Energy storage and drive devices that can be applied to hybrid vehicles

A technology for hybrid electric vehicles and driving devices, which is applied in the arrangement of multiple different prime movers of power devices, pneumatic power devices, and general power devices, etc. The recycling process of kinetic energy feedback is not efficient, and it is difficult for the battery to achieve high-power charging in a short time, so as to achieve the effect of improving power performance and fuel economy, low quality, and low equipment power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

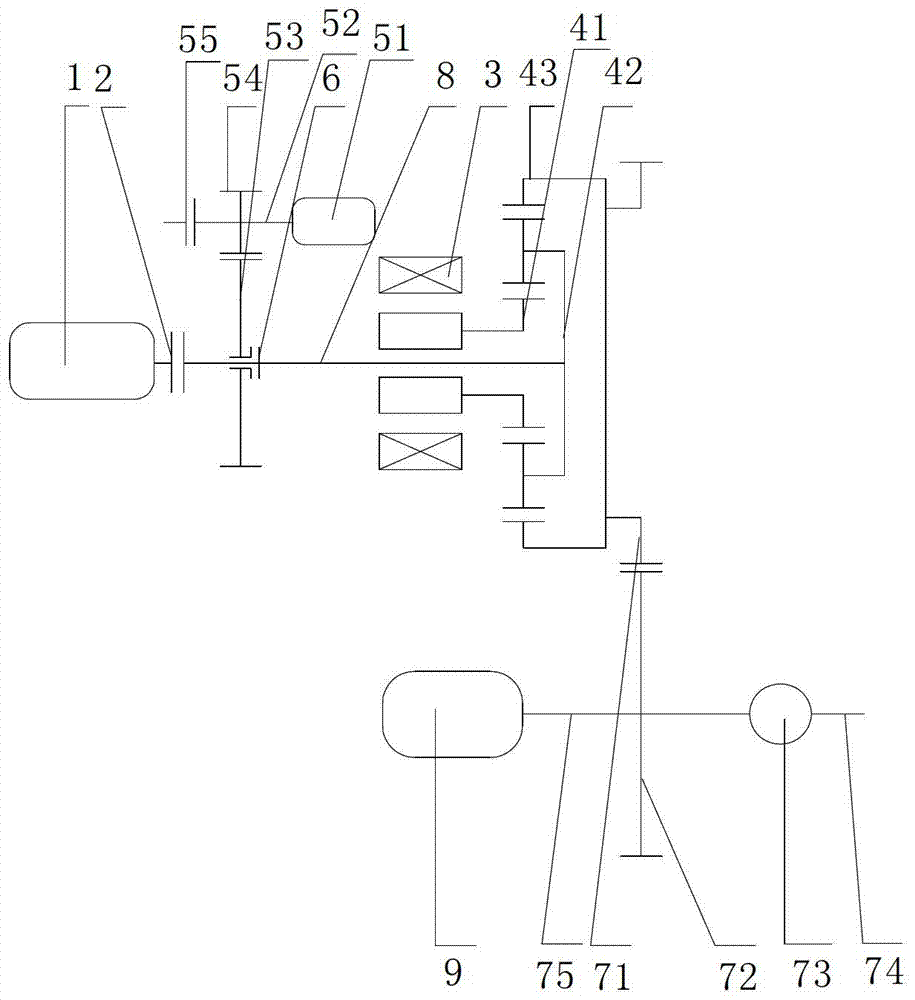

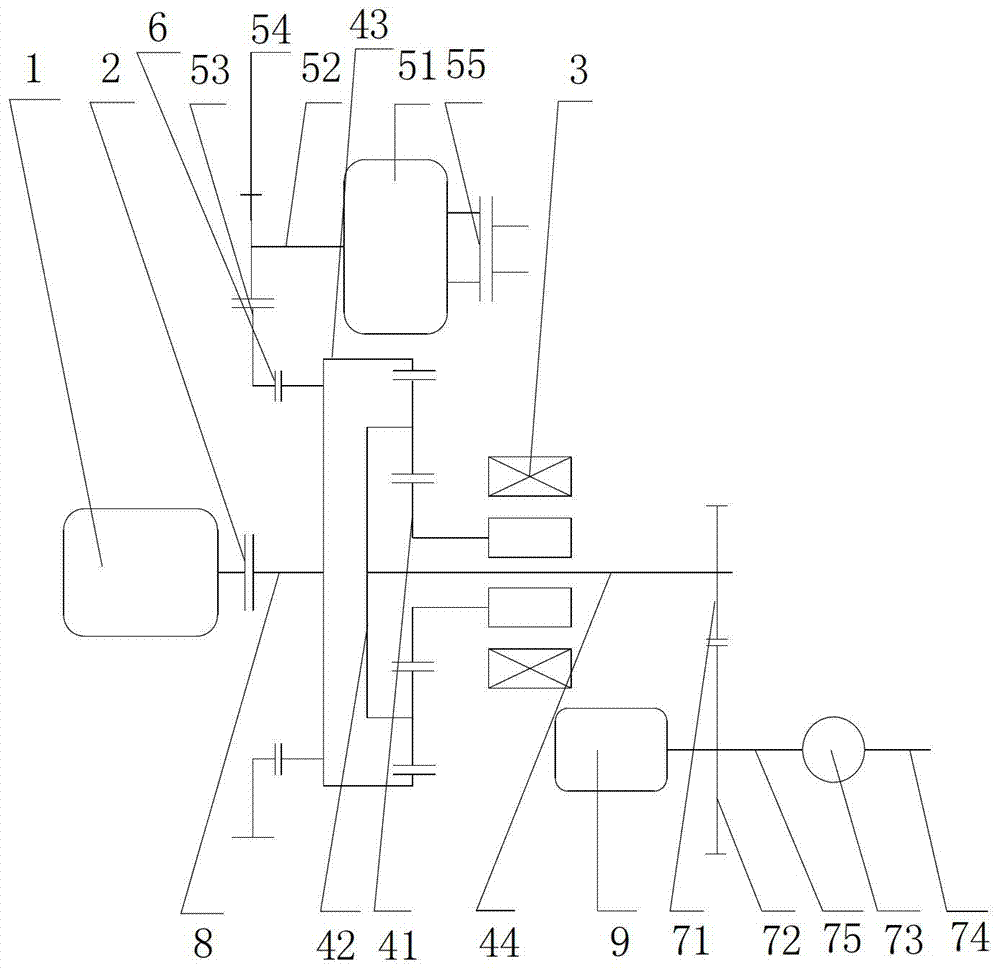

[0027] See figure 1 , which can be applied to the energy storage and driving device of a hybrid electric vehicle; including an engine 1, a first clutch 2, a first motor / generator 3, a power distribution