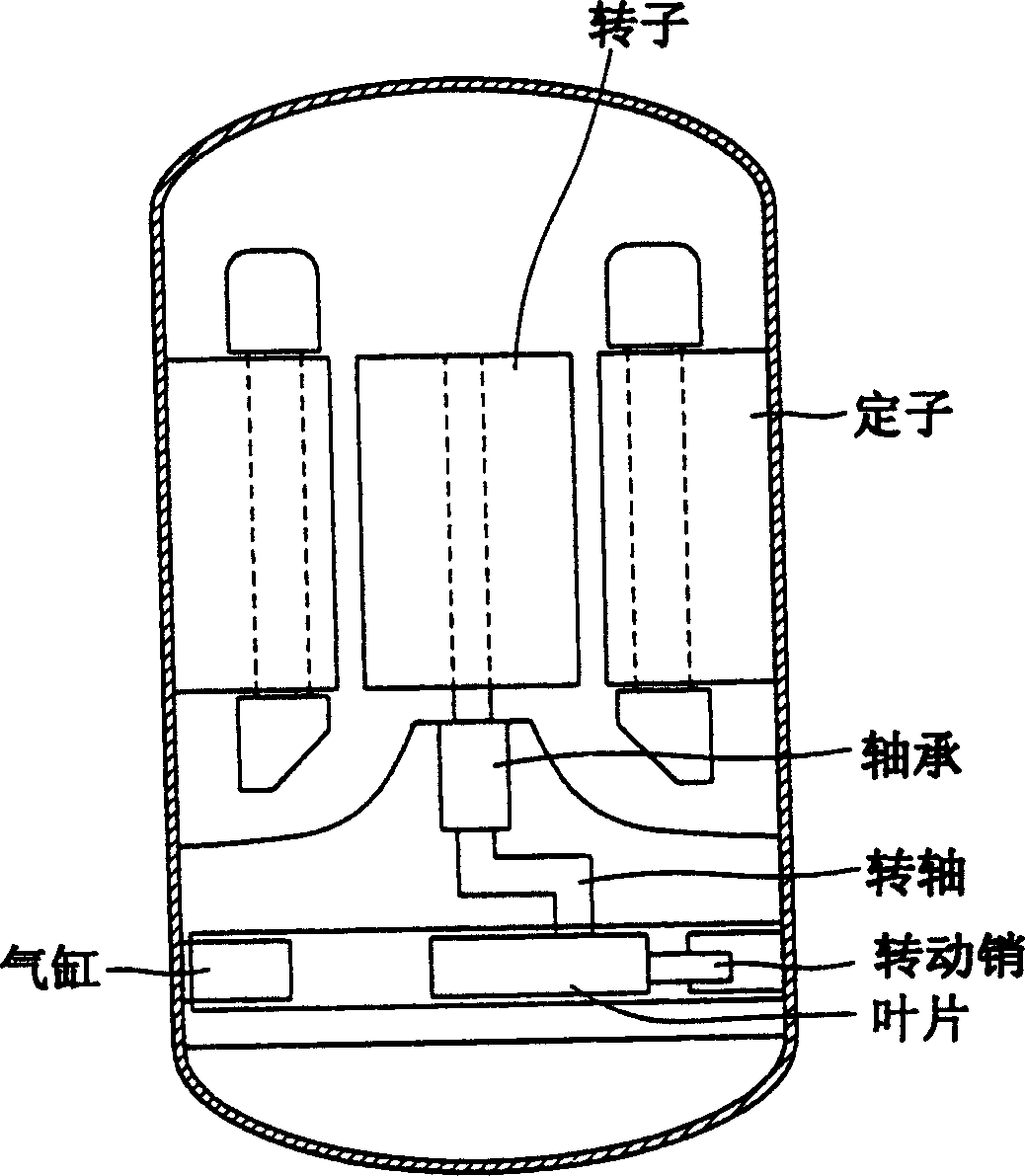

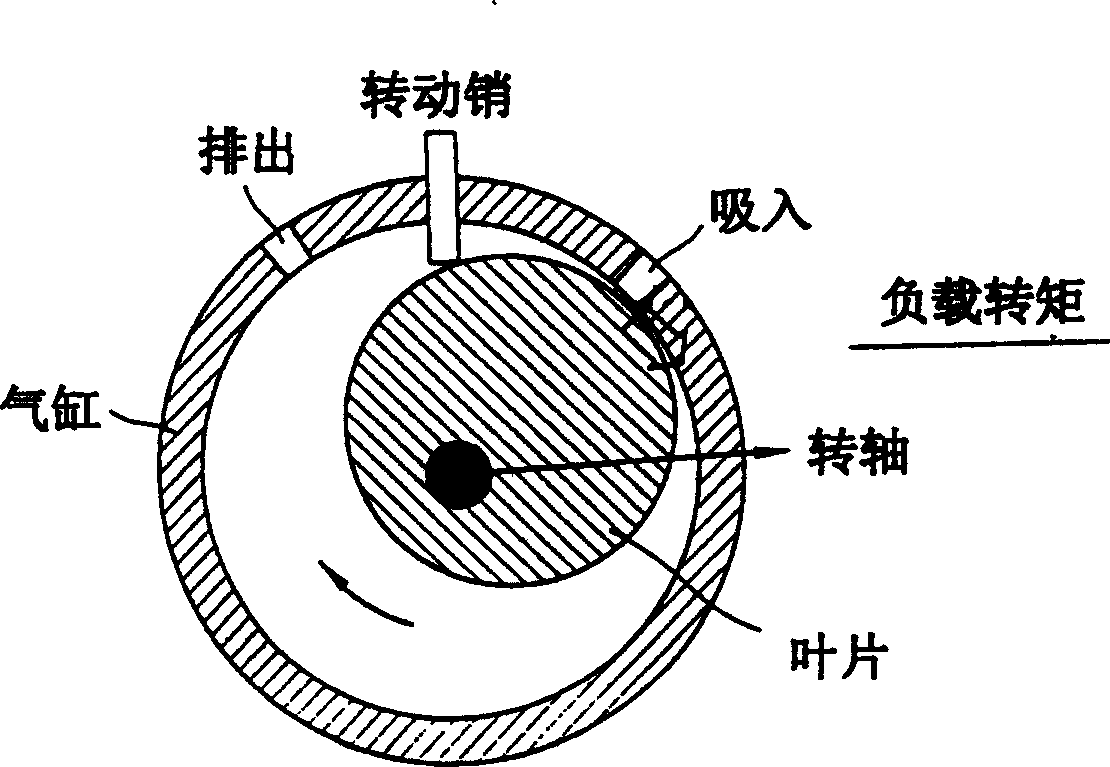

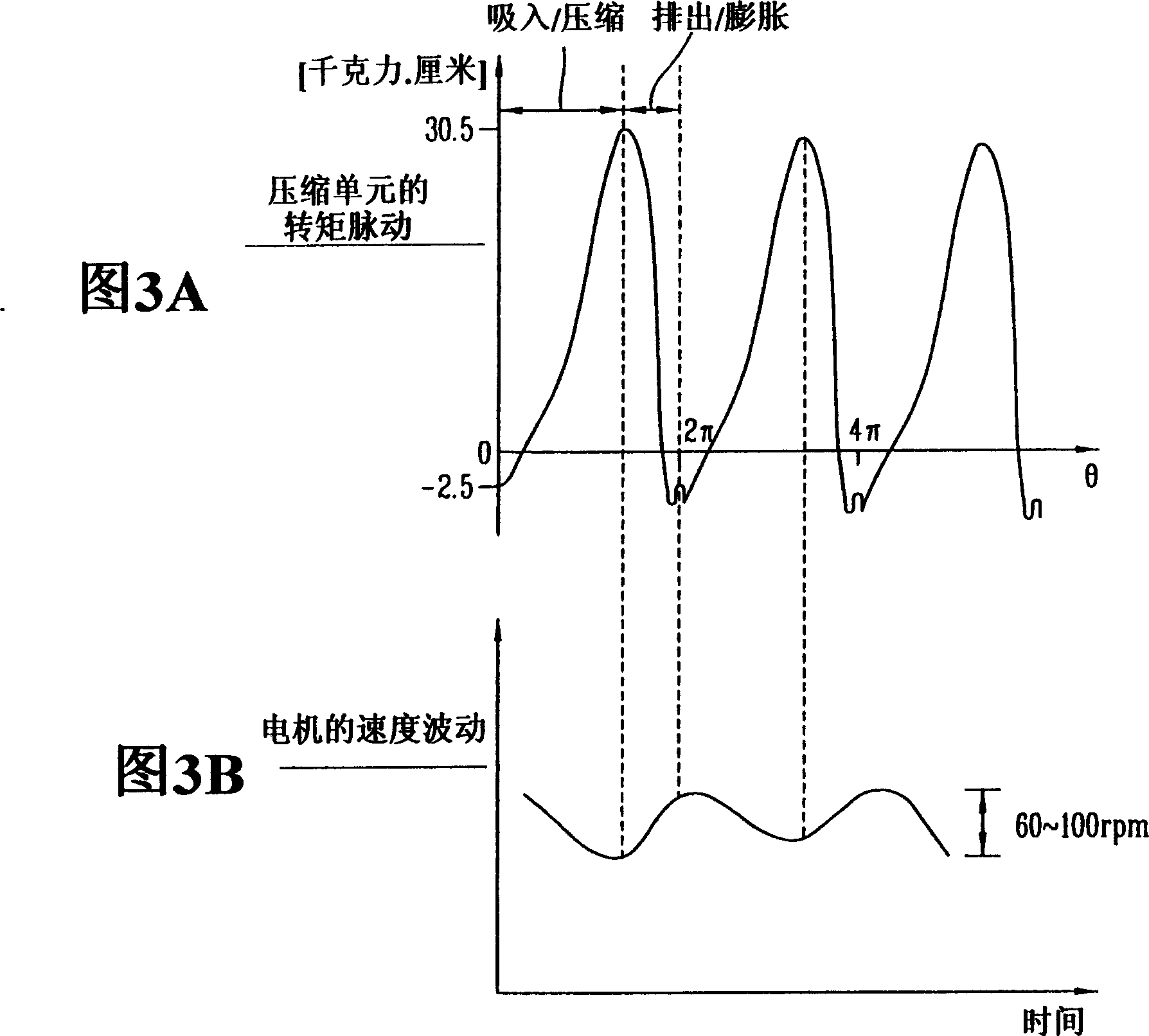

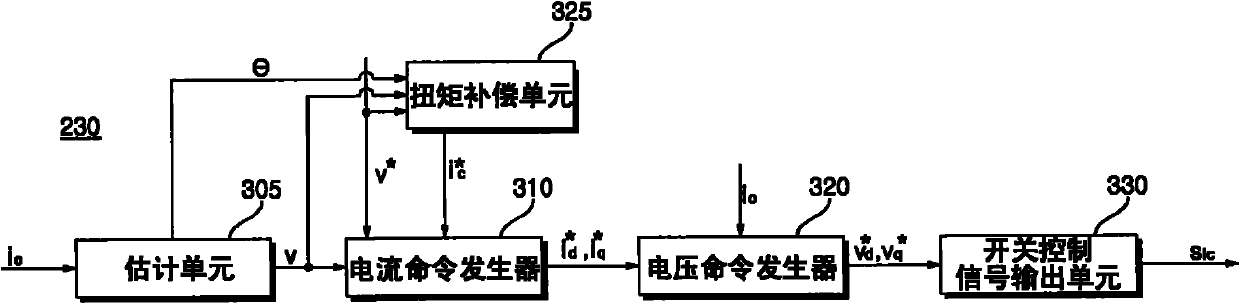

Method for inhibiting speed fluctuation, control device and compressor control system

ActiveCN104113253AGuaranteed uptimeSuppresses speed fluctuationsElectronic commutation motor controlVector control systemsControl systemReference current

The invention discloses a method for inhibiting speed fluctuation of a permanent magnet synchronous motor. The method includes the steps of: obtaining a target rotating speed omega_ref, a feedback rotating speed, and a fluctuation rotating speed delta(omega), a q axis inductor Lq and a permanent magnet flux linkage (phi)f of the permanent magnet synchronous motor; performing PI adjustment on delta(omega) to obtain a q axis reference current Iq_ref, and obtaining a q axis target voltage Ud* according to Iq_ref, omega_ref, delta(omega) and (phi)f; performing PI control on a q axis actual voltage according to Ud* so as to obtain a q axis compensating current Iq_add; obtaiing a d axis target voltage Ud* according to Iq_ref, Iq_add, omega_ref, delta(omega) and Lq, and performing PI control on a d axis actual voltage according to Ud* to obtain a d axis compensating current Id_add; superposing Iq_add and Iq_ref to perform feedforward compensation on a q axis current, and superposing Id_add and a d axis reference current to perform feedforward compensation on a d axis current. The inhibition method can realize effective inhibition of speed fluctuation in operation of the permanent magnet synchronous motor by performing feedforward compensation on the d axis current and the q axis current. The invention also discloses a control device of the permanent magnet synchronous motor and a compressor control system.

Owner:GUANGDONG MEIZHI COMPRESSOR

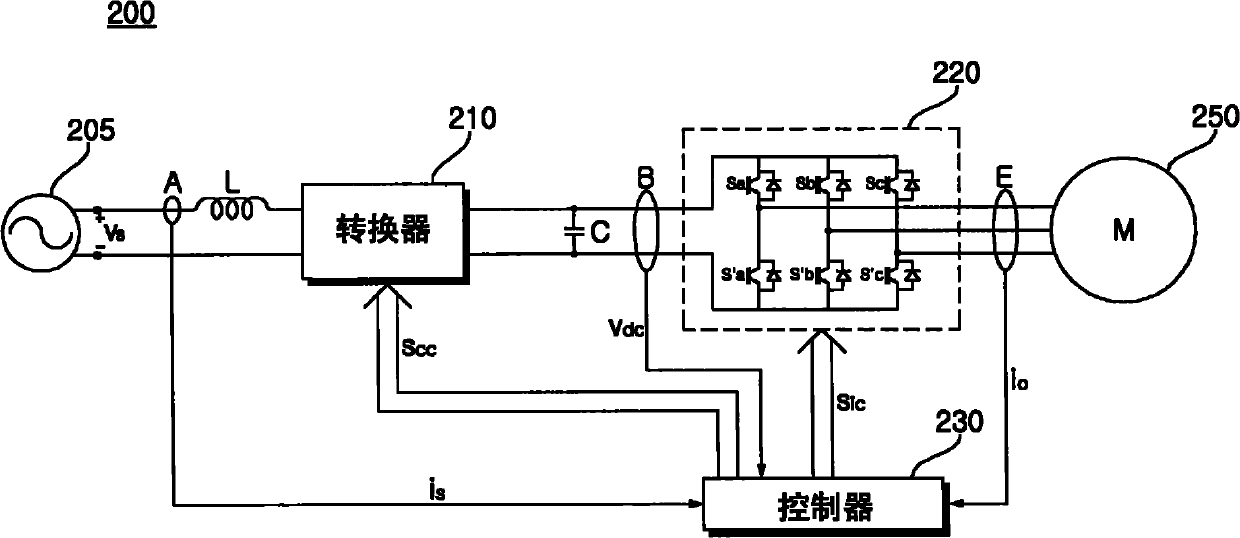

Apparatus for compensating for speed error of motor

InactiveCN1599232AReduce speed fluctuationsReduce vibrationTorque ripple controlVector control systemsControl theory

The present invention discloses an apparatus for compensating for a speed error of a motor which can reduce a speed ripple of the motor resulting from load characteristics, and which also can reduce vibrations and noises. The apparatus for compensating for the speed error of the motor divides a rotational section corresponding to one complete revolution of a rotor of the motor into a plurality of preset rotational sections, determines a speed compensation value in each divided rotational section on the basis of a difference value between a reference speed and a previous estimated speed, and compensates for the speed error of the motor on the basis of the speed compensation value.

Owner:LG ELECTRONICS INC

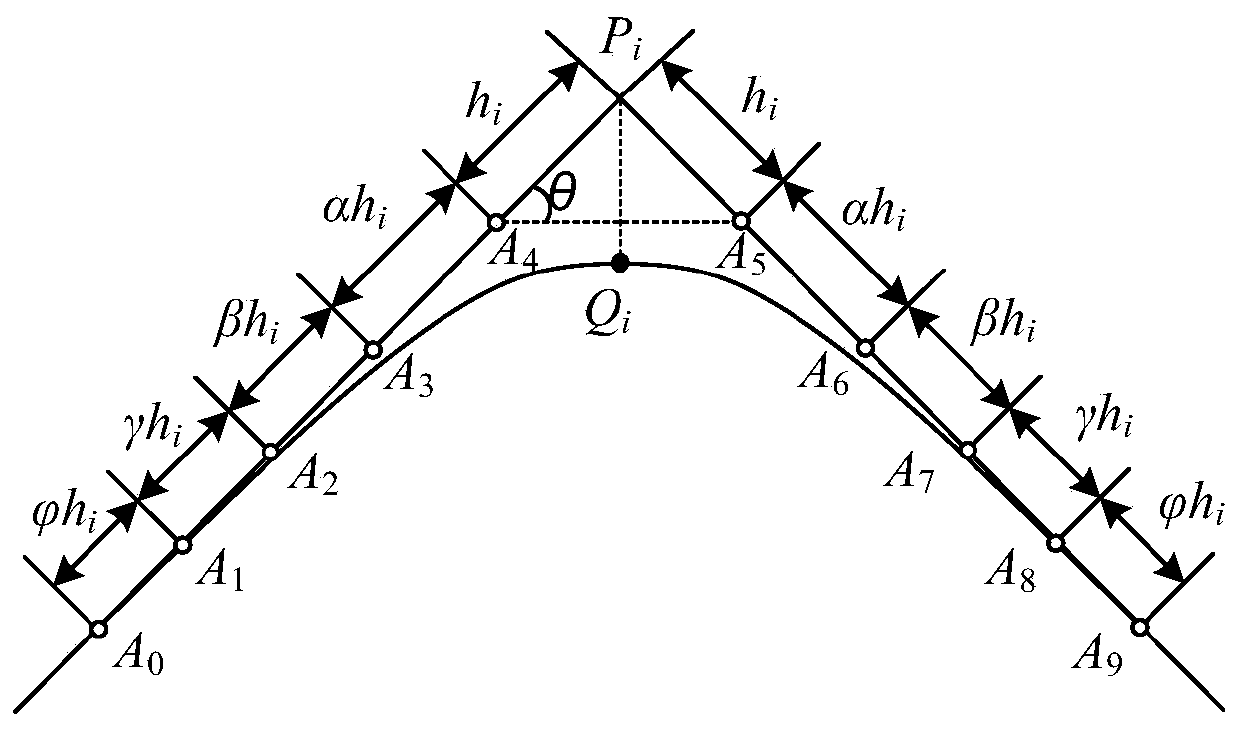

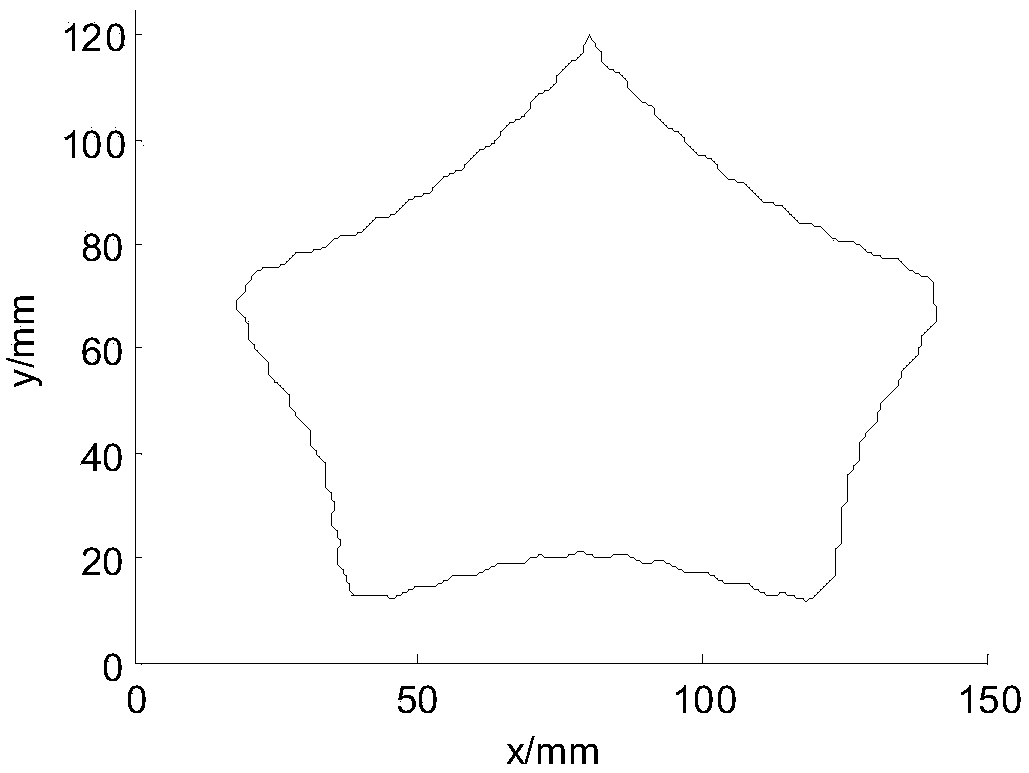

Tool track interpolation and speed planning method based on machine tool vibration suppression

