Chenille spinning machine

A spinning machine and machine head technology, applied in the field of chenille spinning machines, can solve the problems of inability to install dust removal devices, affect the health of workers, and high investment and production costs, and achieve good spinning stability, simple structure, and low loss low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

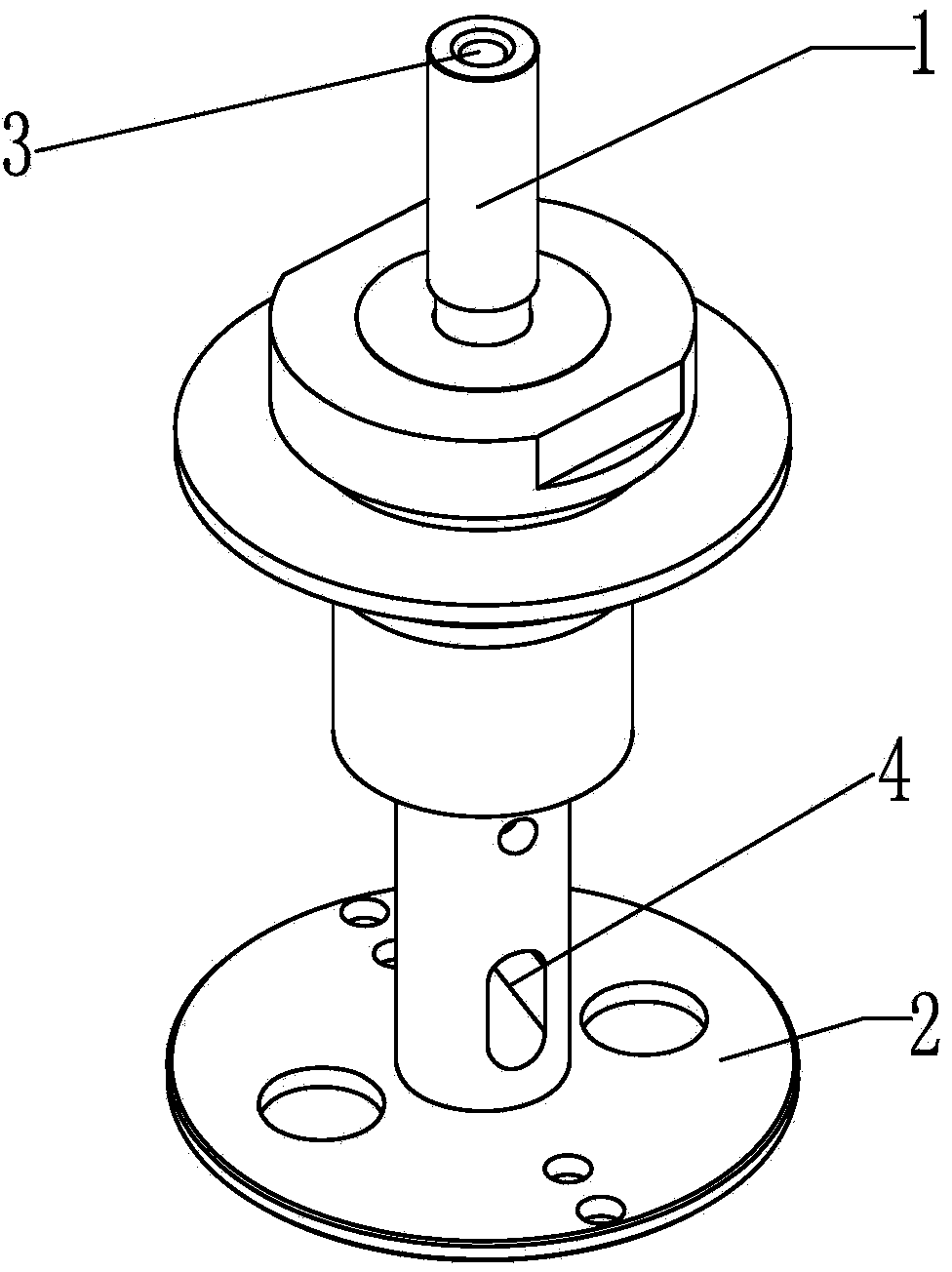

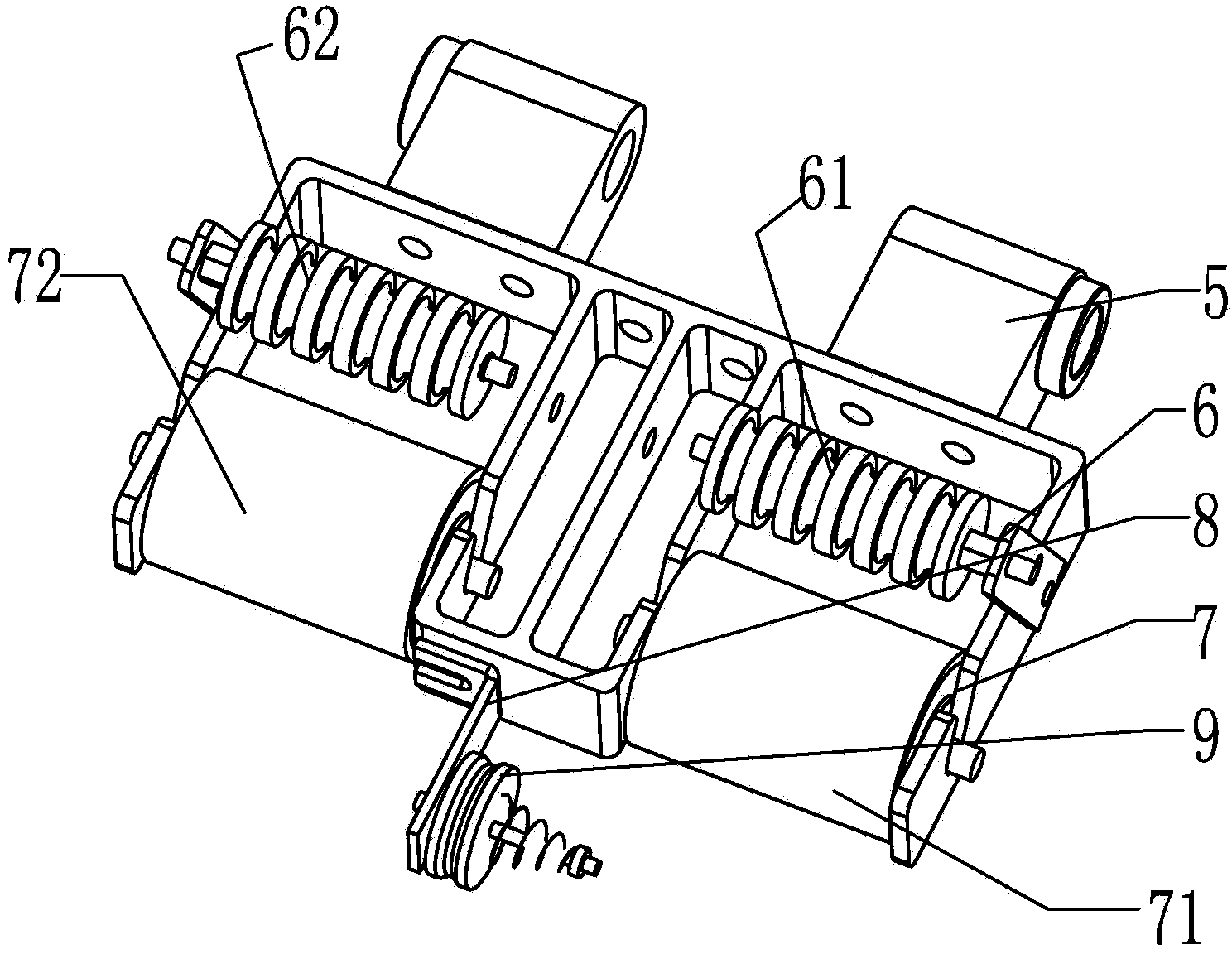

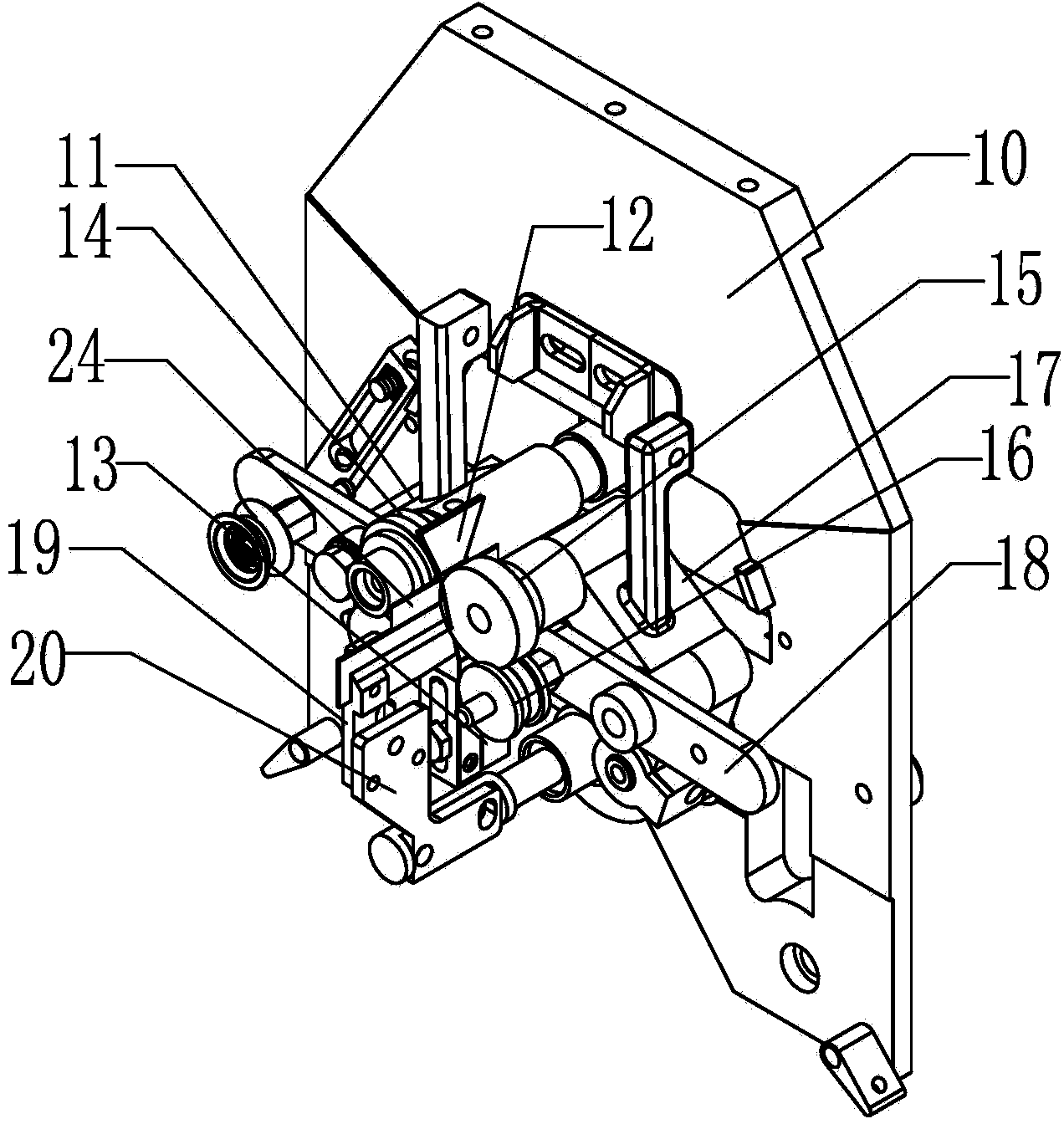

[0036] Such as Figure 1 to Figure 6 Shown, a kind of chenille spinning machine comprises wallboard frame, beam body, spinning system and main panel 10, and beam body is framed between wallboard frame, and main panel 10 is fixed on beam body, and wallboard machine Lifting guide rails are vertically arranged on the frame, and the spinning system includes electronic machine head, pressure roller part, rotary head part, roller output part, lifting guide mechanism, central balloon yarn guide 21, spindle winding part, winding Spindle drive system and raw yarn creel device.

[0037] The wall panel frame constitutes the frame of the chenille spinning machine. The wall panel frame includes a wall panel body, on which a beam body bracket is welded, and a beam body is erected between the beam body brackets, that is, the beam body is arranged horizontally and runs through the Chenille spinning machine. Most of the parts of the chenille spinning machine are installed on the beam body to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com