mechanism 4, a flywheel module 5, a second clutch 6 and a power output device 7; The power distribution mechanism 4 is a single-row planetary gear transmission.

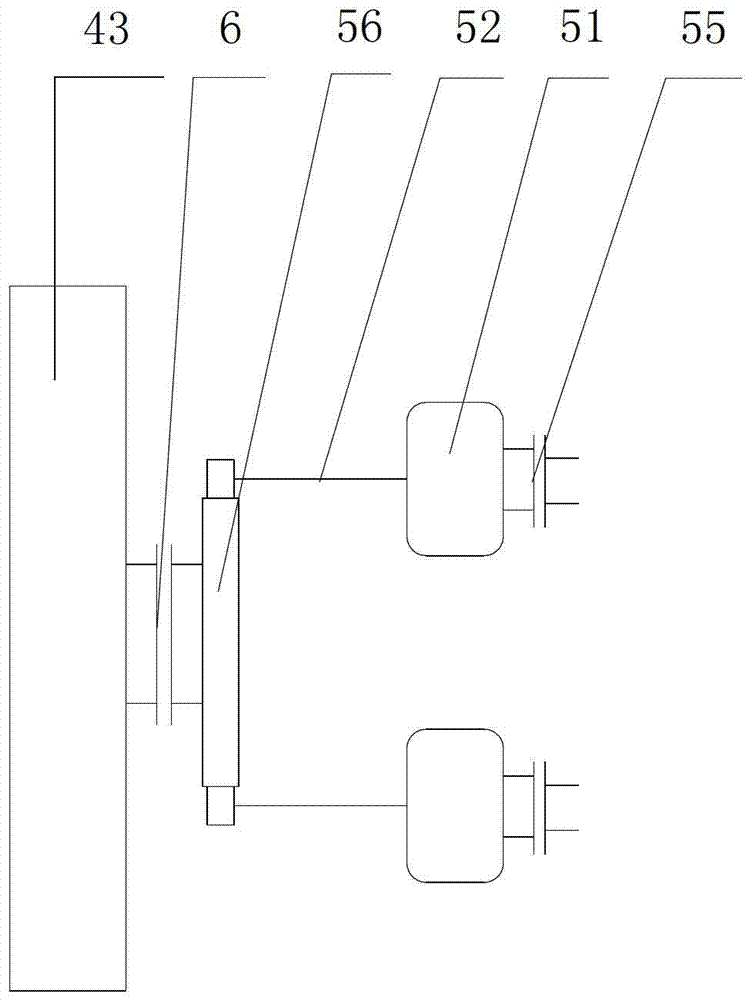

[0028] See image 3 Said flywheel module 5 includes flywheel speed-up driving gear 53, at least one flywheel speed-up driven gear 54 meshed with said flywheel speed-up driving gear 53, at least one flywheel 51, at least one flywheel shaft 52 and at least one flywheel Brake 55; meshing gear pair 56 comprises flywheel speed-up driving gear 53 and flywheel speed-up driven driven gear 54; described power output device 7 comprises deceleration driving gear 71, deceleration driven gear 72, deceleration driven gear shaft 75, speed change device 73, power output shaft 74; the engine 1, the first clutch 2, the first motor / ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com