The invention discloses a tool track interpolation and speed planning method based on machine tool vibration suppression. The method comprises the steps of 1, reading a G01 track point into a numerical control system memory; 2, aiming at a G01 track segment obtained in the step 1, designing a G4 continuous interpolation track meeting a chord error constraint; and 3, designing a speed curve calculation method with smooth acceleration and time optimal under two known conditions for the smooth track obtained in the step 2, and giving a speed planning method under the dynamic performance constraint of each axis of motion. The track generated by the method meets the chord error constraint strictly and can allow the G01 point to pass through, and compared with a G2 corner transition track and aG3 interpolation track, the curvature extreme value at the corner can be further reduced, the speed fluctuation at the corner is relieved, and the impact of the machine tool is reduced. The designed speed planning method can ensure the machining efficiency and improve the vibration suppression level of the machine tool, thereby providing an important means for the development of a numerical control system interpolator of high-speed and high-precision machining.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

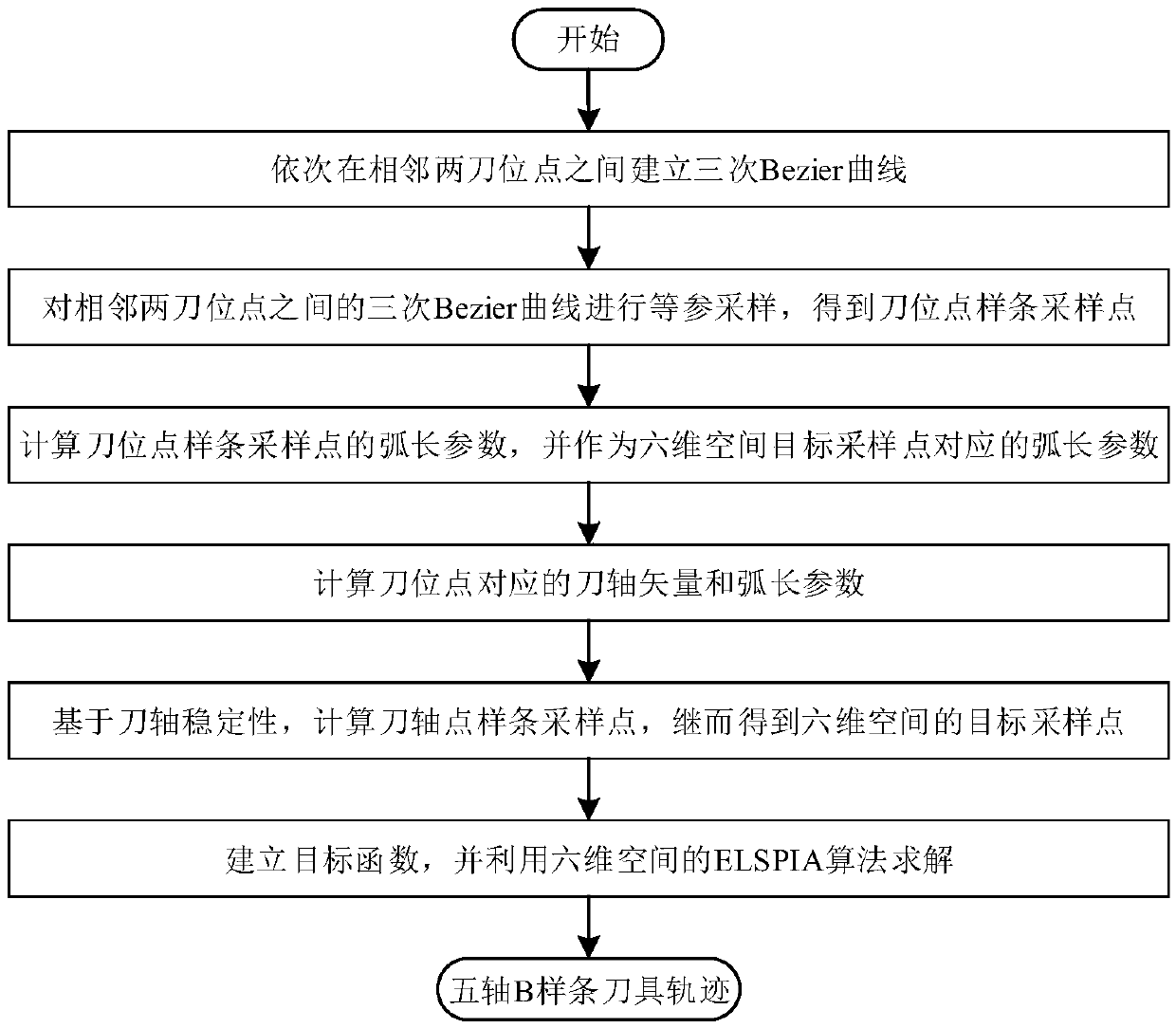

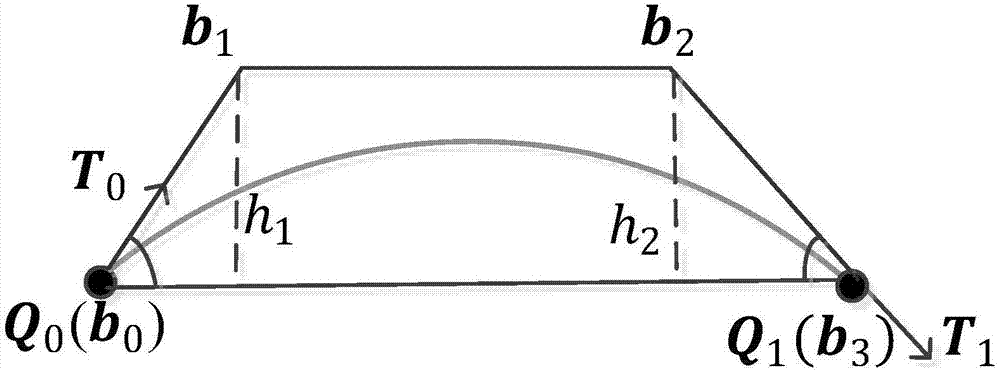

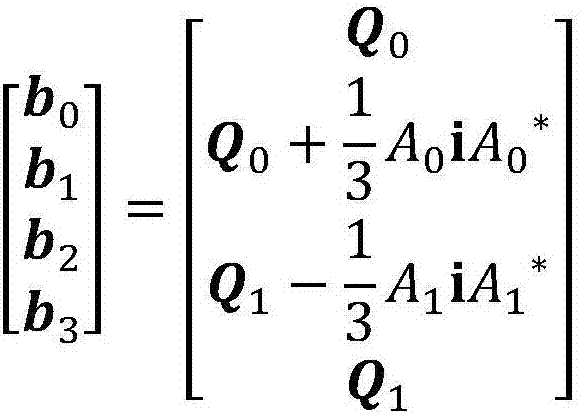

Five-axis B-spline cutter path arc length parameterization method based on cutter axis stability

ActiveCN109062137AImprove fitting efficiencyMeet the processing requirements of stabilityNumerical controlCutter locationEngineering

The invention belongs to the computer-aided machining related technology field, and discloses a five-axis B-spline cutter path arc length parameterization method based on the cutter axis stability. The method comprises the following steps that 1, cubic Bezier curves are established between every two adjacent cutter location points; 2, the cubic Bezier curves between every two adjacent cutter location points are subjected to isoparametric sampling to obtain cutter location point spline sampling points; 3, arc length parameters of the cutter location point spline sampling points are calculated to serve as arc length parameters of target sampling points of a six-dimensional space, and cutter axis vectors and arc length parameters of the cutter location points are calculated; 4, cutter axis point spline sampling points corresponding to the cutter location point spline sampling points are calculated, and then the target sampling points of the six-dimensional space are obtained; and 5, a target function is established according to the target sampling points of the six-dimensional space and the arc length parameters, and a five-axis B-spline cutter path subjected to nearly arc length parameterization is solved accordingly. According to the method, the speed fluctuation during machining is reduced, and the machining quality and efficiency are improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

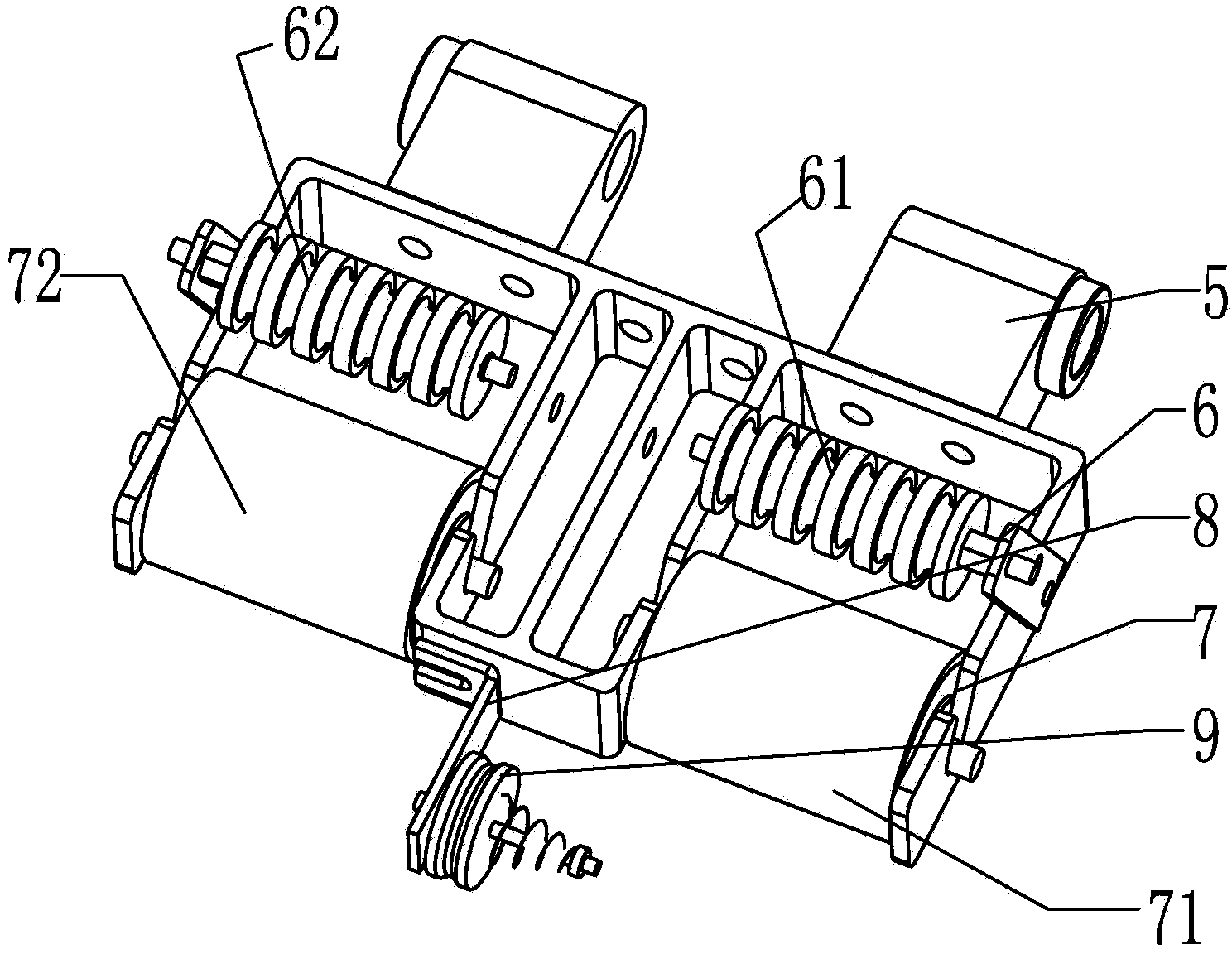

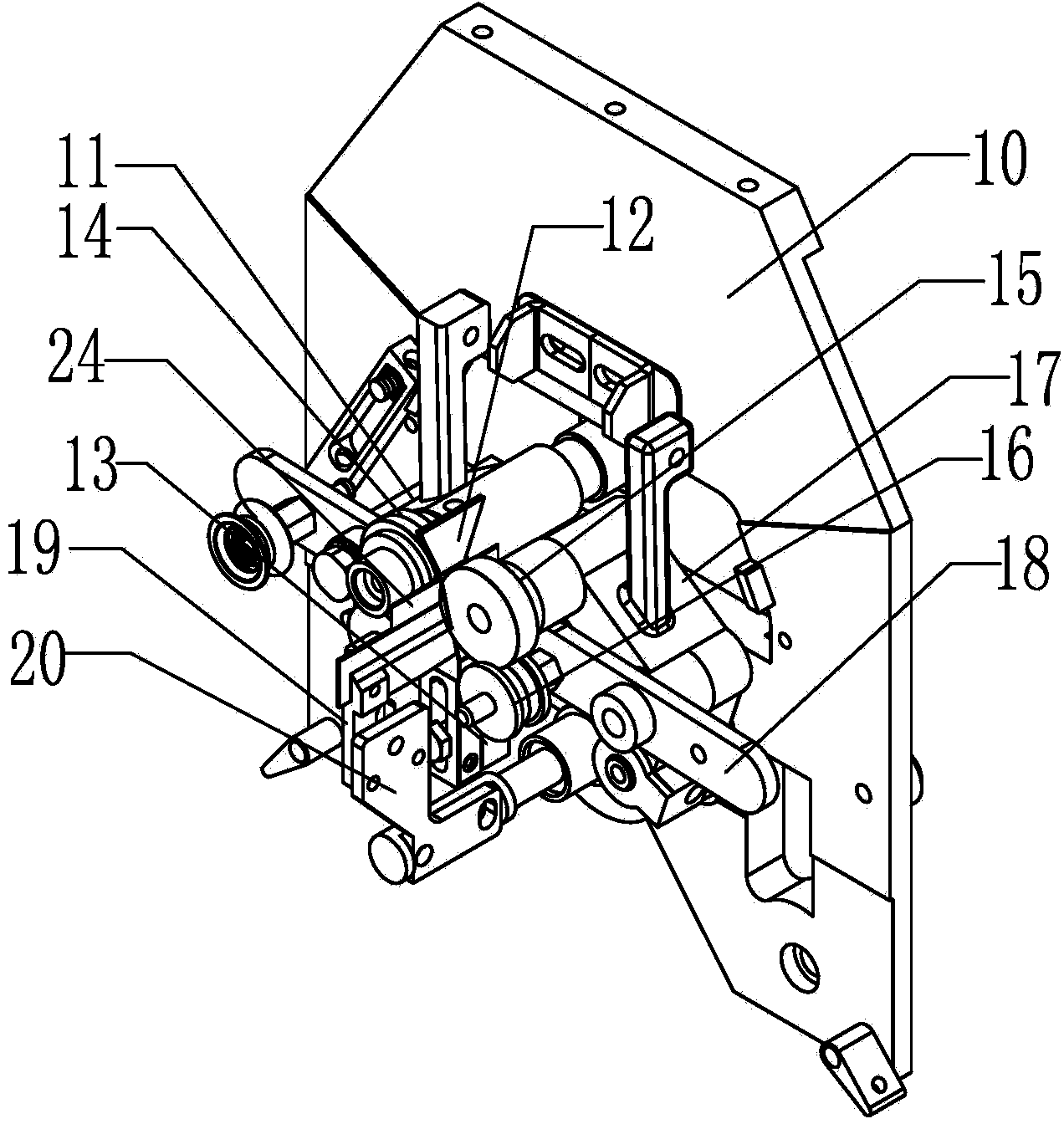

Chenille spinning machine

The invention discloses a chenille spinning machine for spinning chenille yarns. Firstly, knitting wools for spinning the chenille yarns wind an inverted triangle distance cutting sheet through a high-speed swiveling head, and the width of the neck portion of the distance cutting sheet depends on the length of pile yarns. Subsequently, a pressure roller is fed into a grey yarn rack, two core yarns are discharged, one of the core yarns forms a surface layer core yarn of the chenille yarns, and the other one of the core yarns forms a base layer core yarn of the chenille yarns. The knitting wools on the distance cutting sheet are pushed to blades through roller pieces, the blades move in the middle of the neck portion of the distance cutting sheet, and the knitting wools are cut by means of the blades. The cut knitting wools are sideward clamped between the surface layer core yarn and the base layer core yarn, and flaky knitting wools between the two core yarns are scattered towards all sides to form the chenille yarns through downward use of swiveling of reeling spindles. The chenille spinning machine has the advantages of being convenient to operate, high in production efficiency, large in reeling volume, safe, and reliable.

