Small line segment-based speed curve planning method suitable for cutting tool of numerical control device

A speed planning and numerical control device technology, applied in the numerical control field, can solve the problems of reducing processing quality and processing efficiency, frequent fluctuation of kinematic curve, short length of speed planning unit, etc., to reduce speed fluctuation and tool shaking, shorten processing time, The effect of reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

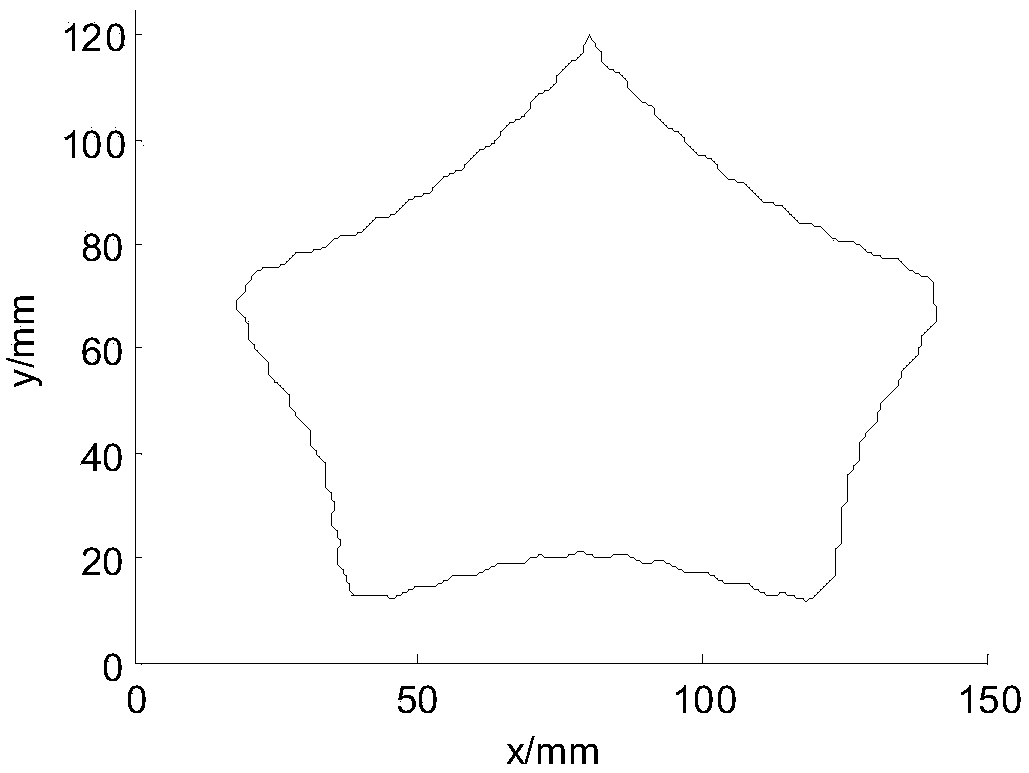

[0065] The GJ301 numerical control system produced by Shenyang High-precision CNC Intelligent Technology Co., Ltd. adopts the Inter Atom N450 processor with a main frequency of 1.66GHZ, 512MB memory, and RTlinux real-time system, and the interpolation period is 0.2ms. Using GJ301 numerical control system to implement a method of smooth compression of the tool path, figure 1 is the graph corresponding to the tool path of the workpiece to be processed,

[0066] Specific steps are as follows:

[0067] (1) Determine the threshold speed value at each corner on the processing path.

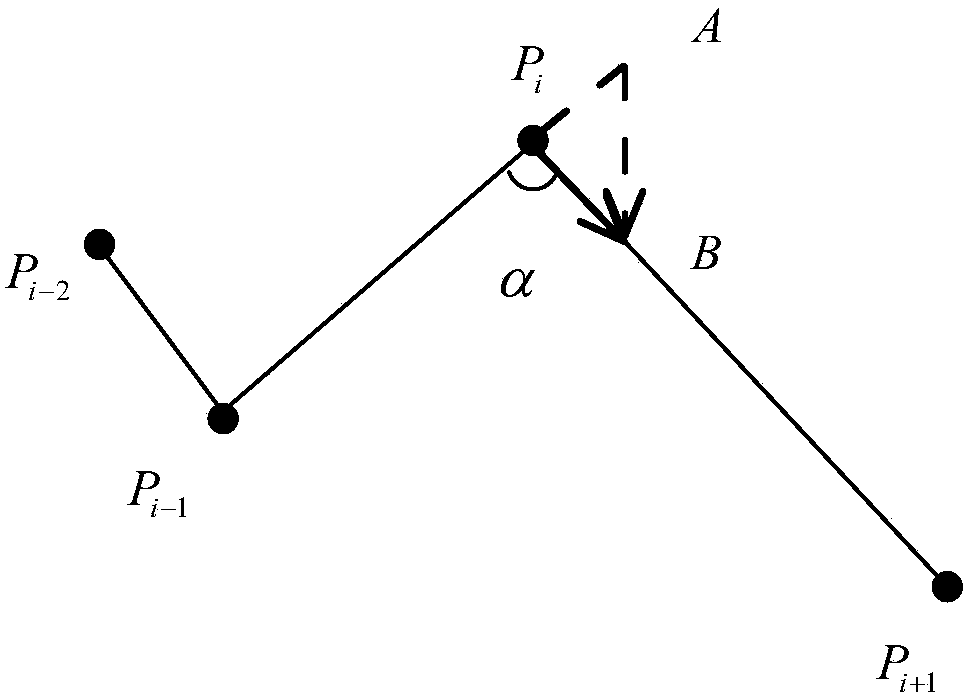

[0068] Such as figure 2 As shown, P i-1 , P i , P i+1 Three consecutive instruction points on the toolpath described by a small line segment, corner ∠P i-1 P i P i+1 with size α, the vector P i A to P i-1 P i a unit vector in the direction, vector P i B to P i P i+1 Unit vector in direction, vector AB is vector P i A and vector P i The difference of B, then the corner ∠P i-1 P i P i+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com