A synchronous pressure roller filter bed device

A pressure roller and filter bed technology, applied in the field of synchronous pressure roller type filter bed devices, can solve the problems of insufficient rolling steel output, folds at the edge of the filter paper, pollution, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

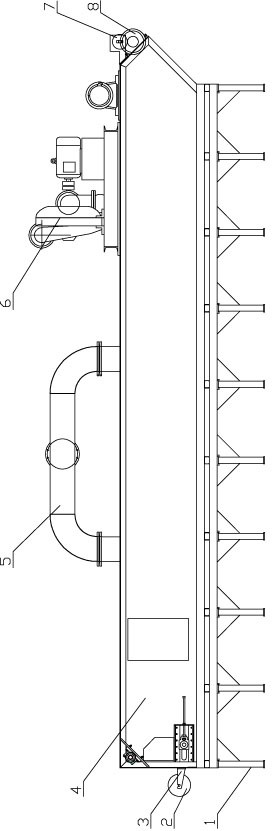

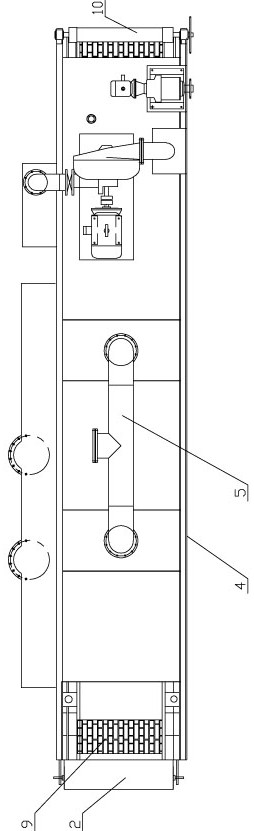

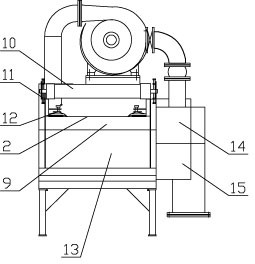

[0015] The present invention is a synchronous pressure roller filter bed device, which has a frame 1, a box body 4 is arranged on the frame body, a chain bed 9 is arranged on the upper part of the box body, and the inner cavity of the box below the chain bed is a clean liquid storage cavity 13, The top of the box is provided with a dirty liquid delivery pipe 5, a fan 6 and a chain bed driving device, the upper and lower parts of the outer wall of the box are respectively provided with an overflow pipe 14 and a clean liquid pipe 15, and the front end of the box is provided with a filter paper holder 3, The filter paper bracket is equipped with filter paper 2, and the filter paper is laid along the upper surface of the chain bed. A sealing edge holding device 12 is provided on the inner wall of the box at the edges of both sides of the filter paper, and a liquid level is also set above the sealing edge holding device on the inner wall of the box. Detection device, the rear end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com