Owner:ZHEJIANG DONGXING TEXTILE MACHINERY

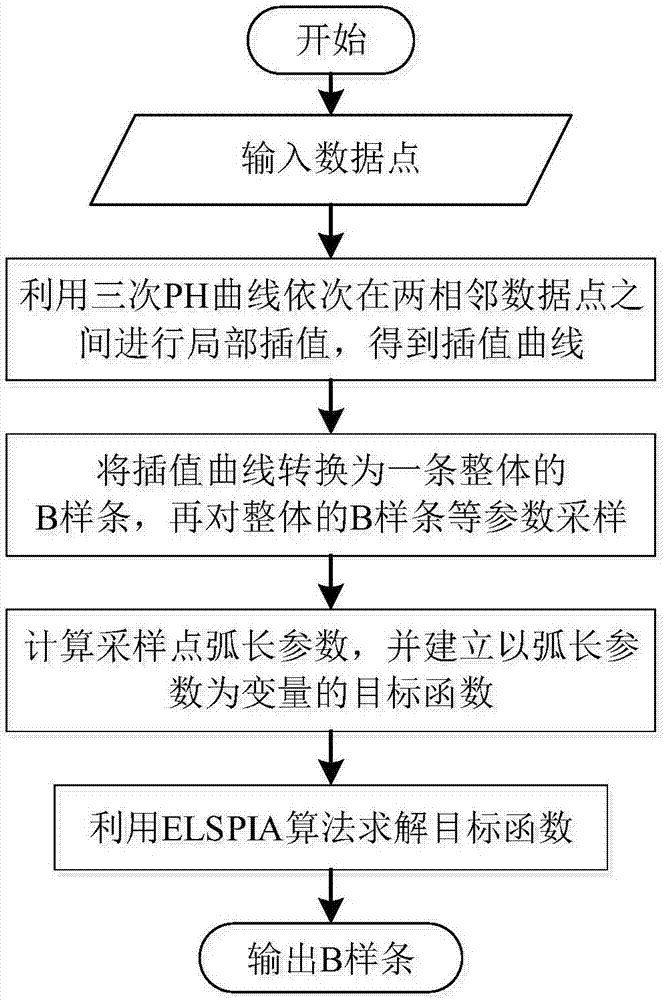

Method of realizing cutter path parameter arc length based on three times of PH curve interpolations

The invention discloses a method of realizing a cutter path parameter arc length based on three times of PH curve interpolations. The method comprises the following steps of (1) using three times of PH curves to carry out local interpolation on two adjacent data points, acquiring several three-times PH curves and using a set of PH curves between the adjacent data points to form an interpolation curve; (2) converting the interpolation curve into one integral B spline curve, and carrying out isoparametric sampling on the integral B spline curve; (3) calculating an arc length parameter of a sampling point and establishing a target function taking the arc length parameter as a variable; (4) using an ELSPIA algorithm to solve the target function, and acquiring a B spline of an approximation parameter arc length. By using the parameter arc length method, the isoparametric sampling is performed on the integral B spline curve, cutter path B spline fitting algorithm efficiency is increased, the parameter arc length is realized, a speed fluctuation during processing is reduced and phenomena of a shape defect of a cutter path and error dissatisfaction are effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

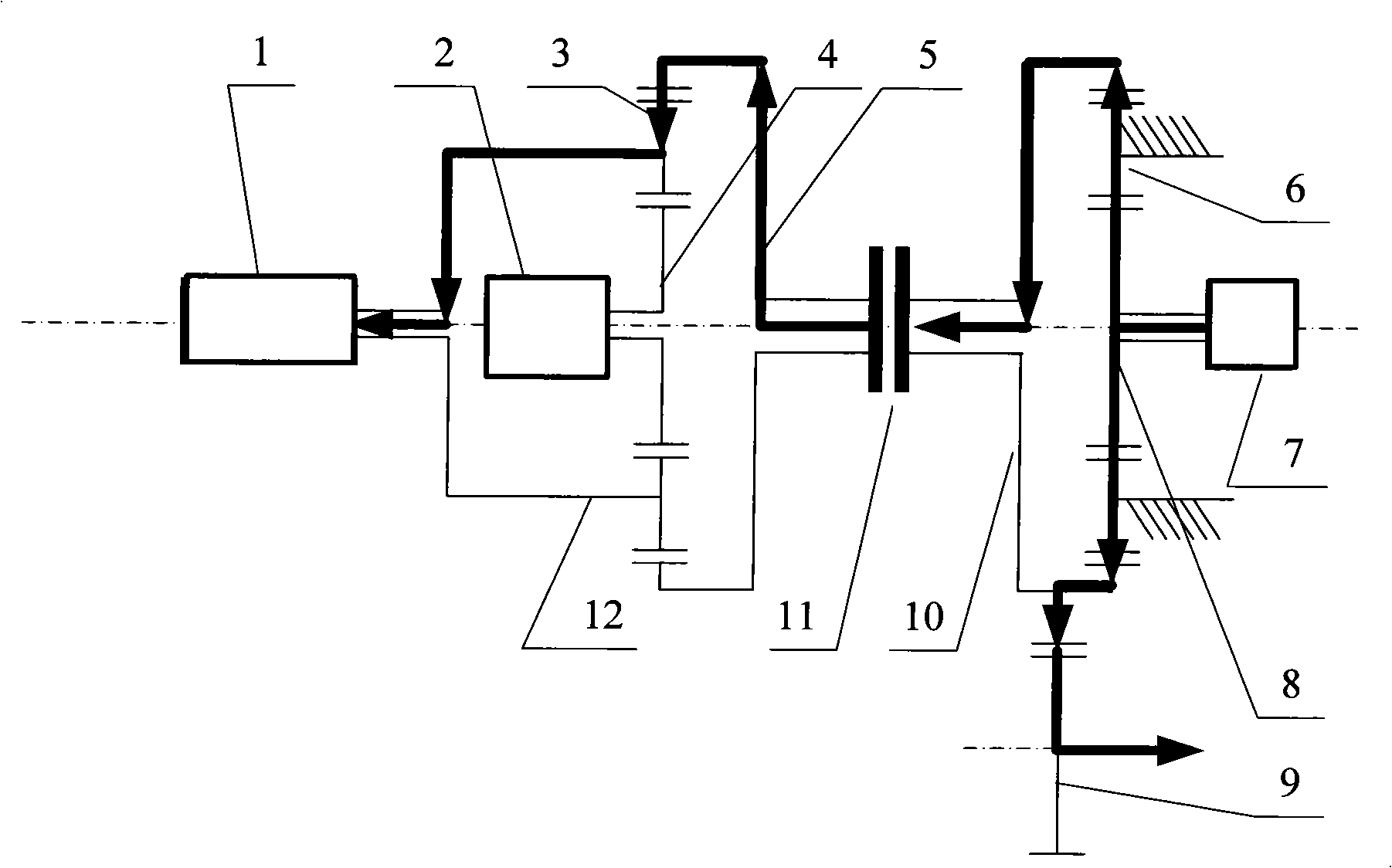

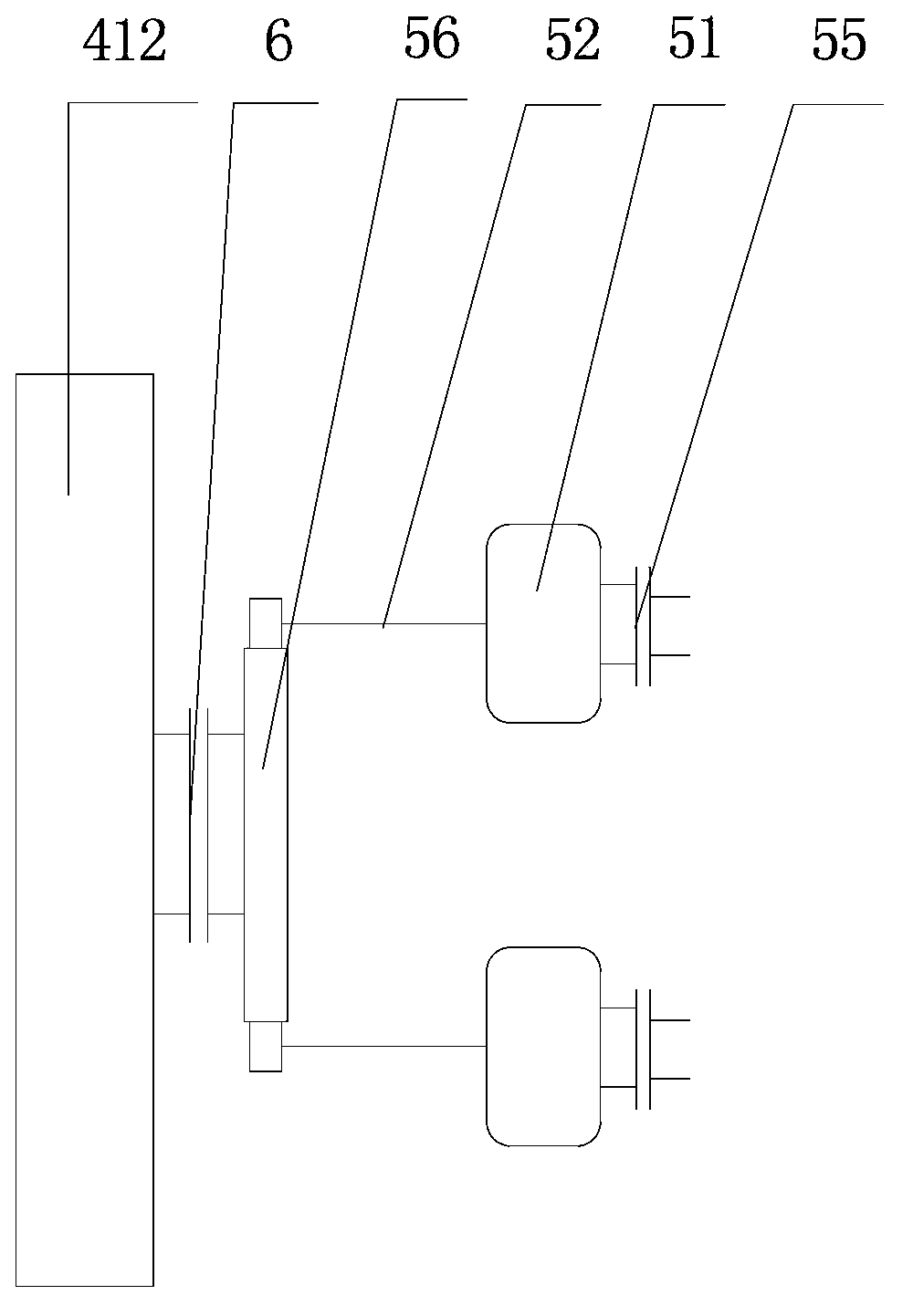

Energy storing and driving device allowed to be applied to hybrid electric vehicle

ActiveCN104097498AImprove powerImprove fuel economyHybrid vehiclesGas pressure propulsion mountingFlywheelBattery electric vehicle

The invention relates to an energy storing and driving device allowed to be applied to a hybrid electric vehicle. The energy storing and driving device comprises an engine, a first clutch, a first motor / generator, a power distribution mechanism, a flywheel module, a second clutch and a power output device, wherein the power distribution mechanism is a double-row planetary gear transmission device; the flywheel module comprises a flywheel speed increasing driving gear, at least one flywheel speed increasing driven gear meshed with the flywheel speed increasing driving gear, at least one flywheel, at least one flywheel shaft and at least one flywheel brake; the power output device comprises a speed reducing driving gear, a speed reducing driven gear, a speed changing device and a power output shaft. The problems that brake energy is low in recovery efficiency and the acceleration performance is poor are solved. The energy storing and driving device has the advantages of high recovery efficiency of the brake energy, excellent acceleration performance, low cost of the finished vehicle and remarkable energy-saving effect.

Owner:CHANGZHOU HAIKE NEW ENERGY TECH

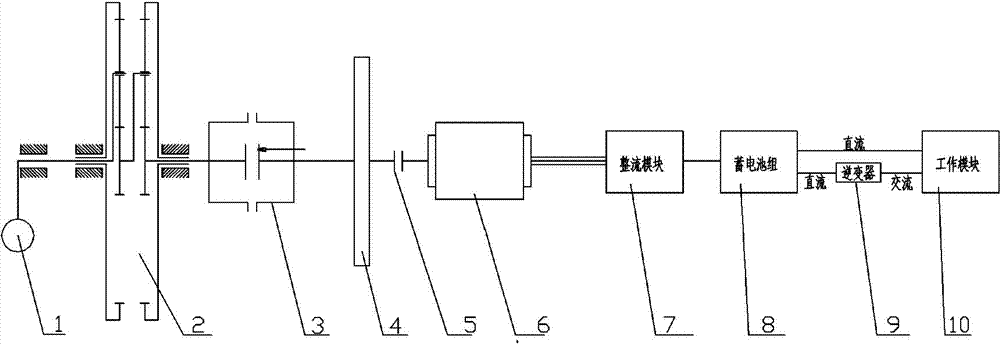

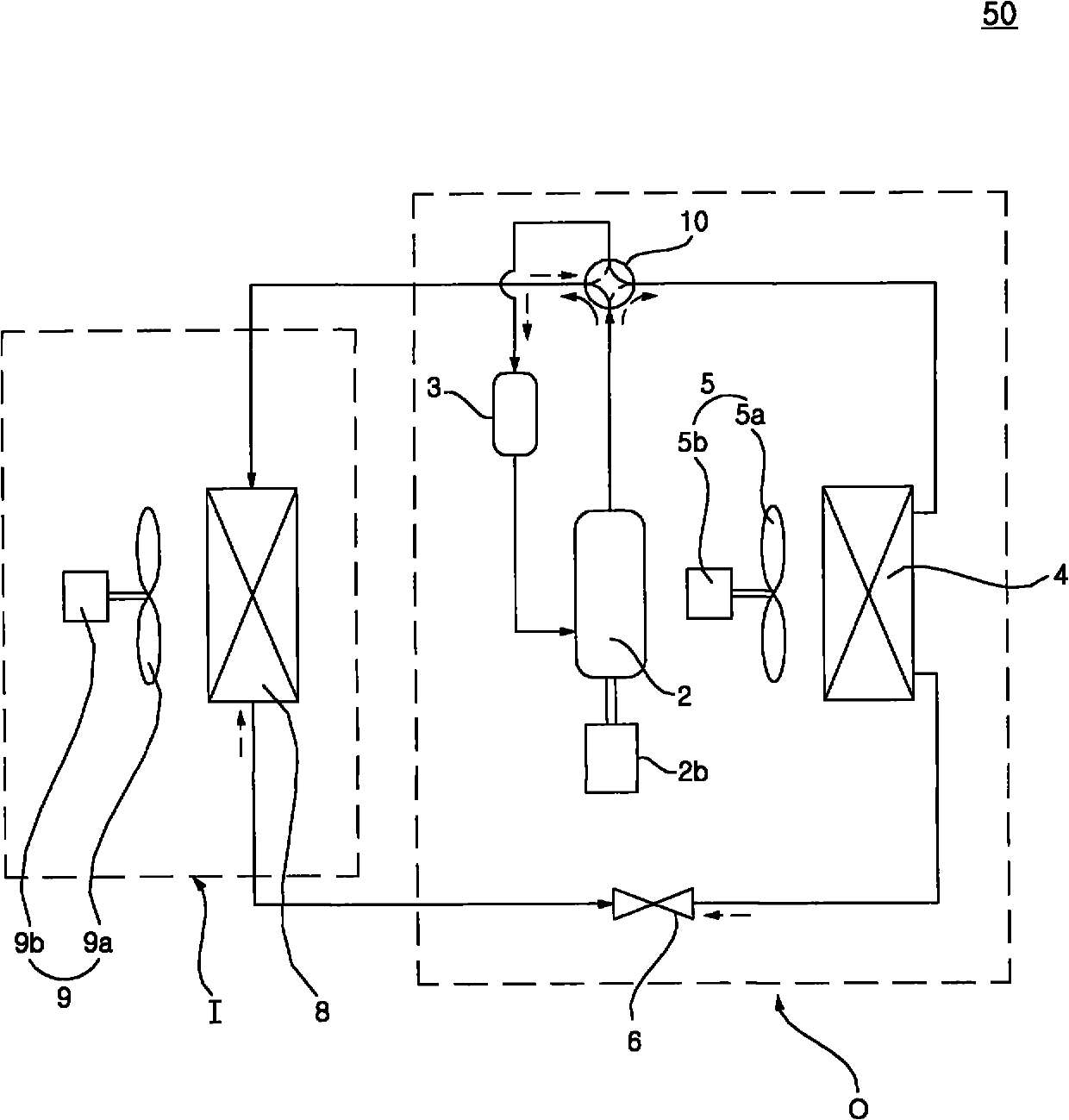

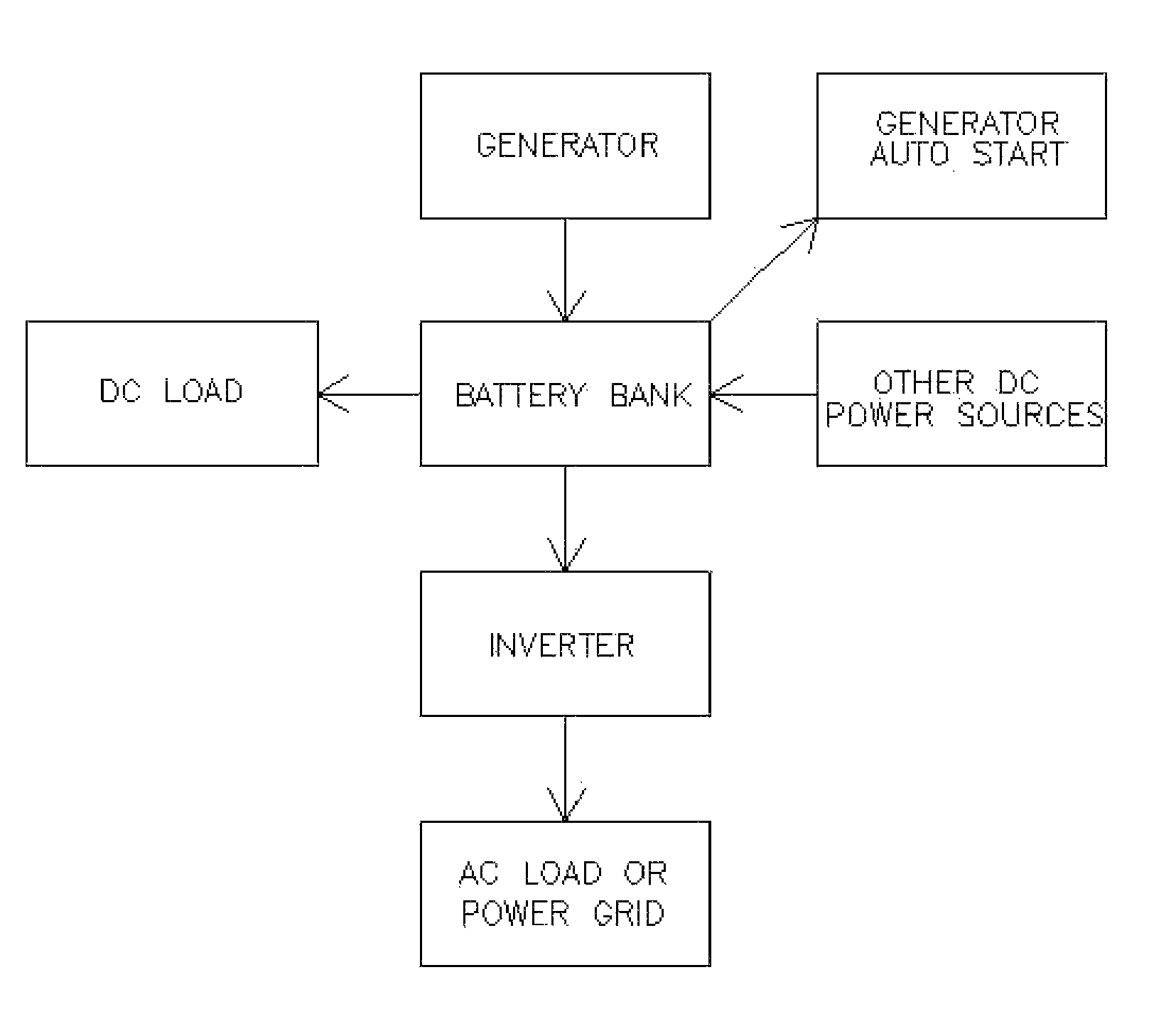

Novel carried type ocean kinetic energy conversion and power generation device

InactiveCN104763577AImprove battery lifeMechanical stabilityBatteries circuit arrangementsMachines/enginesClutchSeawater

