Low-temperature-resistant and sound-proof PVB (polyvinyl butyral) glass intermediate film as well as preparation method and device

A technology for preparing devices and interlayer films, which can be applied to flat products, other household appliances, plastic recycling, etc., can solve problems such as poor sound insulation, easy cracking, and unreasonable proportioning, and achieve improved low temperature resistance, sound insulation performance, The effect of increasing the winding tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

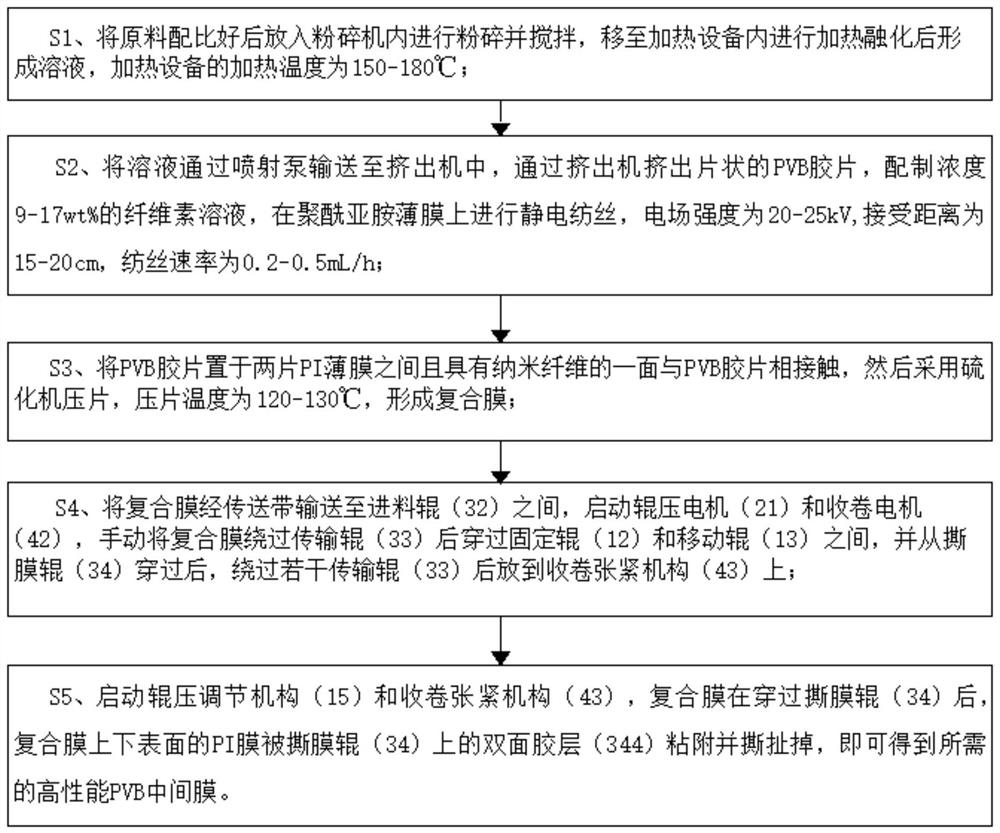

[0061] A PVB glass intermediate film with low temperature resistance and sound insulation, the manufacturing method thereof comprises the following steps:

[0062] S1. Put the raw materials into a pulverizer for pulverization and stirring after the raw materials are properly proportioned, and then move to a heating device for heating and melting to form a solution, and the heating temperature of the heating device is 150 ° C;

[0063] S2. The solution is transported into the extruder through a jet pump, and the sheet-like PVB film is extruded through the extruder to prepare a cellulose solution with a concentration of 9 wt%, and electrospinning is performed on the polyimide film. The electric field strength is 20kV, the receiving distance is 15cm, and the spinning rate is 0.2mL / h;

[0064] S3. The PVB film is placed between two PI films and the side with nanofibers is in contact with the PVB film, and then pressed with a vulcanizer at a temperature of 120°C to form a composite...

Embodiment 2

[0070] A PVB glass intermediate film with low temperature resistance and sound insulation, the manufacturing method thereof comprises the following steps:

[0071] S1. Put the raw materials into a pulverizer for pulverization and stirring after the raw materials are properly proportioned, and then move to a heating device for heating and melting to form a solution, and the heating temperature of the heating device is 160 ° C;

[0072] S2. The solution is transported to the extruder through a jet pump, and the sheet-like PVB film is extruded through the extruder to prepare a cellulose solution with a concentration of 13 wt%, and electrospinning is performed on the polyimide film. The electric field strength is 25kV, the receiving distance is 15cm, and the spinning rate is 0.3mL / h;

[0073] S3. The PVB film is placed between two PI films and the side with nanofibers is in contact with the PVB film, and then pressed with a vulcanizer at a temperature of 125°C to form a composite ...

Embodiment 3

[0079] A PVB glass intermediate film with low temperature resistance and sound insulation, the manufacturing method thereof comprises the following steps:

[0080] S1. Put the raw materials into a pulverizer for pulverization and stirring after the raw materials are properly proportioned, and then move to a heating device for heating and melting to form a solution, and the heating temperature of the heating device is 180 ° C;

[0081] S2. The solution is transported to the extruder through a jet pump, and the sheet-like PVB film is extruded through the extruder to prepare a cellulose solution with a concentration of 17 wt%, and electrospinning is performed on the polyimide film. The electric field strength is 25kV, the receiving distance is 20cm, and the spinning rate is 0.5mL / h;

[0082]S3. The PVB film is placed between two PI films and the side with nanofibers is in contact with the PVB film, and then pressed with a vulcanizer at a temperature of 130°C to form a composite f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com