The invention relates to a novel carried type ocean kinetic energy conversion and power generation device. The novel carried type ocean kinetic energy conversion and power generation device comprises an energy obtaining module, a planetary gear speed increase mechanism, a safe clutch, a flywheel, a coupler, a permanent magnet synchronous generator, a rectification module, a charging energy storage module, an inverter, a working module and other components. The novel carried type ocean kinetic energy conversion and power generation device is installed in an underwater unmanned mobile platform, vibration is generated due to the fact that the platform of the novel carried type ocean kinetic energy conversion and power generation device bears acting force of ocean kinetic energy, symmetrical pendulums in the novel carried type ocean kinetic energy conversion and power generation device swing, wave energy is captured, the rotating speed is increased through planetary gear speed increasers, the wave energy is output the flywheel, and stable mechanical energy is obtained; the generator is driven to generate electricity through high-speed rotation of the flywheel, stable currents are obtained through the rectification module to charge a storage battery module, a storage battery keeps working for a long time, and long-time energy self-supply of the underwater unmanned mobile platform is achieved. By the adoption of the technical scheme that the novel carried type ocean kinetic energy conversion and power generation device is carried on the underwater unmanned mobile platform and completely isolated from seawater, the electromechanical ocean kinetic energy conversion and power generation device is created.

Owner:CHINA THREE GORGES UNIV

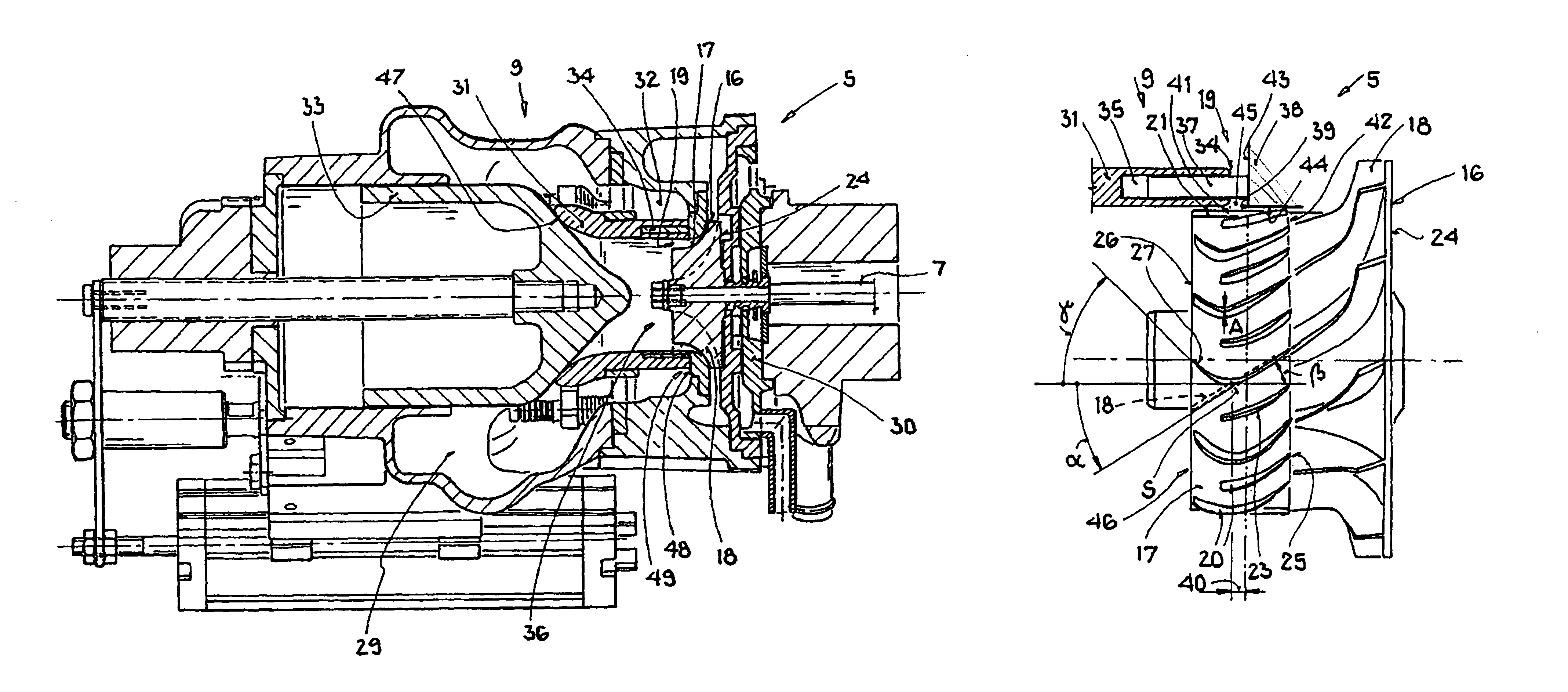

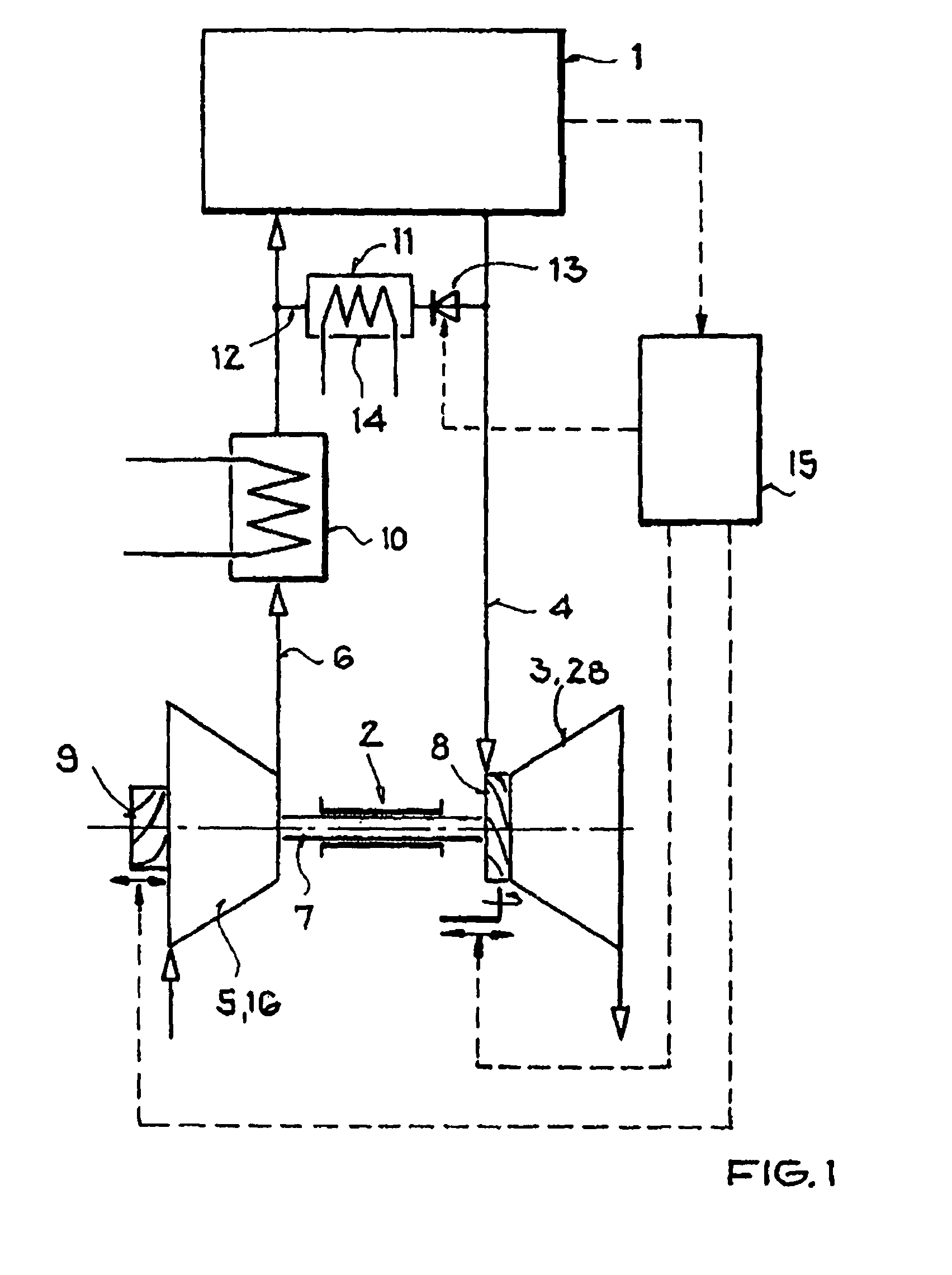

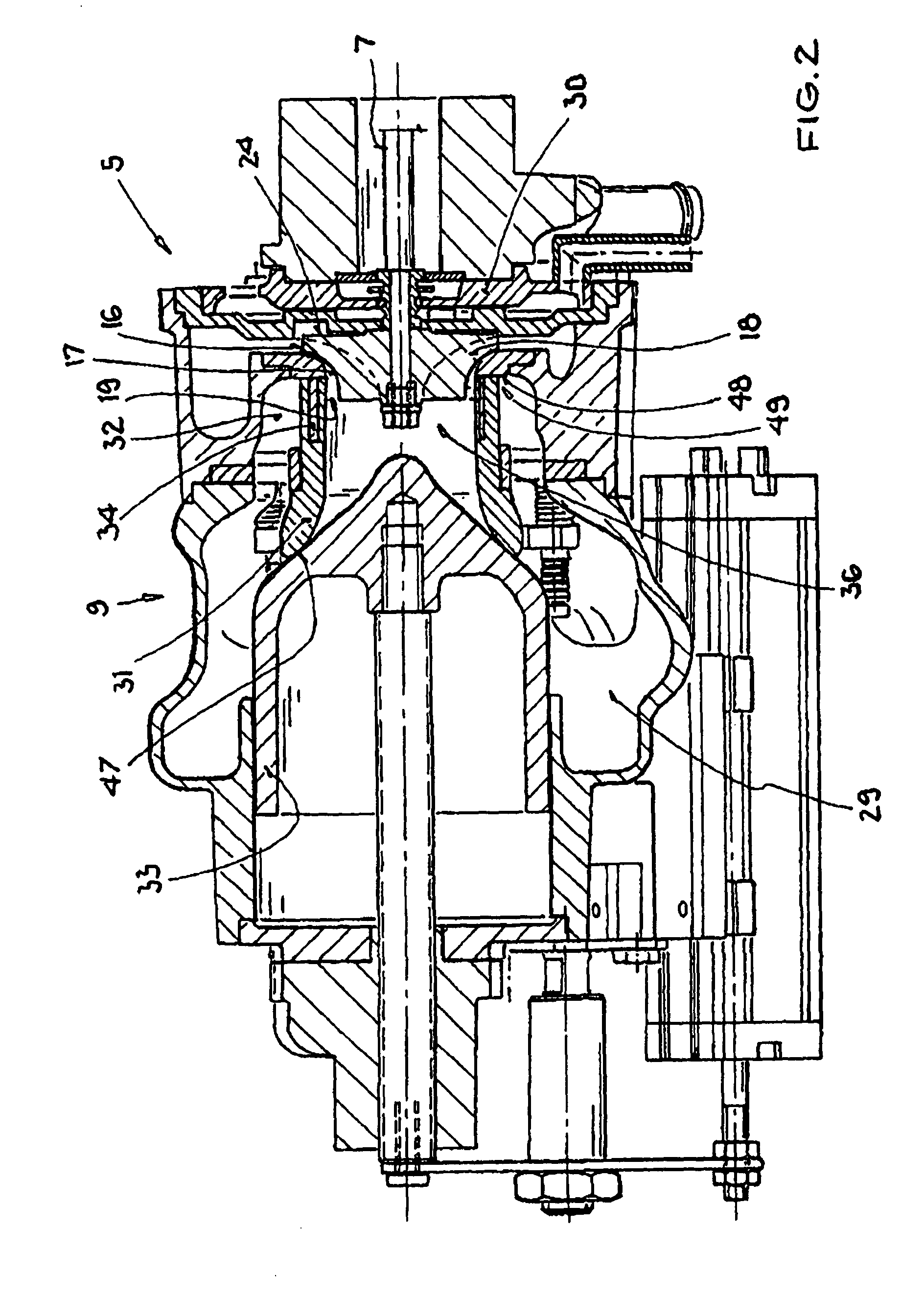

Exhaust gas turbocharger for an internal combustion engine

Owner:DAIMLER AG

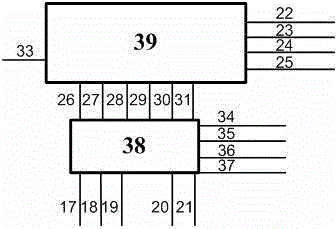

Control characteristic testing device and control strategy of ultrasonic motor servocontrol system

InactiveCN103336523AWith friction self-locking functionGuaranteed uptimeElectric testing/monitoringMotor loadUltrasonic motor

The invention relates to a control strategy and a control characteristic testing device of a travelling wave type ultrasonic motor servocontrol system. The testing device comprises a motor-driven controller, an ultrasonic motor, a permanent magnet brushless DC motor, and a photoelectric encoder, wherein the ultrasonic motor, the permanent magnet brushless DC motor and the photoelectric encoder are arranged on corresponding brackets respectively; the output shaft of the ultrasonic motor is connected with the front end output shaft of the permanent magnet brushless DC motor through a first elastic coupler; a torque sensor is arranged on the first elastic coupler; the back end output shaft of the permanent magnet brushless DC motor is connected with the photoelectric encoder through a second elastic coupler; a magnetic powder brake is arranged on the second elastic coupler; the motor-driven controller is connected with the control end of the ultrasonic motor, the output end of the photoelectric encoder and the output end of the torque sensor. The control characteristic testing device and the control strategy have the advantages that the structure is simpler; motor loading moment adjustment and synchronous speed / moment measurement can be realized according to testing requirements.

Owner:MINJIANG UNIV

Apparatus for driving motor of air conditioner and method for driving the same

InactiveCN101997479ASpeed fluctuations are minimizedReduce speed fluctuationsTorque ripple controlAC motor controlLoad torqueDrive motor

An apparatus and method for driving a motor of an air conditioner are disclosed. A method for driving a motor of an air conditioner includes driving the motor in response to a predetermined speed command, sequentially detecting first and second mechanical angles in response to the speed command or a reference speed being spaced apart from the speed command by a predetermined range, calculating a maximum speed mechanical angle corresponding to a maximum speed ripple of the motor on the basis of the detected first and second mechanical angles, and compensating for load torque of the motor on the basis of the calculated the maximum speed mechanical angle. As a result, the speed ripple is decreased during the constant speed operation.

Owner:LG ELECTRONICS INC

Energy storage and drive devices that can be applied to hybrid vehicles

ActiveCN104097497BImprove powerImprove fuel economyGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelEnergy recovery

The invention relates to an energy storage and driving device applicable to a hybrid vehicle; it comprises an engine, a first clutch, a first motor / generator, a power distribution mechanism, a flywheel module, a second clutch and a power output device; the power distribution mechanism It is a single-row planetary gear transmission; the flywheel module includes a flywheel speed-increasing driving gear, at least one flywheel speed-increasing driven gear meshing with the flywheel speed-increasing driving gear, at least one flywheel, at least one flywheel shaft and at least one Flywheel brake; the power output device includes a deceleration driving gear, a deceleration driven gear, a deceleration driven gear shaft, a speed change device, and a power output shaft; it solves the problems of low braking energy recovery efficiency and poor acceleration performance; braking energy recovery High efficiency, high acceleration, low vehicle cost and remarkable energy saving effect.

Owner:CHANGZHOU HAIKE NEW ENERGY TECH

Lightweight portable electric generator with integrated starter/alternator

InactiveUS8820286B2Improve torque performanceLow costMagnetic circuit rotating partsAir coolingAlternatorFuel efficiency

Owner:MAINSTREAM ENG

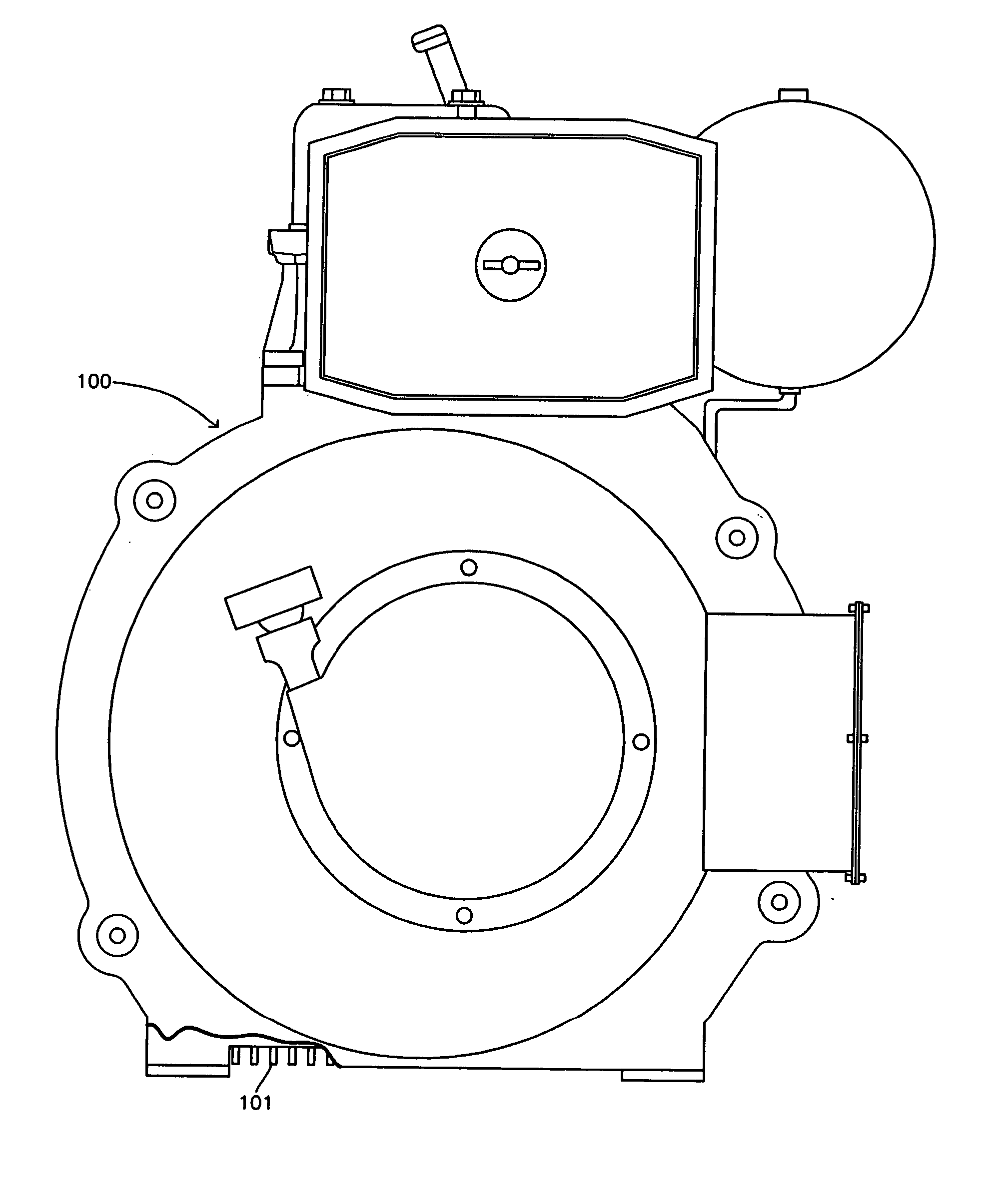

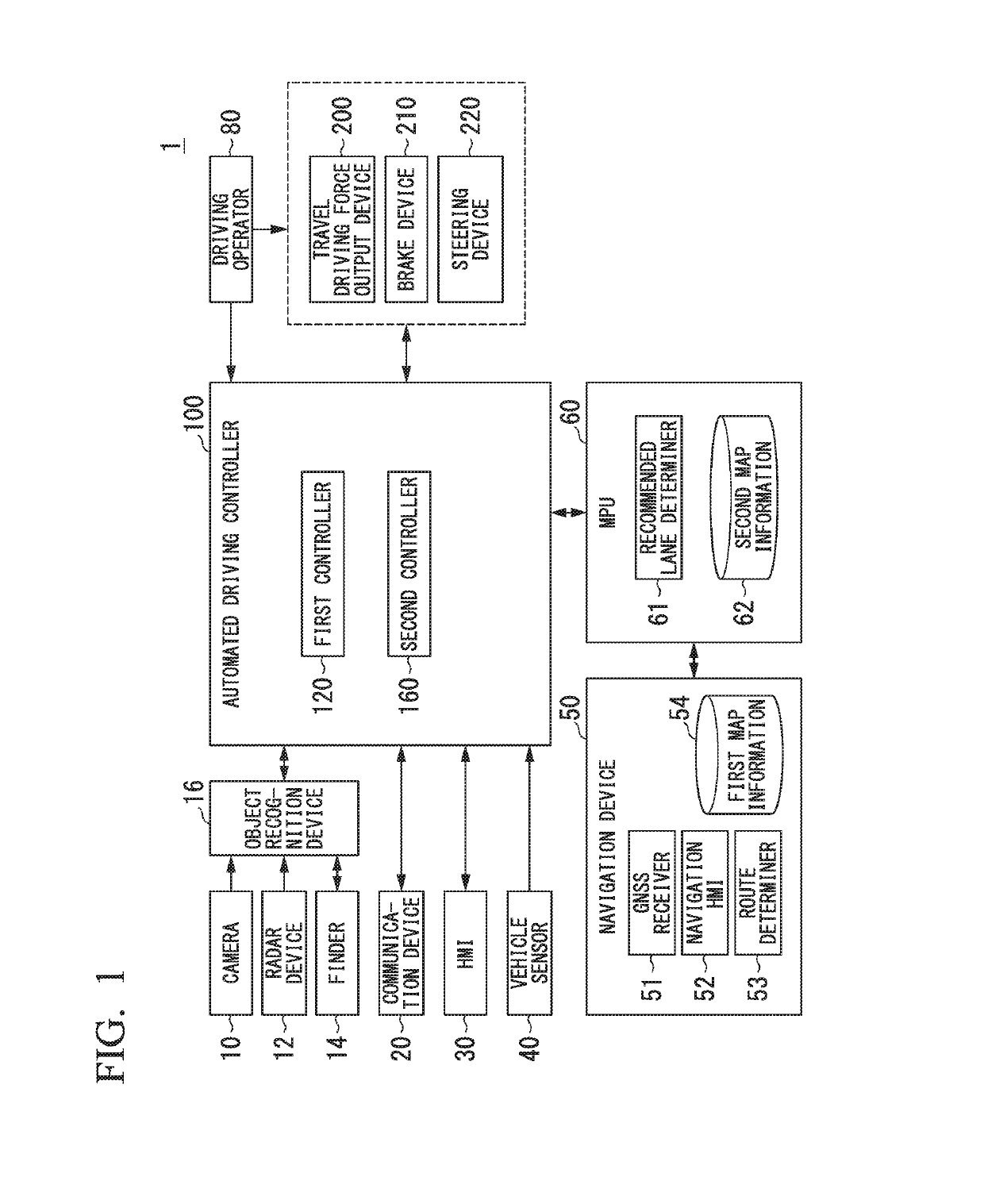

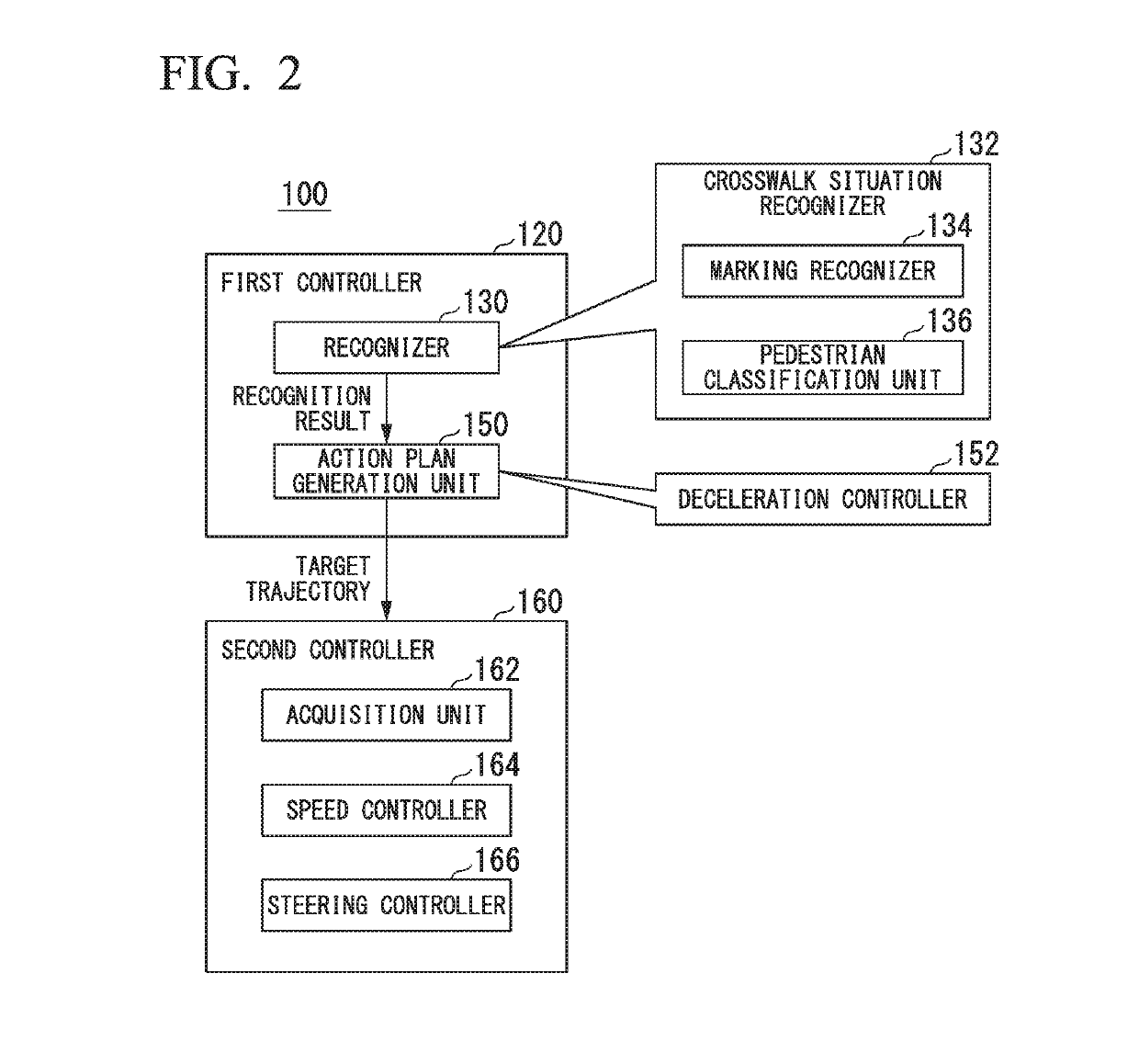

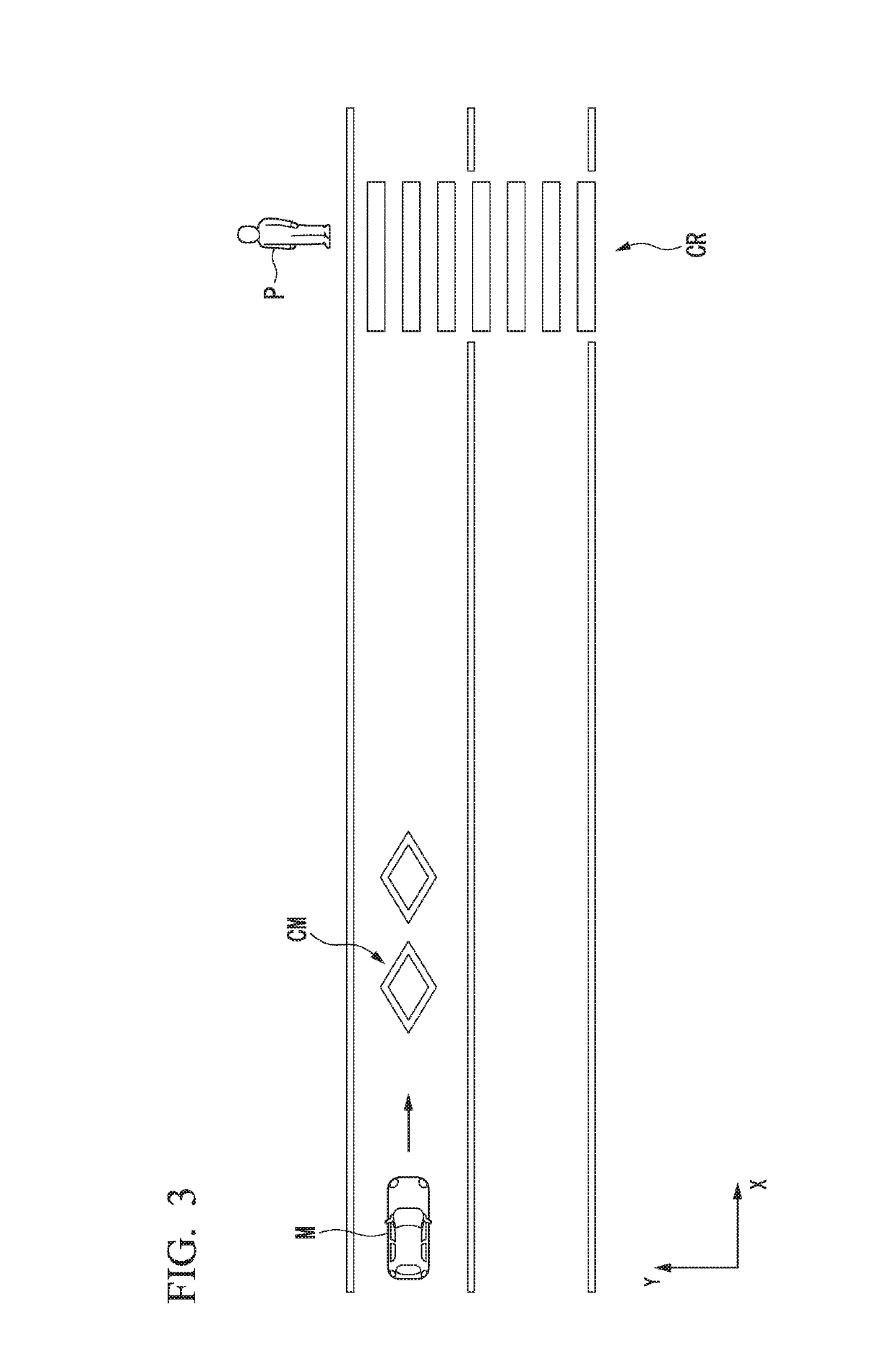

Vehicle control device, vehicle control method, and storage medium

InactiveUS20190146519A1Reduce speed fluctuationsSuppress unpleasant feelingAutonomous decision making processScene recognitionVehicle controlPedestrian crossing

A vehicle control device (100 or 400) includes a recognizer (130 or 432) that recognizes a surrounding situation of a vehicle, and a driving controller (150 and 160, or 452) that controls at least acceleration and deceleration of the vehicle, the driving controller decelerating the vehicle with different deceleration patterns on the basis of whether a pedestrian crossing the crosswalk has been recognized by the recognizer at a point in time when a marking indicating the presence of the crosswalk in advance has been recognized by the recognizer.

Owner:HONDA MOTOR CO LTD

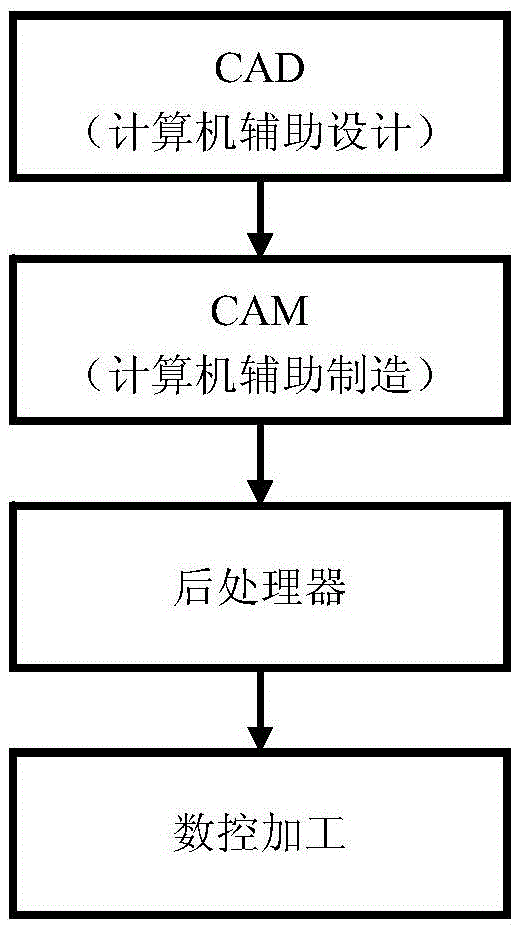

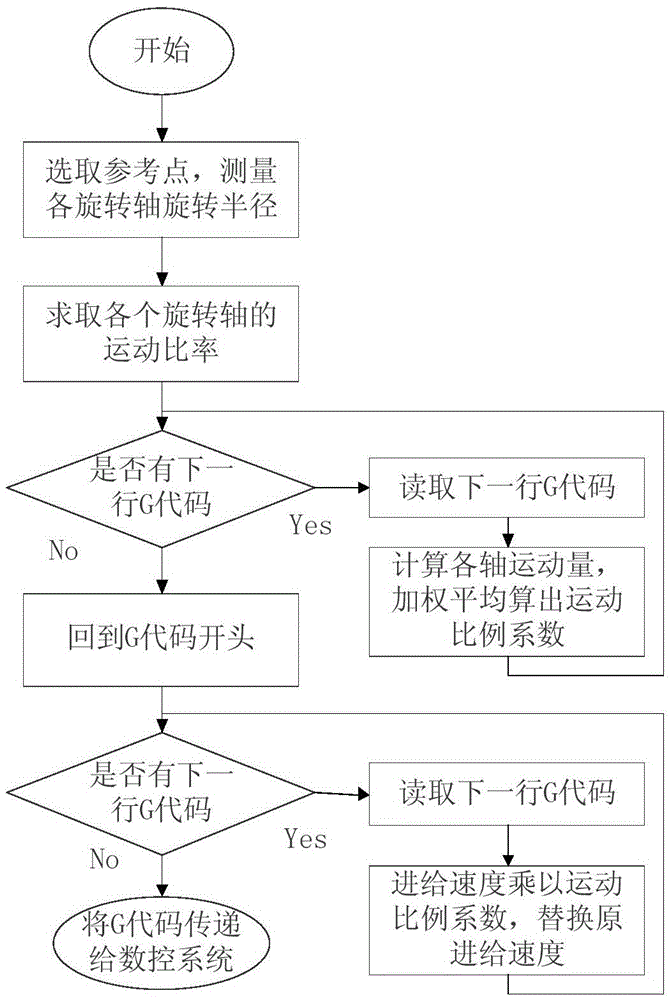

Designing method of feeding speed postprocessor used for multi-axis linkage electrosparking

ActiveCN105643030AProcessing state is stableLarge speed fluctuationElectric circuitsWeighted average methodMulti axis

The invention relates to a designing method of a feeding speed postprocessor used for multi-axis linkage electrosparking. For multi-axis linkage electrosparking machining in which rotary axes are involved, the control object is the relative distance between an electrode and a workpiece, and the unknown radiuses of the rotary axes cause fluctuation of the machining speed. From models of the electrode and the workpiece, the movement coefficients of all movement axes are defined through the rotary radiuses. On the basis, each line of G code movement coefficients are synthesized through a weighted average method to obtain a movement proportionality coefficient, the originally planned feeding speed of each line of G codes is multiplied by the movement proportionality coefficient of the line, and the machining program is updated. Speed fluctuation caused by unmatched dimension can be greatly reduced, the unstable discharging state of movement in which the rotary axes are involved is avoided, the frequency of open circuits and short circuits is reduced, and the electrosparking efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

Small line segment-based speed curve planning method suitable for cutting tool of numerical control device

ActiveCN108303952AReduce jitterReduce speed fluctuationsNumerical controlNumerical controlEngineering

The invention discloses a small line segment-based speed curve planning method suitable for the cutting tool of a numerical control device and relates to a small line segment machining technology in the numerical control technological field. According to the method, velocity planning units are combined, so that the number of determined velocity planning units can be decreased. In a traditional speed planning process, at the starting position of each velocity planning unit, accelerated velocity increases to a maximum value allowed by the system from zero, and decreases to zero at the terminating position of the velocity planning unit. Since the number of the velocity planning units is decreased, and a new speed planning method is adopted, time taken by the change process of the acceleratedvelocity during a machining process can be effectively reduced; and since the velocity planning units are combined, the length of the path of the cutting tool corresponding to a combined new speed planning unit is increased, so that during the machining process, the machining speed of the cutting tool can be maintained for a long time at a maximum value point, and therefore, machining quality is improved, machining time can be effectively reduced, and machining efficiency can be increased.

Owner:YANTAI UNIV

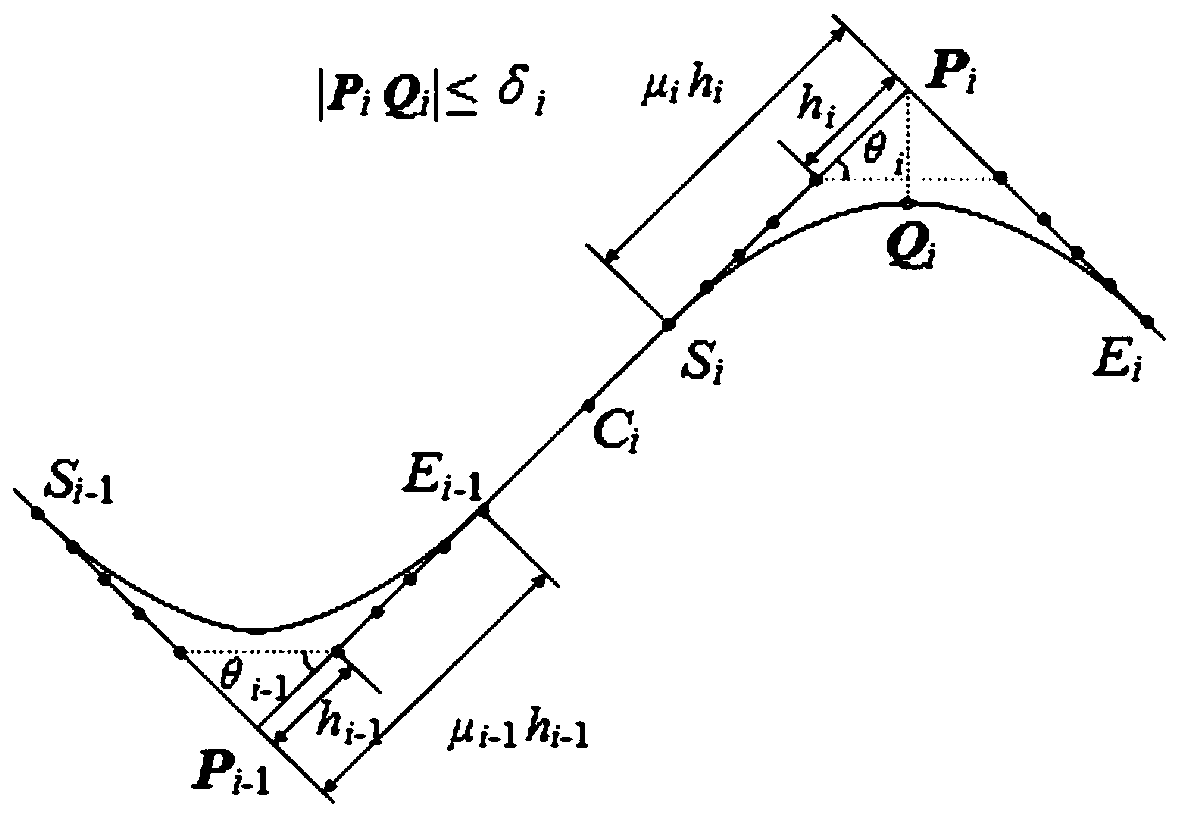

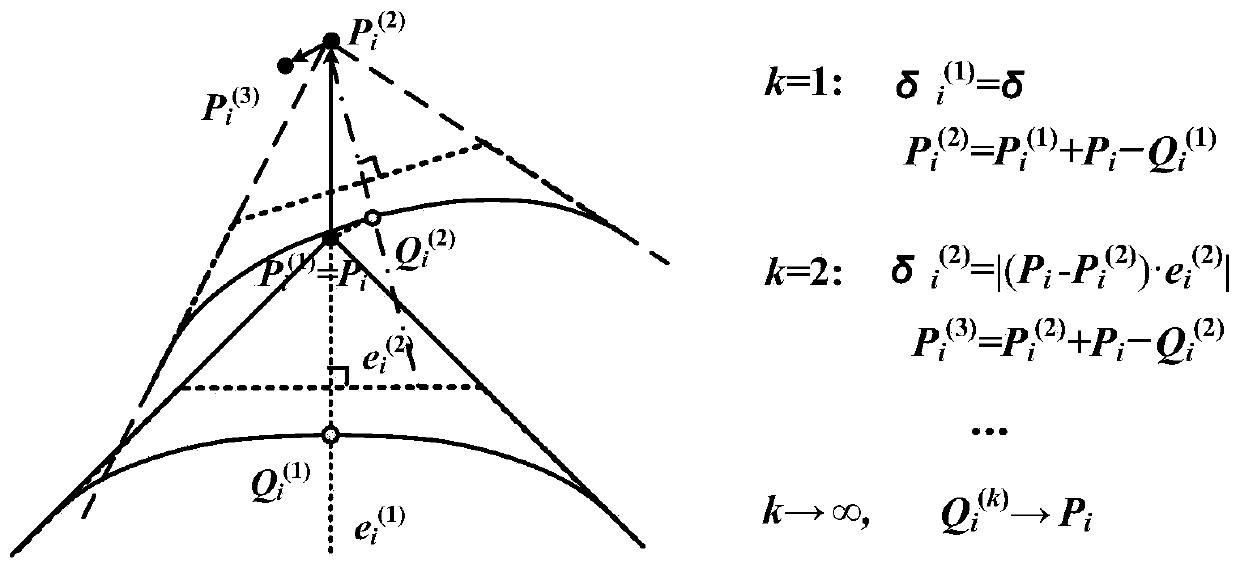

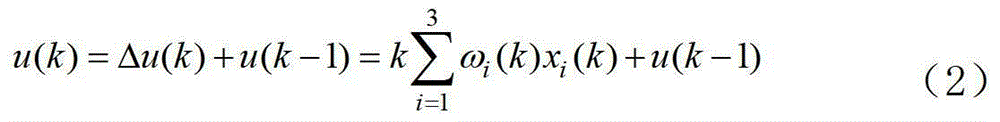

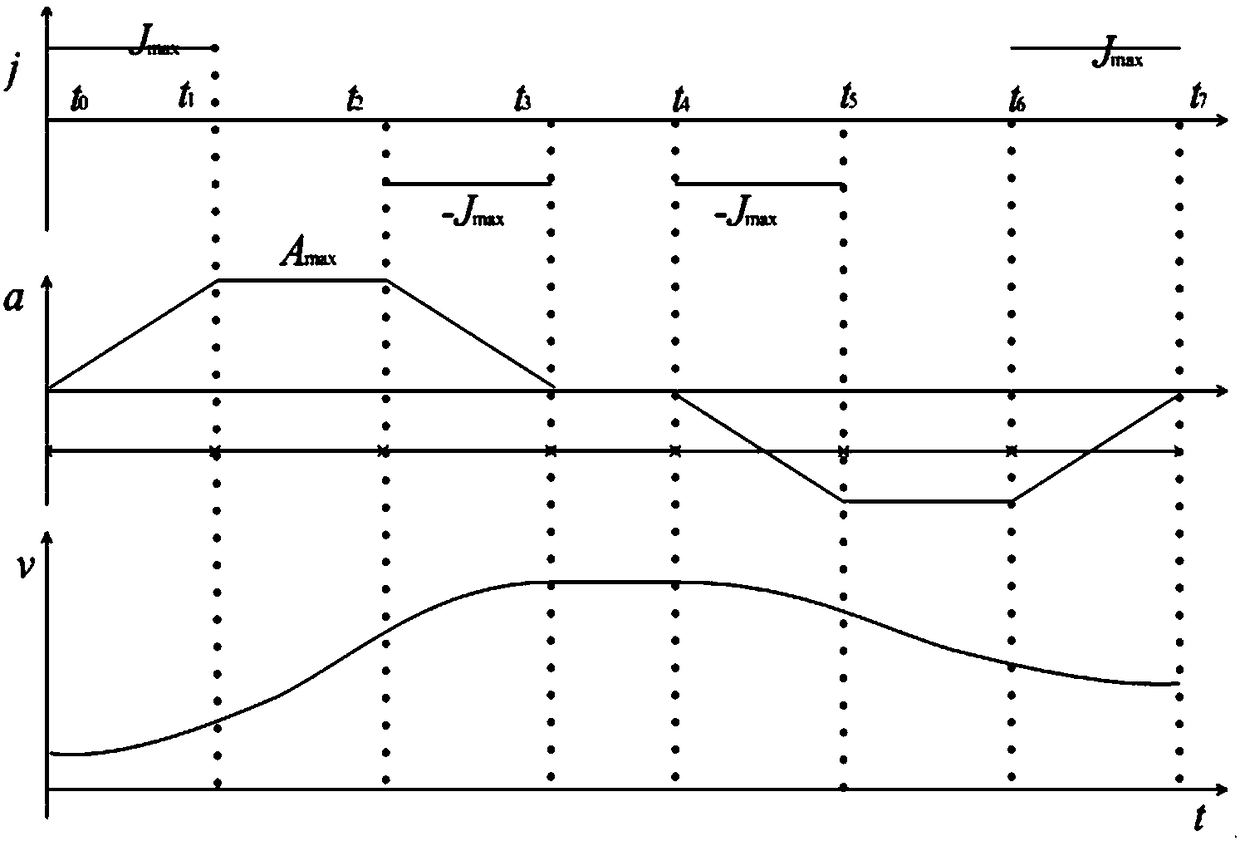

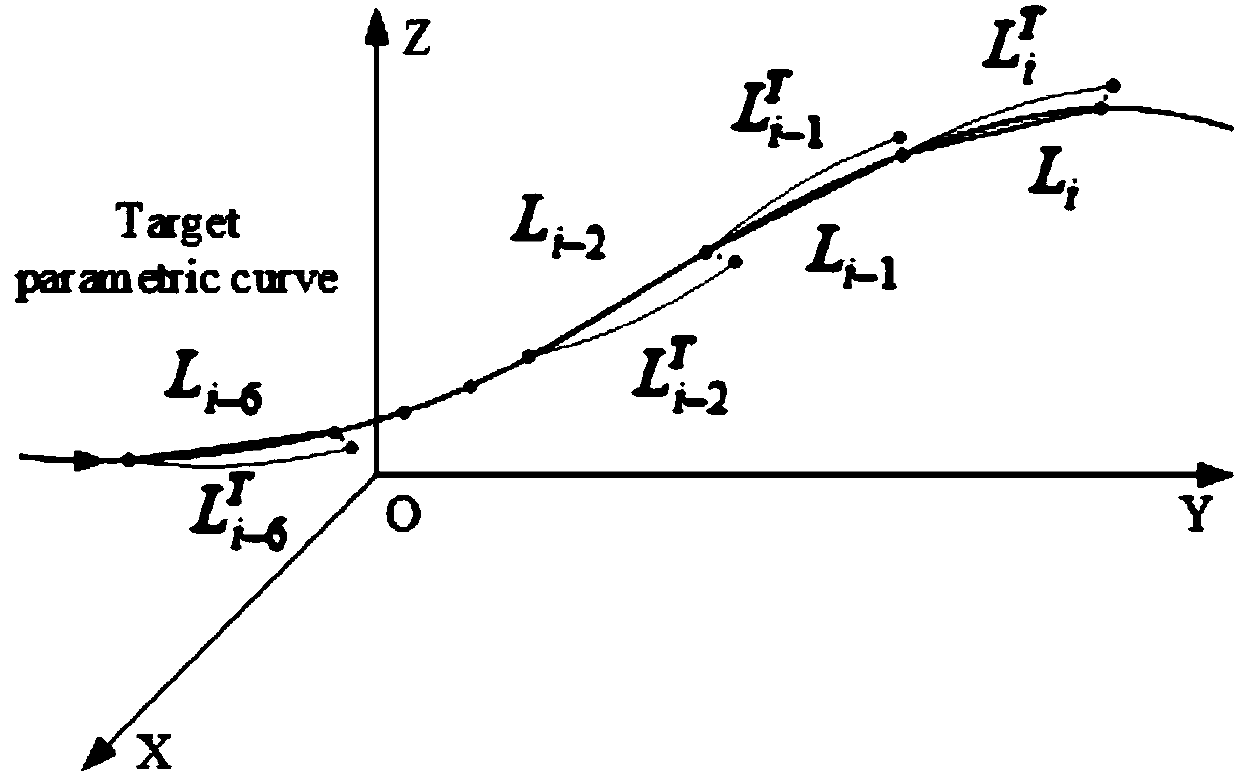

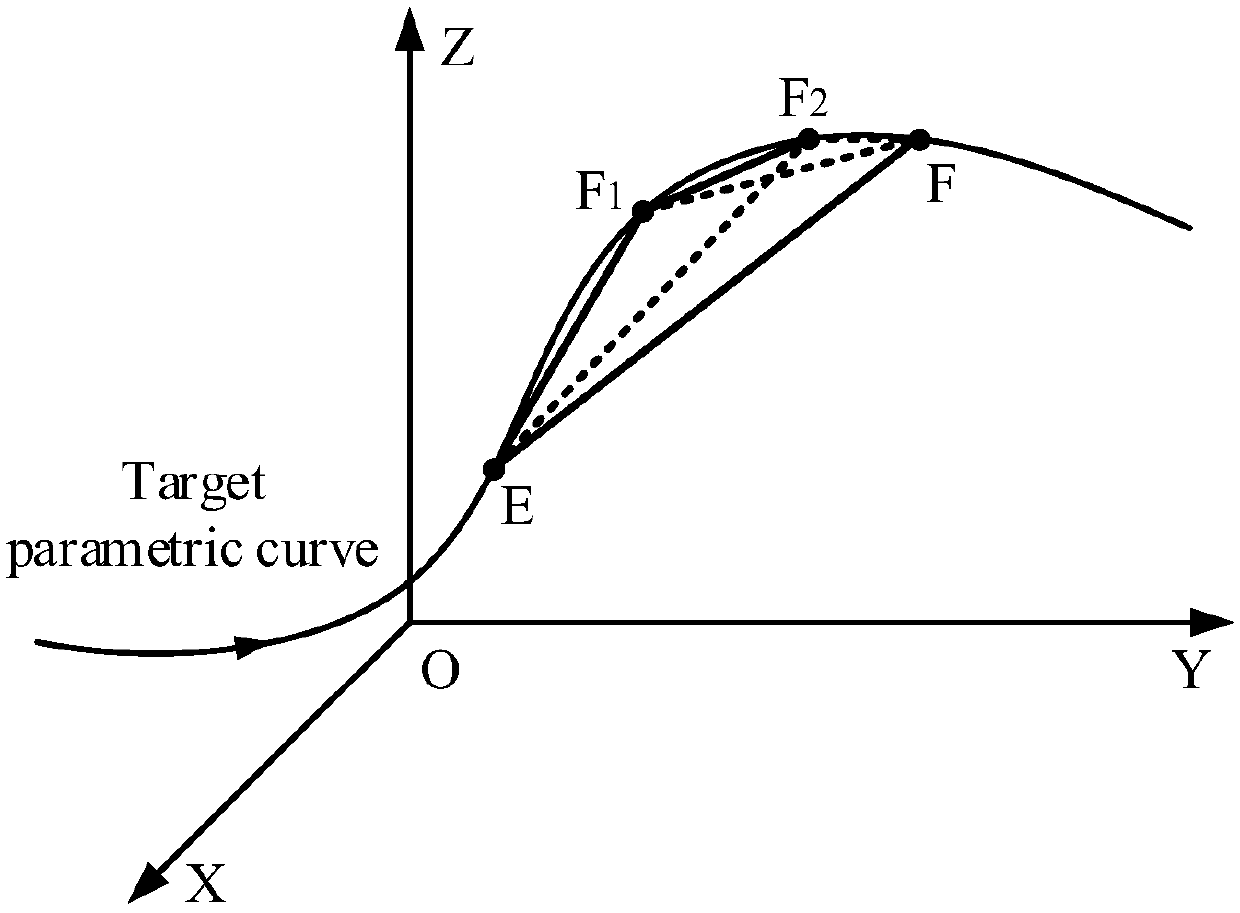

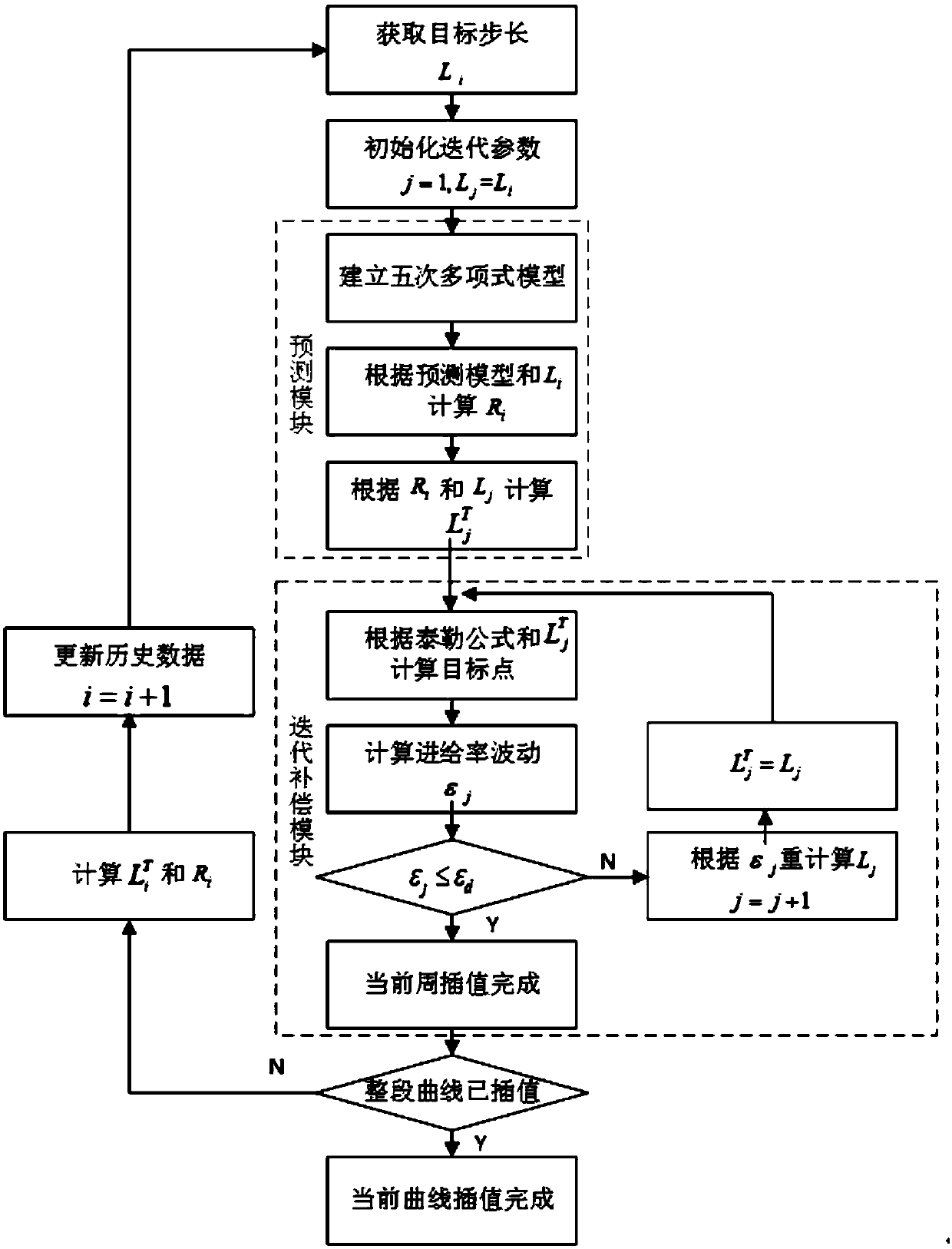

A parameter interpolation method based on prediction and iterative compensation

ActiveCN109597962AReduce speed fluctuationsImprove interpolation accuracyComplex mathematical operationsPrediction algorithmsErrors and residuals

The invention discloses a parameter interpolation method based on prediction and iterative compensation. The method solves the problem that interpolation has errors in the prior art. The parameter interpolation method has the beneficial effects that the interpolation precision can be adjusted by controlling the number of iterations, and the scheme is as follows: the parameter interpolation methodbased on prediction and iterative compensation comprises the steps of: predicting a target length by combining a second-order Taylor formula on the basis of a multi-time polynomial prediction algorithm designed by historical interpolation data to obtain a prediction length; Designing an iterative compensation algorithm based on a second-order Taylor formula and speed fluctuation to approach the target, and adjusting the interpolation precision by controlling the number of iterations; And when interpolation of the period is completed, updating historical data to prepare for next interpolation.

Owner:SHANDONG UNIV

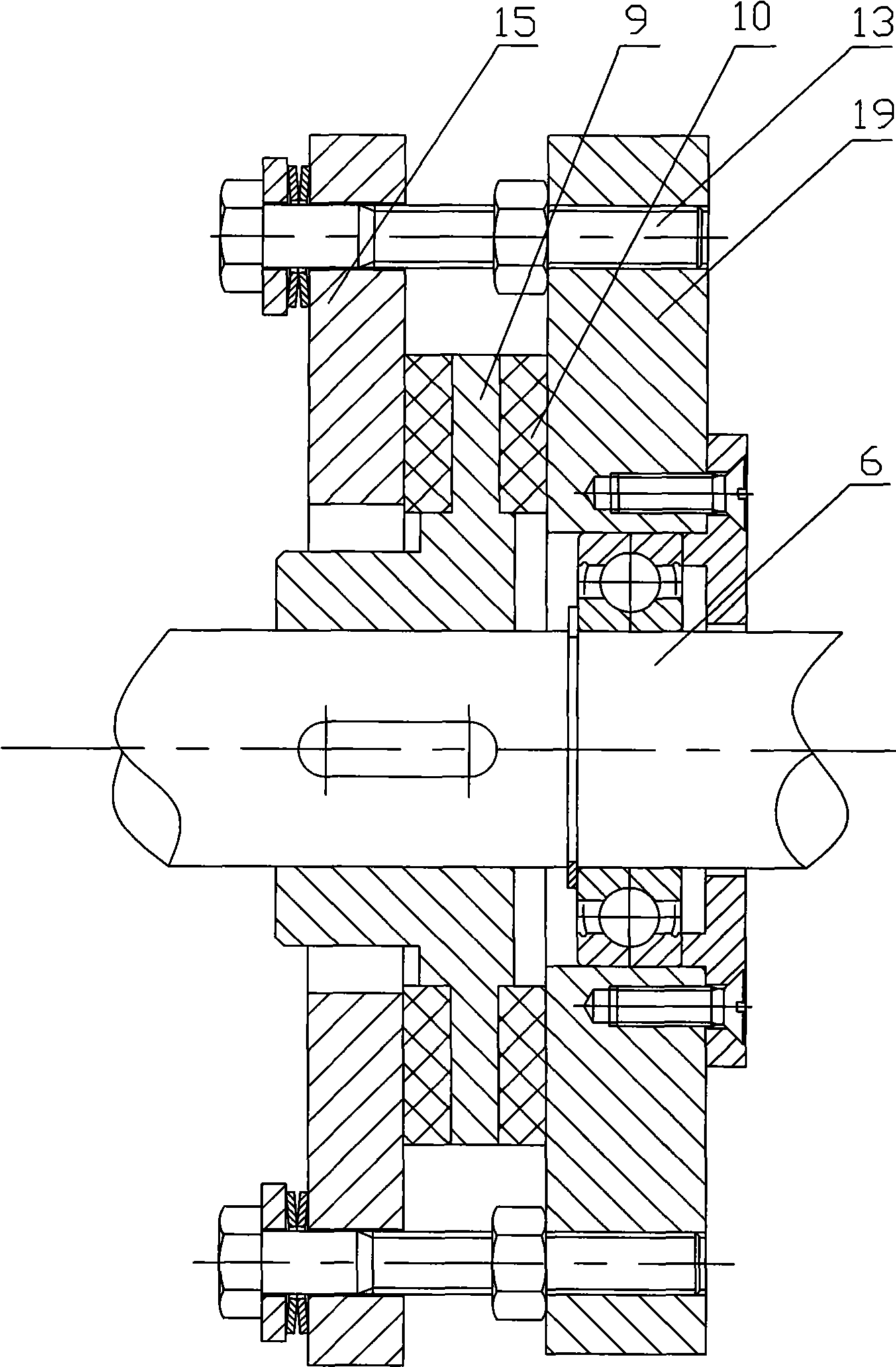

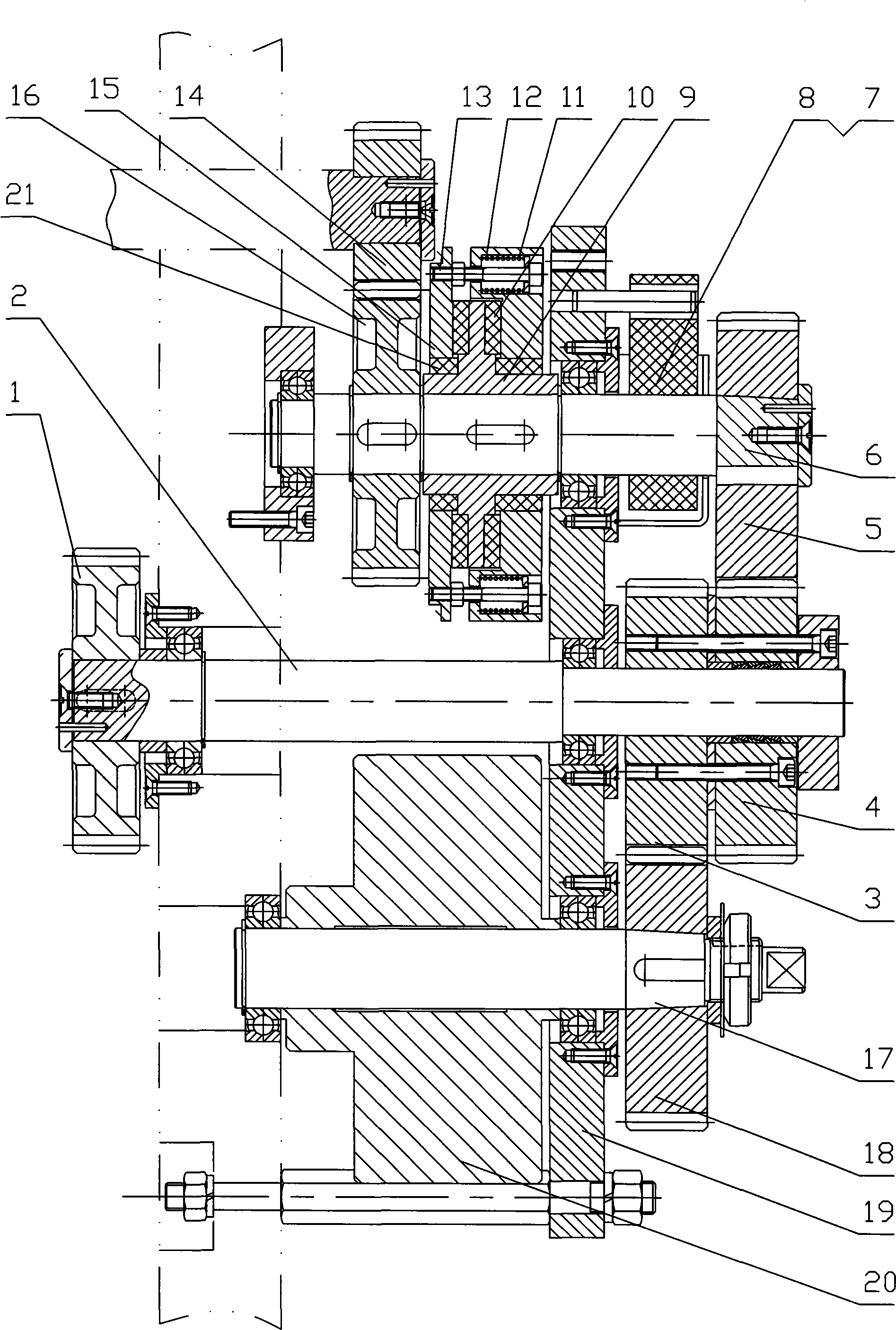

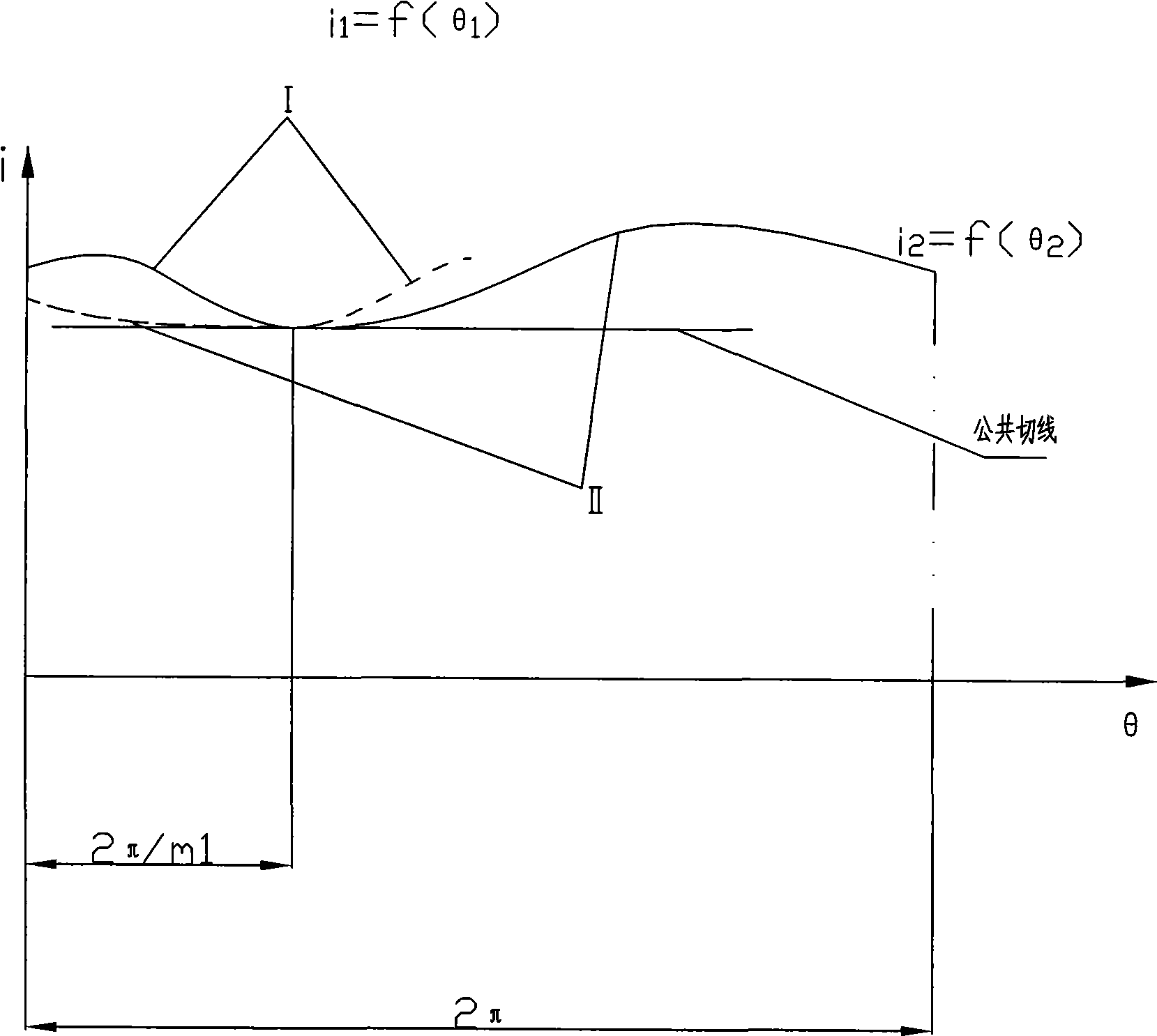

Deformed elliptic gear speed change mechanism for paper transport transmission

A deformed oval gear speed-change mechanism for paper feeding transmission relates to a speed-change mechanism of a paper feeder. The speed-change mechanism of a prior paper feeder adopts an oval gear and can cause instability for paper feeding. The deformed oval gear speed-change mechanism comprises a box body, an input shaft and a transmission shaft supported to the box body, a vibration absorber arranged in the middle of the transmission shaft, and a gear cluster arranged between the transmission shaft and the input shaft. The deformed oval gear speed-change mechanism is characterized in that the gear cluster comprises an external gear pair, two engaged gears of the external gear pair are deformed oval gears which are respectively a first deformed oval gear connected to the input shaft and a second deformed oval gear connected to the external end of the transmission shaft, the vibration absorber comprises a power vibration absorber arranged in the box body with a clearance existing between the power vibration absorber and the box body, wherein the power vibration absorber comprises a power damping disc rotating along with the transmission shaft and a damping flywheel sleeved outside the power damping disc, and a damping friction plate is arranged between the damping flywheel and damping disc. The invention ensures accurate paper feeding and stable paper transmission.

Owner:ZHEJIANG TONGYE PRINTING MACHINERY

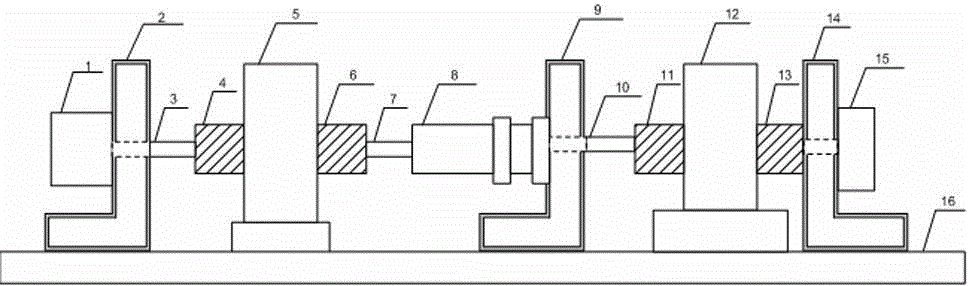

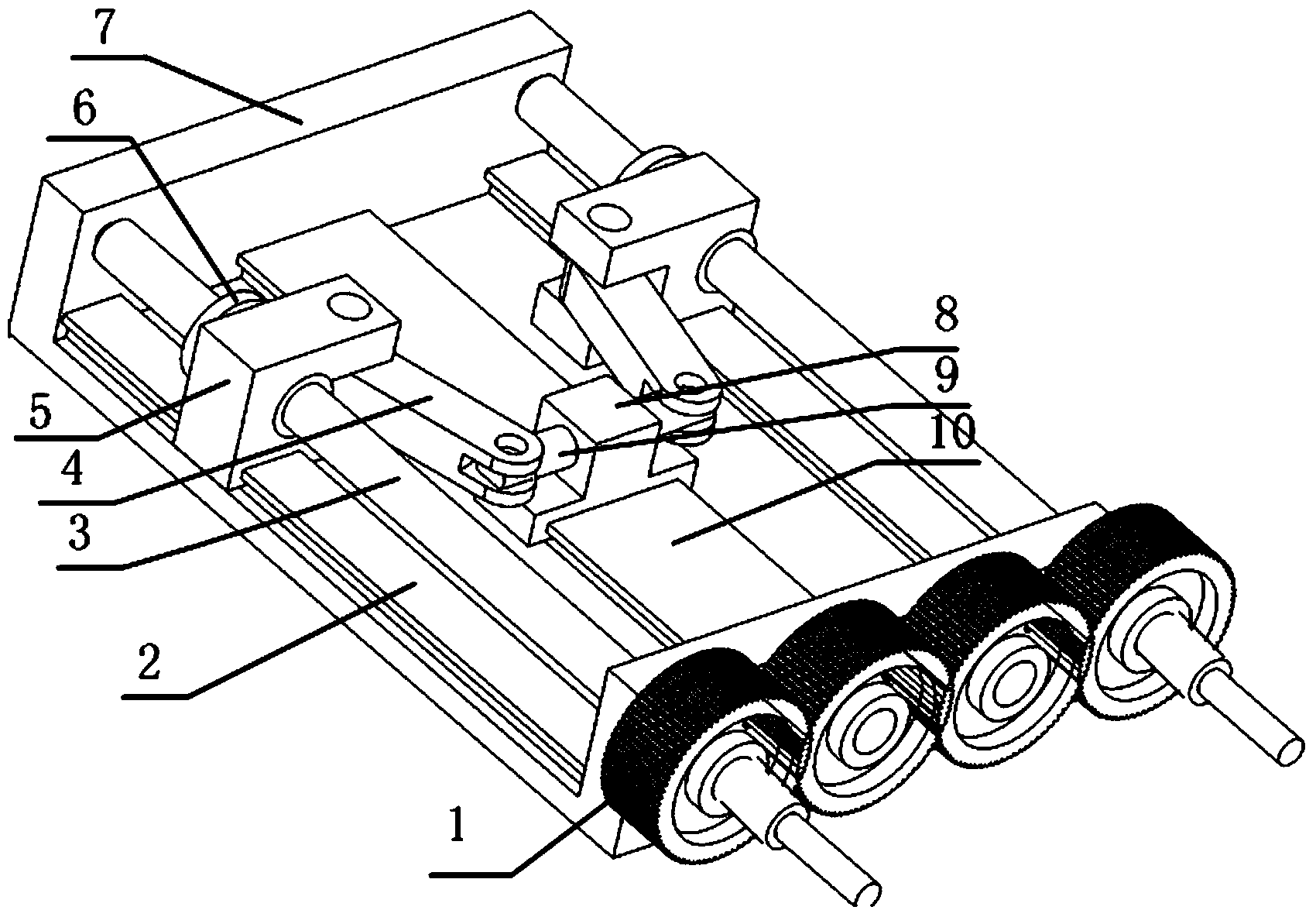

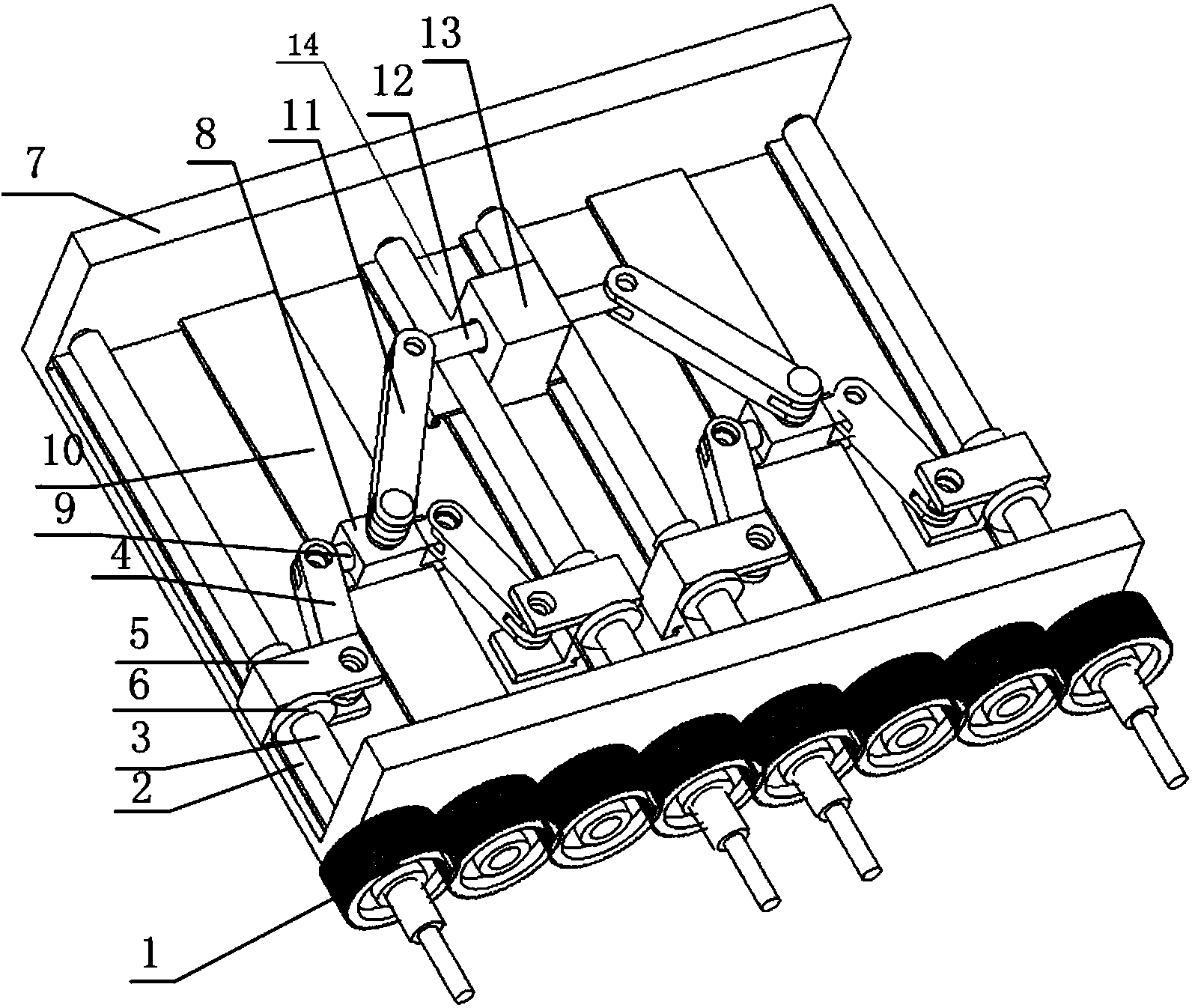

Multi-lead-screw parallel drive device

ActiveCN103939555ALow manufacturing precision and low installation precisionLow manufacturing costGearingMotion errorEngineering

The invention relates to a multi-lead-screw parallel drive device, and belongs to the technical field of mechanical engineering. The device comprises a gear for coordinating the rotating speed of lead screws, more than one pair of parallel lead screws, nuts, nut sliding blocks, linear guide rails, a coordinating rod device and a bearing sliding block, the nuts and the nut sliding blocks are matched with the lead screws, and the linear guide rails are matched with the sliding blocks to be used. The interference phenomenon cannot occur, and jamming caused by low precision of manufacturing and mounting is avoided. The lead screws are fixedly supported, rigidity is large, and the dynamic performance is good. Bearing sliding block errors caused by the motion error of a single lead screw can be reduced through a coordinating mechanism, and precision is improved. Rigid impacts are avoided in the motion process of the whole mechanism, and speed fluctuation of load sliding blocks is far lower than that of the nuts. The mechanism can be expanded, the number of the lead screws can be increased, the number of the lead screws can be two or four or eight or 2N, and the larger the number of the lead screws is, the higher the bearing capacity is, the rigidity is larger, and the speed fluctuation of the sliding blocks is smaller.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST +1

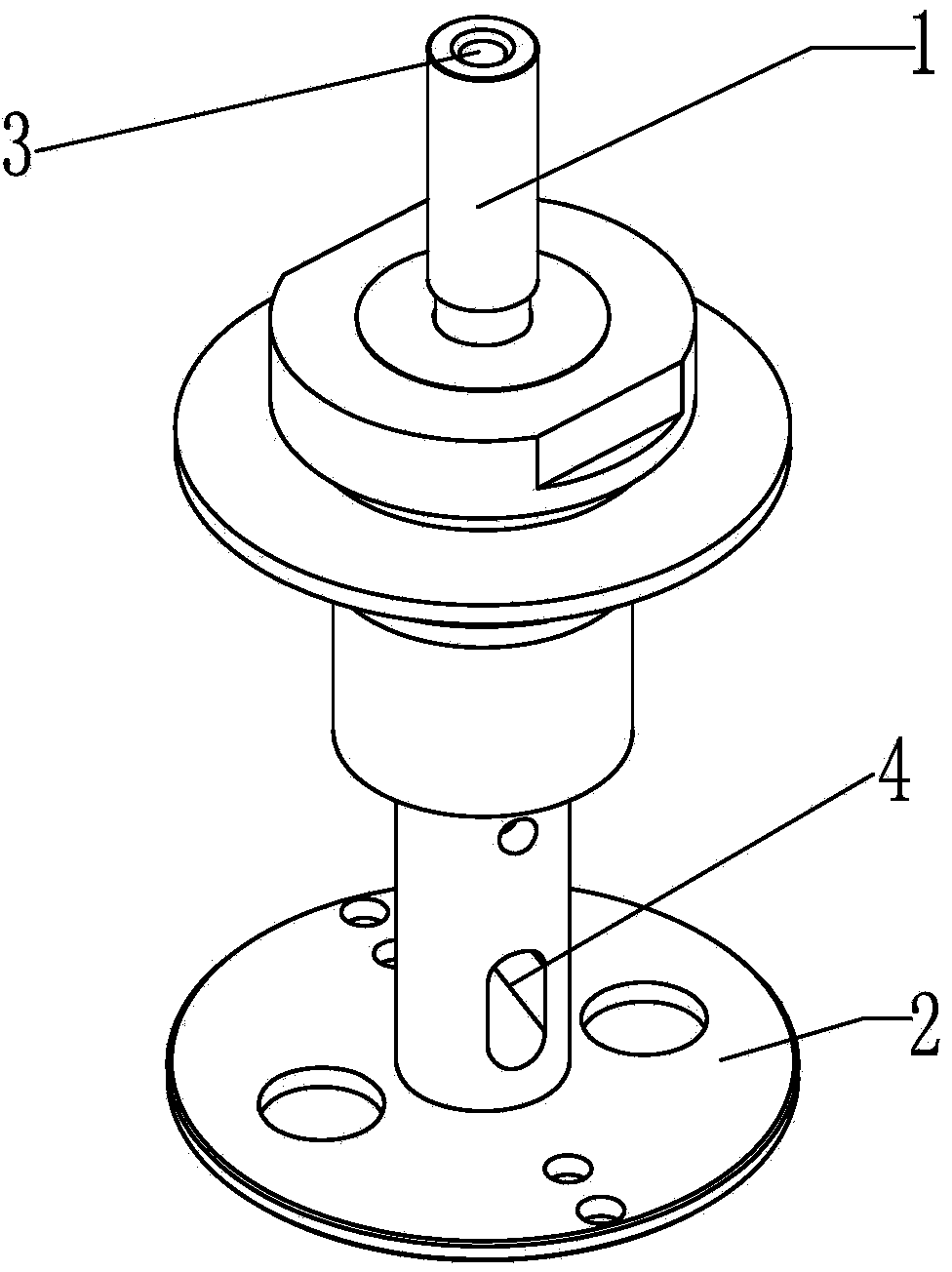

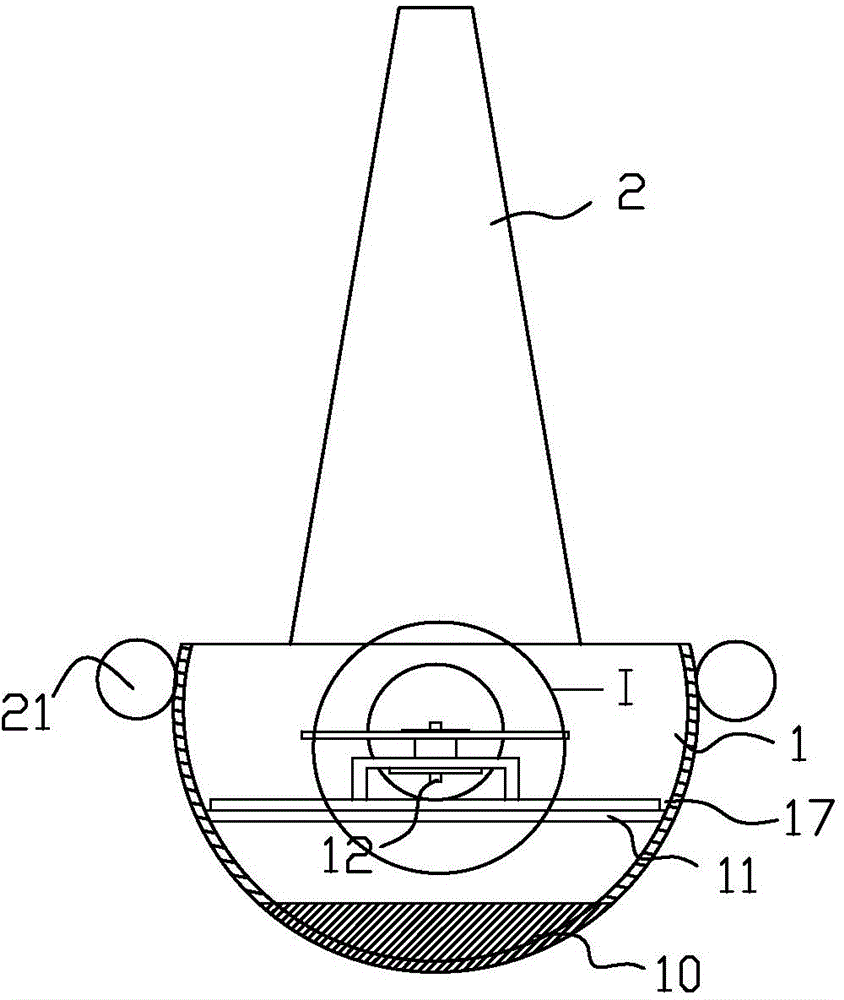

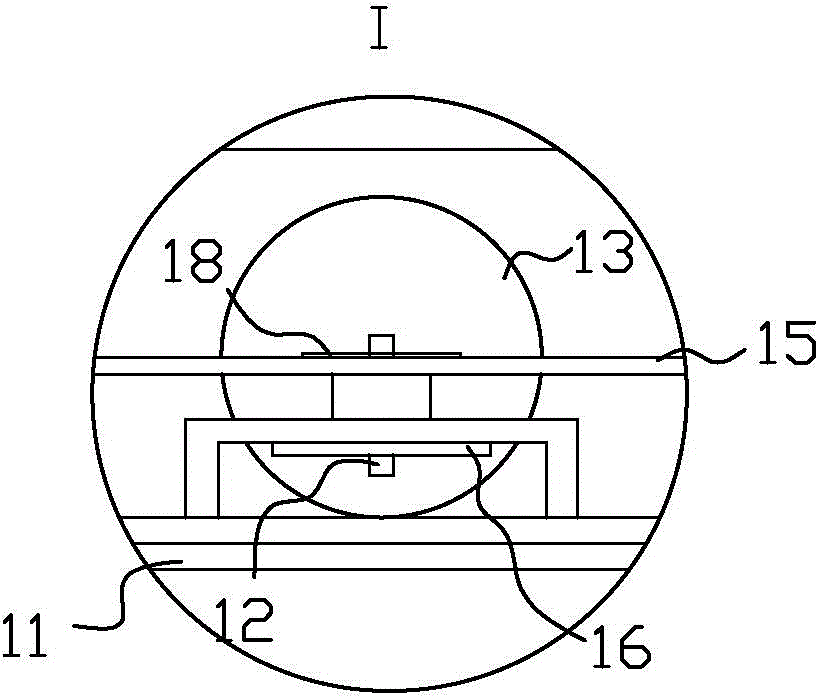

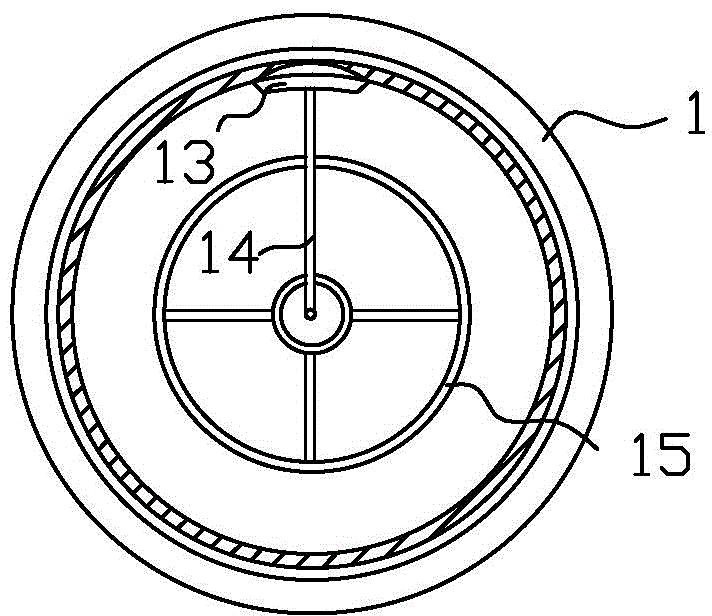

Wave power generation beacon light

InactiveCN104564506ASimple and reasonable structure designGood balanceWaterborne vesselsBuoysFlywheelEnvironmentally friendly

The invention relates to a wave power generation beacon light. The wave power generation beacon light comprises a floater in a milling flat spherical shape and a light post arranged on the upper portion of the floater. The floater comprises a balance weight at the internal bottom end, and an automatic power supply device arranged above the balance weight; the automatic power supply device comprises a horizontal round base, a spindle perpendicularly fixed onto the base, a rotating mechanism, a flywheel and an accelerator, wherein the rotating mechanism, the flywheel and the accelerator are mounted along the axis of the spindle from top to bottom; the output end of the accelerator is connected with a generator which is used for supplying power for a light inside the light post; the rotating mechanism comprises a wheel, a transmission rod, and a one-way rotating device sleeving the spindle; the transmission rod is horizontally arranged and connected with the wheel and the one-way rotating device; the circumference of the base is provided with a ring-shaped track; the edge of the wheel is arranged on the track and moves circularly around the track. The wave power generation beacon light is novel in design, energy-saving, environmentally friendly, reasonable and concise in structure, convenient to maintain and long in service life.

Owner:BEIJING KEBAO YULONG HEAVY MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com